Production method of wind tower flange deformed ring forging

A manufacturing method and technology of special-shaped rings, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of uneven rolling, reduce production efficiency, affect product quality, etc., achieve stable rolling process and improve production efficiency , Improve the effect of product quality

Inactive Publication Date: 2010-08-25

ZHANGJIAGANG HAILU ANNULAR FORGINGS

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional manufacturing method of special-shaped ring forgings for wind tower flanges is generally to forge billet steel rings into rectangular cross-sections, and then process them into wind tower flanges of the required shape according to the drawings. This manufacturing method adopts a single-piece rolling manufacturing process during production , the rolling is not smooth, not only affects the product quality, but also reduces the production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Login to View More

Abstract

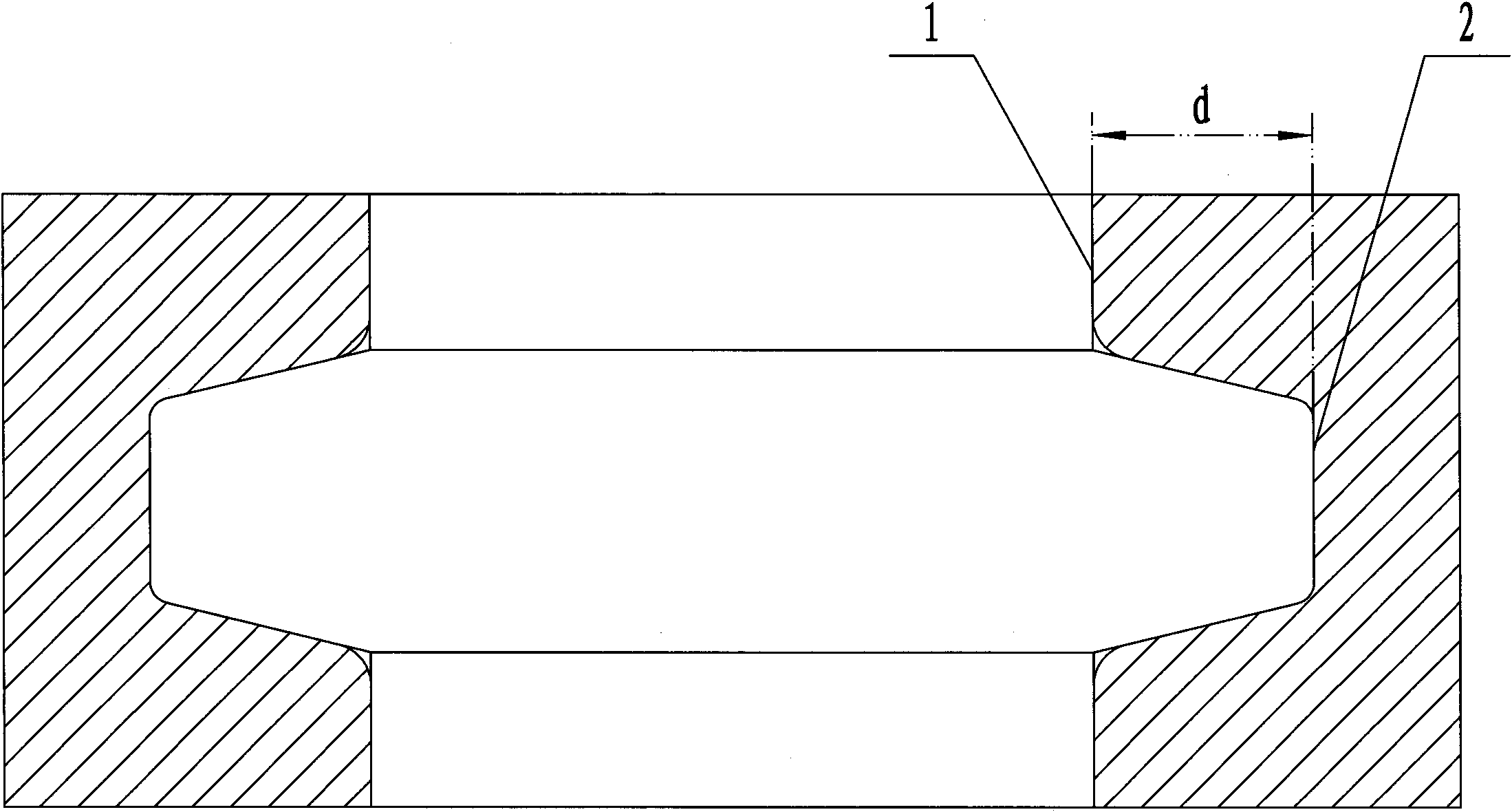

The invention discloses a production method of a wind tower flange deformed ring forging. The wind tower flange deformed ring forging is made of billet by the steps of blanking, blank forging and ring rolling, heating treatment and finish turning. The step of blank forging and ring rolling comprises the steps of: firstly rolling the billet into a ring by a plain barreled roll, wherein the inner wall of the ring is a smooth circumferential surface; and then heating in a furnace; rolling the ring into a workpiece with an annular concave cavity in the middle of the inner wall by a deformed core roll, wherein the deformed core roll is provided with a core roll boss, the core roll boss is twice wider than the connecting face of a tower cylinder of the wind tower flange deformed ring forging, and the height of the core roll boss is equal to the width of a flange connecting boss of the wind tower flange deformed ring forging; and sawing the workpiece from the middle of the side to separate the workpiece into tow parts symmetrically and equally to obtain tow blanks of the wind tower flange deformed ring forging. The invention is a production method of the wind tower flange deformed ring forging, which can improve product quality and has high production efficiency.

Description

technical field The invention relates to a wind power generator equipment MW-level wind turbine tower body flange, and in particular to a method for manufacturing a special-shaped ring forging of the wind tower flange. Background technique The currently used wind tower flanges generally use billet steel as the raw material for processing, and after blanking, forging billet ring rolling, heat treatment, finishing machining and other steps, ring forgings that meet the requirements are made. As shown in FIG. 2 , the inner wall of the wind tower flange special-shaped ring forging includes a flange connection boss 1 and a tower tube connection surface 2 . The traditional manufacturing method of special-shaped ring forgings for wind tower flanges is generally to forge billet steel rings into rectangular cross-sections, and then process them into wind tower flanges of the required shape according to the drawings. This manufacturing method adopts a single-piece rolling manufacturing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P15/00B21H1/06C21D9/40

Inventor 吴君三王雷刚戴玉同胡振奇张毅峰

Owner ZHANGJIAGANG HAILU ANNULAR FORGINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com