A method for forming the surface microstructure of a fuel cell metal cathode plate

A metal cathode and fuel cell technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of high pore processing requirements on the surface of metal cathode plates, unable to meet the requirements of forming accuracy, and achieve low cost, small volume, and size control. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail, and embodiment is as follows:

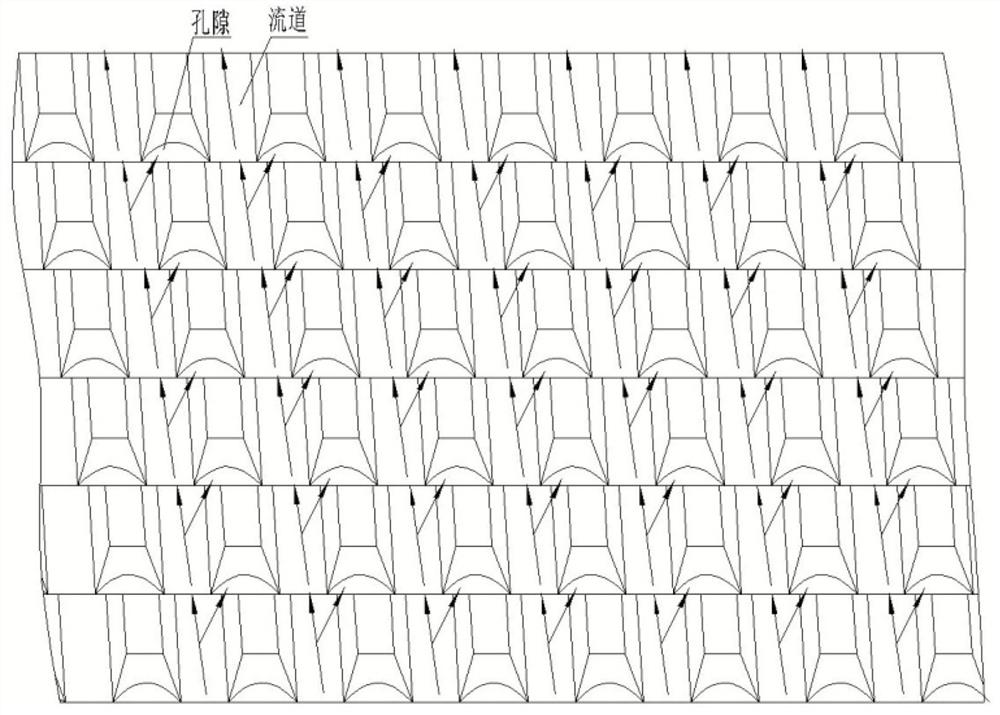

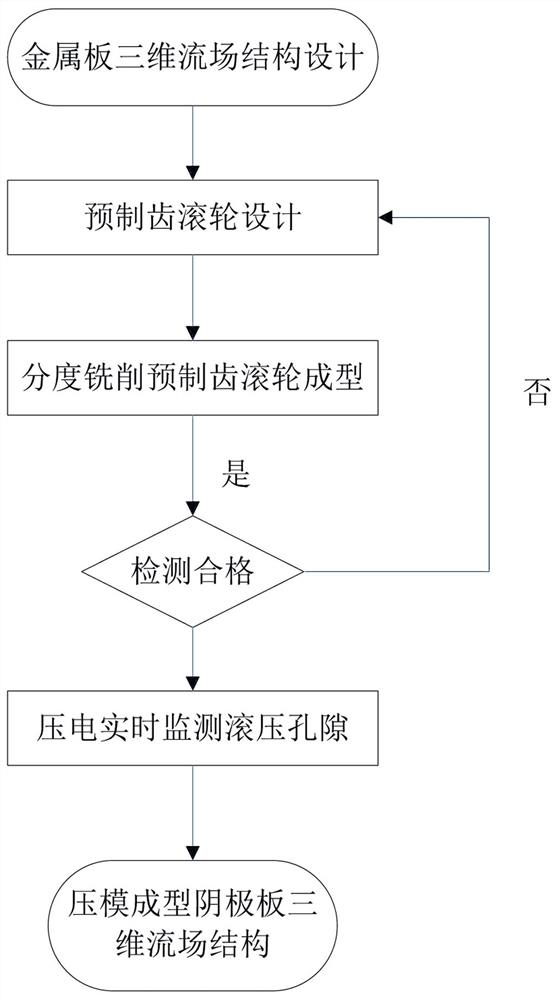

[0021] refer to figure 2 As shown, the present invention is molded on the surface of the metal cathode plate of the fuel cell such as figure 1 The three-dimensional flow field pore microstructure method shown includes the following steps:

[0022] Step 1, according to the pore shape and size of the three-dimensional flow field on the surface of the target metal cathode plate, determine the specification of the prefabricated gear roller for processing.

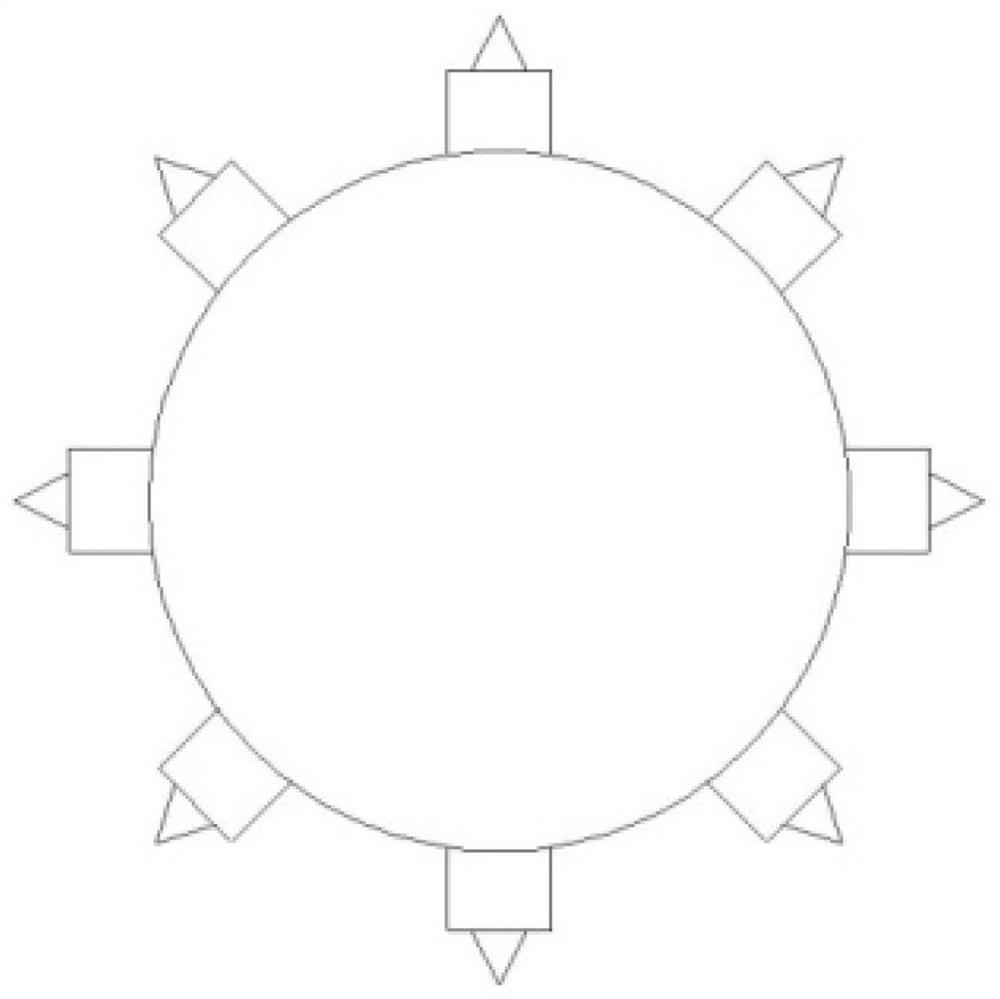

[0023] Step 2, design the specific structure of the prefabricated gear roller.

[0024] Step 3. According to the principle of micro-rolling forming, 200μm grade prefabricated gear rollers are processed: NSK 200μm high-speed milling cutter is used to select the main direction of roller forming by indexing through the technology of variable direction grooving, and milling directly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com