A kind of magnetic composite oxide ceramic membrane with self-sealing pore structure and its preparation method

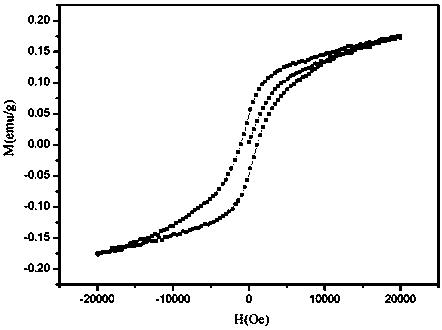

A composite oxide and ceramic membrane technology, applied in anodic oxidation, prosthesis, coating, etc., can solve the problems of poor mechanical properties, many pores of PEO ceramic membranes, poor corrosion resistance, etc., and achieve magnetic mechanical properties and good protection Excellent performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) AZ31 magnesium alloy substrate pretreatment: use 400#, 1000#, 2000#, 4000# sandpaper to polish step by step until smooth, rinse with dilute nitric acid, and then use absolute ethanol and distilled water for ultrasonic cleaning.

[0024] (2) Preparation of electrolyte solution: use 12 g / L sodium silicate, 4 g / L potassium hydroxide and 0.8 g / L potassium ferrocyanide as the electrolyte, and deionized water as the solvent to prepare a strong alkaline composite electrolyte solution .

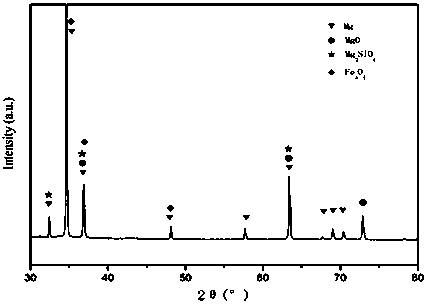

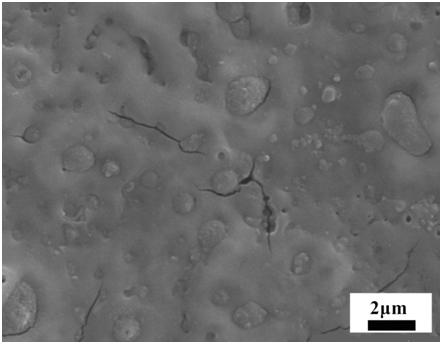

[0025] (3) Plasma electrolytic oxidation treatment: connect the substrate in step (1) to the anode of the DC power supply, and use the stainless steel sheet as the cathode (the distance between the cathode and anode is 3 cm), soak in the electrolyte solution in step (2) Plasma electrolytic oxidation treatment. Using the program boost mode, every 20V increase is maintained for 5 s, the terminal voltage is set to 320 V, and the hold time is 15min. A magnetic composite oxide ceramic film wit...

Embodiment 2

[0028] (1) AZ91 magnesium alloy substrate pretreatment: use 400#, 1000#, 2000#, 4000# sandpaper to polish step by step until smooth, rinse with dilute nitric acid, and then use absolute ethanol and distilled water for ultrasonic cleaning.

[0029] (2) Preparation of electrolyte solution: 8 g / L sodium silicate, 2 g / L potassium hydroxide and 0.4 g / L potassium ferricyanide were used as the electrolyte, and deionized water was used as the solvent to prepare a strong alkaline composite electrolyte solution.

[0030] (3) Plasma electrolytic oxidation treatment: connect the substrate in step (1) to the anode of the DC power supply, and use the stainless steel sheet as the cathode (the distance between the cathode and anode is 3 cm), soak in the electrolyte solution in step (2) Plasma electrolytic oxidation treatment. Using the program boost mode, every 20V increase is maintained for 30s, the terminal voltage is set to 360 V, and the hold time is 20min, a magnetic composite oxide cera...

Embodiment 3

[0033] (1) AZ31 magnesium alloy substrate pretreatment: use 400#, 1000#, 2000#, 4000# sandpaper to polish step by step until smooth, rinse with dilute nitric acid, and then use absolute ethanol and distilled water for ultrasonic cleaning.

[0034] (2) Preparation of electrolyte solution: 14 g / L sodium silicate, 6 g / L potassium hydroxide and 1 g / L potassium ferricyanide were used as the electrolyte, and deionized water was used as the solvent to prepare a strong alkaline composite electrolyte solution.

[0035] (3) Plasma electrolytic oxidation treatment: connect the substrate in step (1) to the anode of the DC power supply, and use the stainless steel sheet as the cathode (the distance between the cathode and anode is 3 cm), soak in the electrolyte solution in step (2) Plasma electrolytic oxidation treatment. Using the program boost mode, every 20V increase is maintained for 10s, the terminal voltage is set to 280V, and the hold time is 5min, a magnetic composite oxide ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com