Titanium alloy variable-pitch milling three-dimensional modeling method based on finite elements

A 3D modeling, titanium alloy technology, applied in 3D modeling, instruments, calculations, etc., can solve the problem of repeated simulation time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

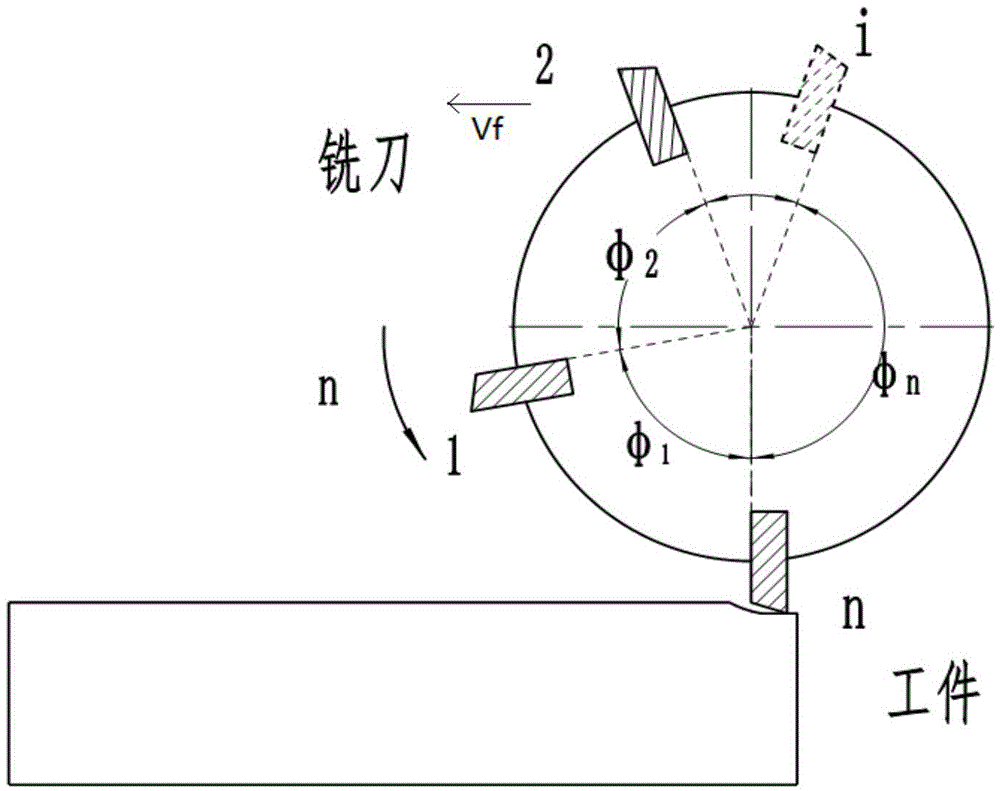

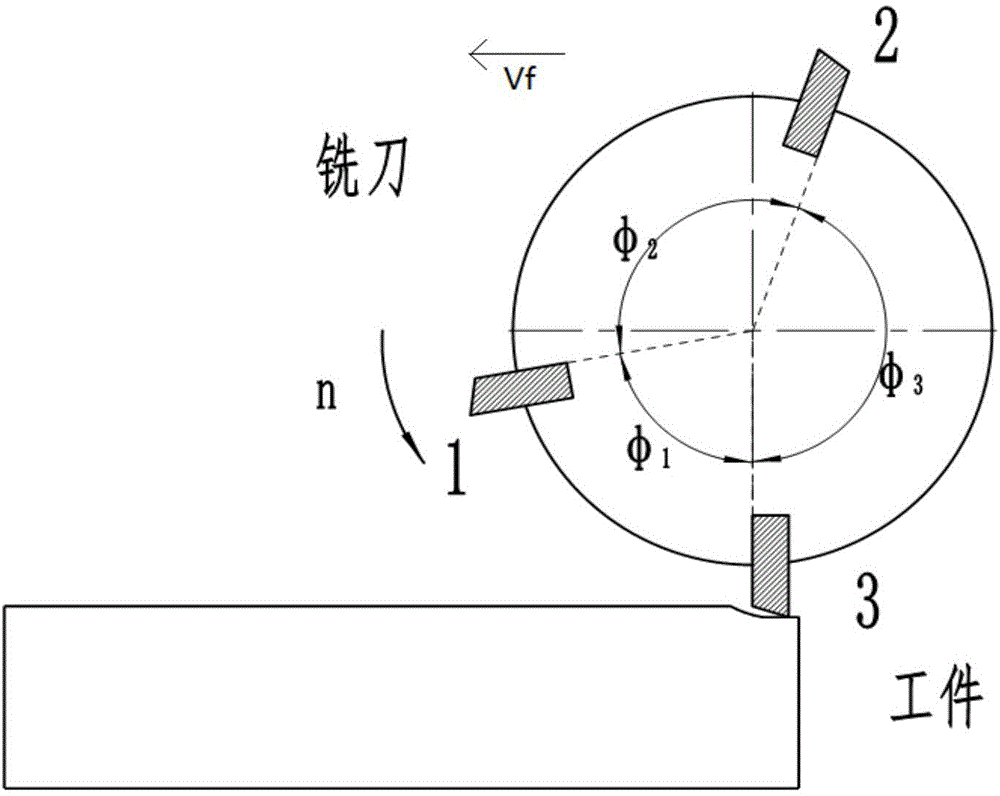

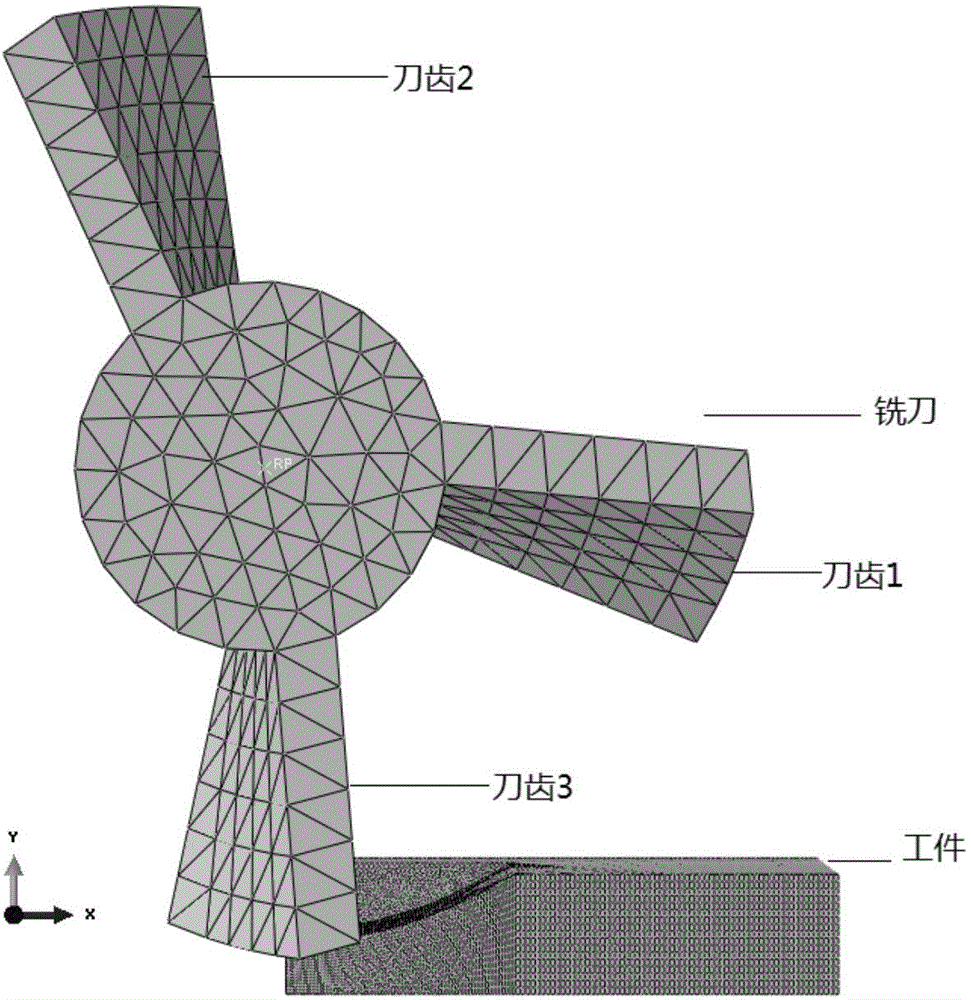

[0044] First, according to the tool system parameters, workpiece and tool material parameters to be used in the experiment, set the tool system parameters, workpiece material parameters, and tool material parameters, and formulate the process parameters; press the milling cutter model for different feeds per tooth Set unequal distances between milling cutters in proportion to establish the geometric model, physical model, contact relationship and movement relationship between the milling cutter and the workpiece; use the ABAQUS / Explicit solver for analysis and calculation, and obtain the milling force and cutter under different feeds per tooth The predicted value of the tip temperature.

[0045] In this embodiment, the version of the finite element software ABAQUS is selected as 6.12-1, the titanium alloy type is Ti6Al4V, the milling cutter material is WC cemented carbide, and the three-dimensional modeling of titanium alloy variable pitch milling based on finite element is perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com