Biological rolling oil and preparation method thereof

A rolling oil and biological technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of high consumption of surfactants and extreme pressure antifriction agents, high cost of multiple hydrogenated mineral oils, and difficulty in waste oil treatment and other issues, to achieve obvious environmental protection effect, improve rolling quality and work efficiency, and reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

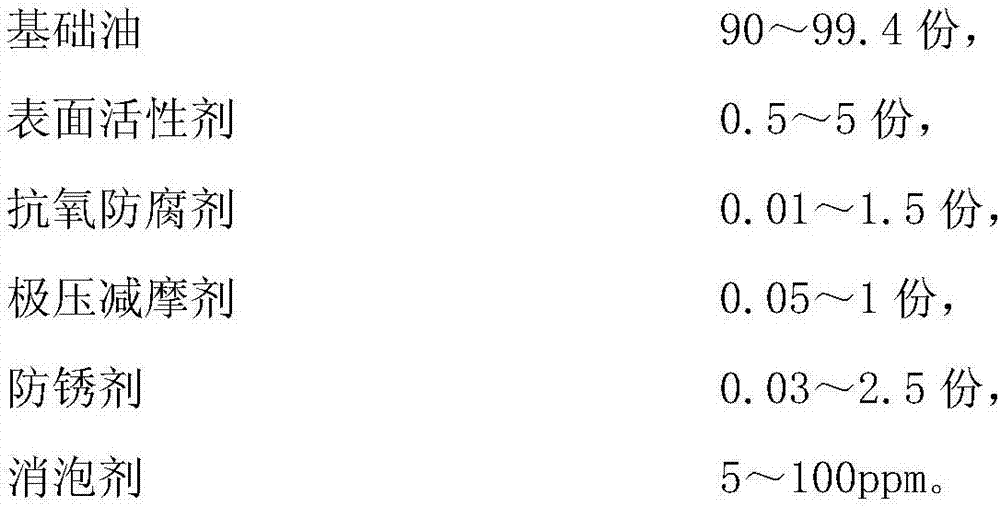

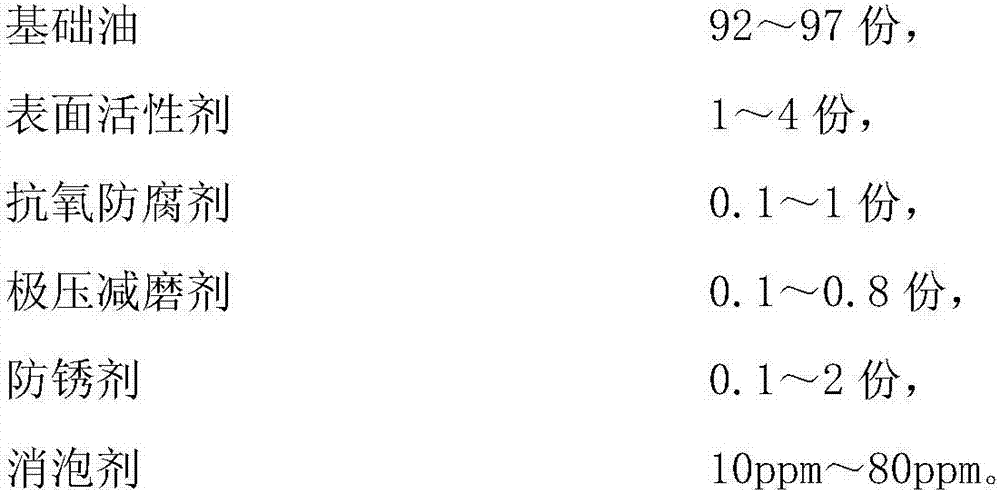

Method used

Image

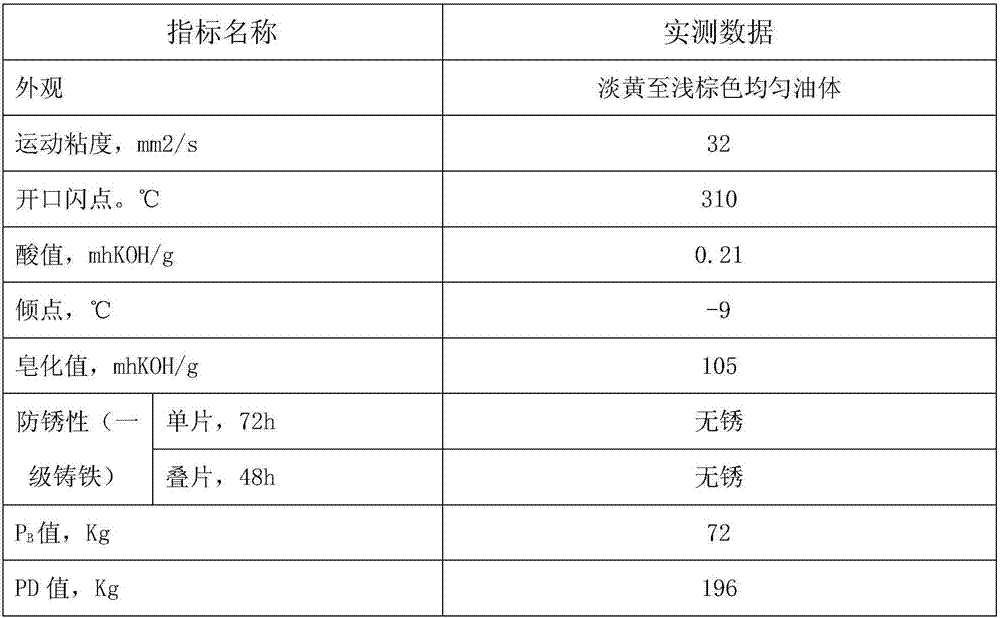

Examples

Embodiment 1

[0023] This example provides a kind of biological rolling oil, which is prepared by blending the following components according to mass percentage and heating to 30-80°C under stirring, and the base oil is transgenic soybean oil:

[0024] Table 1 Example 1 bio-rolling oil composition

[0025] component name mass percentage base oil 92% Compound Additives 8%

[0026] The sum of the above components is 100%. The quality of the base oil is 920kg, and the quality of the composite additive is 80kg. The composition of composite additives is shown in Table 2:

[0027] Table 2 Embodiment 1 composite additive composition

[0028] component name parts by weight base oil 10.8 Surfactant 1 Antioxidant preservative 0.5 extreme pressure wear reducer 0.2 Rust inhibitor 1 Defoamer 10PPm total 13.5

[0029] The sum of the above components is 100%. The base oil content in the composite additive does not ac...

Embodiment 2

[0042] This example provides a kind of biological rolling oil, the production quality is 1000kg, the following components are blended according to weight percentage, under stirring state, heated to 30-80 ℃, and the base oil is first-class refined waste edible oil , The refined waste edible oil mentioned here is the degree of refining determined according to the color and acid value. The higher the degree of refining, the lighter the color and the lower the acid value. The first-grade refined waste edible oil is clear and transparent, with an acid value lower than 0.3mgKOH / g; the second-grade refined waste edible oil is golden and transparent, with an acid value lower than 0.8mgKOH / g; the third-grade refined waste edible oil is darker in color and has an acid value lower than 1.5mgKOH / g, acid value Fourth-grade refined waste edible oil is dark in color, acid value is lower than 3mgKOH / g, but it is relatively transparent under the light. The composition of bio-rolling oil is show...

Embodiment 2

[0043] Table 4 Example 2 bio-rolling oil composition

[0044] component name mass percentage base oil 88% Compound Additives 12%

[0045] The sum of the above components is 100%. The quality of base oil is 880kg, and the quality of composite additive is 120kg.

[0046] Wherein the composite additive composition is shown in Table 5:

[0047] Table 5 embodiment 2 composite additive composition

[0048] component name parts by weight base oil 15 Surfactant 4 Antioxidant preservative 0.4 extreme pressure wear reducer 0.5 Rust inhibitor 0.1 Defoamer 10ppm total 20

[0049] The sum of the above components is 100%. The base oil content in the composite additive does not account for the content of base oil in table 4, so the total mass fraction of base oil=88%+12%×15 / 20=97% in the present embodiment (defoamer mass unit is ten thousand parts one, so it is ignored in the calculation).

[0050] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com