Battery cell winding method and equipment

A kind of battery core and equipment technology, applied in the field of battery core winding method and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

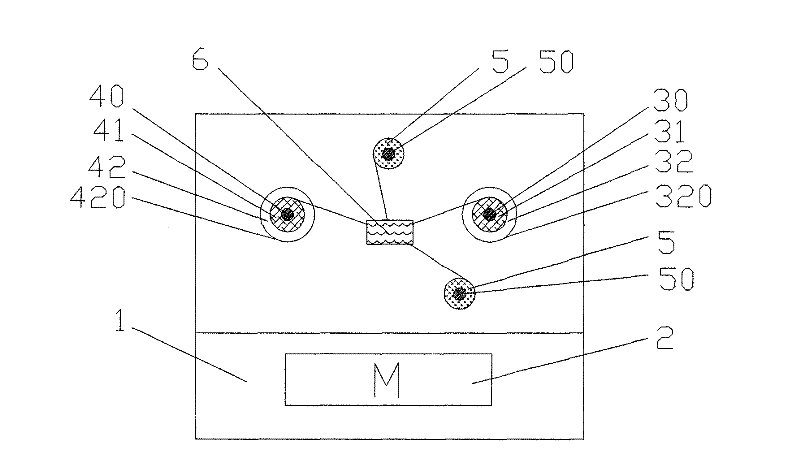

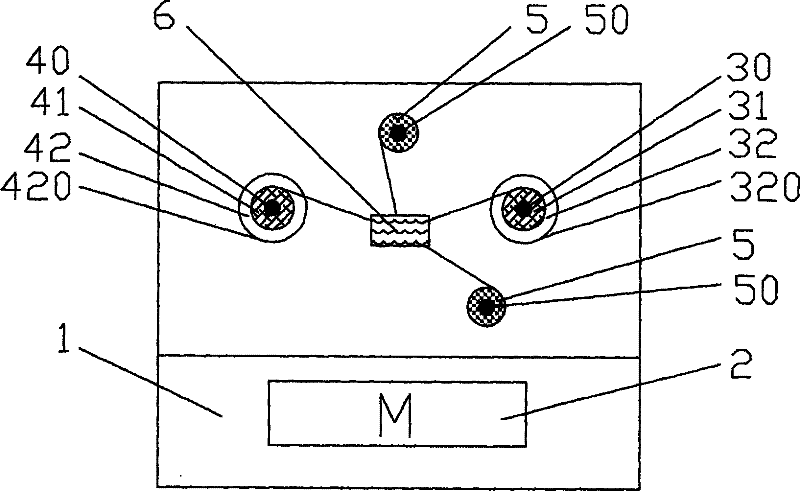

[0031] see figure 1 , a battery winding device of the present invention, the device comprises a frame 1, a motor 2 arranged in the frame 1, a positive electrode sheet feeding mechanism 31 fixedly connected to the frame, a negative electrode sheet feeding mechanism 41, an isolation The film feeding mechanism 5 and the winding mechanism 6 also include a positive electrode sheet heating mechanism 32 and a negative electrode sheet heating mechanism 42 .

[0032] The positive electrode sheet feeding mechanism 31, the negative electrode sheet feeding mechanism 41, and the separator feeding mechanism 5 are distributed around the winding mechanism 6, so that the materials can be concentrated in one place to complete the winding action.

[0033] The positive electrode sheet feeding mechanism 31, the negative electrode sheet feeding mechanism 41, and the separator feeding mechanism 5 are sequentially provided with a positive electrode sheet tension adjustment shaft 30, a negative electr...

Embodiment 2

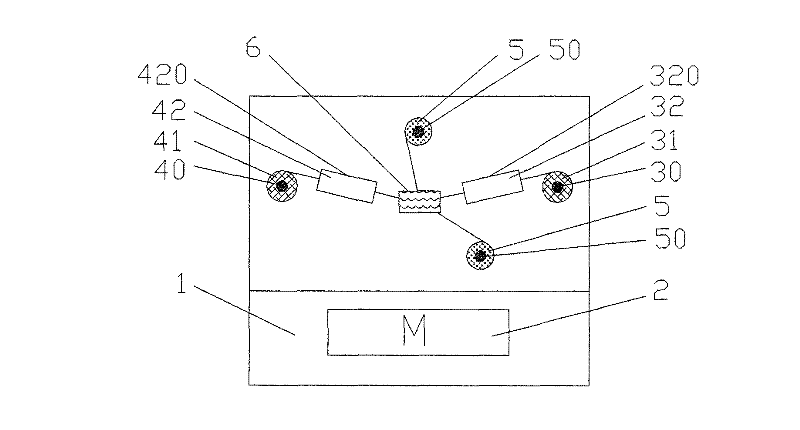

[0038] see figure 2 , the present invention is a kind of battery winding equipment, the heating method of the positive plate heating mechanism 32 and the negative plate heating mechanism 42 is infrared heating. The positive pole piece heating mechanism 32 and the negative pole piece heating mechanism 42 are arranged outside the whole roll of pole piece, to heat the single pole piece before winding, so that the pole piece can be heated more evenly. Others are the same as in Embodiment 1, and will not be repeated here.

[0039] The steps of the cell winding method are as follows:

[0040] First, prepare the pole piece and the isolation film. The pole piece and the isolation film should be prepared into continuous coils to facilitate continuous production. Then install the pole piece and the isolation film. The adjustment method is directional installation; second, start the motor and the positive and negative electrode heating mechanism, set the temperature in the positive el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com