Crack grouting simulation testing device based on visual detection and testing method

A simulation test and grouting technology, applied in the field of formation fracture grouting, can solve the problems of poor surrounding rock stability, easy formation of formation fractures, poor grouting fluid permeability, etc., and achieves strong practical performance, high simulation accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

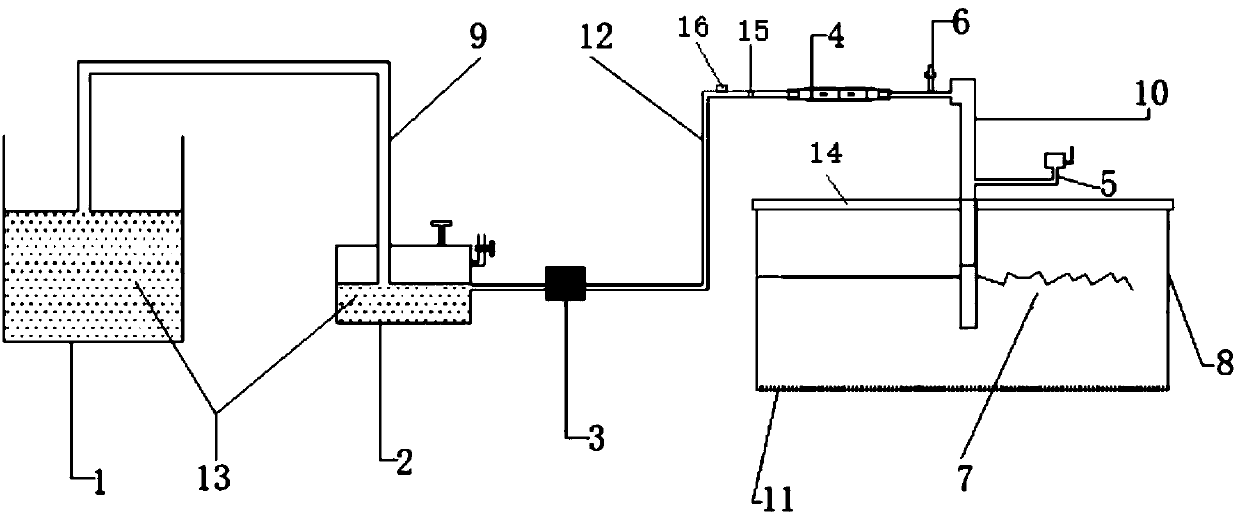

[0045] The invention provides a visual detection crack grouting simulation test device, specifically as figure 1 As shown, it includes a grouting pool 1, a high-pressure grouting pump 2, a monitoring system 3, a one-way valve 4, an overflow valve 5, a pressure limiting valve 6, a simulated crack 7 on the coal seam floor, and a test box 8: in this embodiment, The monitoring system 3 includes flow meters and pressure gauges. The structure and function of each part are as follows:

[0046] The simulated fissure 7 of the coal seam floor is a massive structure, and part of the top surface of the simulated fissure 7 of the coal seam floor is a plane and the other part is an uneven curved surface;

[0047] The grouting tank 1 is used to store the slurry 13, and the grouting tank 1 communicates with the inlet of the high-pressure grouting pump 2 through the first high-pressure pipeline 9;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com