Patents

Literature

34 results about "Pore microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

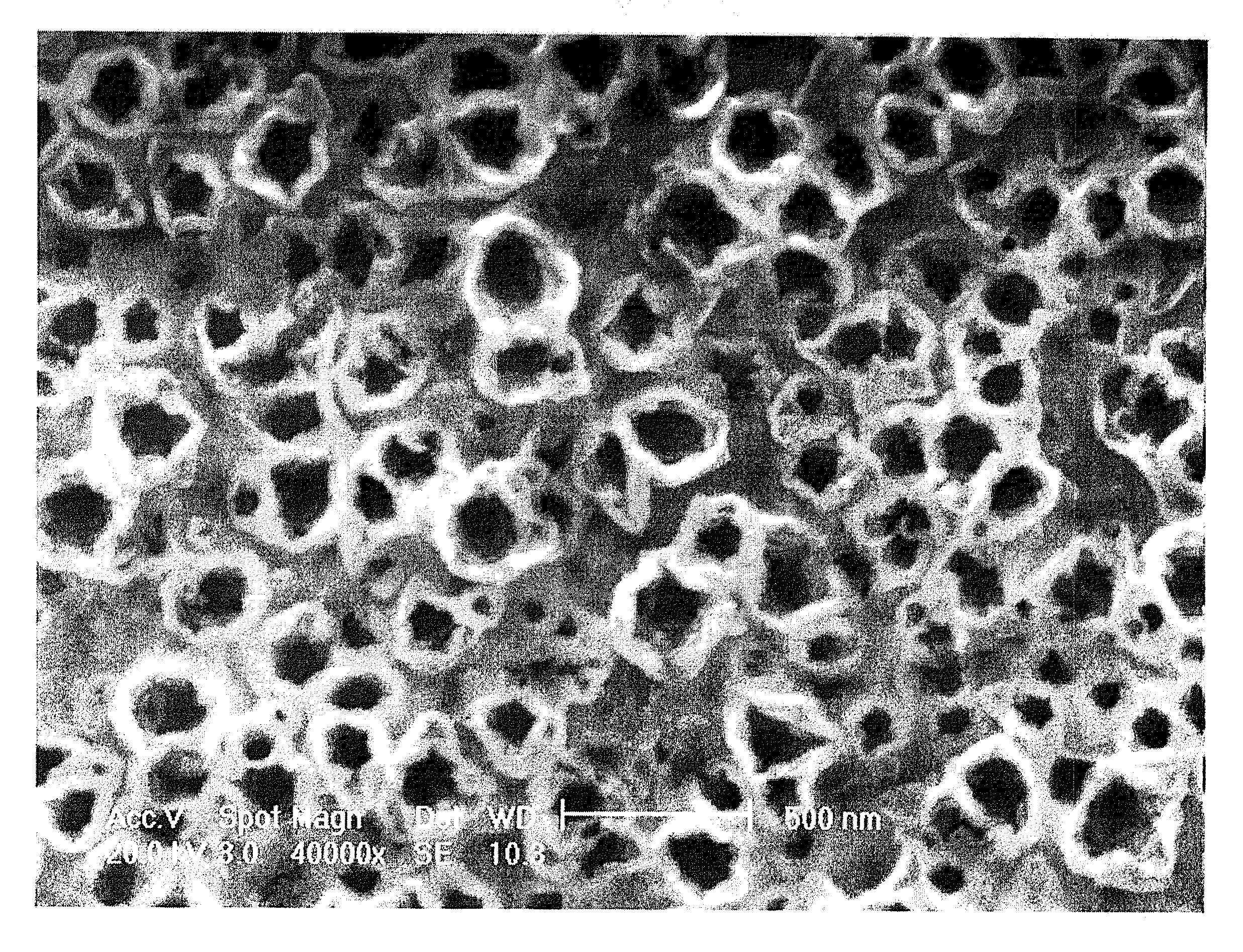

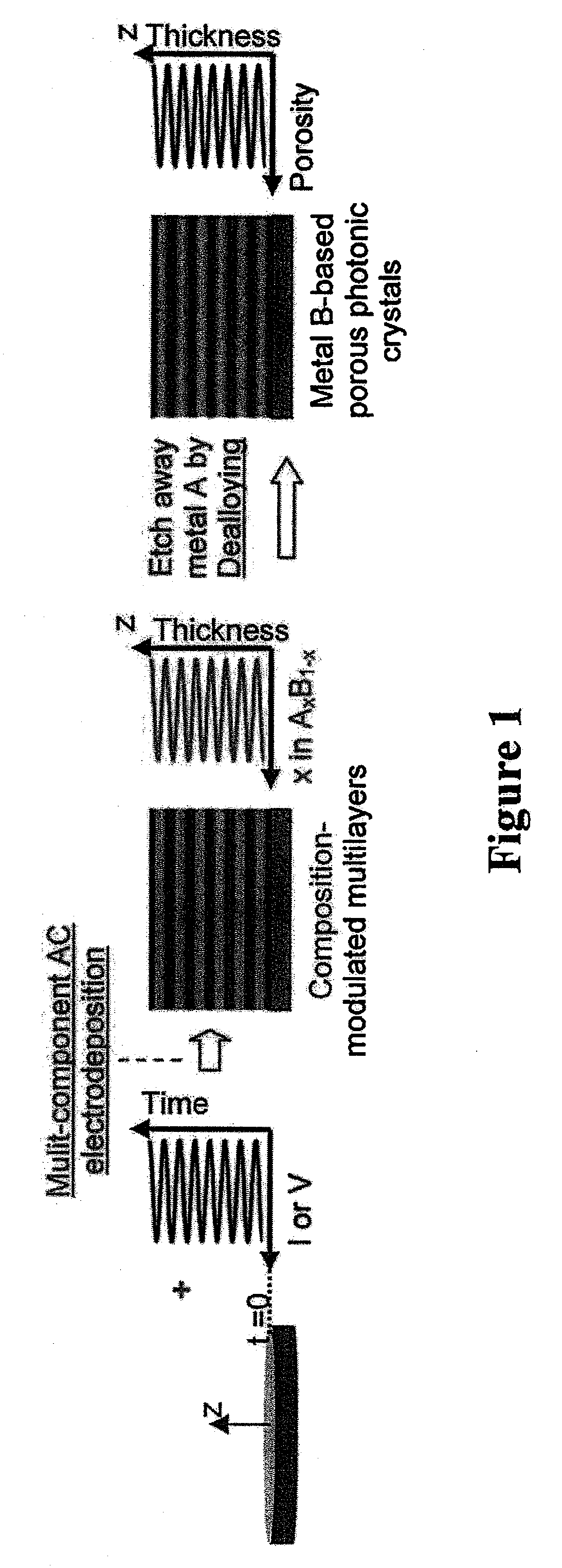

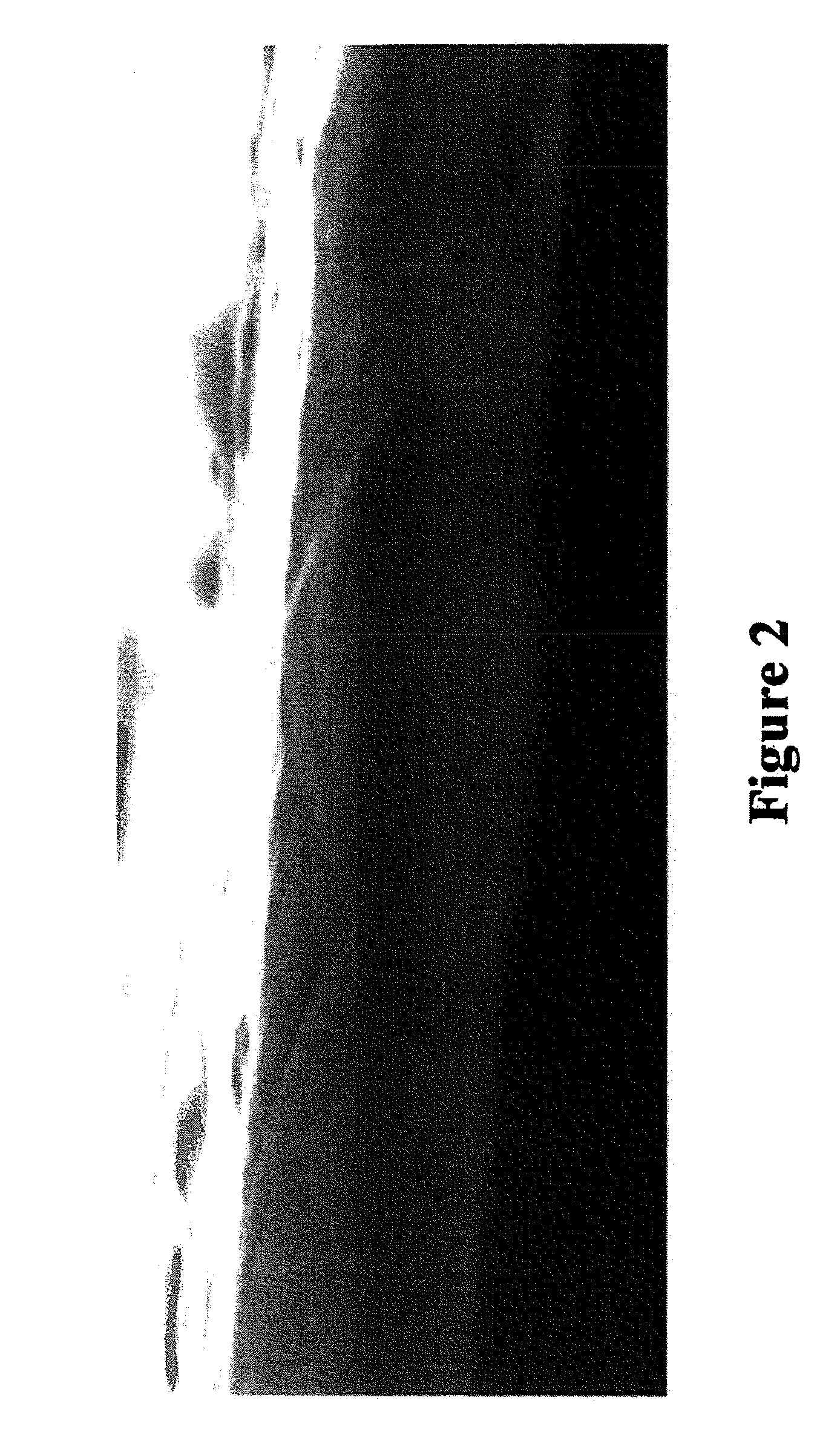

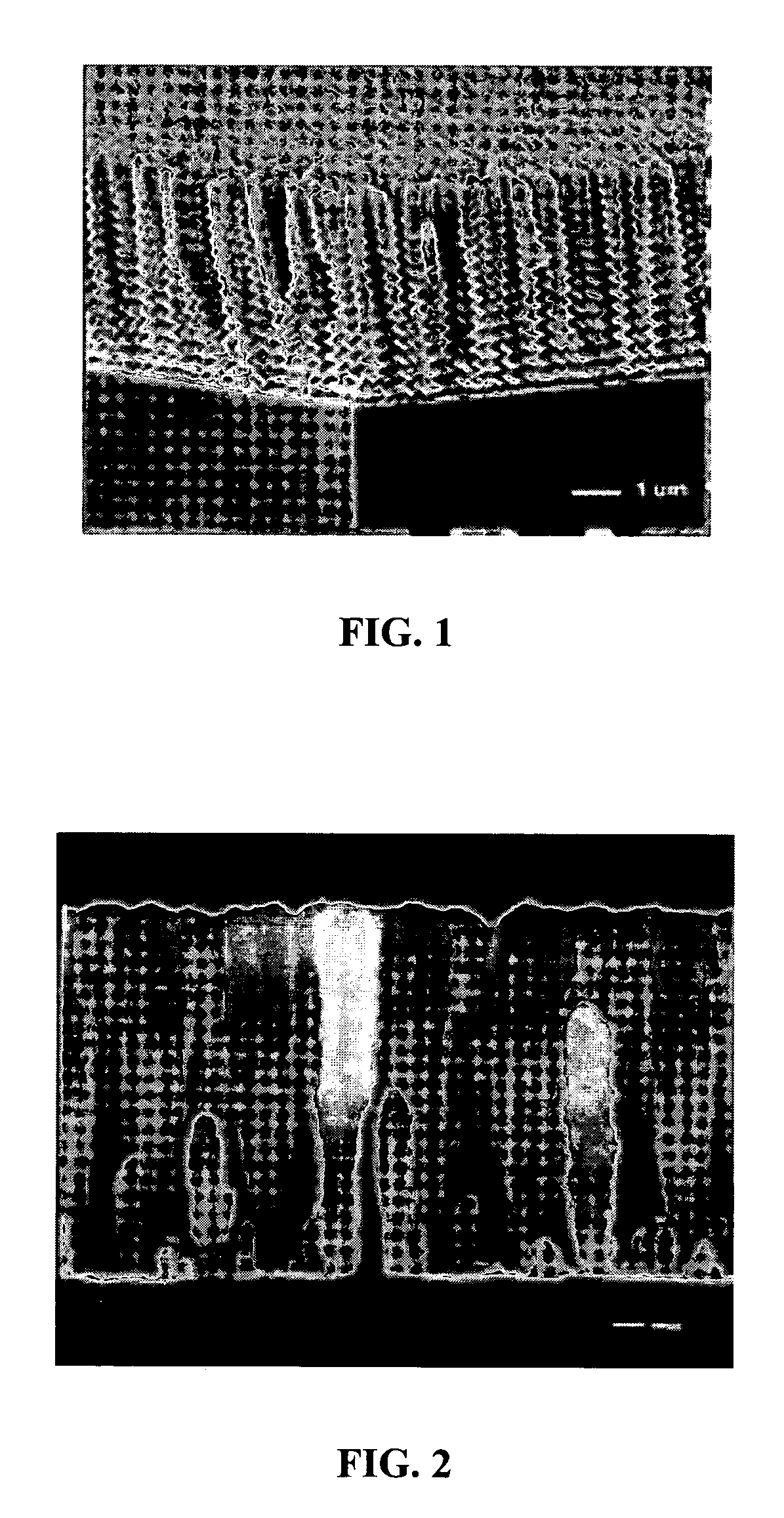

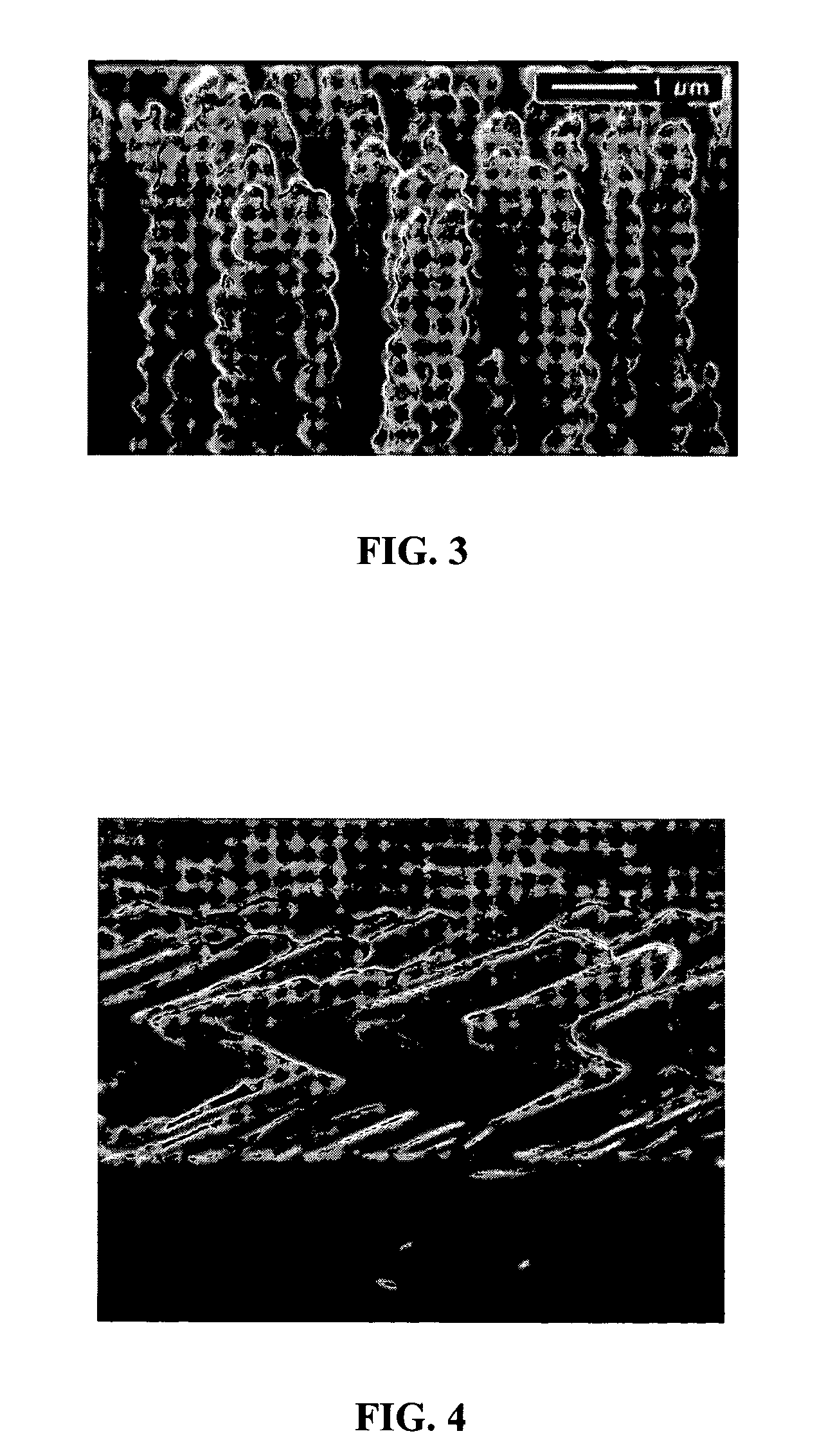

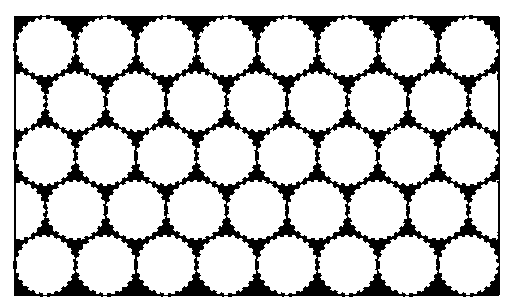

Method of making foraminous microstructures

InactiveUS20100147800A1Simple structureImprove efficiencyPaper/cardboard articlesDecorative surface effectsPhotonicsDepth direction

A foraminous microstructure or film that has photonic or plasmonic properties is made by forming a structure or film composed of at least two constituent materials so that the compositional ratio of the constituent materials varies in a depth direction of the structure, and then removing one of the materials from the structure.

Owner:CITY UNIVERSITY OF HONG KONG

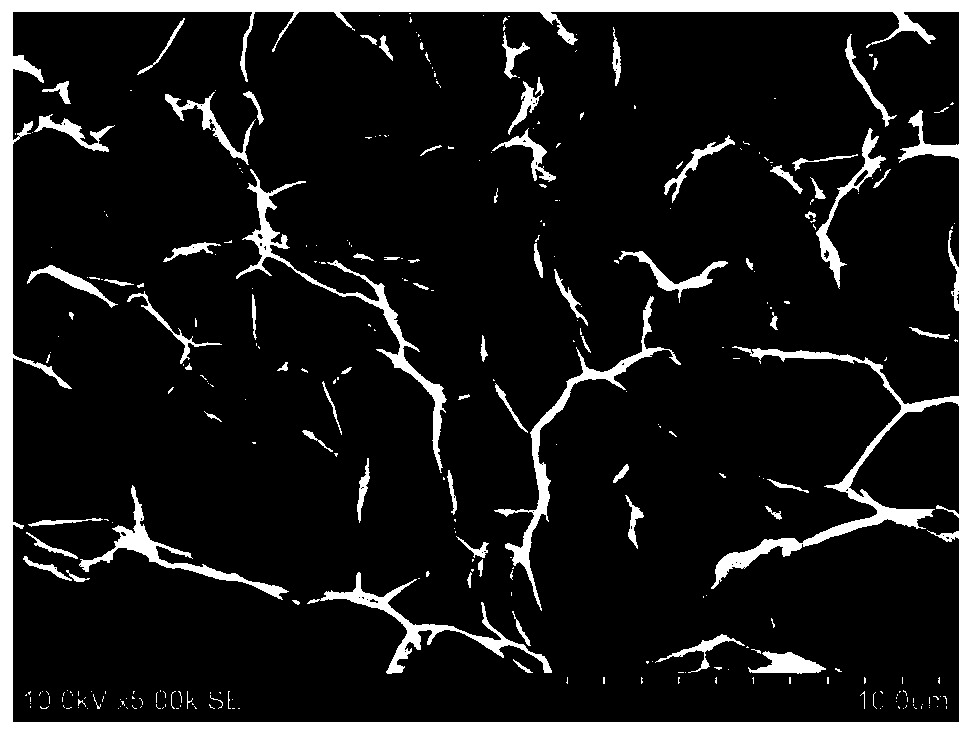

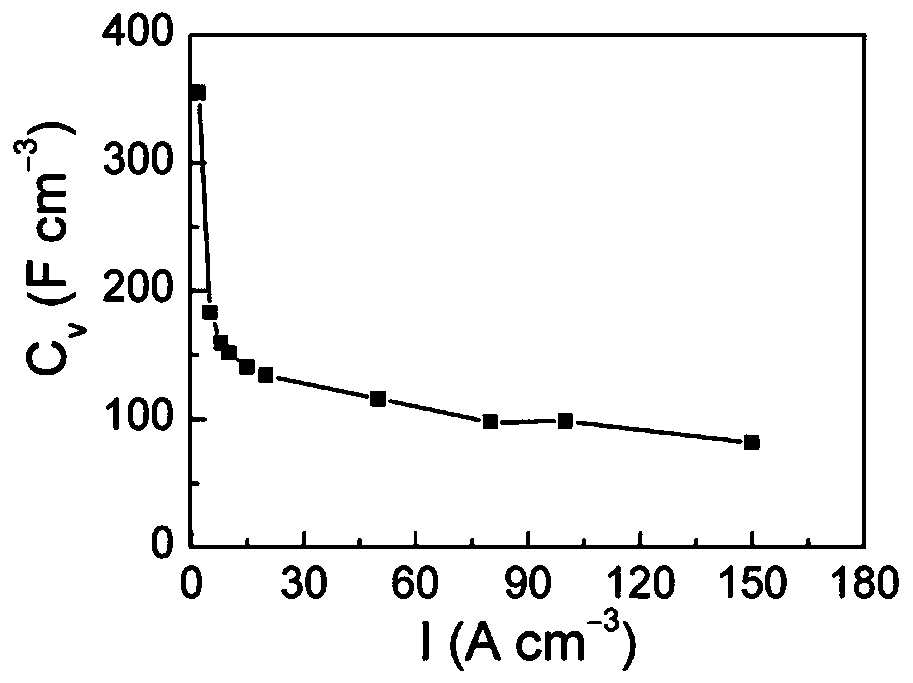

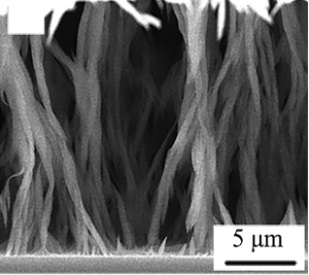

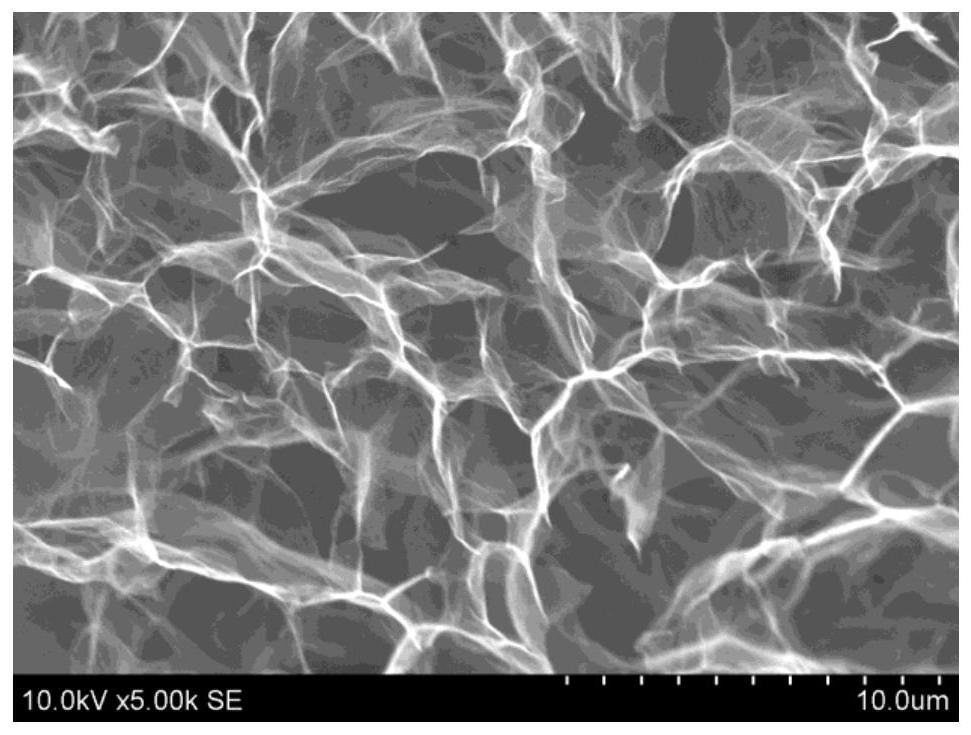

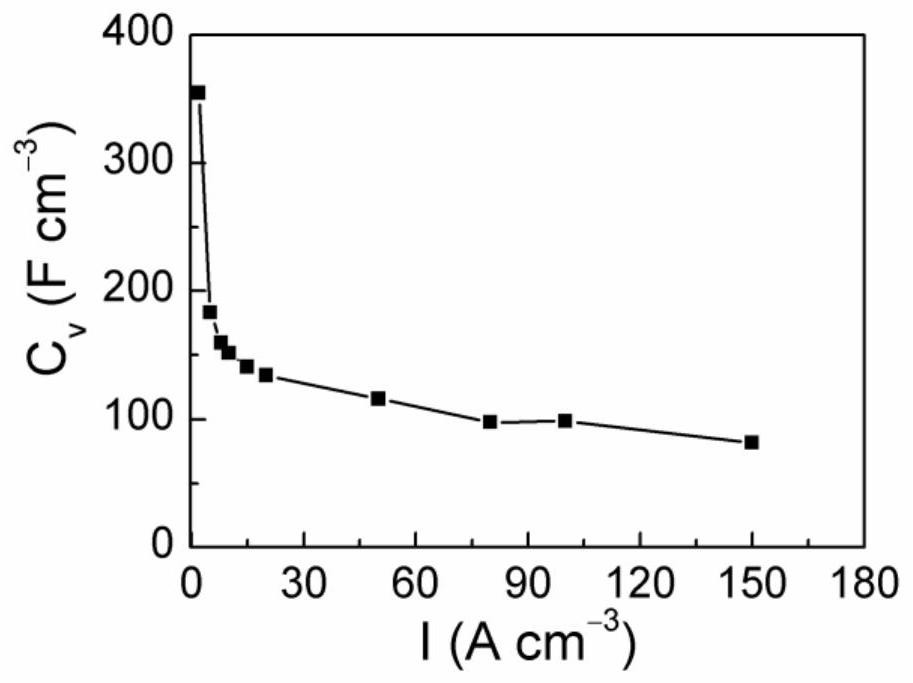

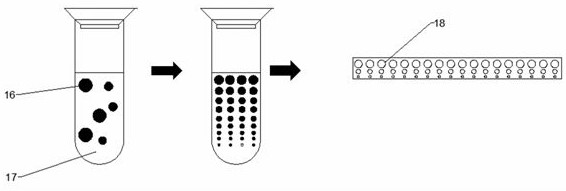

Preparation method of graphene/polyethylenedioxythiophene composite fiber assembly body

ActiveCN110085436ALow costEasy to operateHybrid capacitor electrodesHybrid/EDL manufactureFiberHigh activity

The invention relates to a preparation method of a graphene / polyethylenedioxythiophene composite fiber assembly body, and belongs to the fields of materials and electrochemistry. The composite material takes oxidized graphene and PEDOT:PSS as raw materials, and the raw materials are assembled into a dual-network porous composite fiber by hydrothermal reaction. Compared with the prior art, types ofgraphene precursors of the graphene / polyethylenedioxythiophene composite fiber assembly body are taken into full considerwtion, the new ideal of assembling graphene and polyethylenedioxythiophene together is provided, and the composite fiber porous microstructure and conductive characteristics are regulated effectively. The composite fiber can be directly used as an electrode of fiber super capacitor, as well as a high conductive porous carrier to bear other high-activity materials. The method is low inc cost, convenient to operate, short in production period and easy to realize industrial production.

Owner:BEIJING UNIV OF TECH

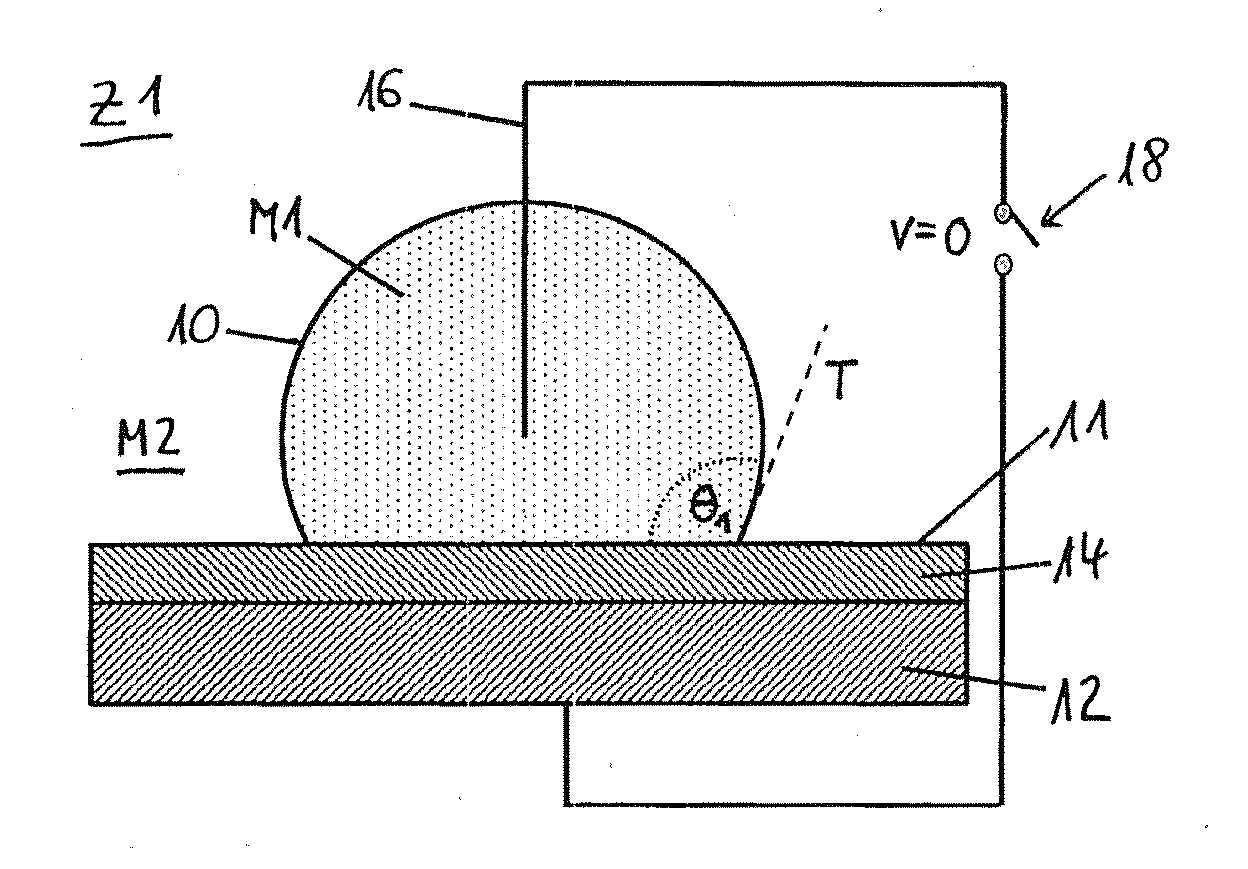

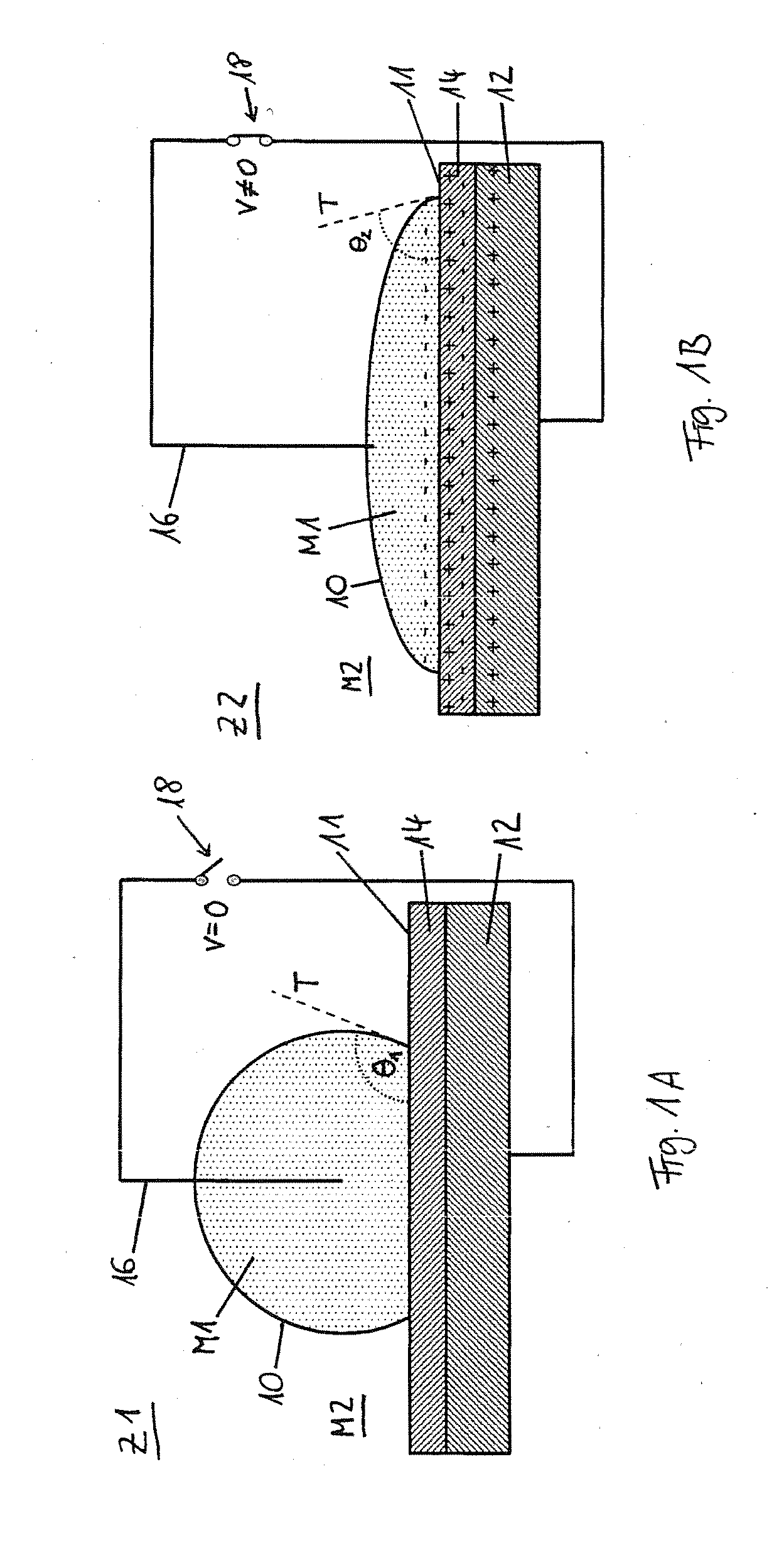

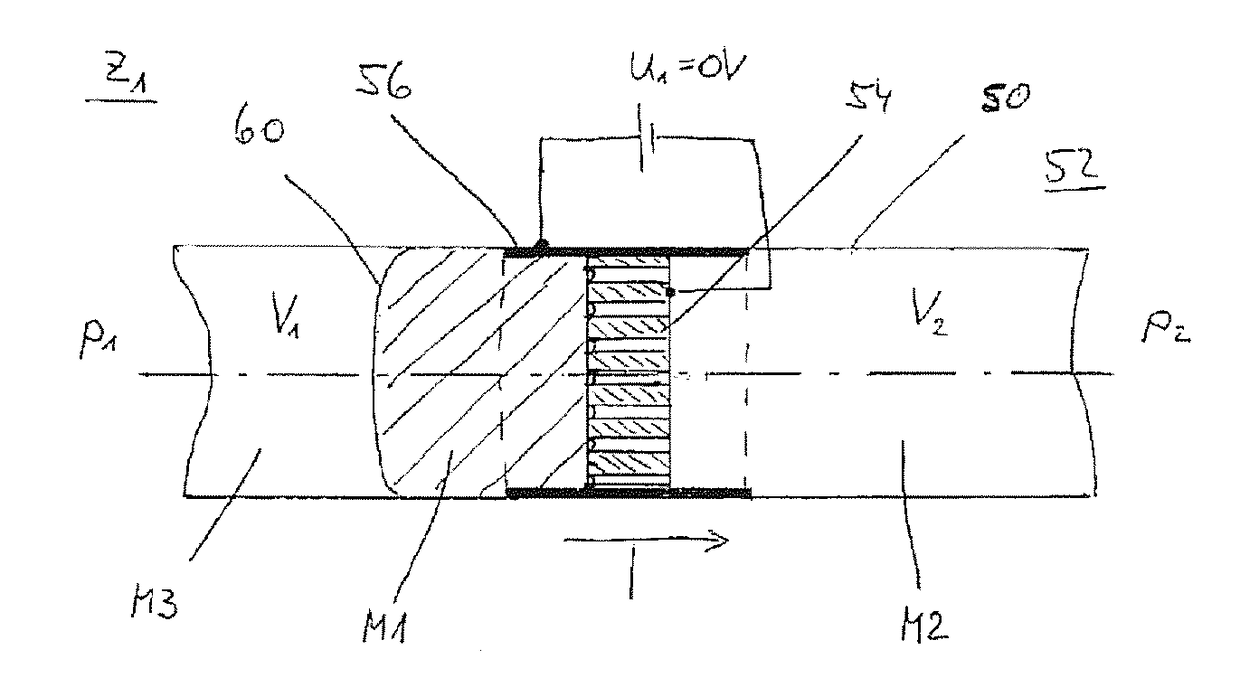

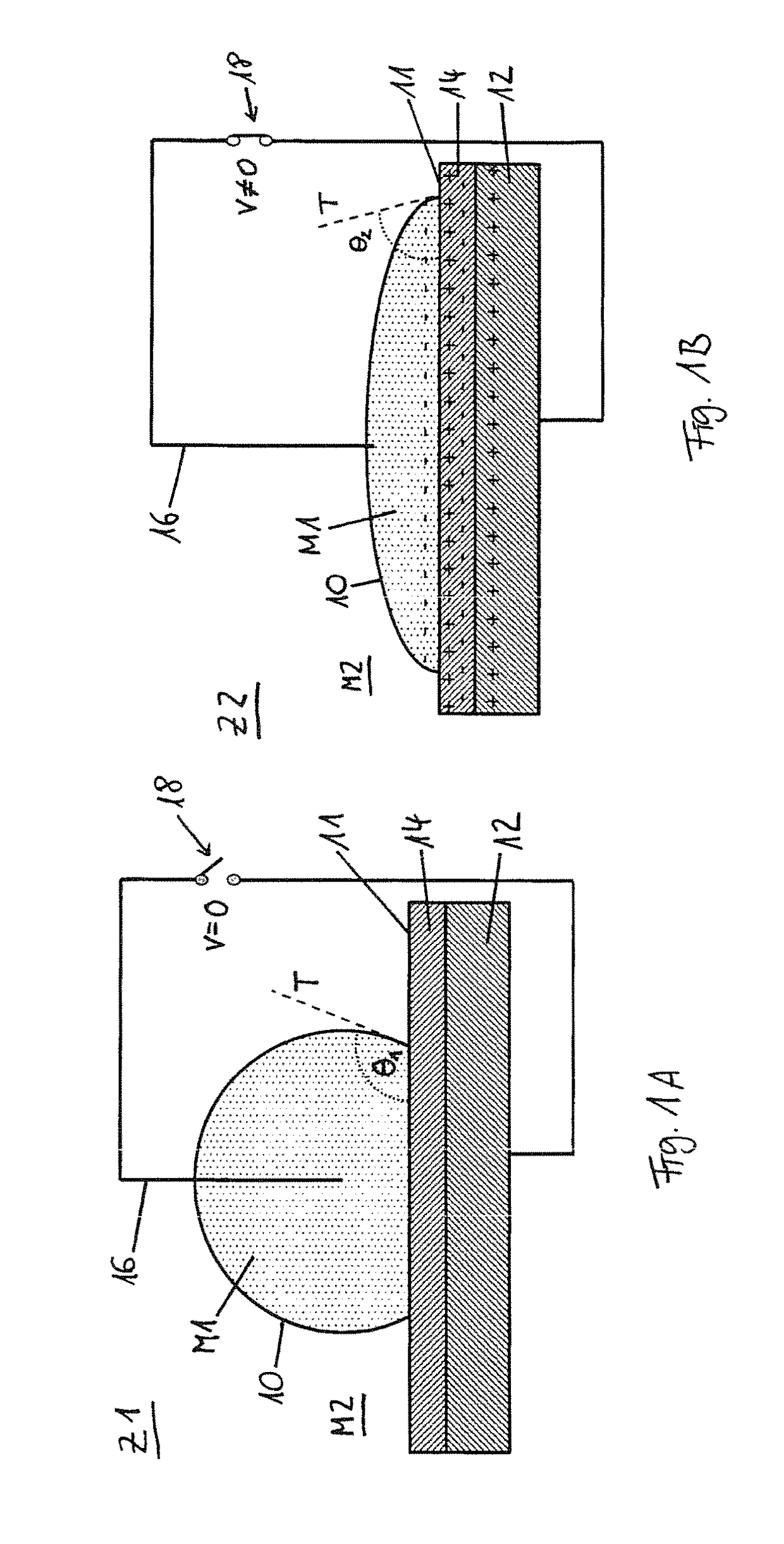

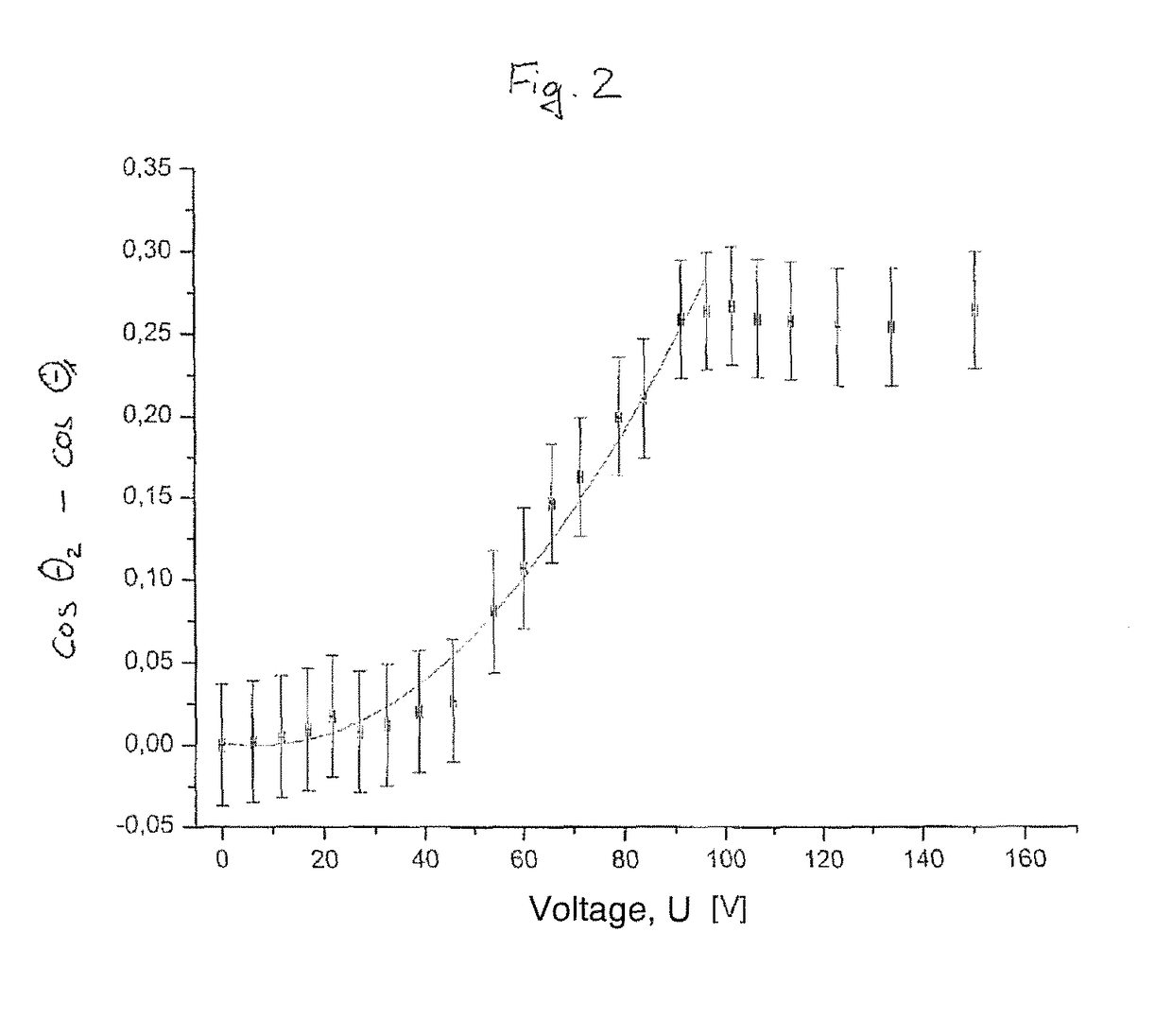

Fluidic system, use, and method for operating the same

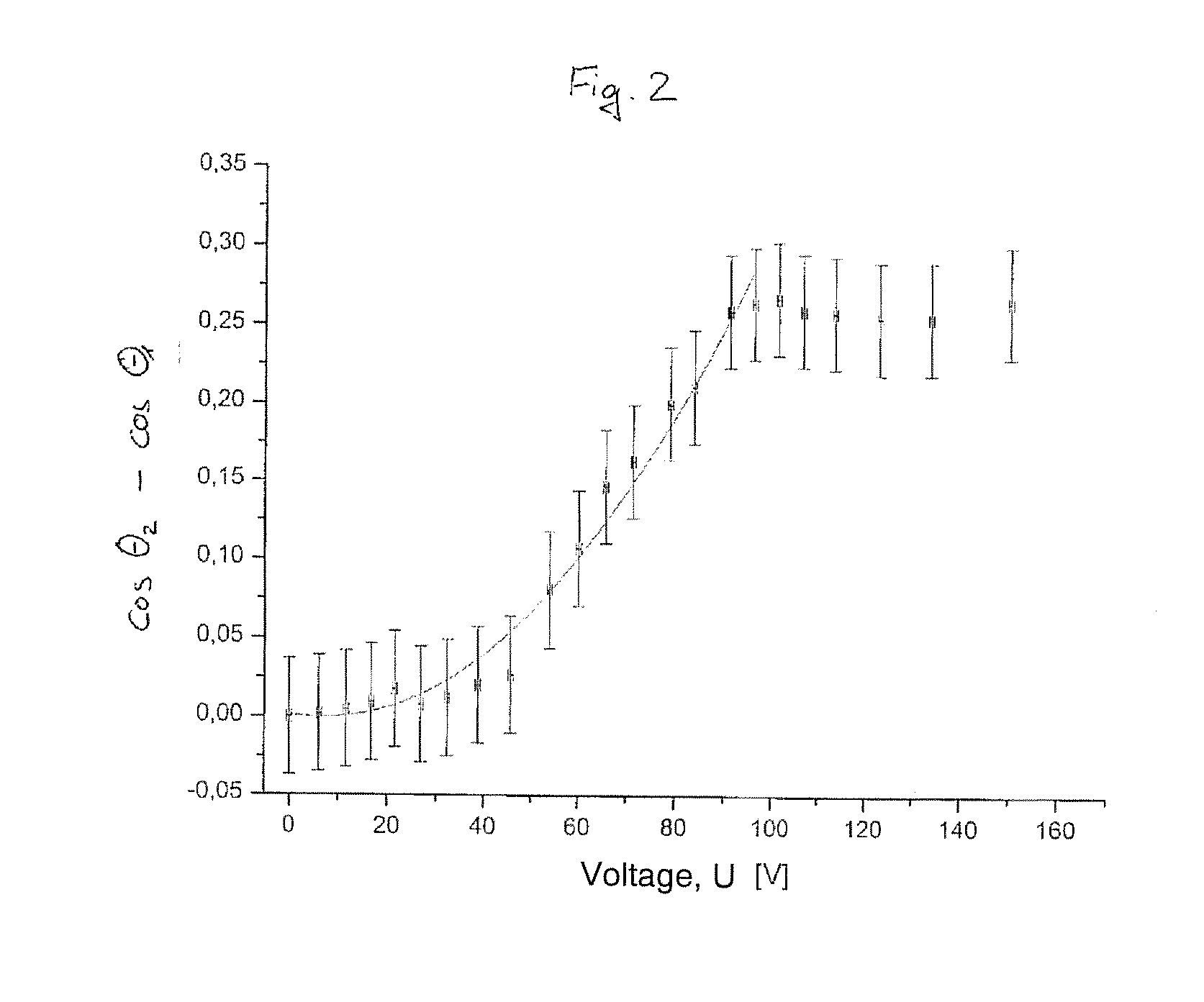

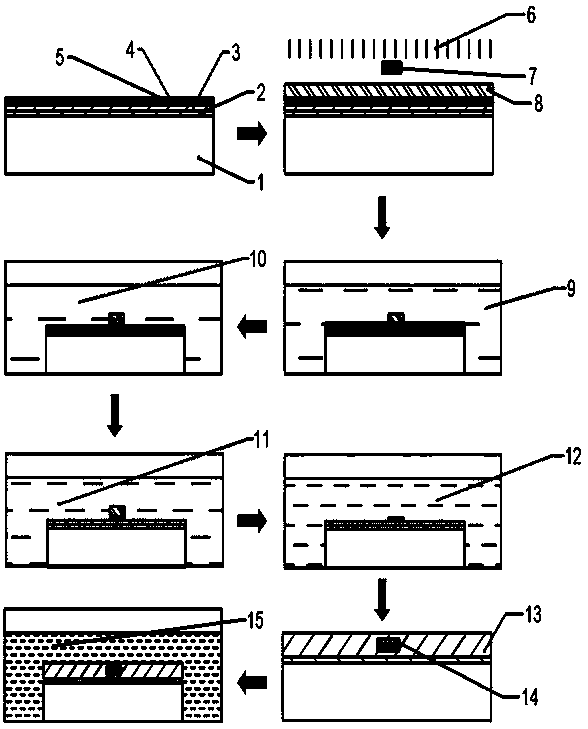

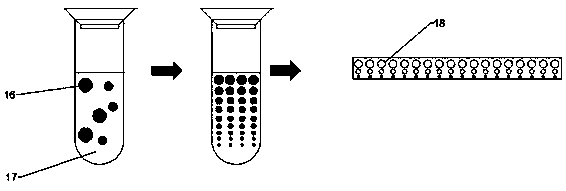

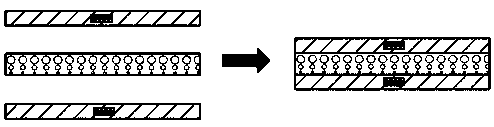

ActiveUS20150047732A1Improve efficiencyAvoid excessive wearValve arrangementsCircuit elementsElectromagnetic radiationFluid system

A fluidic system having a first volume, a second volume and a membrane geometrically separating the two volumes, which has an open-pore microstructure for the passage of a first medium and a second medium. There is a contact angle (θ) between the interface of the media and the pore surface. A first electrical field in the region of the membrane and a first electromagnetic radiation and a first heating of the membrane define a first state (Z1), in which the membrane is not wetted or is less wetted by the first medium and is more heavily wetted by the second medium such that a first contact angle θ1>90° is formed between the pore surface and the interface. The first medium and the second medium and the pore surface have a surface energy of which at least one surface energy can be reversibly changed in such a way that a second contact angle θ2<θ1 occurs between the pore surface and the interface in a second state (Z2).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

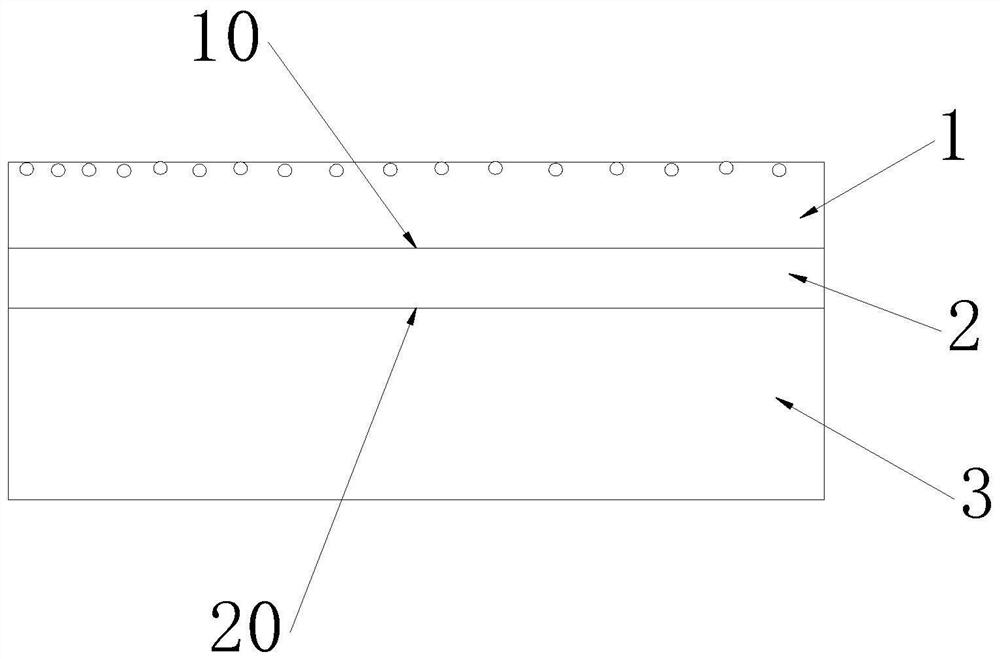

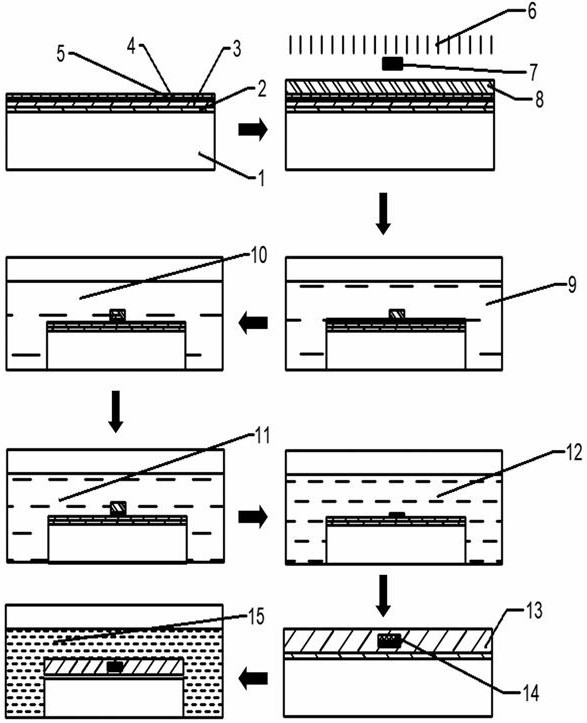

Polydimethylsiloxane film, flexible capacitive sensor and preparation method thereof

ActiveCN110763256AHigh sensitivityImprove linearityConverting sensor output electrically/magneticallyCapacitanceMetallic electrode

The invention belongs to the field of flexible sensors and discloses a polydimethylsiloxane film, a flexible capacitance sensor and a preparation method thereof. The sensor comprises an upper electrode layer, a middle dielectric layer and a lower electrode layer, and the upper electrode layer and the lower electrode layer are the same in structure and each comprises a flexible base material and liquid metal embedded in the base material. The middle dielectric layer is arranged between the upper electrode layer and the lower electrode layer and is provided with a multi-layer stepped mesoporousmicrostructure, and the linearity of the flexible capacitive sensor is improved compared with that of a flexible capacitive sensor without the dielectric layer. When the sensor is under pressure or isclose to a conductor, the pressure on the sensor or the distance between the conductor and the sensor is obtained by measuring the change of the capacitance of the sensor. The invention also discloses the preparation method of the sensor. According to the invention, the flexible capacitive sensor based on a liquid metal electrode and the dielectric layer with the multi-layer stepped mesoporous microstructure is designed, and the high sensitivity of the flexible sensor is realized.

Owner:GUANGDONG SYGOLE INTELLIGENT TECH CO LTD

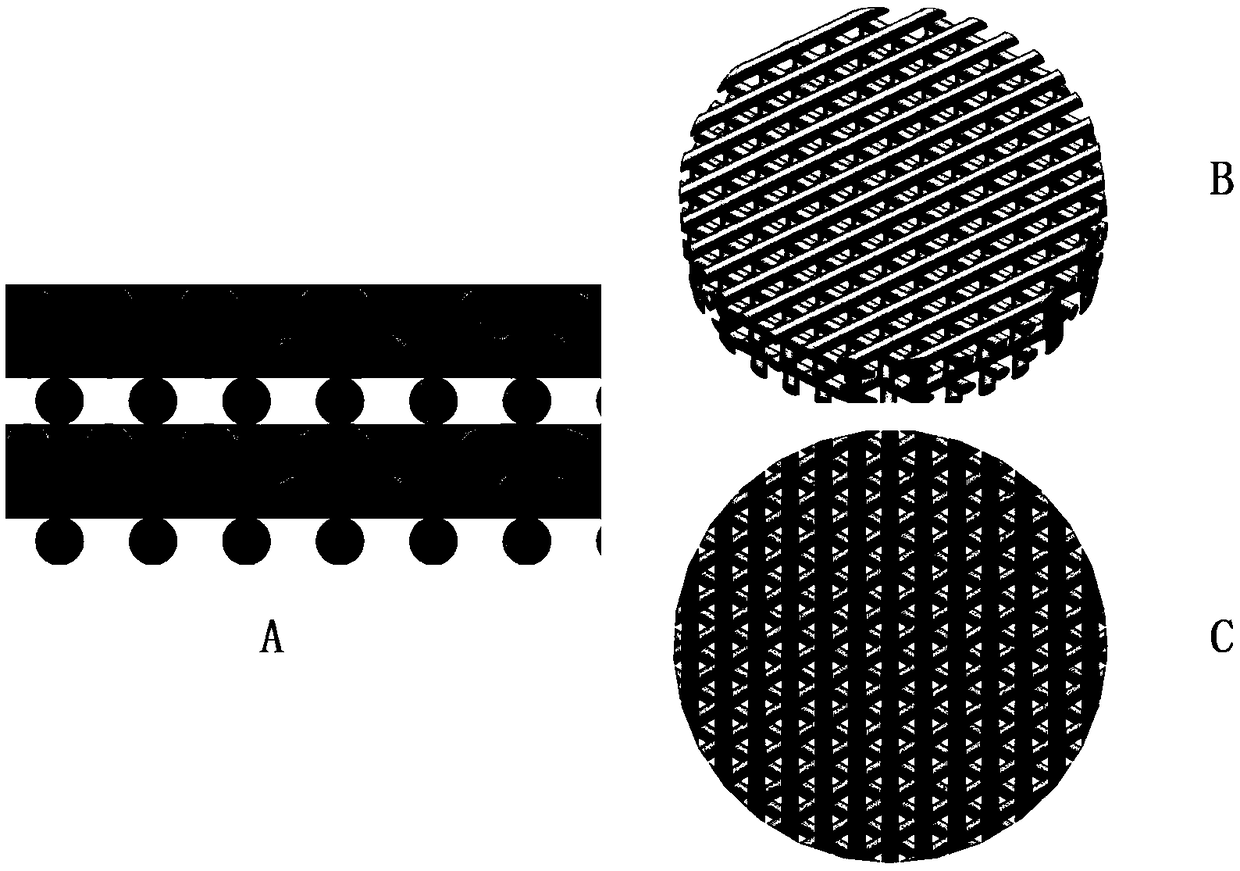

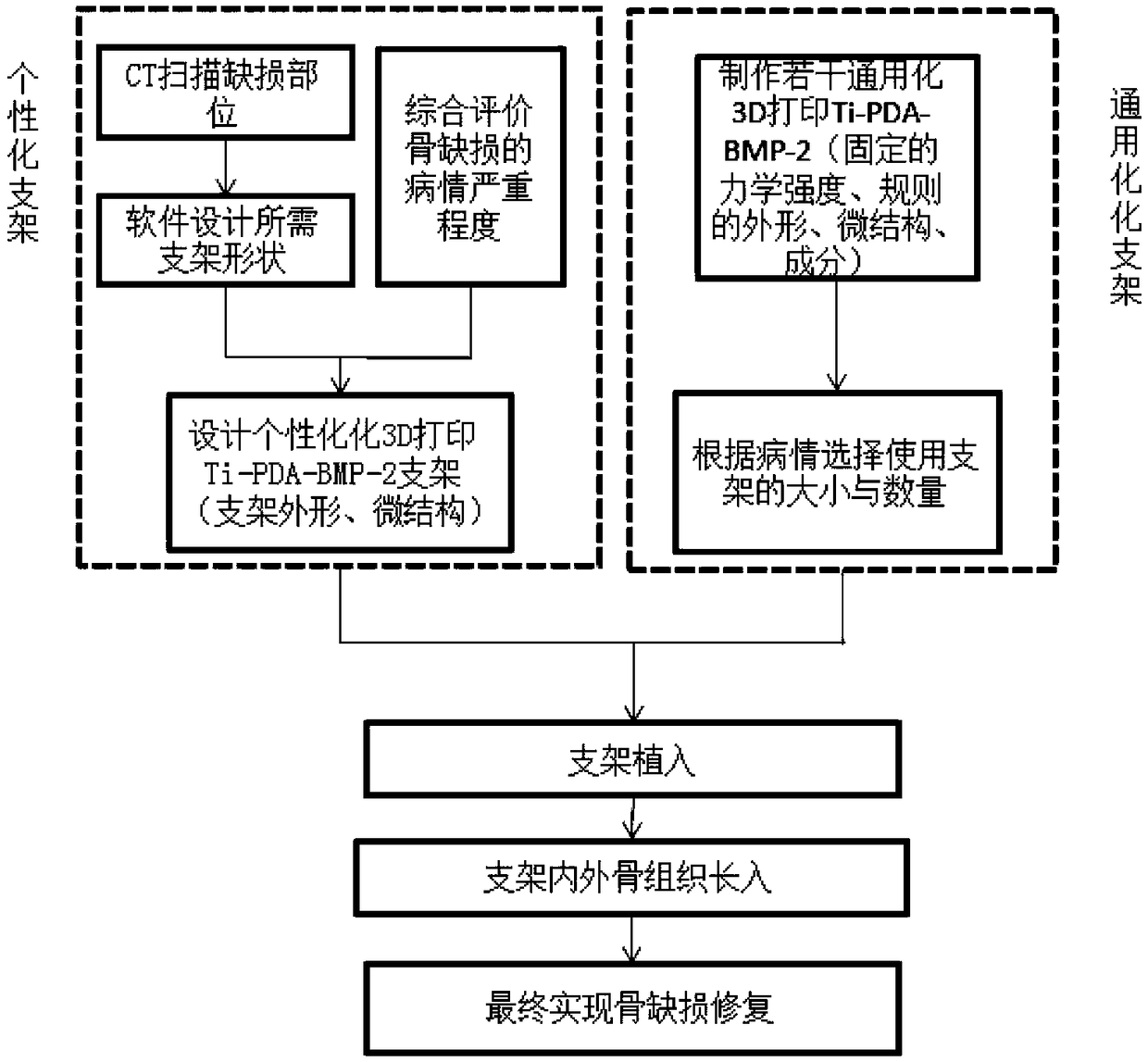

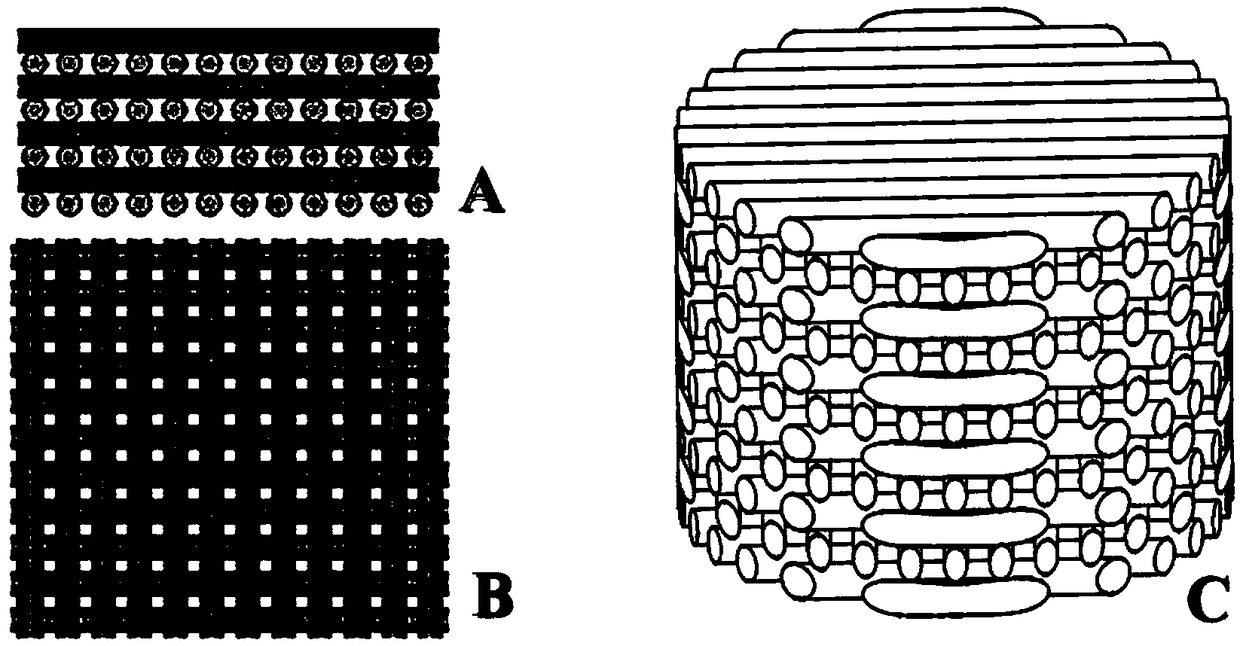

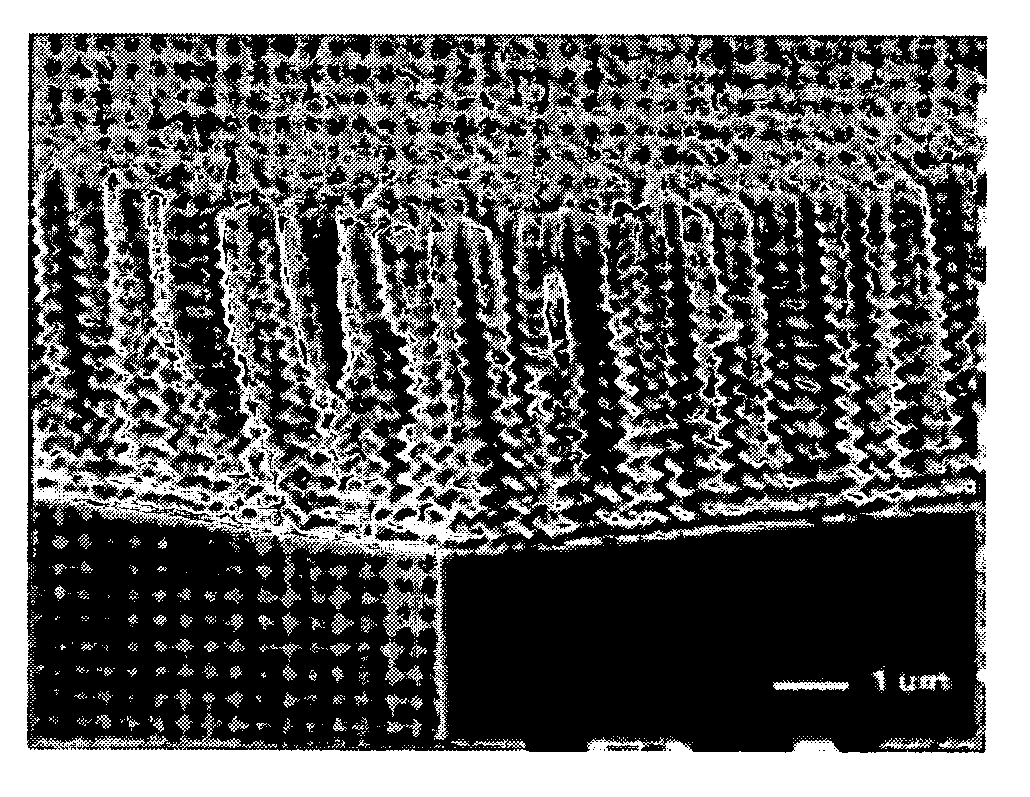

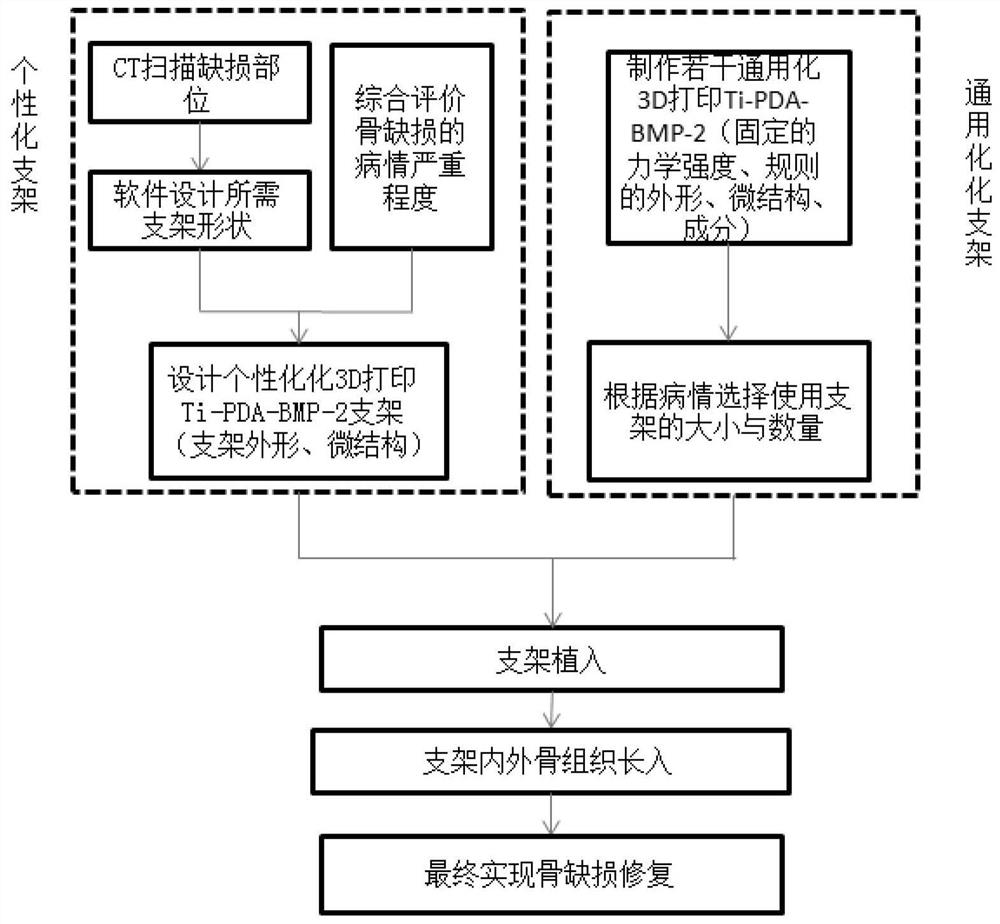

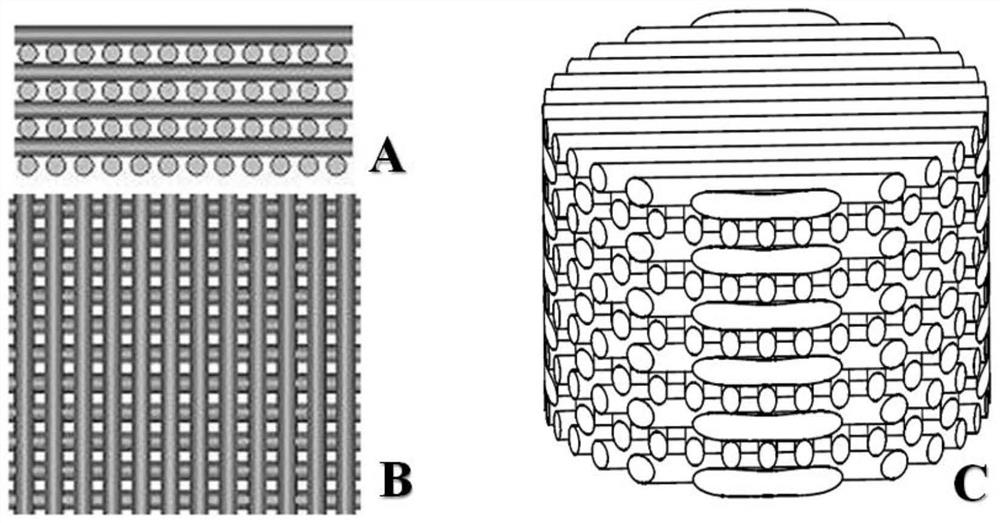

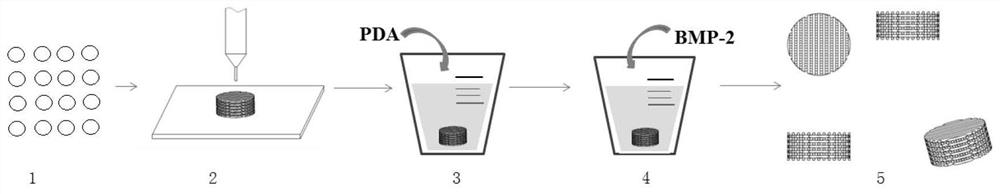

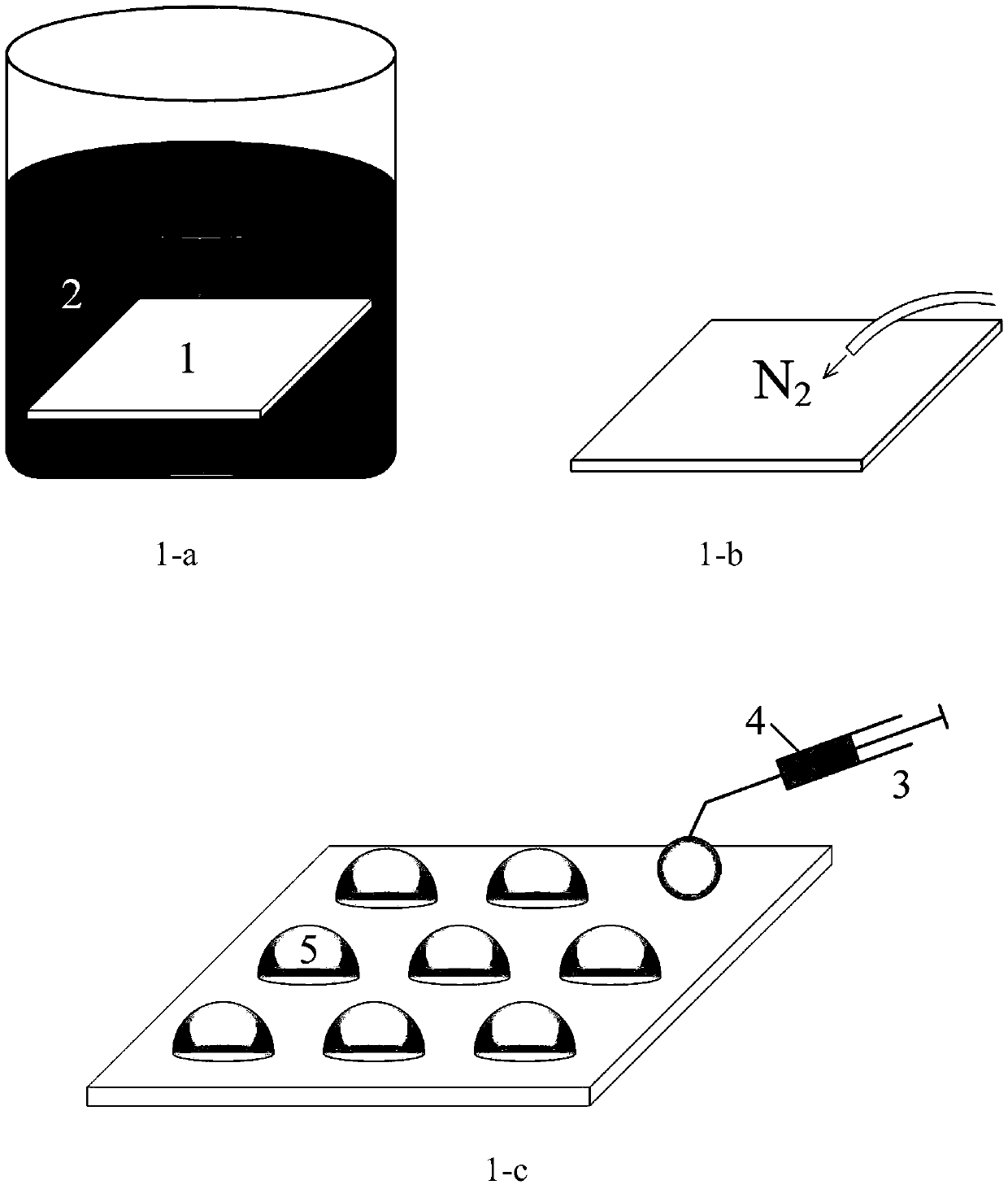

3D printed Ti-PDA-BMP-2 bone defect repair tissue engineering scaffold and preparation method thereof

InactiveCN108939156AAchieve fine controlAchieve sustained releaseAdditive manufacturing apparatusTissue regenerationFiberRepair tissue

The invention discloses a 3D printed Ti-PDA-BMP-2 bone defect repair tissue engineering scaffold and a preparation method thereof. The 3D printed Ti-PDA-BMP-2 bone defect repair tissue engineering scaffold is prepared from Ti6Al4V powder through a 3D printing technology and has a controllable shape, a pore microstructure and controllable physicochemical properties. A biological factor BMP-2 with bone repair ability is bonded to the engineering scaffold through polydopamine on the fiber surfaces and is used for repair and treatment on bone defects. The engineering scaffold has the advantages ofsimple and reliable structure, controllable shape and microstructure, simple and efficient surface modification, reliable mechanical property, high biological activity and safety, convenient implantation, small trauma and low cost.

Owner:南京冬尚生物科技有限公司

Capacitor anode formed of metallic columns on a substrate

ActiveUS7149076B2Increase capacitanceLiquid electrolytic capacitorsCapacitor electrodesCapacitanceHigh capacitance

Capacitor anodes that include metallic columns formed on a substrate so as to form a porous microstructure and methods of making the anodes are described. The metallic columns can be distinct from one another and project outward from the substrate. Also described is the formation of the metallic columns on the substrate by vapor deposition, including glancing angle deposition (GLAD), and by etching a portion of a metal layer. High capacitance capacitors made from the capacitor anodes are also described.

Owner:GLOBAL ADVANCED METALS USA

Thin-layer chromatoplate having ordered micro-nano structure and manufacturing method thereof

InactiveCN103267825AHigh-resolutionIncrease flow rateComponent separationStationary phaseNano structuring

The invention discloses a thin-layer chromatoplate having an ordered micro-nano structure and a manufacturing method thereof. The thin-layer chromatoplate comprises a base plate and a stationary phase on the base plate. The stationary phase comprises a skeleton having an ordered micro-nano inverse opal structure, and a mesoporous microstructure. The skeleton having the ordered micro-nano inverse opal structure is prepared by a photonic crystal film as a template. The surface of the skeleton having the ordered micro-nano inverse opal structure is modified by the mesoporous microstructure. The thin-layer chromatoplate utilizes the photonic crystal having the inverse opal structure as the skeleton. The inverse opal structure can provide enough micro- and nano-mesopores so that a flowing rate can be greatly improved; and a thin-layer chromatographic resolution ratio is obviously improved and good reappearance is obtained. Through combination of the thin-layer chromatogram and photonic crystals, an application scope is greatly expanded.

Owner:SOUTHEAST UNIV

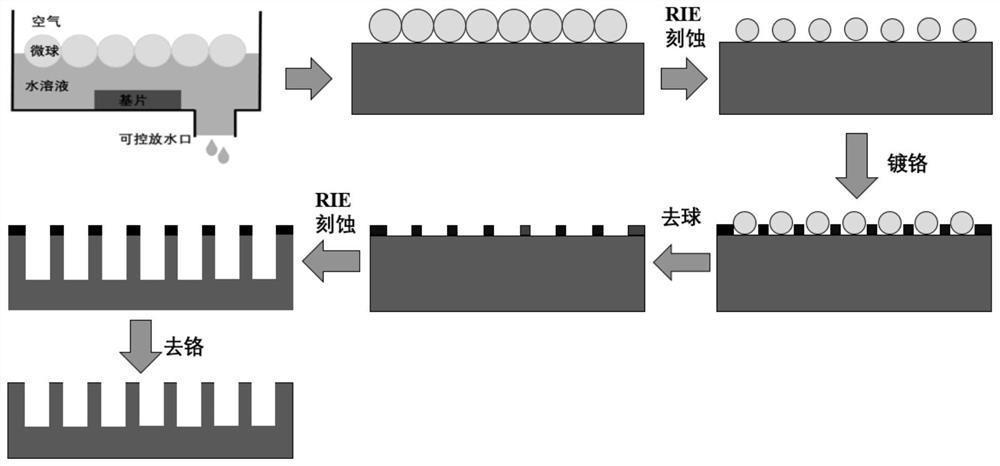

Manufacturing method of silicon-based deep hole microstructure

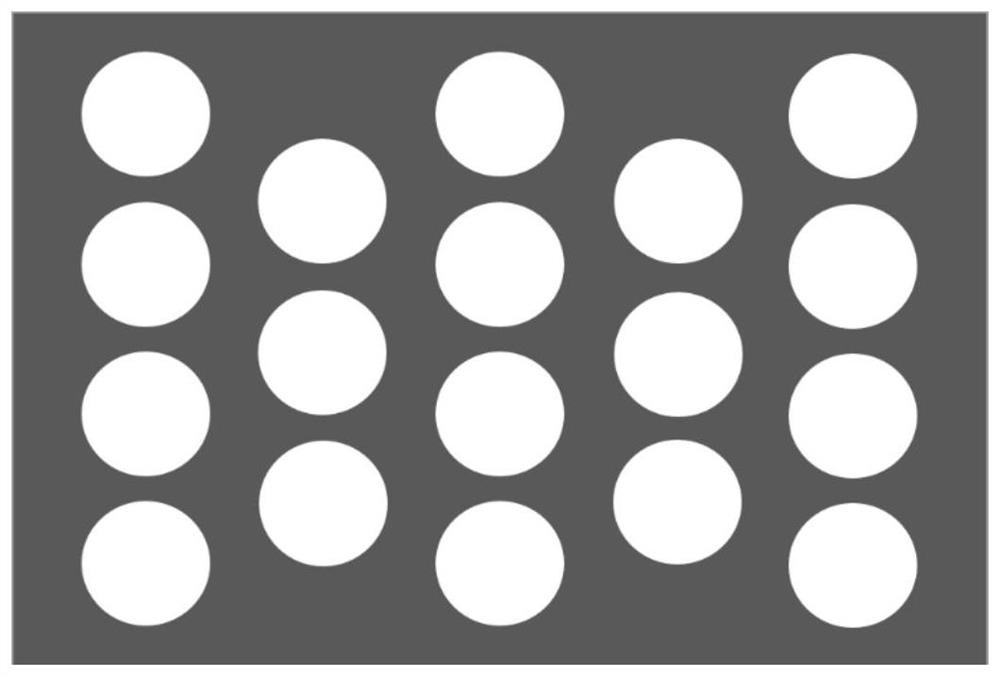

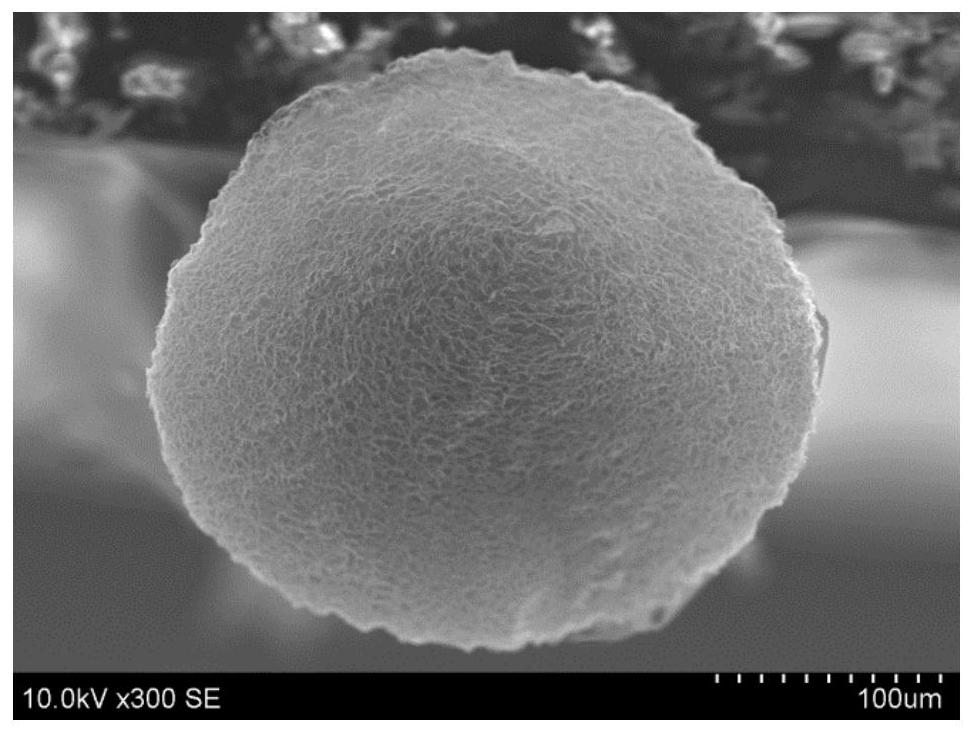

PendingCN111816558AIncrease the areaLow costDecorative surface effectsSemiconductor/solid-state device manufacturingMicrospherePolystyrene

A manufacturing method of a silicon-based deep-hole microstructure comprises the following steps: firstly, sequentially putting a silicon wafer into hydrogen peroxide and ammonia water, respectively soaking for 10 minutes, then cleaning with distilled water, putting in a clean place, and airing for later use; preparing turbid liquid in microsphere deionized water, selecting an original microspheresolution with an appropriate size of 400nm-100mu m, adding ethanol of which the volume is twice of that of the original microsphere solution, and performing ultrasonic treatment in an ultrasonic instrument for half an hour, so that polystyrene and ethanol are uniformly mixed; enabling the microspheres to form single-layer ordered arrangement on the liquid level; transferring the arranged microspheres to a silicon wafer by using a liquid level sedimentation method; reducing the sizes of the microspheres to obtain specific sizes; depositing 10-20 nm chromium metal on the etched sample wafer through a coating technology, and removing microspheres to form a microstructure with a hole array on a chromium film; and taking the chromium film with the hole array as a mask, removing the chromium film after etching, and finally manufacturing the silicon-based deep hole microstructure. A simple, efficient, large-area and low-cost method is provided for microstructuring the silicon-based material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Discrete element method-based double-layer porous asphalt pavement drainage characteristic analysis method

PendingCN112131805AExpress adhesionPerformance graininessDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationSoil science

The invention relates to a discrete element method-based double-layer porous asphalt pavement drainage characteristic analysis method, and belongs to the technical field of double-layer porous asphaltpavement drainage characteristics. By means of the discrete element simulation technology, the problems that irregular geometrical shapes and surface textures of aggregate are difficult to explain bya continuous medium pavement model, and adhesive force, viscoelastic plasticity, pore microstructure and drainage performance between an upper surface layer and a lower surface layer in a porous asphalt pavement influence each other are solved. According to the method, a double-layer porous asphalt pavement model is established mainly through discrete element software, coupling calculation is conducted on the double-layer porous asphalt pavement model and fluid dynamics software, and the double-layer porous asphalt pavement drainage characteristic rule is obtained through analysis. Accordingto the method, the irregular geometrical shape of the aggregate, the asphalt adhesive force and the granularity and the viscoelastic plasticity of the mixture can be well expressed, the asphalt mortarand gap three-phase structure formed by the drainage asphalt mixture serving as coarse aggregate, fine aggregate and an asphalt cementing material is effectively simulated, and the improvement of a model and drainage characteristic research accuracy is facilitated.

Owner:NANJING FORESTRY UNIV

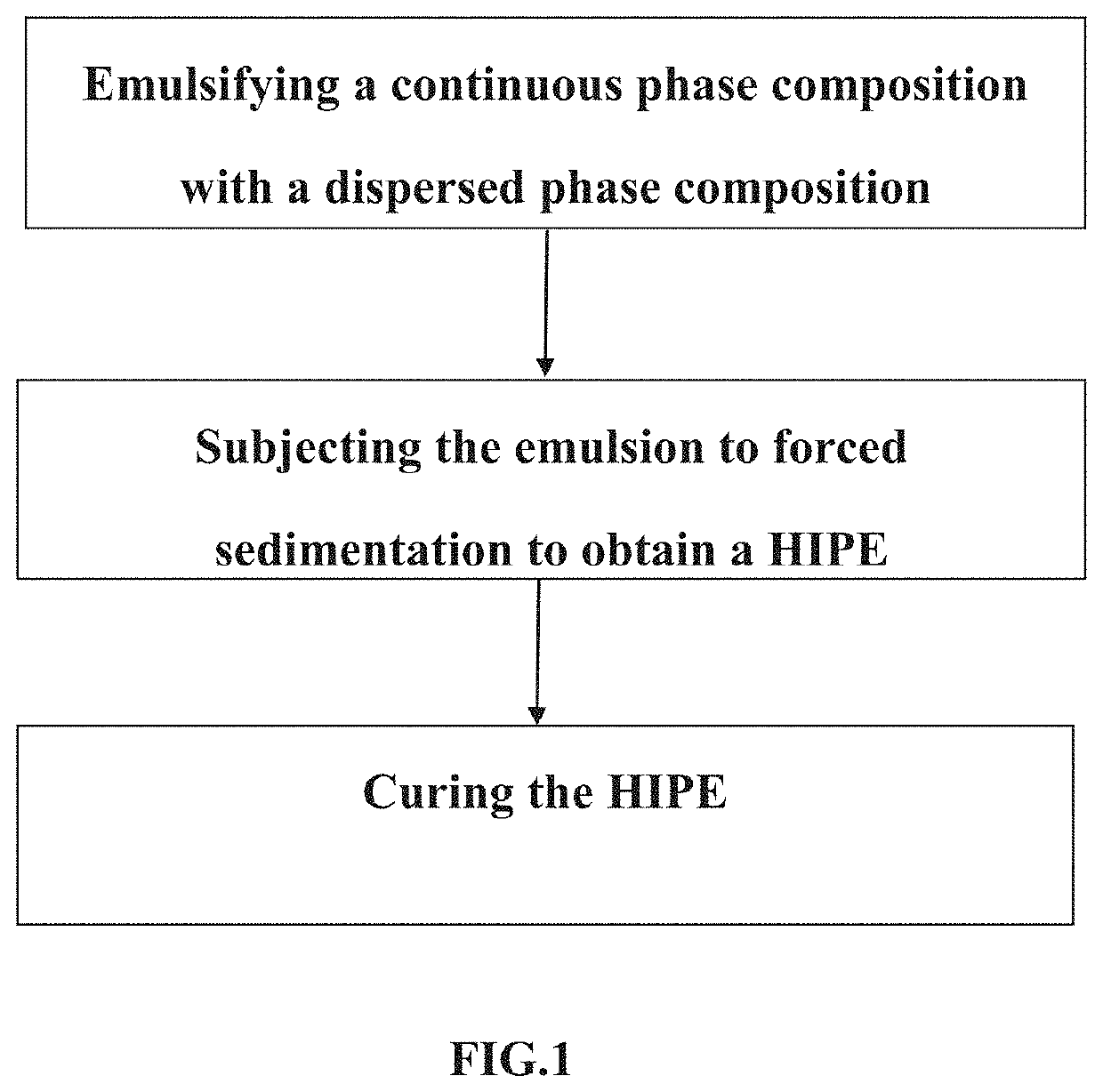

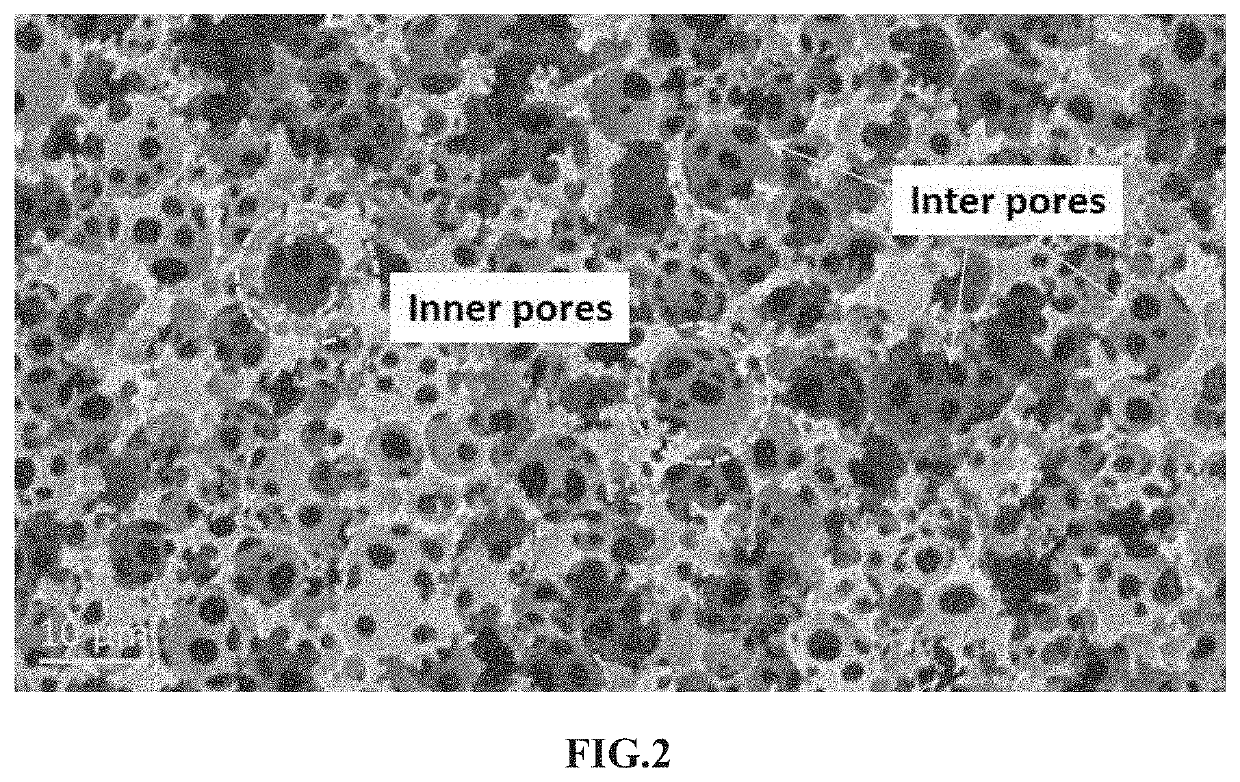

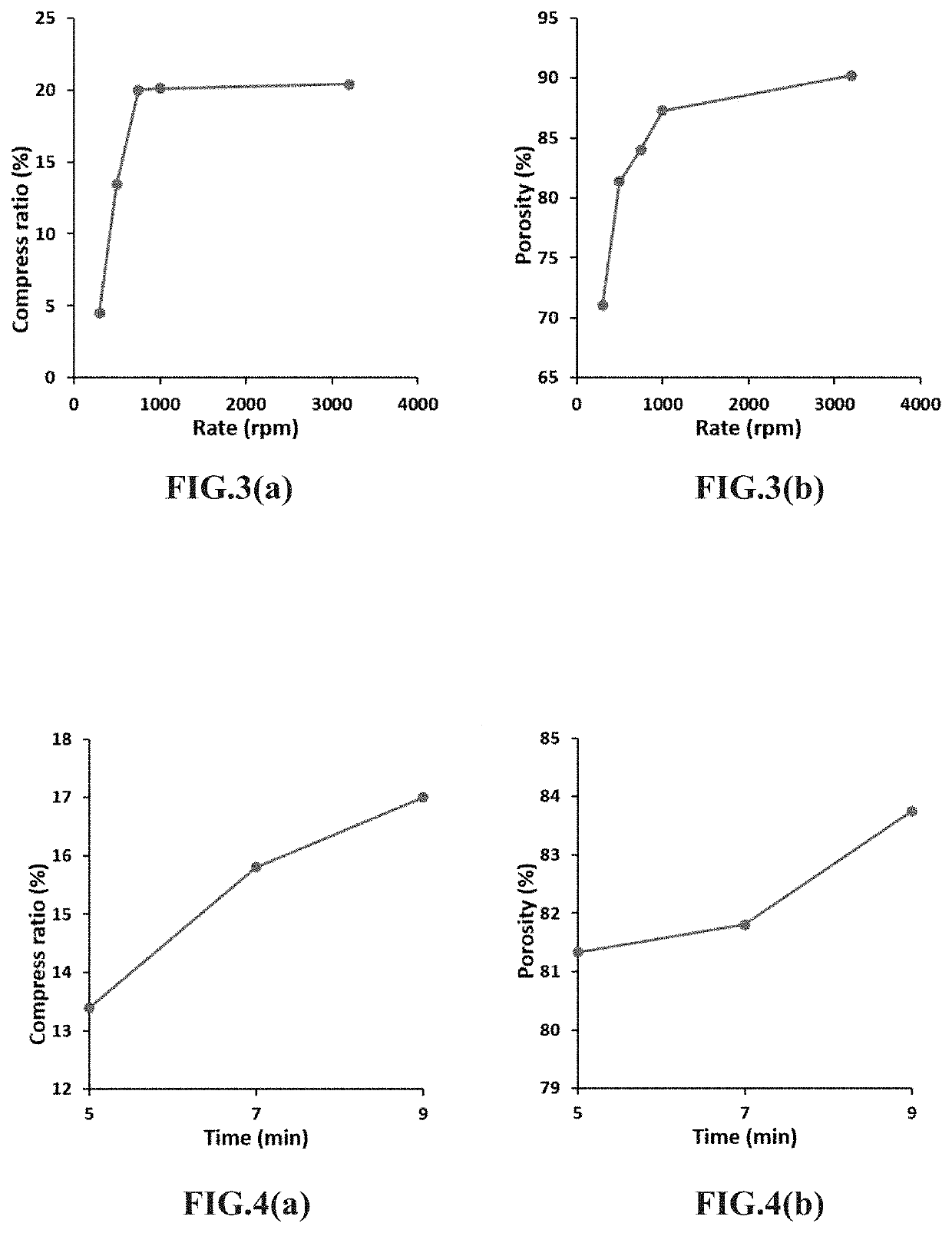

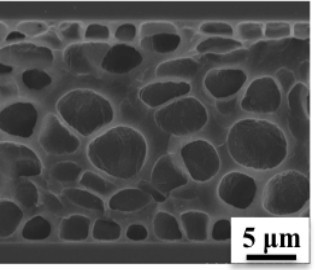

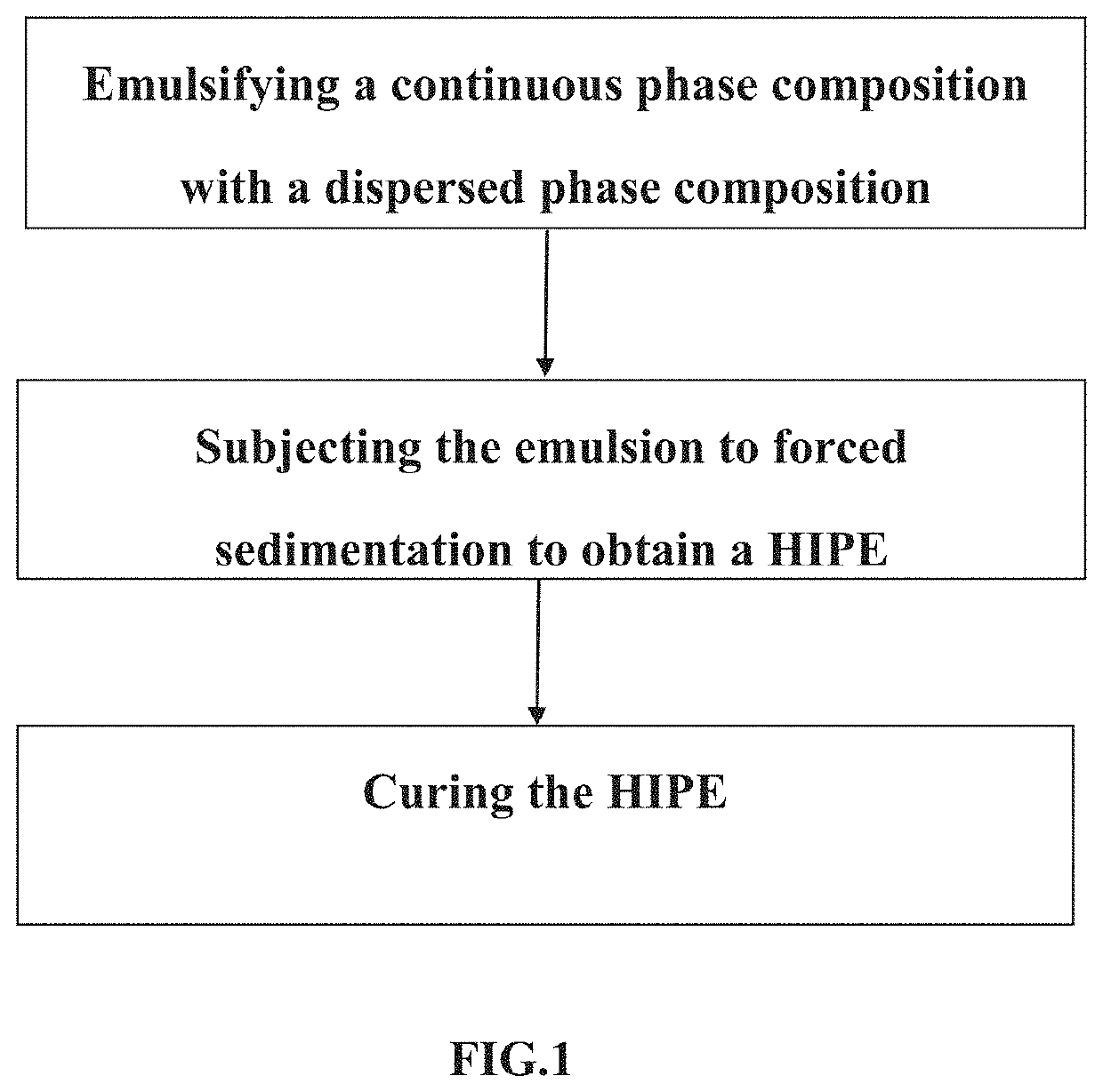

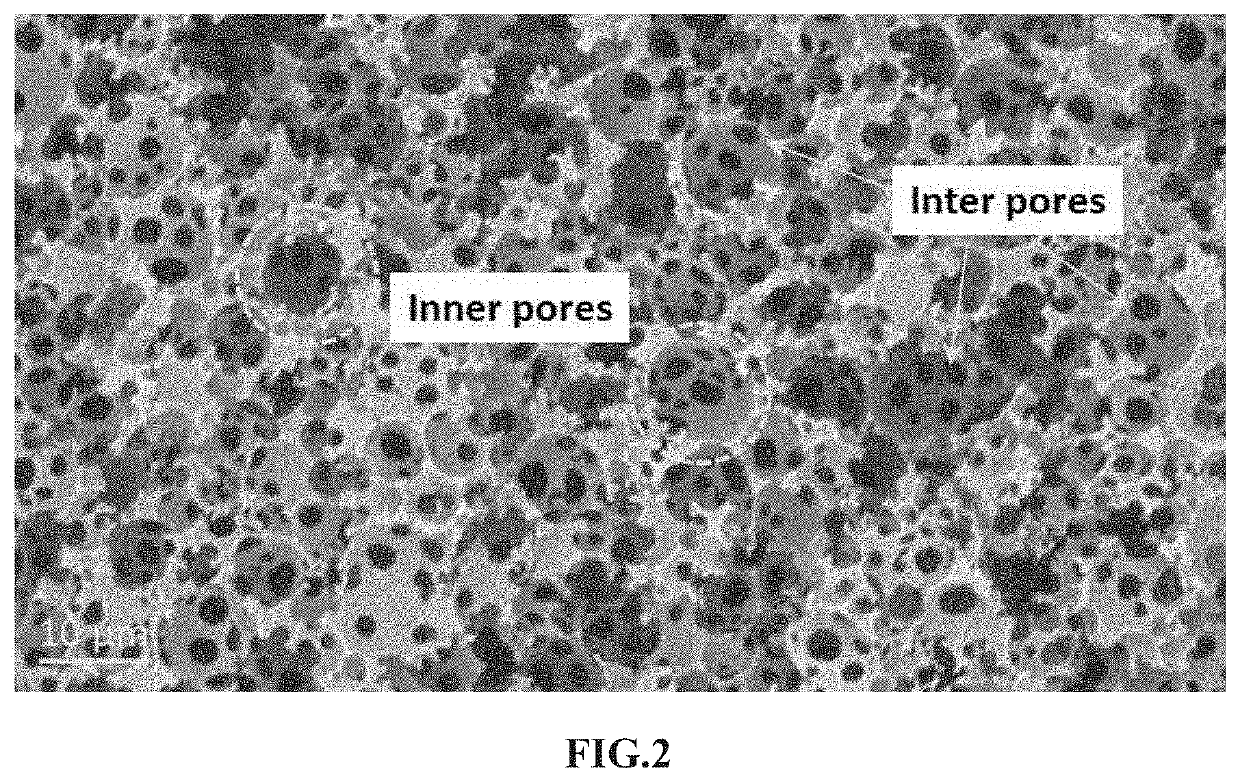

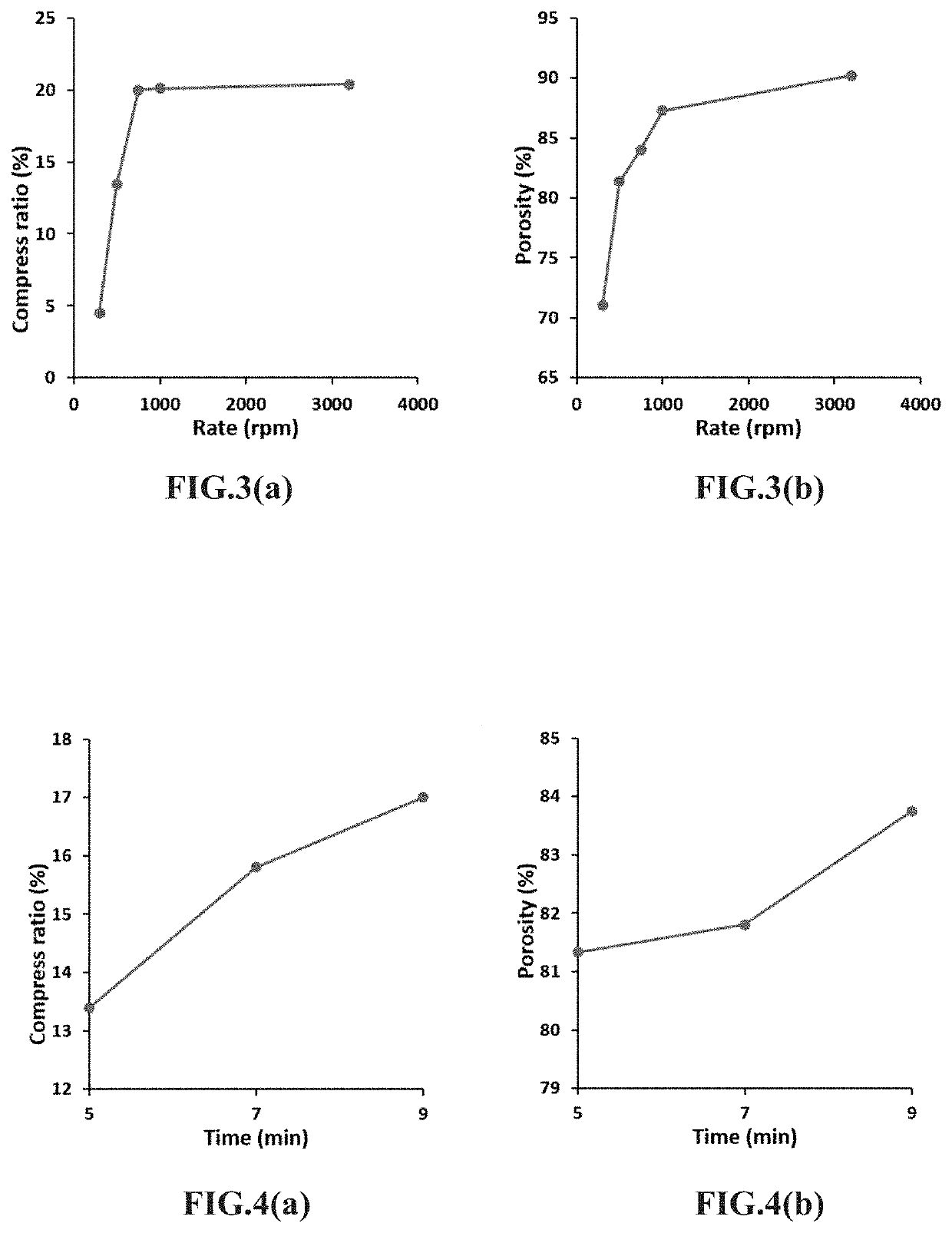

Method for producing porous microstructure

The invention relates to production of a porous microstructure using the high internal phase emulsion (HIPE) templating technology. The invented method involves subjecting an emulsion prepared by emulsification of two immiscible phases to forced sedimentation, such as subjecting the emulsion to centrifugation, so as to increase the volume ratio of the dispersed phase to the continuous phase to obtain a high internal phase emulsion (HIPE), following by curing the continuous phase, whereby the porous microstructure thus produced has an increased porosity.

Owner:TANTTI LAB INC

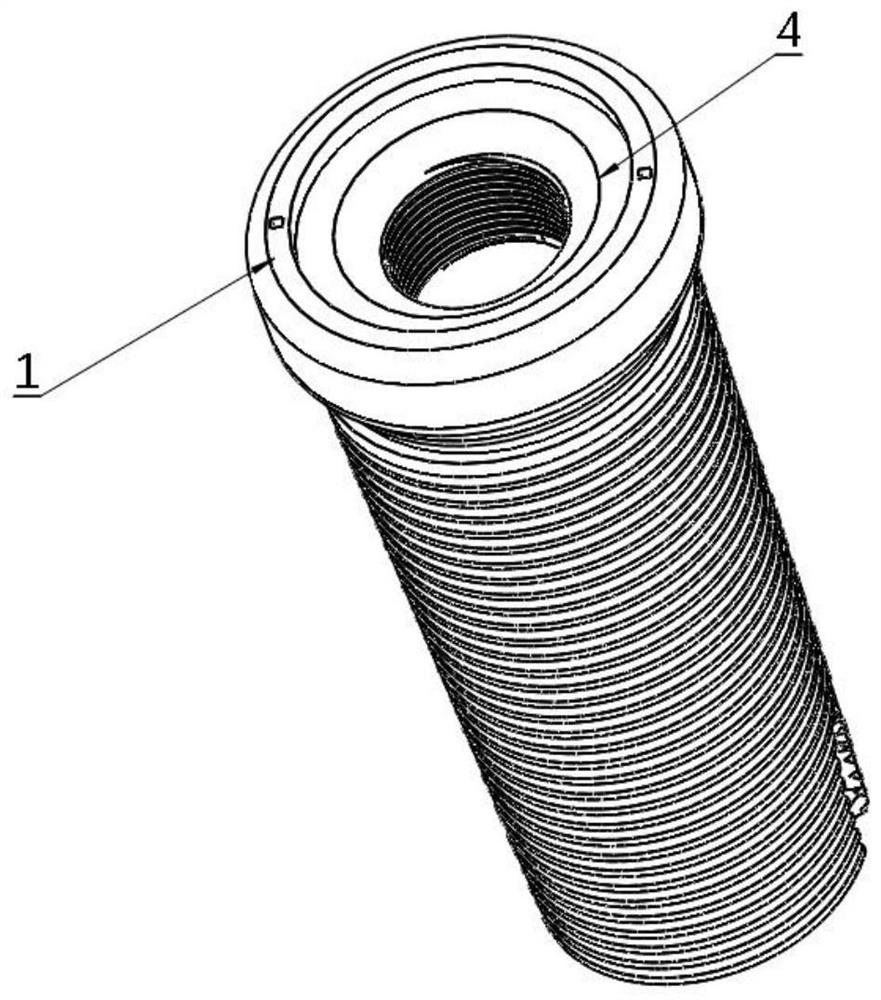

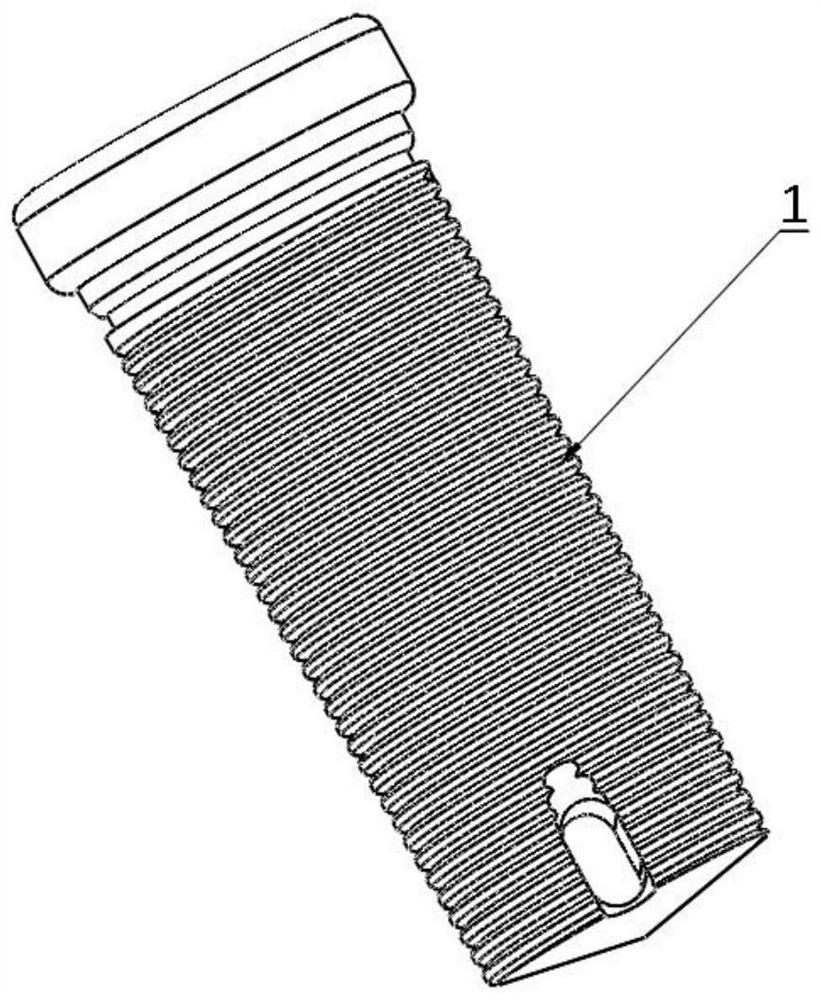

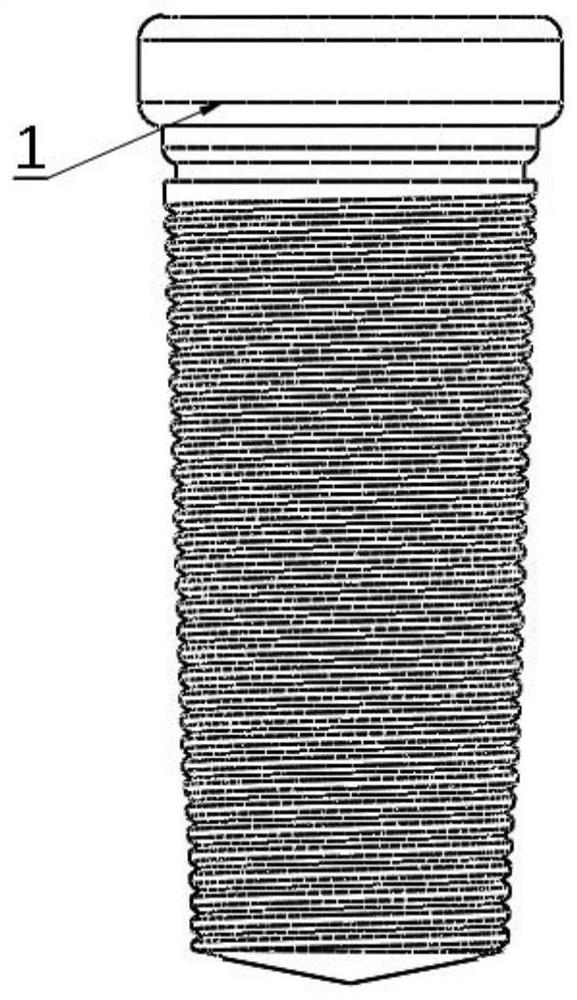

Artificial implant tooth root based on shape memory alloy porous microstructure

InactiveCN112472335AGood biomaterial compatibilityReduce loosenessDental implantsTissue regenerationShape-memory alloyBiomaterial compatibility

The invention relates to the technical field of artificial implant tooth roots, and discloses an artificial implant tooth root based on a shape memory alloy porous microstructure. The artificial implant tooth root comprises a tooth root core body, the tooth root core body is wrapped with a tooth root shell, and the periphery of the tooth root shell is provided with an external thread; the tooth root core body comprises a base and a porous microstructure which is in butt joint with the bottom of the base and has shape memory, and a threaded hole with an opening in the top is formed in the base;the periphery of the base is sleeved with an elastic backing ring, and the elastic backing ring is embedded into the inner side wall of the tooth root shell and abuts against the inner side wall of the shell from top to bottom; after the tooth root core body is subjected to longitudinal acting force, the porous microstructure is compressed and deformed, the porous microstructure is deformed and expanded, the side acting force applied to the tooth root shell is applied, and stress stimulation with a certain magnitude is performed on alveolar bone, so that the alveolar bone and an artificiallyimplanted tooth root have good biological material compatibility; the osteoporosis phenomenon caused by the stress shielding effect is avoided, and the possibility of failure caused by loosening and falling of the implant can be greatly reduced.

Owner:广州恒尚科技有限公司

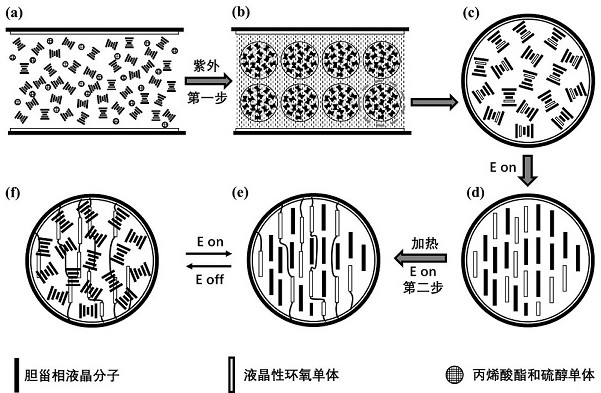

Liquid crystal/polymer composite electric control dimming film and preparation method thereof

ActiveCN114779516AReduce Orientation DifficultyUnique Composite MicrostructureNon-linear opticsLiquid crystal compositionsPolymer sciencePolymer network

The invention relates to a liquid crystal / polymer composite electric control dimming film and a preparation method thereof, the liquid crystal / polymer composite electric control dimming film comprises a liquid crystal material, a polymer matrix and two layers of ITO conductive films, the polymer matrix is of a porous microstructure and is clamped between the two layers of ITO conductive films, the liquid crystal material is dispersed in the polymer matrix to form liquid crystal microdroplets, and the liquid crystal microdroplets are dispersed in the polymer matrix. The liquid crystal microdroplets have a vertically oriented polymer network; the polymer matrix is prepared from a first polymerizable monomer through first-step photopolymerization or thermal polymerization, and the macromolecular network is prepared from a second polymerizable monomer through second-step photopolymerization or thermal polymerization. A two-step polymerization method is adopted, firstly, a polymer matrix of a porous microstructure similar to PDLC is constructed through first-step polymerization, then a vertically-oriented polymer network is constructed in liquid crystal microdroplets through second-step polymerization, and therefore the unique composite microstructure is achieved.

Owner:PEKING UNIV

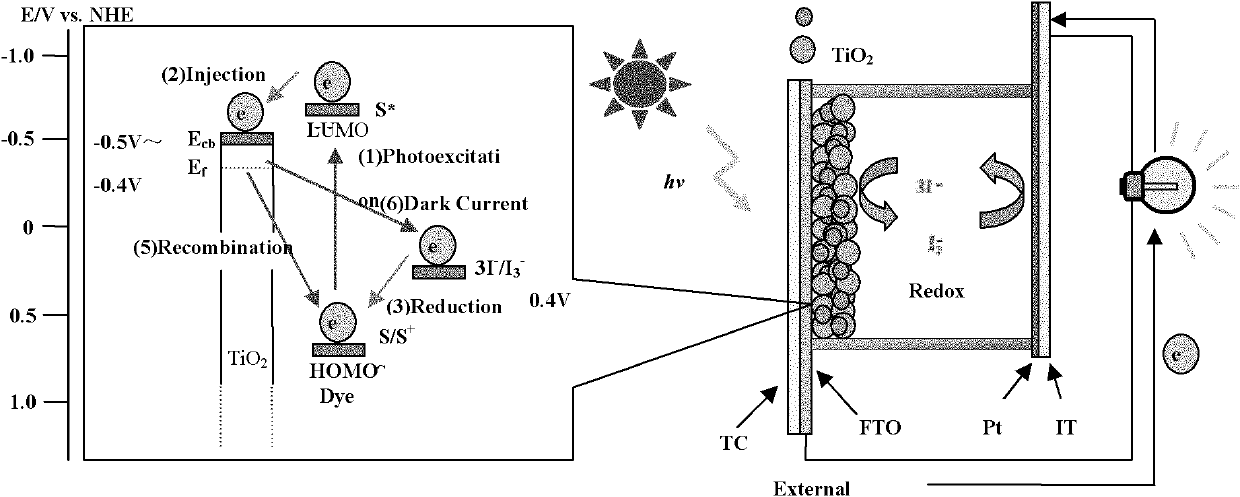

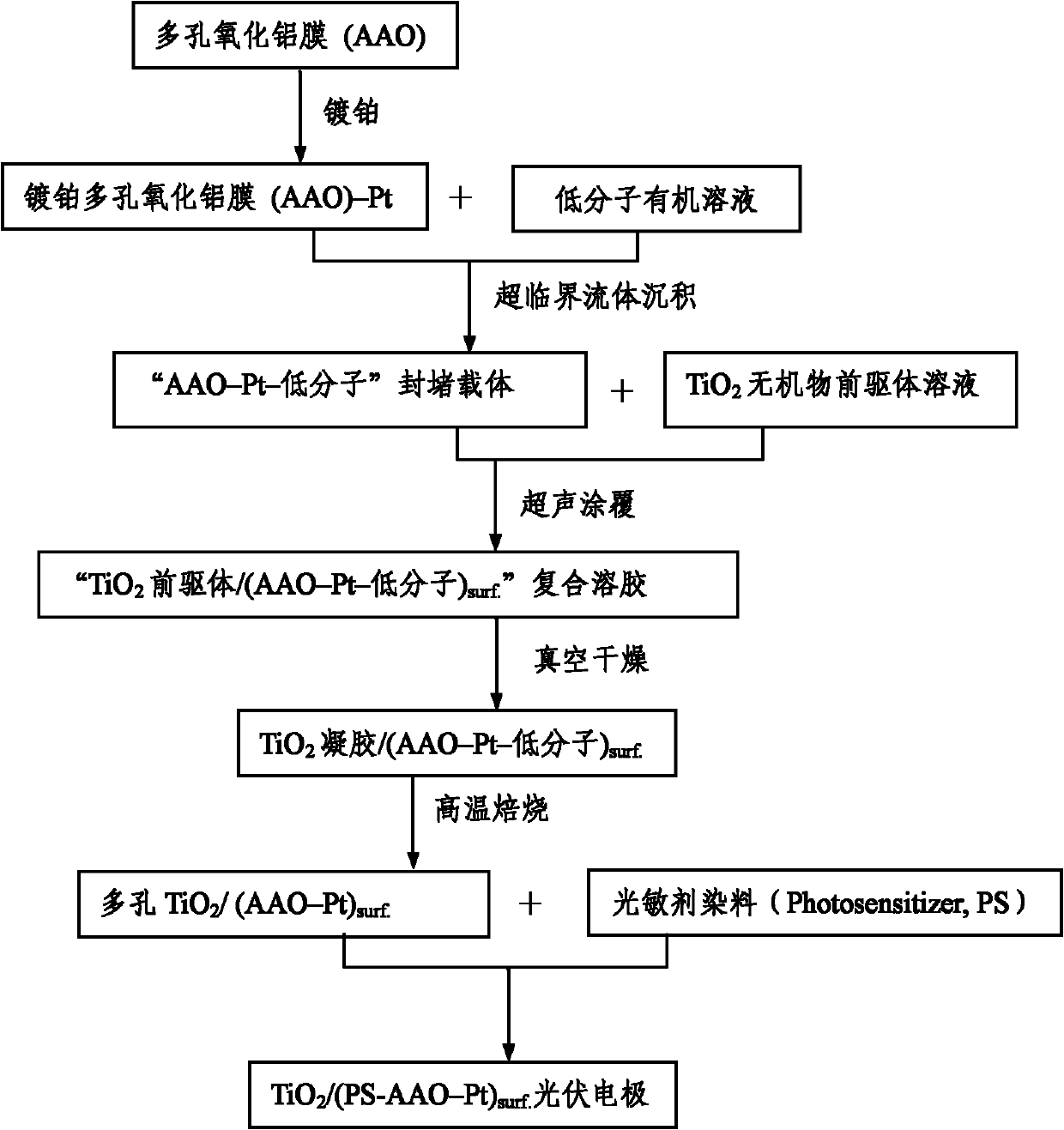

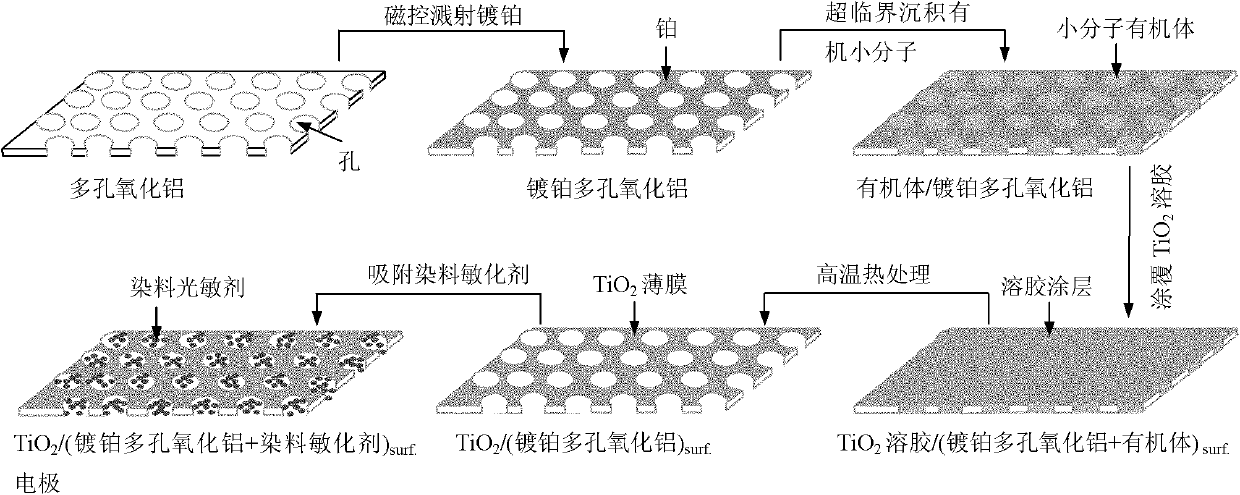

Dye-sensitized externally loaded TiO2/(PPA-Pt) surf. film electrode and preparation process thereof

InactiveCN102005302AImprove stabilityImprove long-term effectLight-sensitive devicesFinal product manufacturePrecipitationPore microstructure

The invention discloses a dye-sensitized externally loaded TiO2 / (PPA-Pt) surf. film electrode and a preparation process thereof. Low molecular weight organic substance solution is permeated into pores by using supercritical fluid precipitation technology and using platinum-plated porous aluminum oxide (PPA-Pt) with high specific surface area as a template, and then condensation and precipitation are performed to realize plugging of the pores of a porous material. The loading of a nano TiO2 film only on the surface of the porous PPA-Pt is realized by using the porous PPA-Pt and the porous material as double templates and adopting a sol-gel method and thermal treatment, the original pore microstructure property of a carrier is recovered, and an externally loaded TiO2 / (PPA-Pt) surf. film electrode photovoltaic cell is synthesized. The film electrode has good stability and long-acting property; and the preparation process is simple and easy for industrialized production, prepares the externally loaded TiO2 / (PPA-Pt) surf. film electrode with novel structure and good physical and chemical properties, and makes positive contribution to developing research theories, technology and methods of porous materials and externally loaded nano materials.

Owner:JISHOU UNIVERSITY

Method for producing porous microstructure

Owner:TANTTI LAB INC

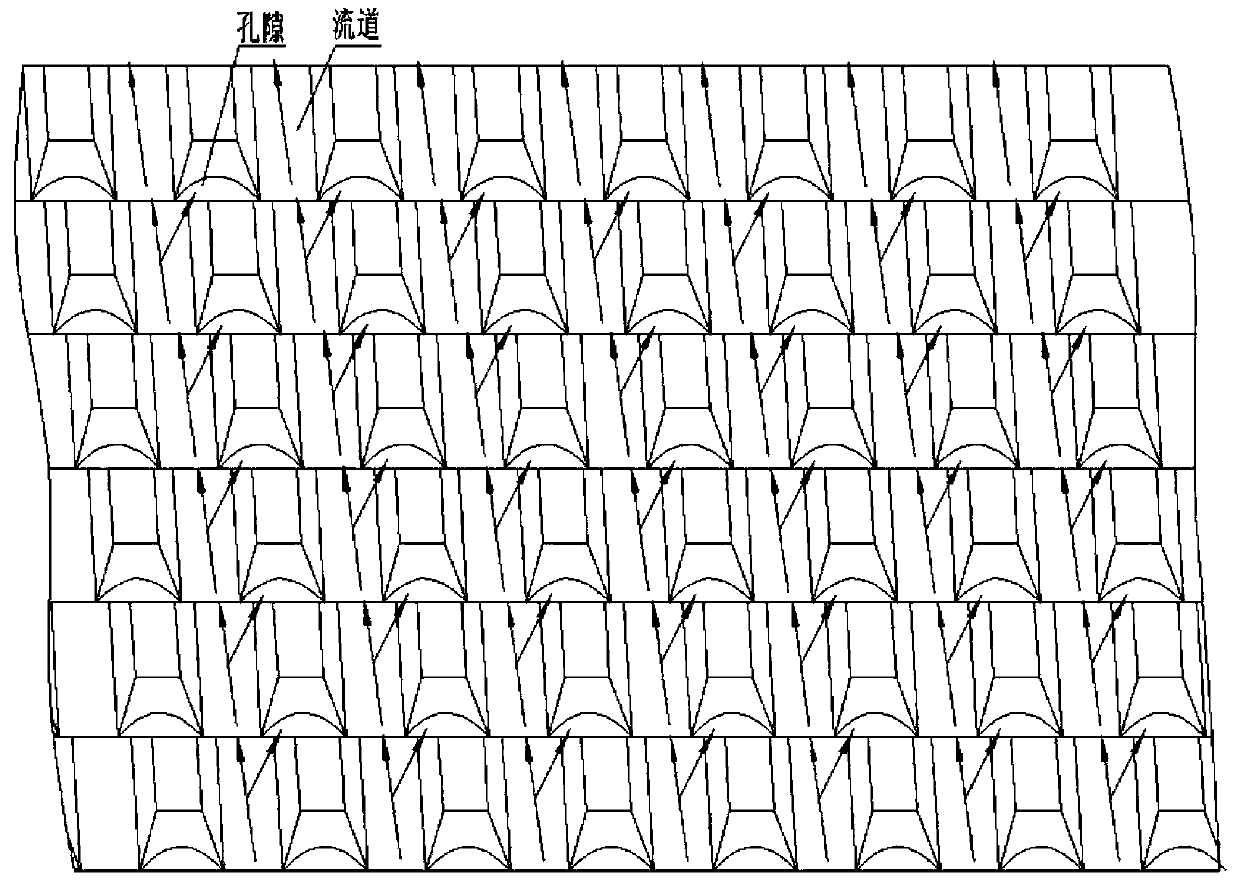

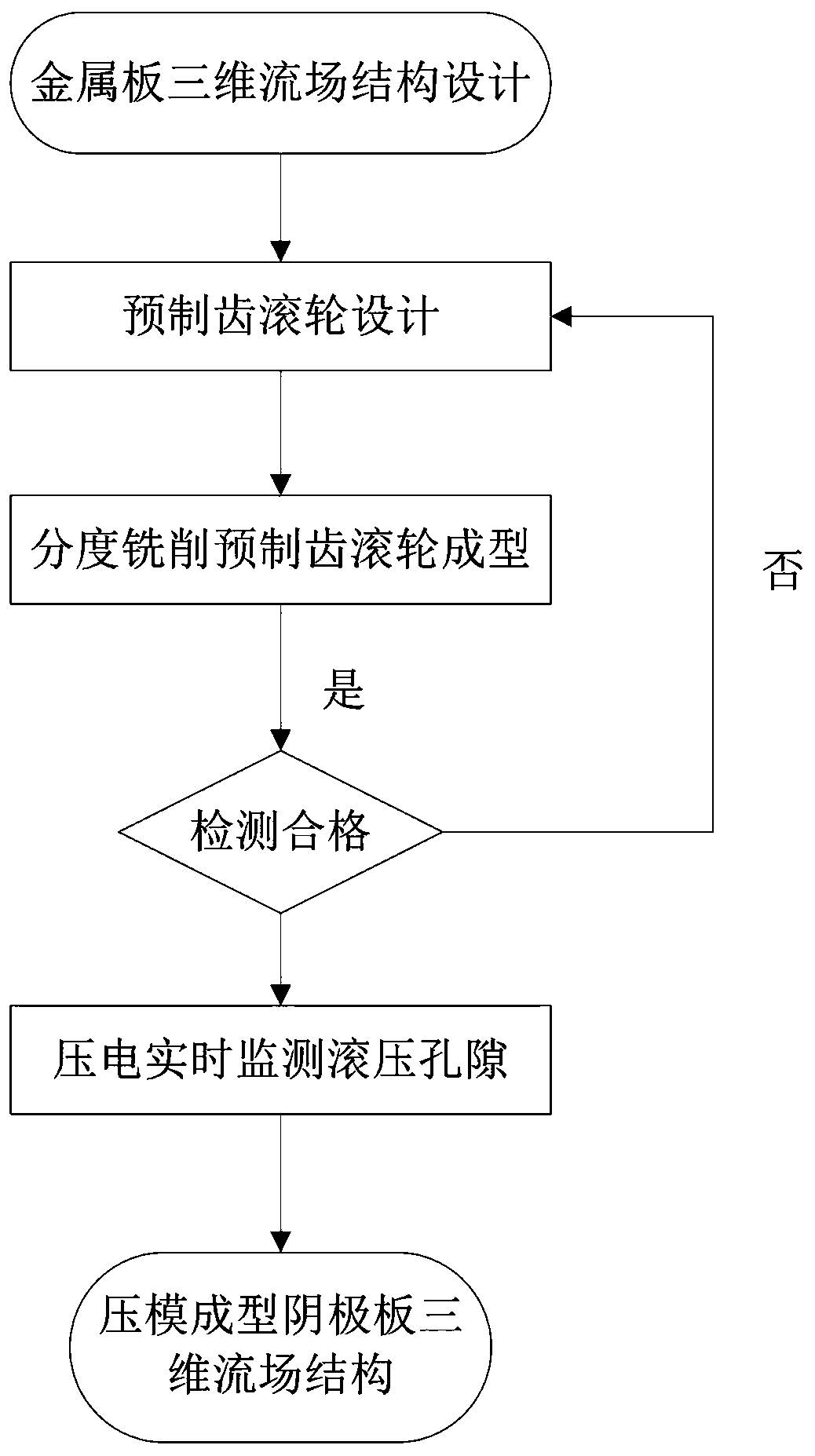

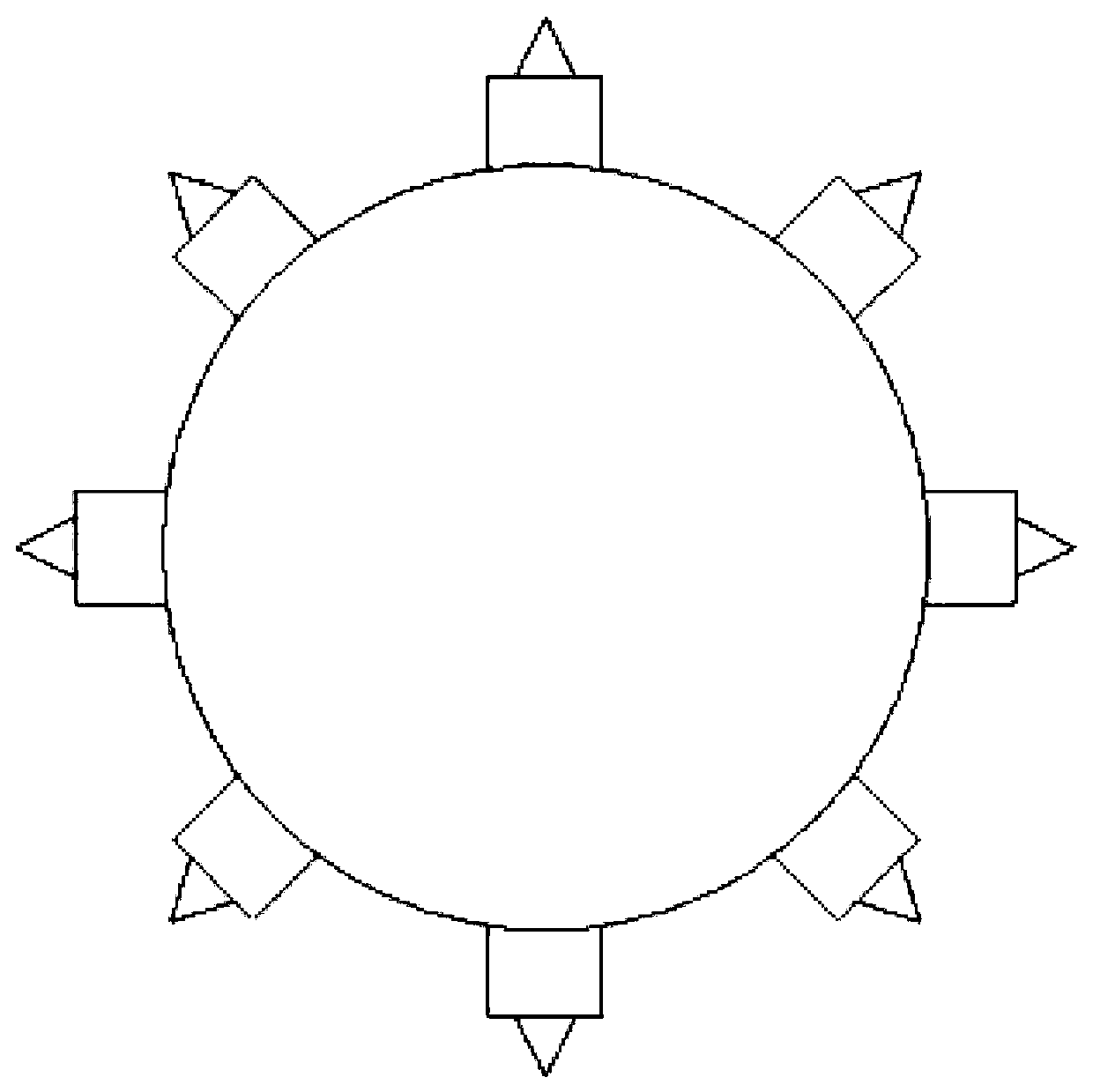

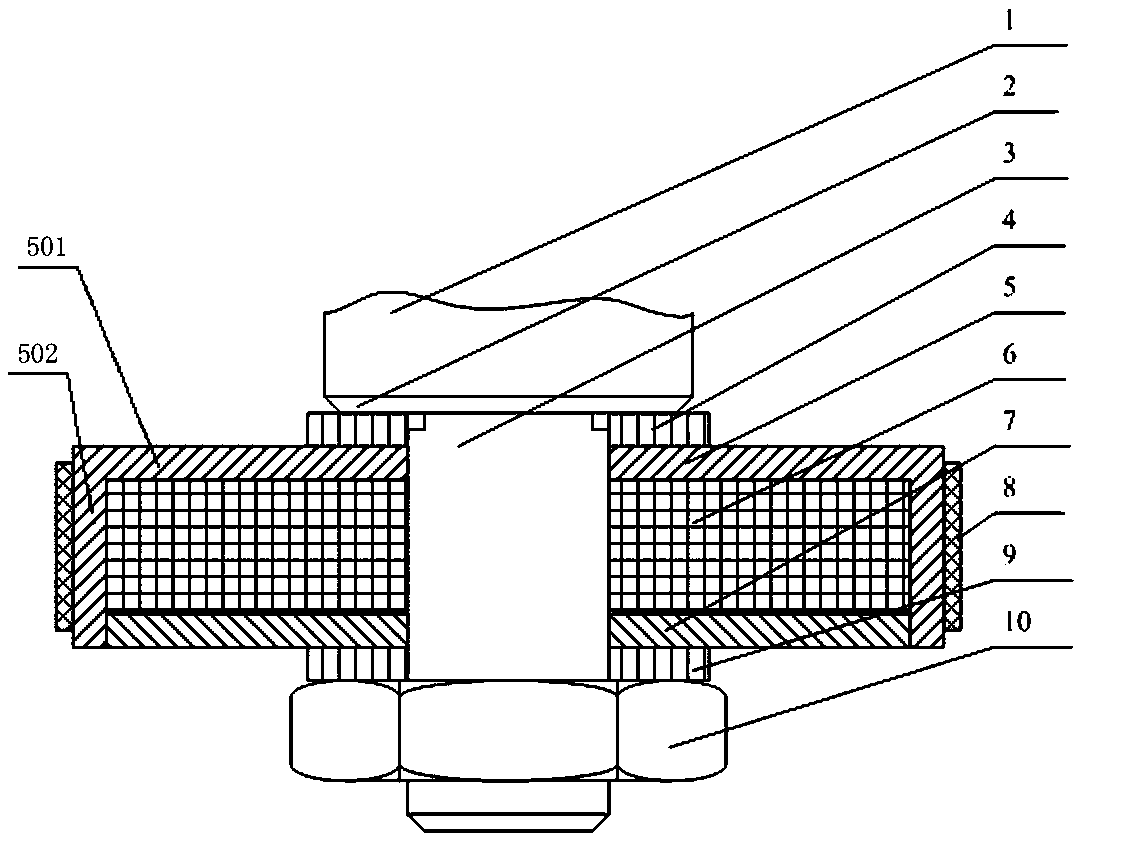

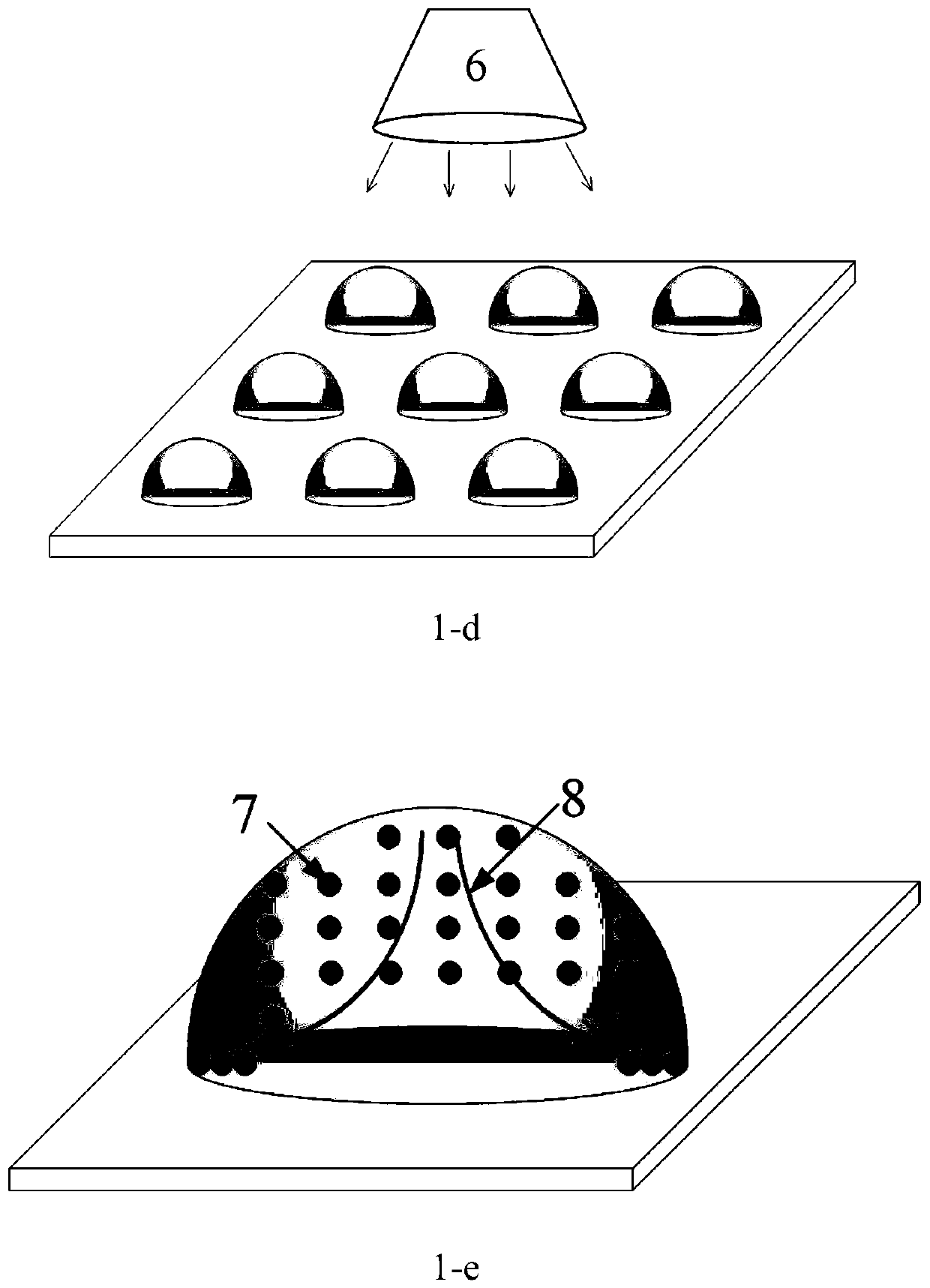

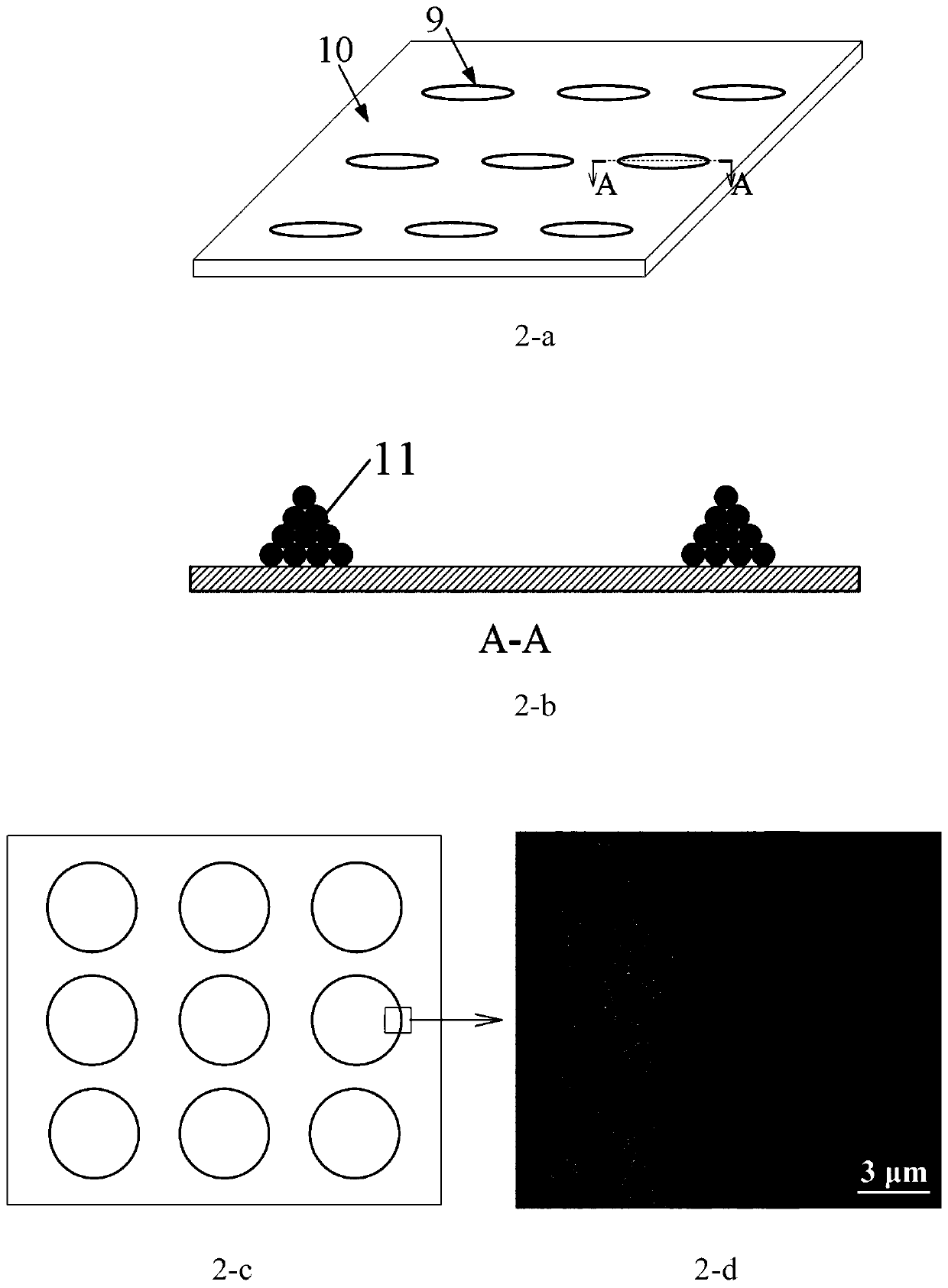

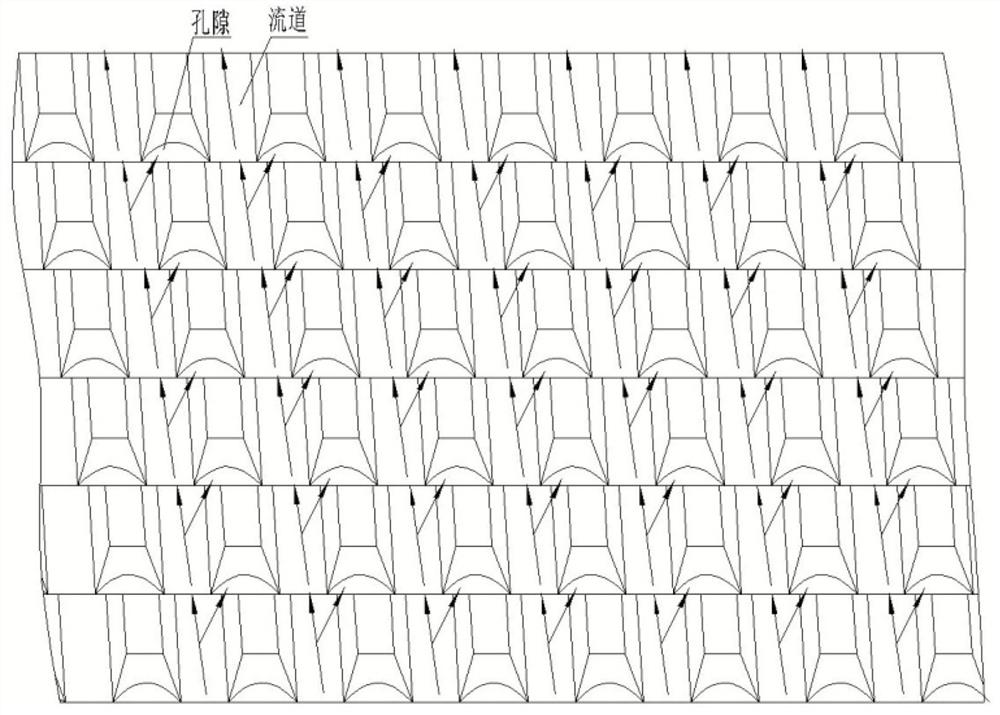

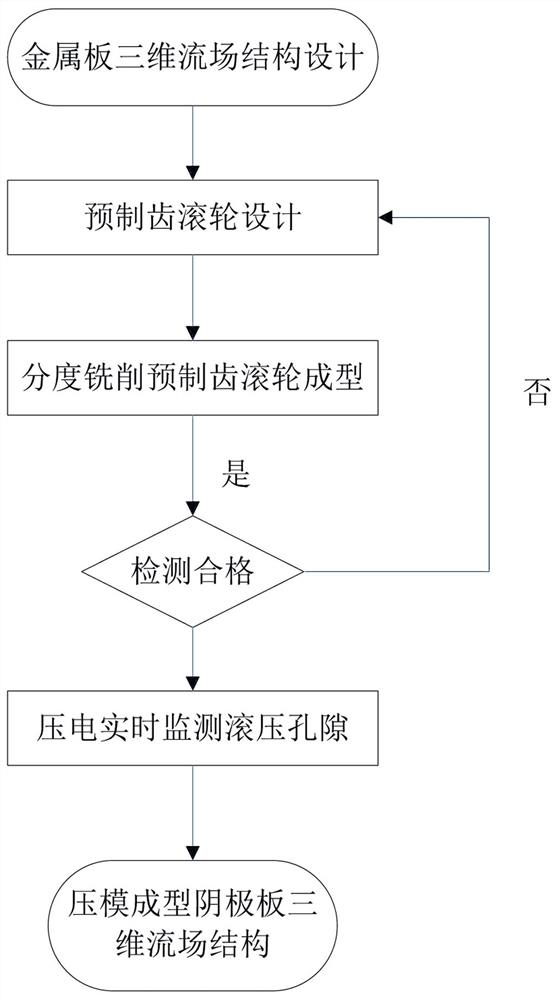

Method for forming surface microstructure of fuel cell metal cathode plate

The invention discloses a method for forming a surface microstructure of a fuel cell metal cathode plate. The method firstly accurately designs the roller of the mechanical and electrical system by using a piezoelectric brake loading material micro-deformation method, and then completes the research and development work of the 200[mu]m-class micro-groove device to obtain a mechanical structure anda servo control system conforming to the electromechanical precision thereof. The invention proposes a method for processing pores of a double-layer cathode plate and proposes a processing method fora roller capable of suppressing pores of 200[mu]m, and finally combines a mechanical micro-rolling method with real-time piezoelectric braking to single-roll form a 200[mu]m-class surface pore microstructure, which has high production efficiency, accurate dimensional control and easy preparation of metal surface texture in large quantities.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

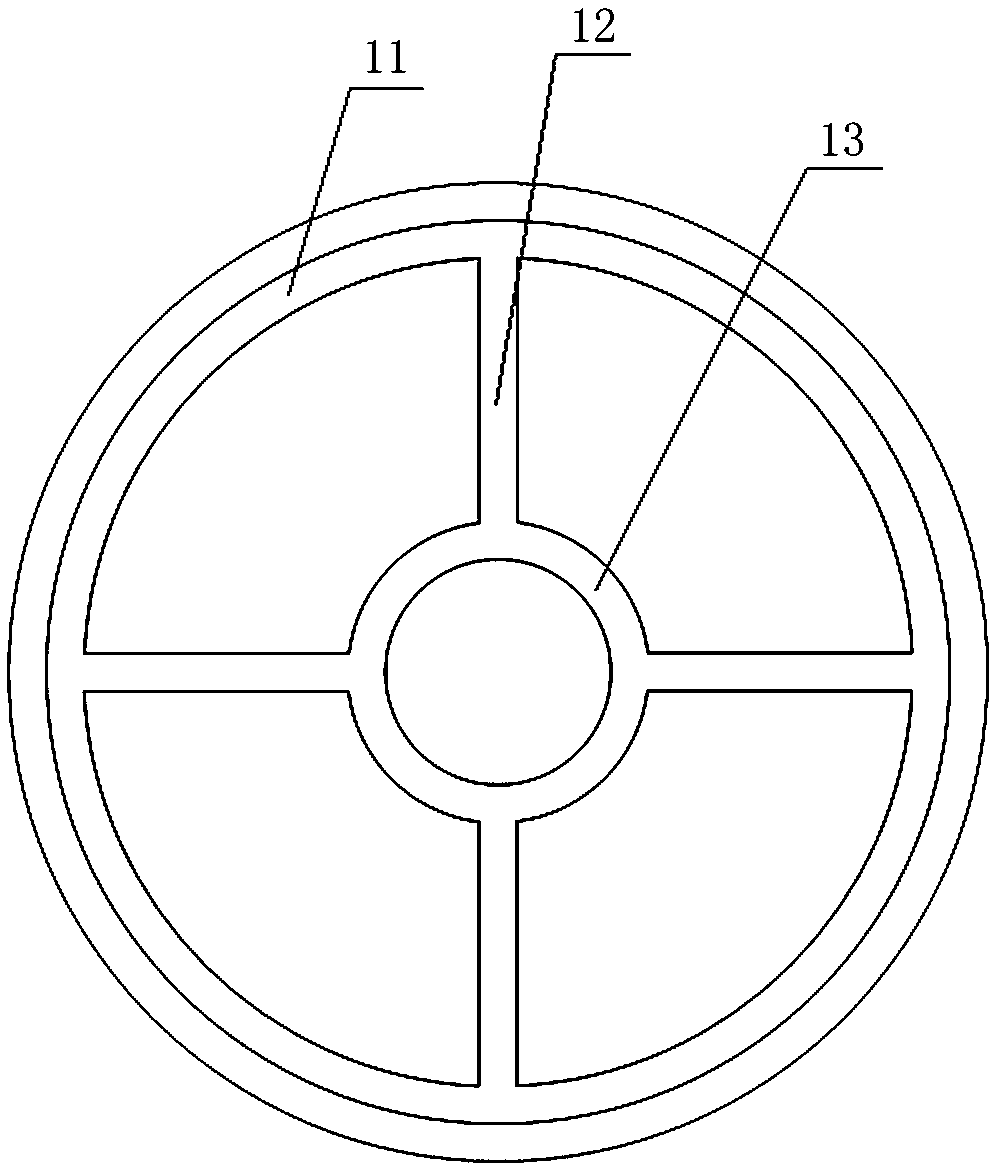

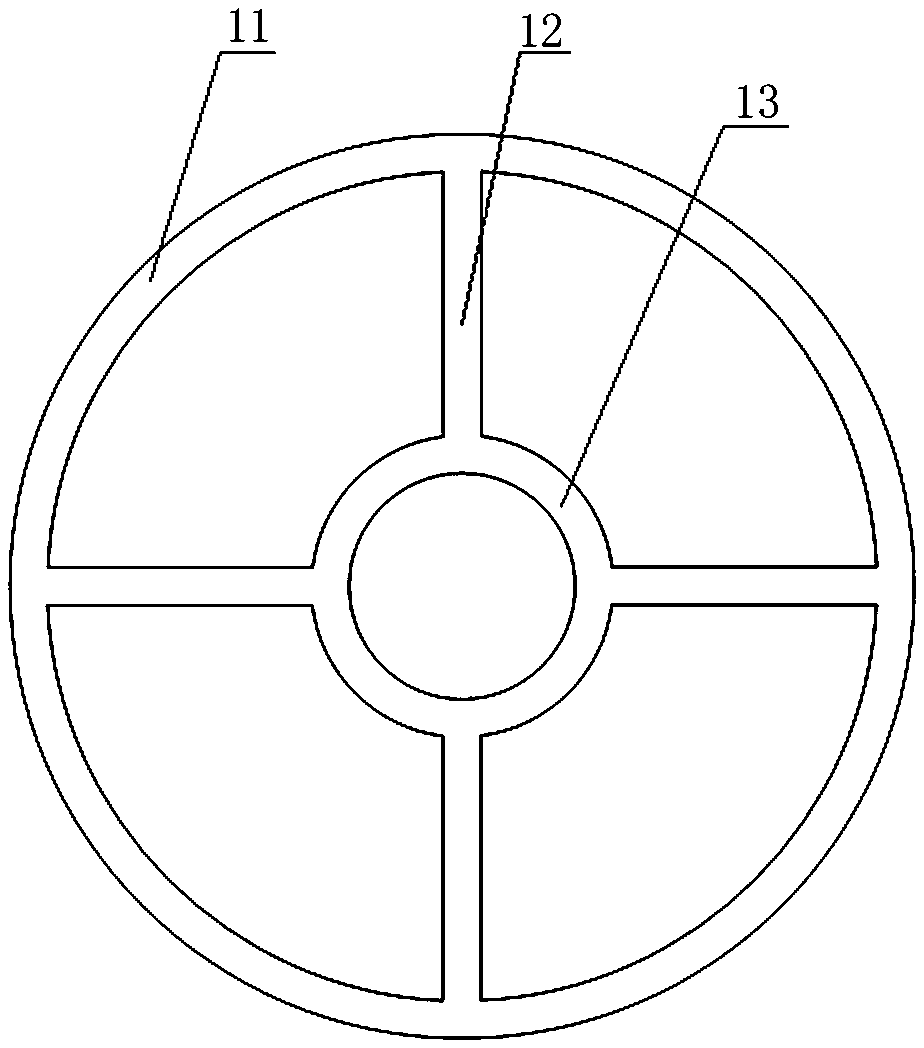

Shock absorber piston valve structure

InactiveCN108468745AAvoid distortionIncrease contact areaSpringsShock absorbersCavitationEngineering

The invention discloses a shock absorber piston valve structure, and relates to the field of shock absorbers. The shock absorber piston valve structure comprises a piston rod which is composed of a coaxial large-diameter section and journal section; a piston valve is arranged on the journal section of the piston rod and comprises a valve element which sleeves the journal section of the piston rod;the valve element is made of a porous material; a plurality of through holes I communicating with one another are formed in the valve element; oil cavities which are formed in the upper part and thelower part of the valve element separately can communicate with each other through the through holes I; a covering body covering the valve element is arranged on the valve element; and a plurality ofthrough holes II penetrating through the covering body in the axial direction are formed in the upper side and the lower side of the covering body. According to the shock absorber piston valve structure, the porous material is applied to a valve element structure of the shock absorber piston valve, irregular pore microstructures inside the porous material are utilized, so that energy dissipation is generated when compressed oil liquid flows through the pore microstructures, and damping force is generated; and a large number of pore structures on the surface of the porous material are utilized,the contact area of the porous material and the upper oil cavity and the lower oil cavity is increased, and therefore under the high-speed working condition, and the phenomena that the working characteristics of the shock absorber are distorted, and cavitation of the oil liquid is generated can be avoided.

Owner:YANGZHOU UNIV

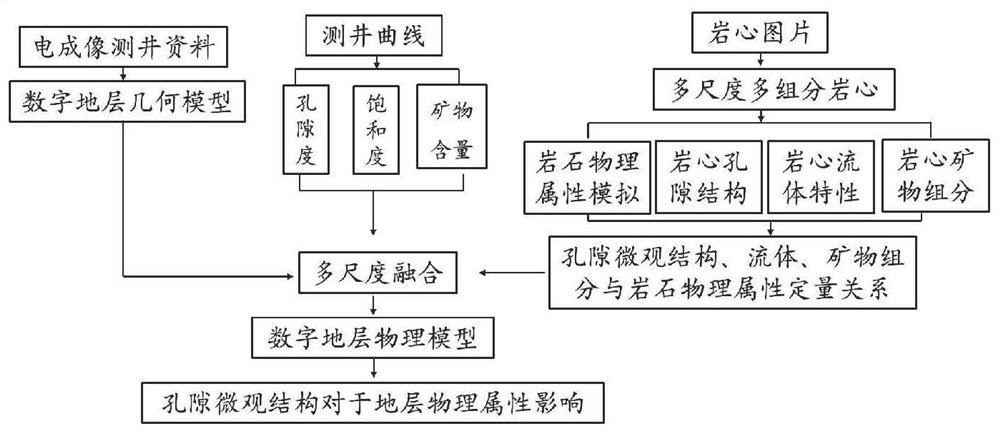

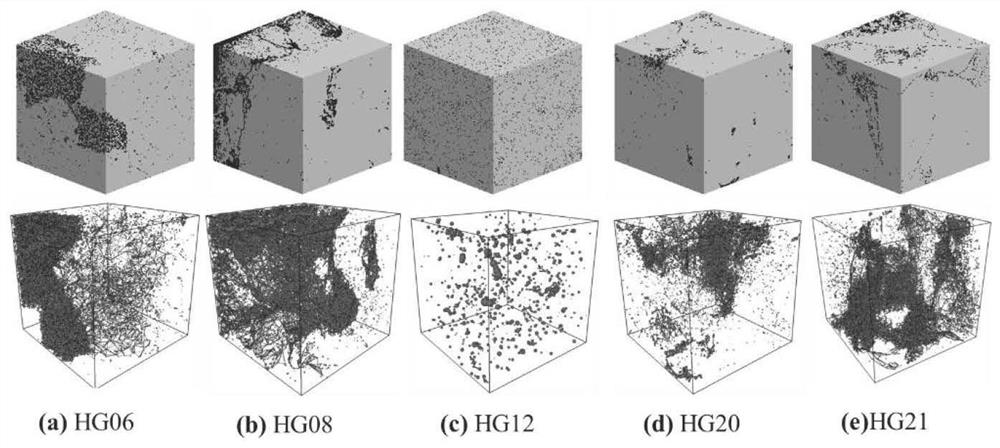

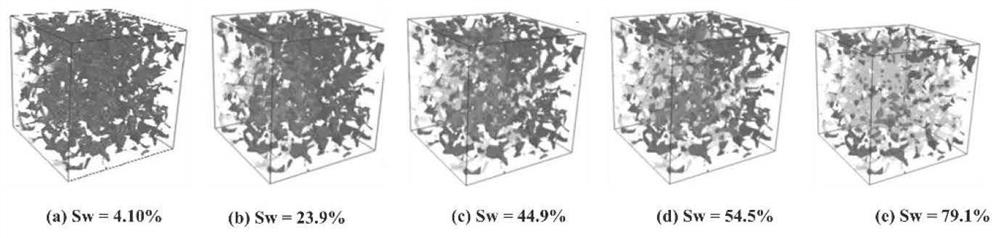

Unconventional reservoir multi-scale fusion method based on digital core technology

PendingCN114325845AIncrease reservesEmission reductionElectric/magnetic detectionAcoustic wave reradiationRock coreWell logging

An unconventional reservoir multi-scale fusion method based on the digital core technology comprises the steps that 1, a tight sandstone three-dimensional digital stratum initial physical model is constructed according to electric imaging logging information and logging curve data; 2, according to a three-dimensional digital rock physical experiment of the compact sandstone digital core, establishing a quantitative relation model of a pore microstructure, fluid characteristics, mineral components and rock physical attributes; 3, fusing the resistivity reflecting the pore microstructure into the three-dimensional digital stratum physical model of the logging detection scale by adopting a finite element resistivity numerical simulation method, and obtaining a digital stratum resistivity curve; and 4, based on the tight sandstone three-dimensional digital stratum, determining the influence of the pore microstructure on the physical properties of the stratum. A quantitative relationship between a core micro-pore structure and physical attributes is established by adopting a three-dimensional digital rock physical experiment based on a digital core, and memory consumption is reduced through physical attribute fusion.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fluidic system, use, and method for operating the same

ActiveUS9726302B2Improve efficiencyAvoid excessive wearValve arrangementsUltrafiltrationElectromagnetic radiationFluid system

A fluidic system having a first volume, a second volume and a membrane geometrically separating the two volumes, which has an open-pore microstructure for the passage of a first medium and a second medium. There is a contact angle (Θ) between the interface of the media and the pore surface. A first electrical field in the region of the membrane and a first electromagnetic radiation and a first heating of the membrane define a first state (Z1), in which the membrane is not wetted or is less wetted by the first medium and is more heavily wetted by the second medium such that a first contact angle Θ1>90° is formed between the pore surface and the interface. The first medium and the second medium and the pore surface have a surface energy of which at least one surface energy can be reversibly changed in such a way that a second contact angle Θ2<Θ1 occurs between the pore surface and the interface in a second state (Z2).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

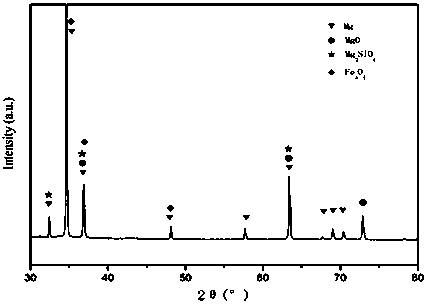

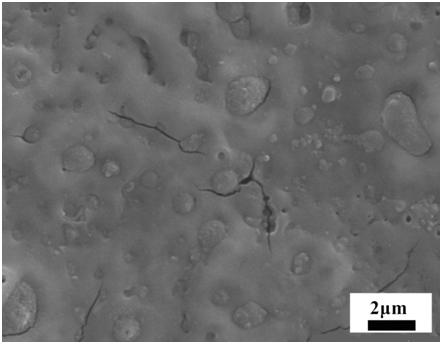

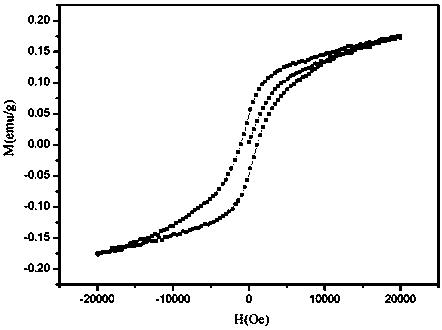

A kind of magnetic composite oxide ceramic membrane with self-sealing pore structure and its preparation method

ActiveCN109295488BUnique self-sealing pore structureAvoid enteringAnodisationElectrolytic inorganic material coatingOxide ceramicElectrolytic agent

The invention discloses a magnetic composite oxide ceramic membrane with a self-hole-sealing structure and a preparation method. The method includes the following steps that (1), magnesium alloy is subjected to surface pre-treatment; (2), a strongly-basic composite electrolyte solution containing sodium silicate, potassium hydroxide and an iron complex is prepared; and (3), the magnesium alloy inthe step (1) is adopted as a matrix, connected with an anode of a direct current power source and put in a quartz reactor containing the electrolyte solution in the step (2), plasma electrolytic oxidation treatment is carried out, and the magnetic ceramic membrane with the self-hole-sealing structure is prepared on the surface of metal in situ. The component of the prepared membrane is MgO-SiO2-Fe3O4 composite oxide, and the magnetic composite oxide ceramic membrane has magnetism, the special self-hole-sealing micro-structure, good adhesive force and anti-corrosion performance and good application potential.

Owner:广东省科学院生物与医学工程研究所

Preparation method of PET with light scattering porous micro-foaming structure and diffusion film

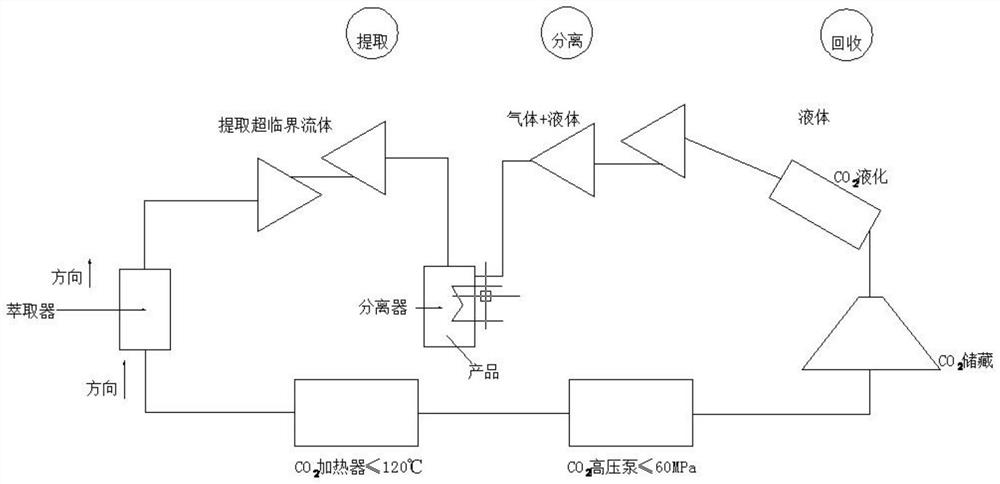

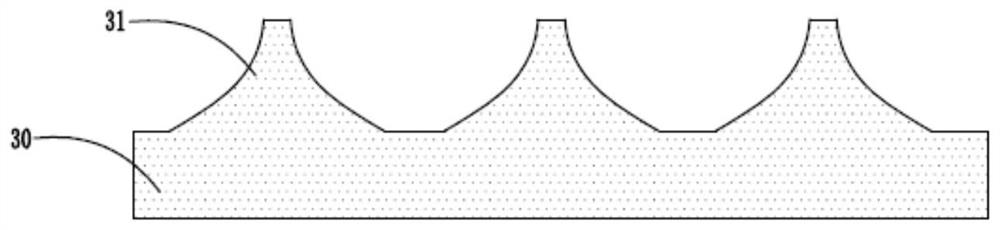

ActiveCN113504590AImprove diffusion abilityAdhesion is not lowDiffusing elementsBulk chemical productionPolymer scienceSeparation technology

The invention discloses a preparation method of PET with a light scattering porous micro-foaming structure and a diffusion film. The PET with the light scattering porous micro-foaming structureis realized through a pressure transformation method, the preparation method specifically comprises the following steps: CO2 supercritical gas is dissolved in a PET material, CO2 and PET are uniformly mixed through saturation to form a homogeneous system, CO2 nucleation is achieved through a phase separation technology, and then bubble growth is prevented through a pressure reduction method; compared with a traditional diffusion film diffusion layer surface coated with organic / inorganic diffusion particles to enhance the light diffusion capacity, the porous microstructure is prepared on the diffusion layer surface of the diffusion film, the problems that a traditional diffusion film is uneven in display brightness, diffusion particles fall off, friction is prone to occurring, and warping is serious are solved, meanwhile, and the light transmittance, the haze, the ink adhesive force and the surface impedance are not lower than those of a traditional diffusion film.

Owner:博讯光电科技(合肥)有限公司

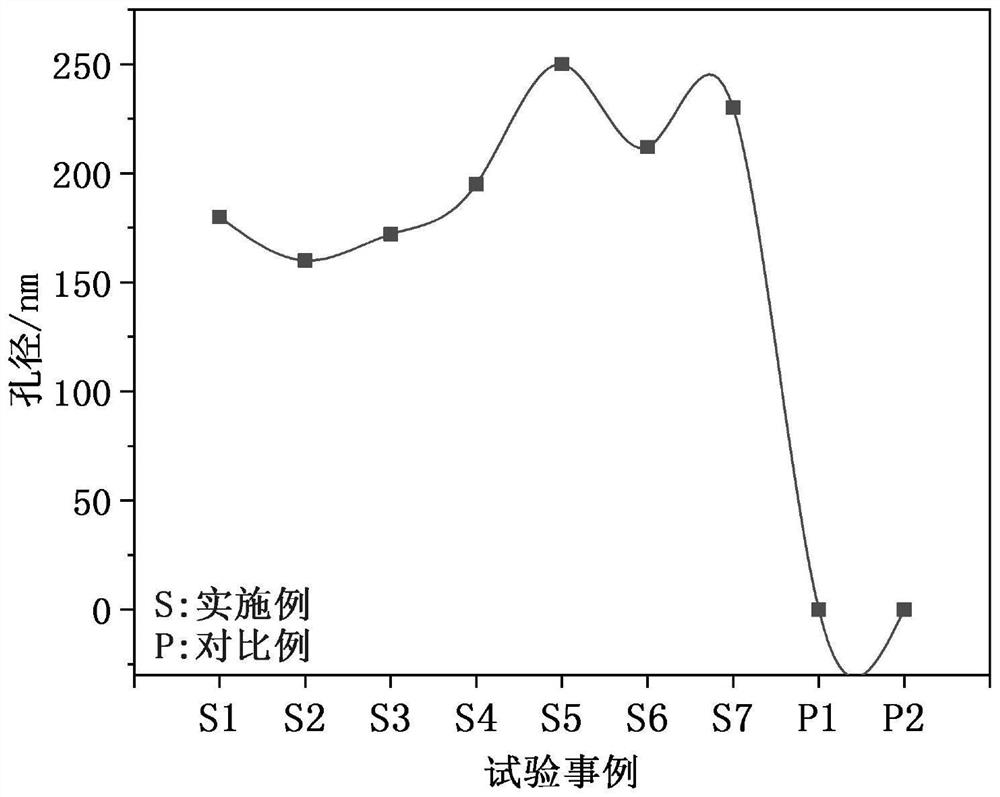

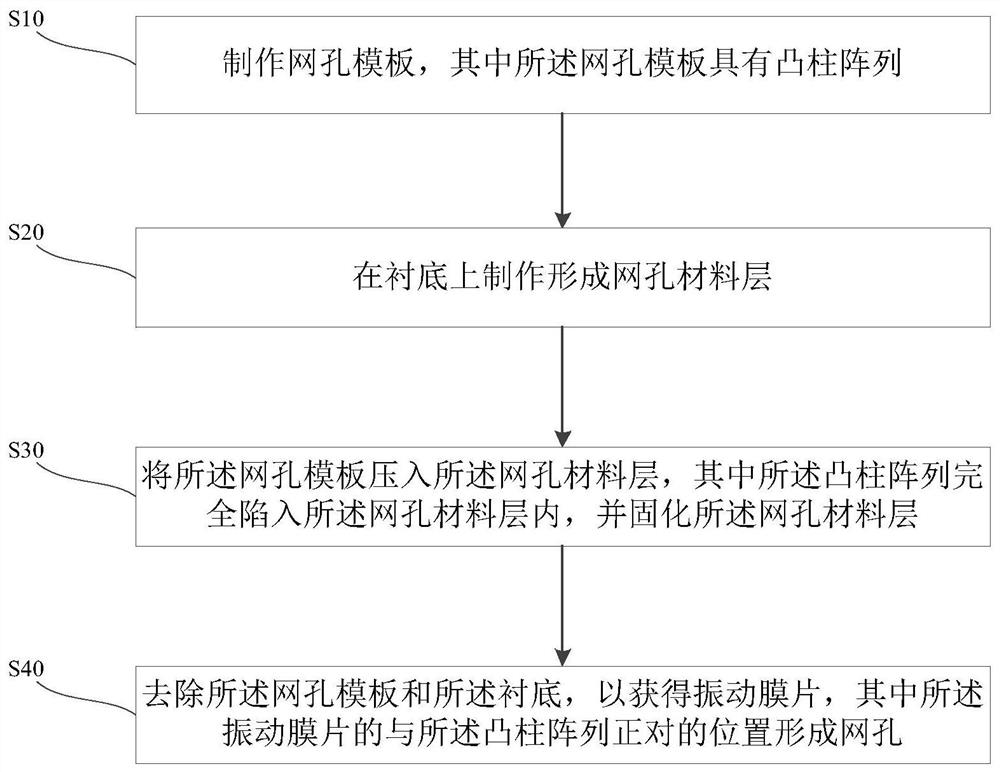

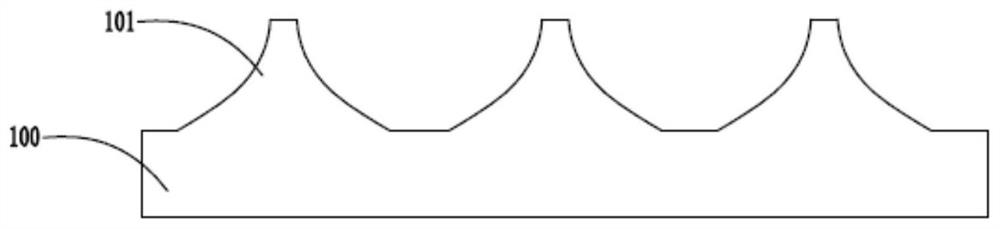

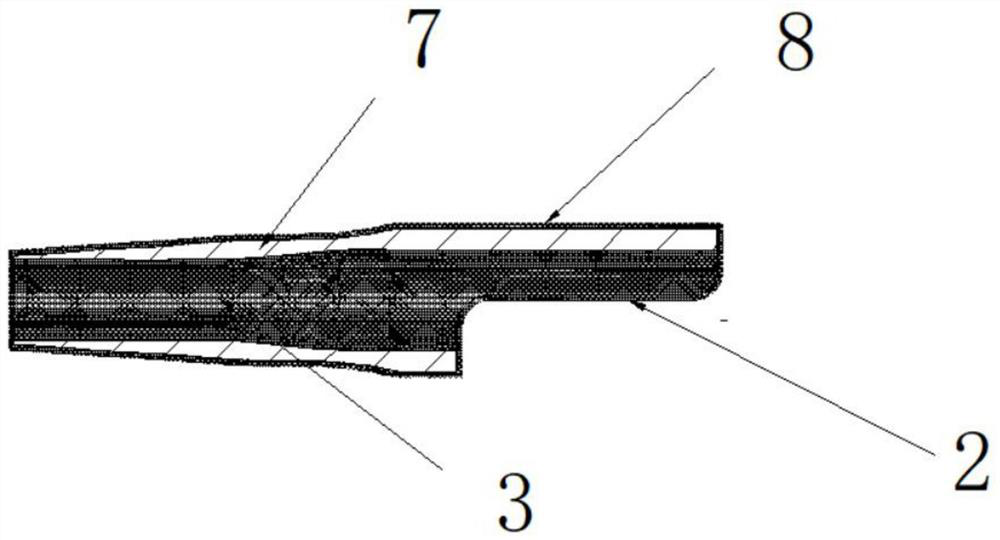

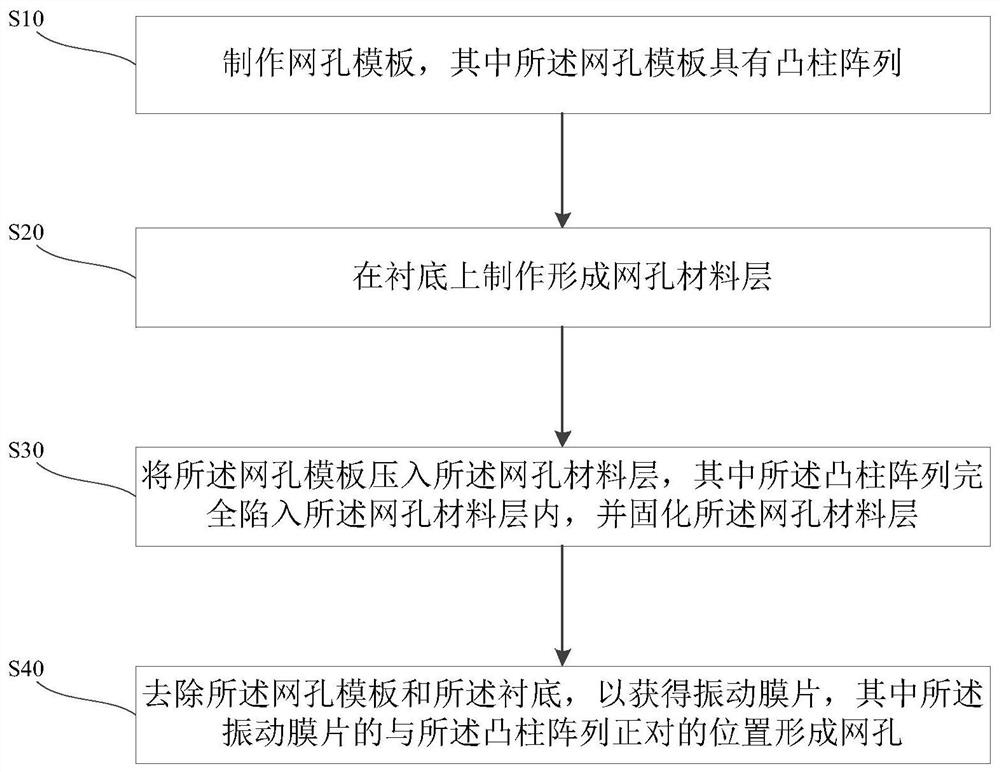

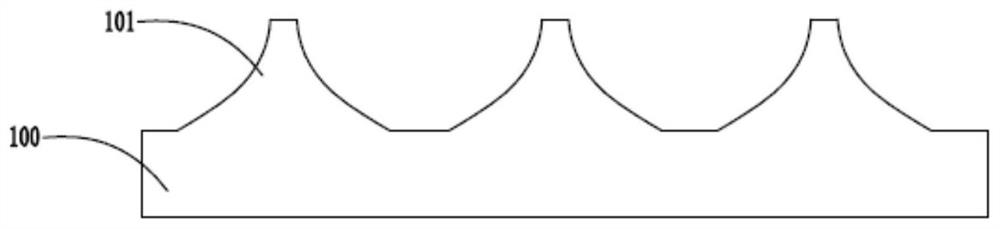

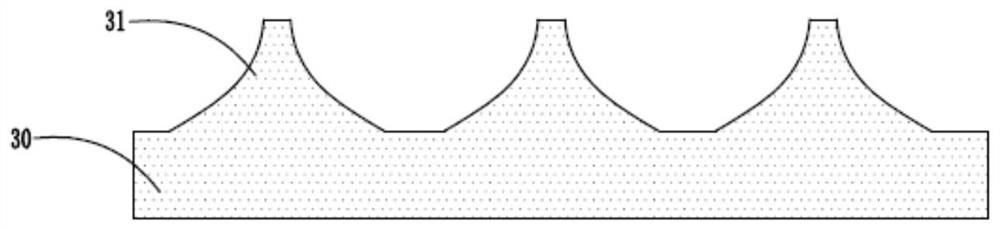

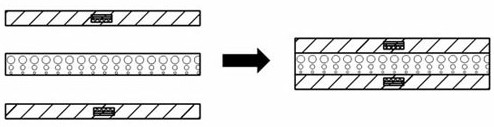

Mesh microstructure for high-viscosity liquid atomization and its manufacturing method

The invention discloses a mesh microstructure for high-viscosity liquid atomization and a manufacturing method thereof. The manufacturing method includes: making a mesh template, wherein the mesh template has an array of convex columns; forming a mesh material layer on a substrate; embossing the mesh template on the mesh material layer, wherein the The protrusion array is completely immersed in the mesh material layer, and the mesh material layer is solidified; the mesh template and the substrate are removed to obtain a vibrating diaphragm, wherein the vibrating diaphragm and the A mesh is formed at the position directly opposite to the array of protrusions. The mesh microstructure can realize atomization from low viscosity to high viscosity liquid at room temperature, and the atomization is sufficient, the volume of atomized droplets is small, the flow rate is large, the surface of the mesh is flat, strong and easy to clean, and the production method is stable and efficient. Easy to repeat.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

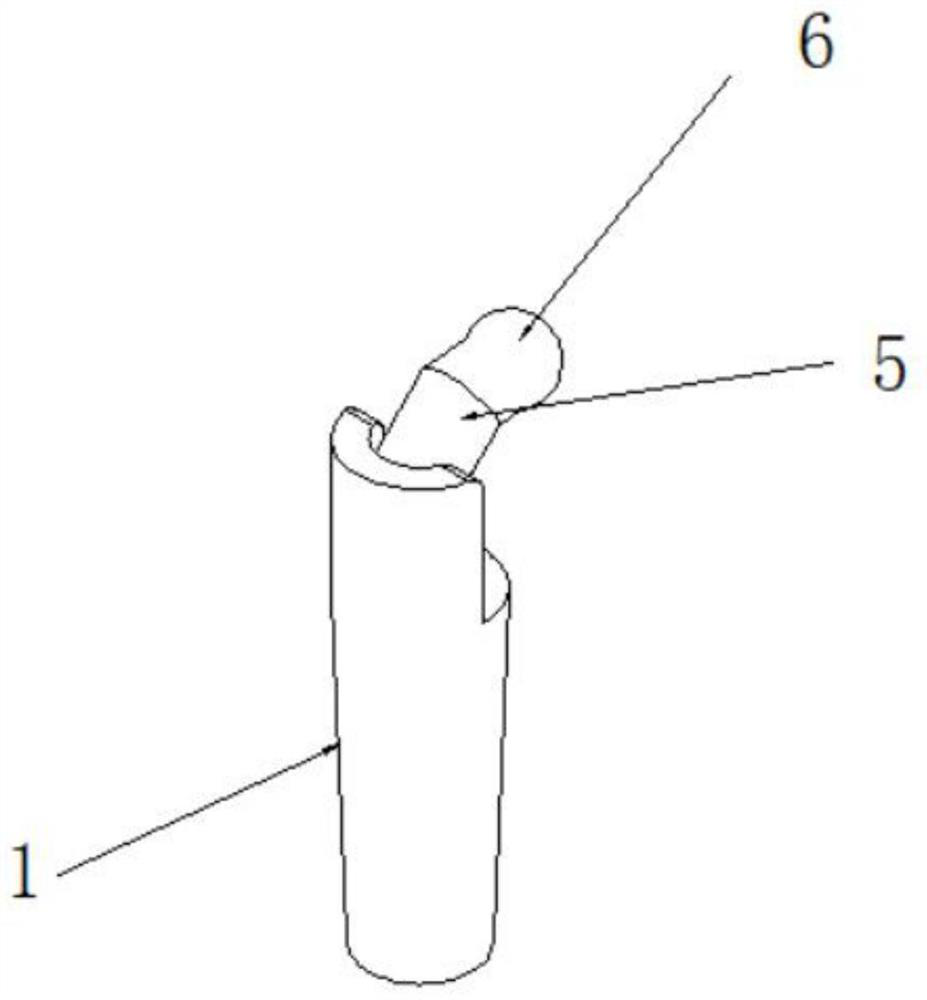

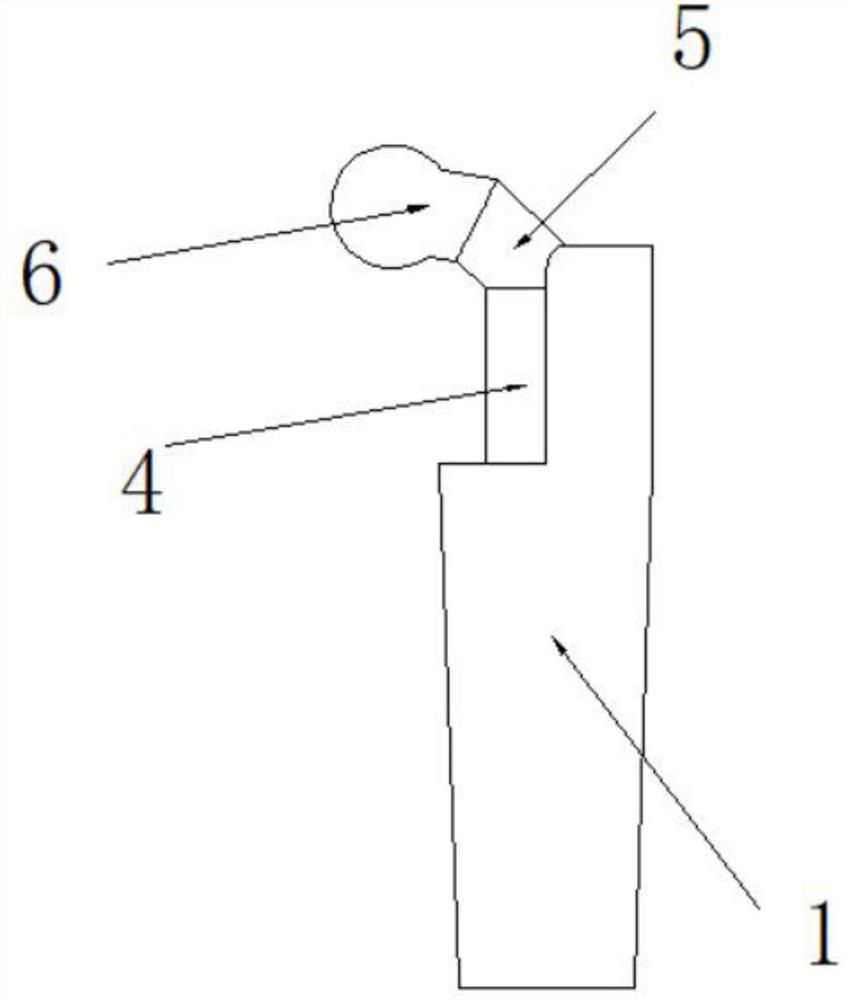

Hip joint prosthesis based on shape memory alloy porous microstructure

PendingCN113679515AGood biomaterial compatibilityReduce loosenessJoint implantsFemoral headsShape-memory alloyBiomaterial compatibility

The invention discloses a hip joint prosthesis based on a shape memory alloy porous microstructure, and relates to the technical field of hip joint prostheses. The hip joint prosthesis based on the shape memory alloy porous microstructure comprises a hip joint prosthesis body, a cavity is formed in the hip joint prosthesis body, a first connecting body is rotationally installed in the cavity, a second connecting body is embedded in one end of the first connecting body, a ball head prosthesis is embedded in one end of the second connecting body, and the hip joint prosthesis internally comprises a hip joint prosthesis core body and a hip joint prosthesis shell. According to the hip joint prosthesis, after the hip joint prosthesis is subjected to acting force, the porous microstructure generates compression deformation and deformation expansion, stress stimulation of a certain magnitude is conducted on the hip joint bone, good biological material compatibility is achieved between the hip joint bone and the hip joint prosthesis, the osteoporosis phenomenon caused by the stress shielding effect is avoided, and the possibility that the implant becomes loose and falls off to lose efficacy can be greatly reduced.

Owner:广州恒尚科技有限公司 +1

Mesh microstructure for atomizing high-viscosity liquid and manufacturing method thereof

ActiveCN112517309ASmall drop sizeHigh trafficLiquid spraying apparatusVibrating membraneMechanical engineering

The invention discloses a mesh microstructure for atomizing high-viscosity liquid and a manufacturing method of the mesh microstructure. The manufacturing method comprises the steps that a mesh template is manufactured, wherein the mesh template comprises a convex column array; a mesh material layer is formed on a substrate; the mesh material layer is imprinted on the mesh template, wherein the convex column array is completely sunken into the mesh material layer, and the mesh material layer is solidified; and the mesh template and the substrate are removed to obtain a vibrating membrane, wherein meshes are formed in the position, exactly facing the convex column array, of the vibrating membrane. The mesh microstructure can achieve normal-temperature atomization of low-viscosity liquid andthe high-viscosity liquid, atomization is sufficient, the atomized liquid drop is small in size and large in flow, the meshes are smooth in surface, firm and easy to clean, and the manufacturing method is stable in technology and easy to repeat.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A kind of preparation method of graphene/polyethylenedioxythiophene composite fiber assembly

ActiveCN110085436BLow costEasy to operateHybrid capacitor electrodesHybrid/EDL manufactureFiberSupercapacitor

Owner:BEIJING UNIV OF TECH

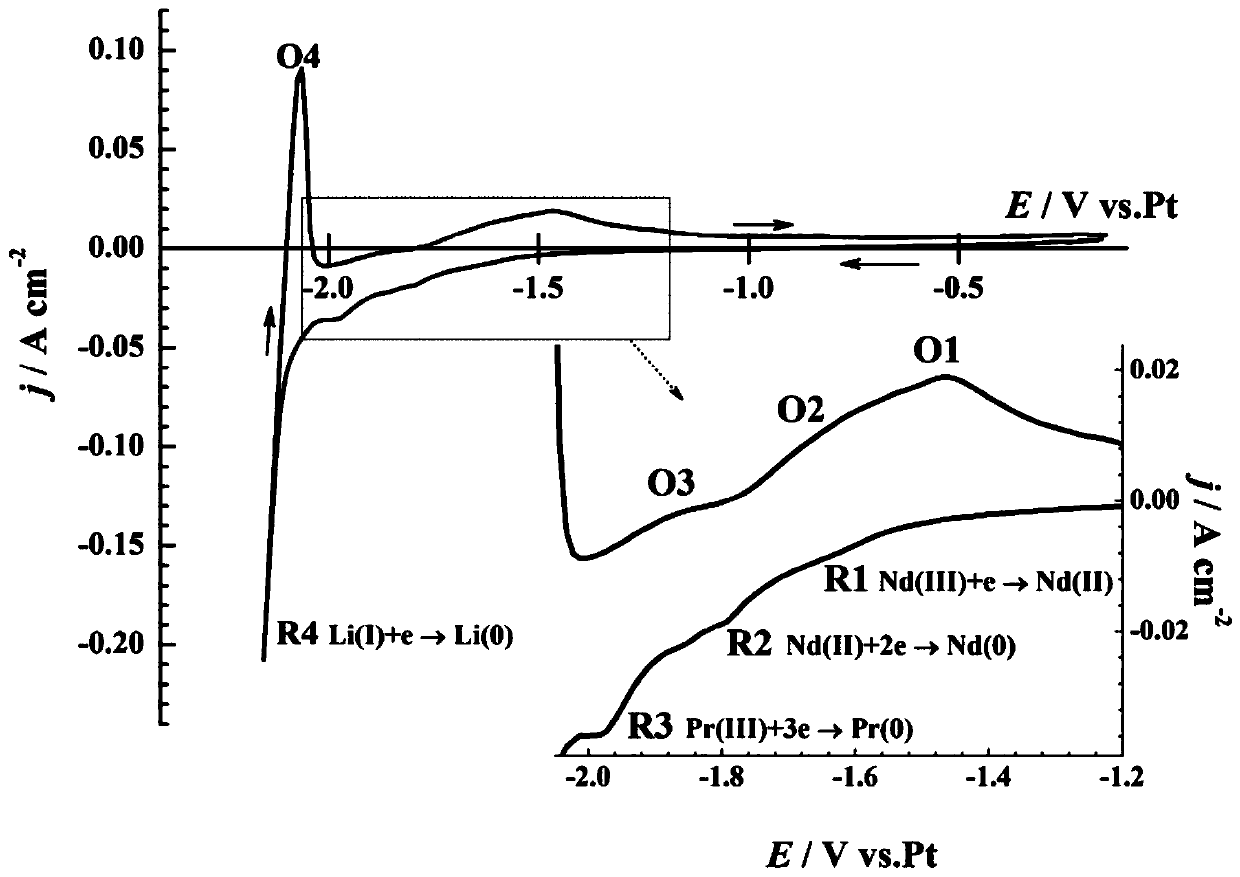

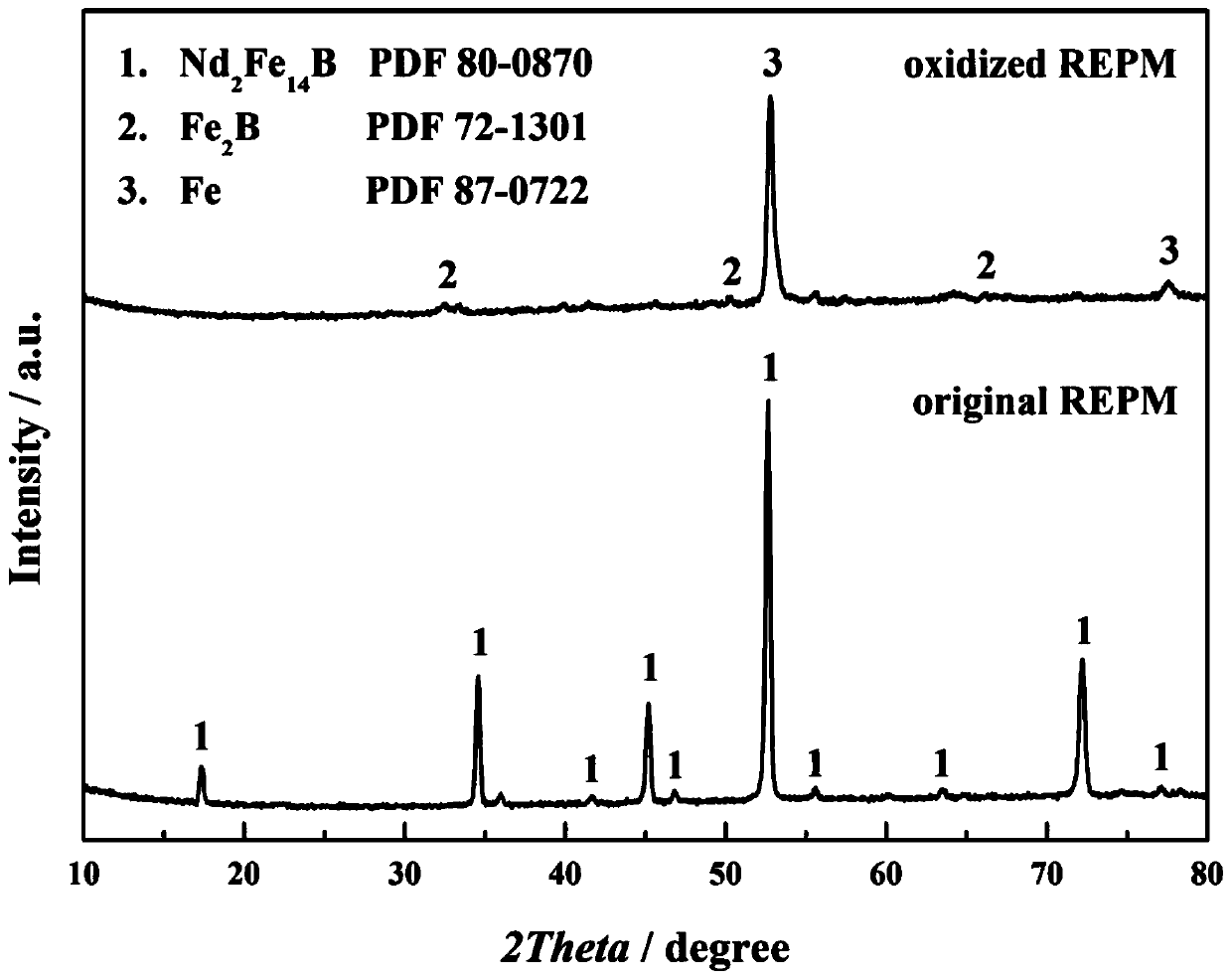

Method for separating rare earth elements from NdFeB alloy waste and directly preparing rare earth metals

The invention relates to a method for separating rare earth elements from neodymium iron boron alloy scrap and directly preparing rare earth metal. The method comprises the following steps: the cut neodymium iron boron alloy scrap is directly used as an anode, the rare earth elements in the alloy are selectively dissolved by controlling the potential of the anode, and the neodymium iron boron alloy scrap is enabled to form an open-pore microstructure by controlling the current density of the anode so as to promote rapid dissolution of the rare earth elements in the alloy into an electrolyte; only rare earth ions and lithium ions exist in the electrolyte, the rare earth metal can be directly prepared through electrolysis. By the method provided by the invention, not only the rare earth elements can be effectively separated from the neodymium iron boron alloy scrap, but also the rare earth metal can be directly prepared; meanwhile, no gas is produced during an anode reaction, so that environment pollution caused by anode gas produced during the conventional rare earth metal production is avoided; the method has good environmental, social and economic benefits.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

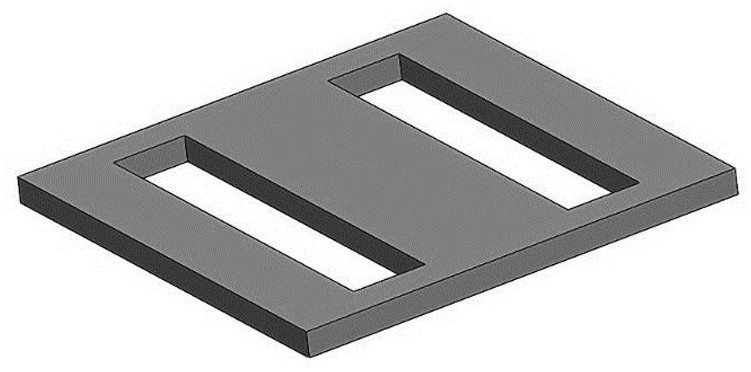

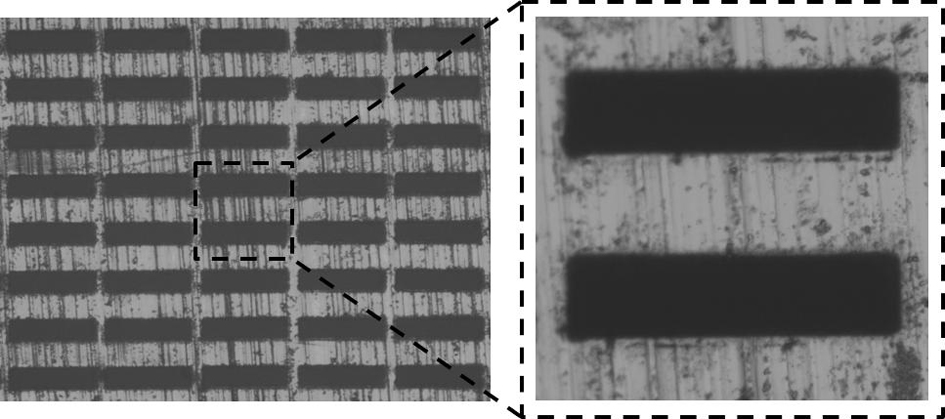

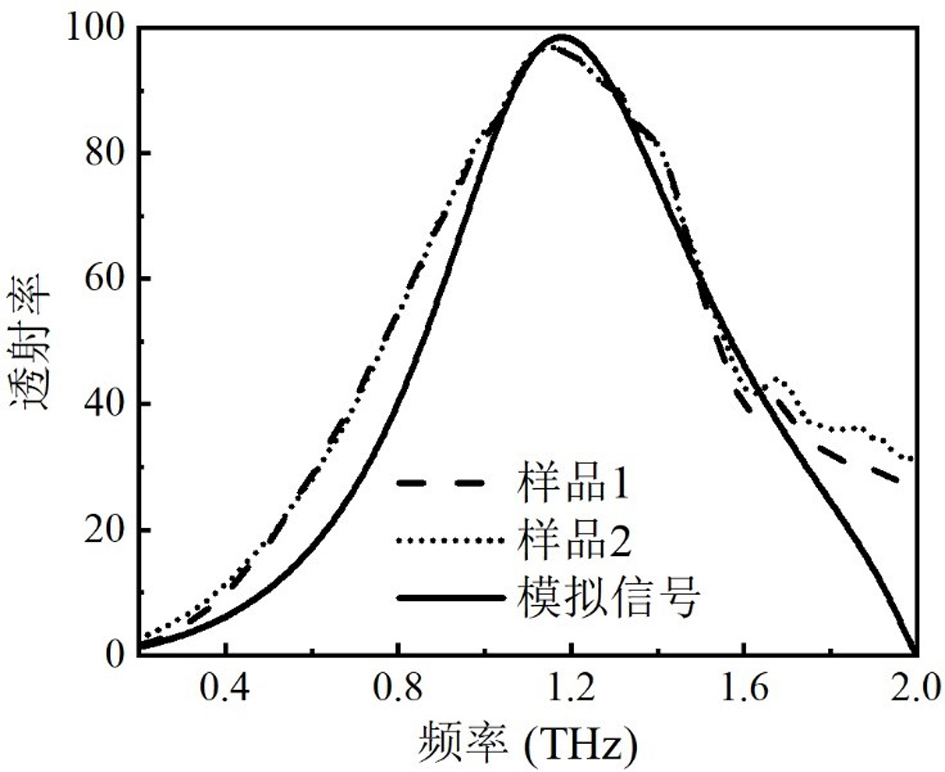

Terahertz metasurface structure with periodic through hole microstructure and preparation method of terahertz metasurface structure

PendingCN114374095ASimple and fast processingImprove processing efficiencyConductive material removal by irradiationAntennasRectangular apertureFemto second laser

The invention provides a terahertz metasurface structure with a periodic through hole microstructure and a preparation method of the terahertz metasurface structure, and the terahertz metasurface structure with the periodic through hole microstructure is formed by taking two rectangular holes with the same shape and size as a unit array and arranging the two rectangular holes in a periodic array. A femtosecond laser direct writing technology is adopted in the preparation method, thin film metal is directly processed, the manufacturing process is simple and rapid, the processing efficiency is high, raw materials are cheap and easy to obtain, and large-scale industrial production is facilitated. Meanwhile, a high-multiple focusing objective lens is used for reducing the ablation area, so that the machining error is reduced, the actual machining size better conforms to the design size, and the needed standard is achieved.

Owner:FUZHOU UNIV

3D printed ti-pda-bmp-2 bone defect repair tissue engineering scaffold and preparation method thereof

InactiveCN108939156BAchieve fine controlAchieve sustained releaseAdditive manufacturing apparatusTissue regeneration3d printRepair tissue

The invention discloses a 3D printed Ti-PDA-BMP-2 bone defect repair tissue engineering scaffold and a preparation method thereof. The 3D printed Ti-PDA-BMP-2 bone defect repair tissue engineering scaffold is prepared from Ti6Al4V powder through a 3D printing technology and has a controllable shape, a pore microstructure and controllable physicochemical properties. A biological factor BMP-2 with bone repair ability is bonded to the engineering scaffold through polydopamine on the fiber surfaces and is used for repair and treatment on bone defects. The engineering scaffold has the advantages ofsimple and reliable structure, controllable shape and microstructure, simple and efficient surface modification, reliable mechanical property, high biological activity and safety, convenient implantation, small trauma and low cost.

Owner:南京冬尚生物科技有限公司

A photothermal evaporation surface and its preparation and application

ActiveCN109879344BReduce spacingIncrease interface areaGeneral water supply conservationSeawater treatmentPhotothermal conversionNanofluid

The invention discloses a photothermal evaporation surface, and a preparation method and an application thereof, and belongs to the technical field of solar photothermal utilization. The photothermalevaporation surface is formed by attaching porous microstructures, which are periodically arranged in an array, to the surface of a substrate, and every porous microstructure is a coffee ring-shaped structure formed by the accumulation of nanoparticles; and a micro-droplet generator is used to periodically arrange nanofluid droplets on the surface of the substrate in the array manner, and heatingis carried out to evaporate the droplets until dryness in order to form the coffee ring-shaped porous microstructures, periodically arranged in the array manner, on the surface of the substrate. The photothermal evaporation surface provided by the invention has a high photothermal conversion efficiency and can be repeatedly used, and the preparation method has the advantages of very small use amount of the nanofluid required for preparing the high-efficiency photothermal evaporation surface, low cost, and facilitation of industrial application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method for forming the surface microstructure of a fuel cell metal cathode plate

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Polydimethylsiloxane film, flexible capacitive sensor and preparation method thereof

ActiveCN110763256BHigh sensitivityImprove linearityConverting sensor output electrically/magneticallyCapacitanceMetallic electrode

The invention belongs to the field of flexible sensors, and discloses a polydimethylsiloxane film, a flexible capacitive sensor and a preparation method thereof. The sensor includes an upper electrode layer, an intermediate dielectric layer and a lower electrode layer, and the upper and lower electrode layers have the same structure. Both include a flexible base material and liquid metal embedded in the base material; the intermediate dielectric layer is between the upper and lower electrode layers, which has a multi-layer stepped mesoporous microstructure. Compared with the flexible capacitive sensor without the dielectric layer, The linearity of the flexible capacitive sensor is improved; when the sensor is subjected to pressure or is approached by a conductor, the pressure on the sensor or the distance between the conductor and the sensor is obtained by measuring the change of the capacitance of the sensor. The invention also discloses a preparation method of the sensor. Through the present invention, a flexible capacitive sensor based on a liquid metal electrode and a dielectric layer of a multi-layer stepped mesoporous microstructure is designed to realize high sensitivity of the flexible sensor.

Owner:GUANGDONG SYGOLE INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com