Thin-layer chromatoplate having ordered micro-nano structure and manufacturing method thereof

A thin-layer chromatographic plate and a technology of micro-nano structure are applied in the field of thin-layer chromatographic plate and its preparation to achieve the effect of extending the application range, lowering the detection limit and improving the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

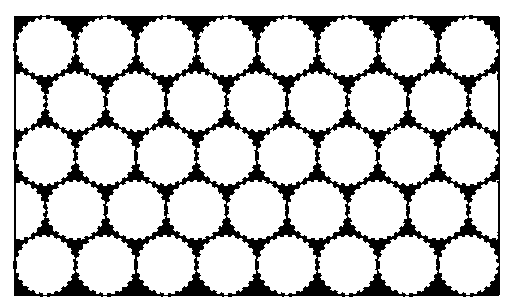

Embodiment 1

[0033] Monodisperse solid polystyrene microspheres with a particle size ranging from tens of nanometers to several microns were prepared by the improved St?ber method. Take 1ml, 2.5vol% PS colloidal solution with a particle size of 240nm and add it to 20ml ultrapure water, then add 0.3ml TEOS prepolymer solution to it, stir at room temperature for 1h and set aside. Insert the glass slide treated with piranha solution vertically into the prepared precursor solution, let it stand at 65°C for 2 days, and then dry it in a constant temperature oven. The drying temperature is controlled at 105-110°C, and the drying time is about 2-3 hours. After drying, it was placed in a muffle furnace for calcination at 500 °C for 4 h and then cooled to room temperature. Observation by SEM shows that the obtained TLC film has an inverse opal structure. Finally, the prepared inverse opal structure was immersed in a silica gel solution prehydrolyzed with a block copolymer surfactant for 24 h, so th...

Embodiment 2

[0038] Monodisperse solid silica microspheres with a particle size ranging from tens of nanometers to several micrometers were prepared by the improved Stäber method. The growth of the monodisperse mesoporous silica shell was achieved by adding a surfactant to control the seed growth, and finally the mesoporous silica microspheres with good monodispersity were obtained. Subsequently, a mesoporous silica colloidal solution with a particle size of 1 um and a concentration of 45% was selected, and a photonic crystal film with a highly ordered micro-nano structure was prepared by a vertical deposition method. Put the film at 65°C for 2 days and then dry it in a constant temperature oven. The drying temperature is controlled at 105-110°C, and the drying time is about 2-3 hours. After drying, add the pre-prepared polystyrene solution dropwise on the surface of the film Let it stand for a period of time, so that the polystyrene solution completely fills the gaps between the silica mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com