Method for producing porous microstructure

a microstructure and porous technology, applied in the field of porous microstructure production, can solve problems such as mechanical strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Unless specified otherwise, the following terms as used in the specification and appended claims are given the following definitions. It should be noted that the indefinite article “a” or “an” as used in the specification and claims is intended to mean one or more than one, such as “at least one,”“at least two,” or “at least three,” and does not merely refer to a singular one. In addition, the terms “comprising / comprises,”“including / includes” and “having / has” as used in the claims are open languages and do not exclude unrecited elements. The term “or” generally covers “and / or”, unless otherwise specified. The terms “about” and “substantially” used throughout the specification and appended claims are used to describe and account for small fluctuations or slight changes that do not materially affect the nature of the invention.

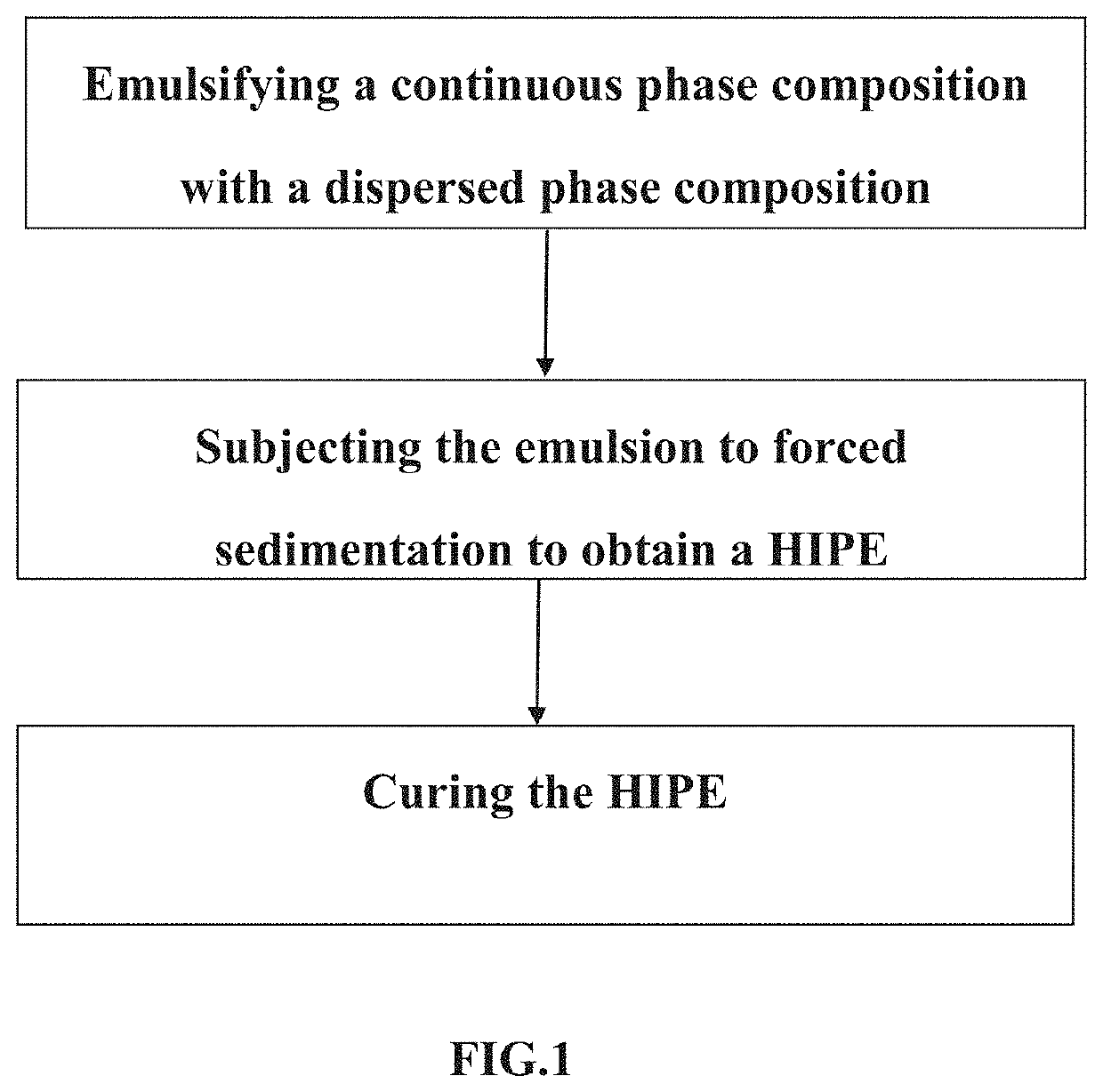

[0024]The invention provides a method for producing a porous microstructure. According to the embodiment shown in FIG. 1, the invented method comprises th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Compression ratio | aaaaa | aaaaa |

| Compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com