Simulation system and calibration method for hydrodynamic power of parallel pump system of primary coolant circuit of reactor

A fluid power, simulation system technology, applied in the field of simulation system, can solve the problem of inaccurate simulation effect, and achieve the effect of reducing the test cost, reducing the test cost and increasing the simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

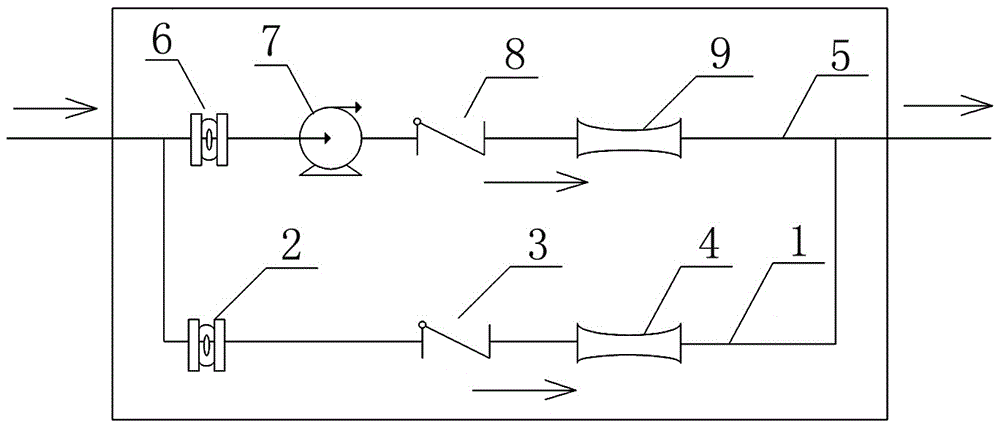

[0038] Such as figure 1 As shown, the hydrodynamic simulation system of the reactor primary circuit parallel pump system of the present invention includes a main pump simulation branch and a standby pump simulation branch connected in parallel with the main pump simulation branch.

[0039] The standby pump simulation branch includes a parallel pipeline 1 , a first resistance regulator 2 arranged on the parallel pipeline 1 , a first check valve 3 and a first flow meter 4 . The main pump simulation branch includes a main pipeline 5 , and a second resistance regulator 6 , a main pump 7 , a second check valve 8 and a second flow meter 9 arranged on the main pipeline 5 .

[0040] The method for calibrating the simulation system of the present invention is as follows:

[0041] (1) Under the condition of forced circulation, adjust the resistance on the simulated branch of the main pump so that the hydraulic characteristics are the same as those of the prototype main pump branch;

...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is:

[0051] The first resistance adjusting member 2, the first check valve 3 and the first flowmeter 4 are sequentially arranged on the parallel pipeline 1 along the water flow direction in the parallel pipeline 1;

[0052] The second resistance adjustment member 6 , the main pump 7 , the second check valve 8 and the second flowmeter 9 are sequentially arranged on the main pipeline 5 along the water flow direction in the main pipeline 5 .

[0053] The flow state of fluid in the present invention in the present embodiment is:

[0054] Under the condition of forced circulation, the 2 main pumps are running, and in the simulation branch of the main pump, the fluid flows through the second resistance regulator 6 , the main pump 7 , the second check valve 8 and the second flow meter 9 in sequence. At this time, in the standby pump simulation branch, the first check valve 3 cuts off the return flow at the outlet of the...

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 or embodiment 2 is that: the first resistance adjustment member 2 and the second resistance adjustment member 6 in this embodiment are preferably orifice-type resistance adjustment valves. Both the first flowmeter 4 and the second flowmeter 9 are Venturi flowmeters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com