Preparation method of zinc or zinc alloy super hydrophobic surface with antifriction and wear-resisting property

A super-hydrophobic surface and wear-resistant technology, which is applied in the field of super-hydrophobic surface preparation of metals, can solve the problems of poor corrosion resistance and wear resistance, low melting point, heavy specificity, etc., and achieve excellent anti-friction and anti-wear properties , easy industrial production, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

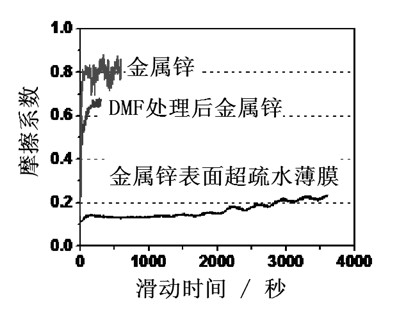

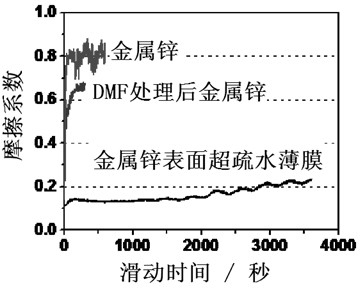

[0017] refer to figure 1 , the preparation method of the zinc or zinc alloy superhydrophobic surface with antifriction and wear resistance of the present embodiment, comprises the following steps:

[0018] 1. Ultrasonic clean the zinc plate (99.9% purity) with absolute ethanol and deionized water in sequence to remove the grease on the sample, and dry it with nitrogen before use.

[0019] 2. Soak the above-treated zinc plate in a solution containing 4% N, N-dimethylformamide (volume ratio), and heat it in an oven at a constant temperature of 65°C for 24 hours. After the zinc flakes were taken out, they were washed with deionized water and absolute alcohol, and dried with nitrogen gas.

[0020] 3. Soak the above-mentioned treated zinc flakes in 0.01mol / L stearic acid ethanol solution at room temperature for 24 hours. After taking them out, wash them with absolute ethanol and dry them with nitrogen to obtain a superhydrophobic surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com