Preparation method of friction-reduction anti-adhesion nano organic film based on micro device

A nano-organic and micro-device technology, applied in electrolytic organic material coating, process for producing decorative surface effects, micro-structural technology, etc., can solve problems such as adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

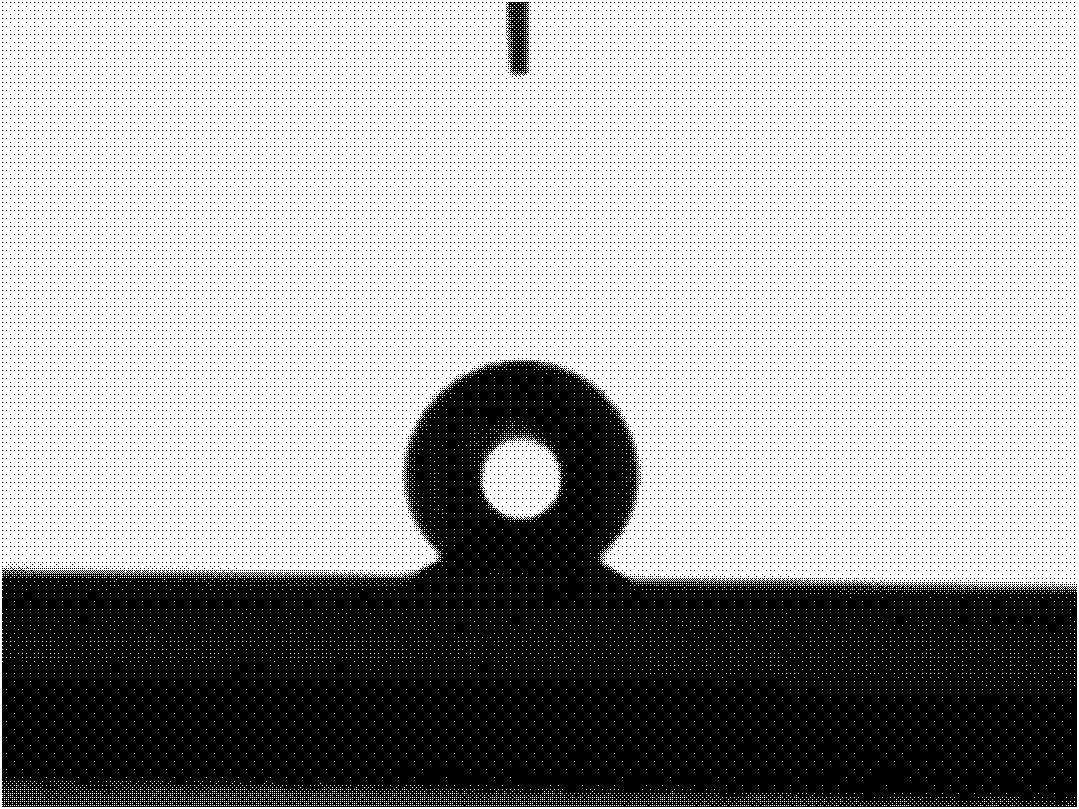

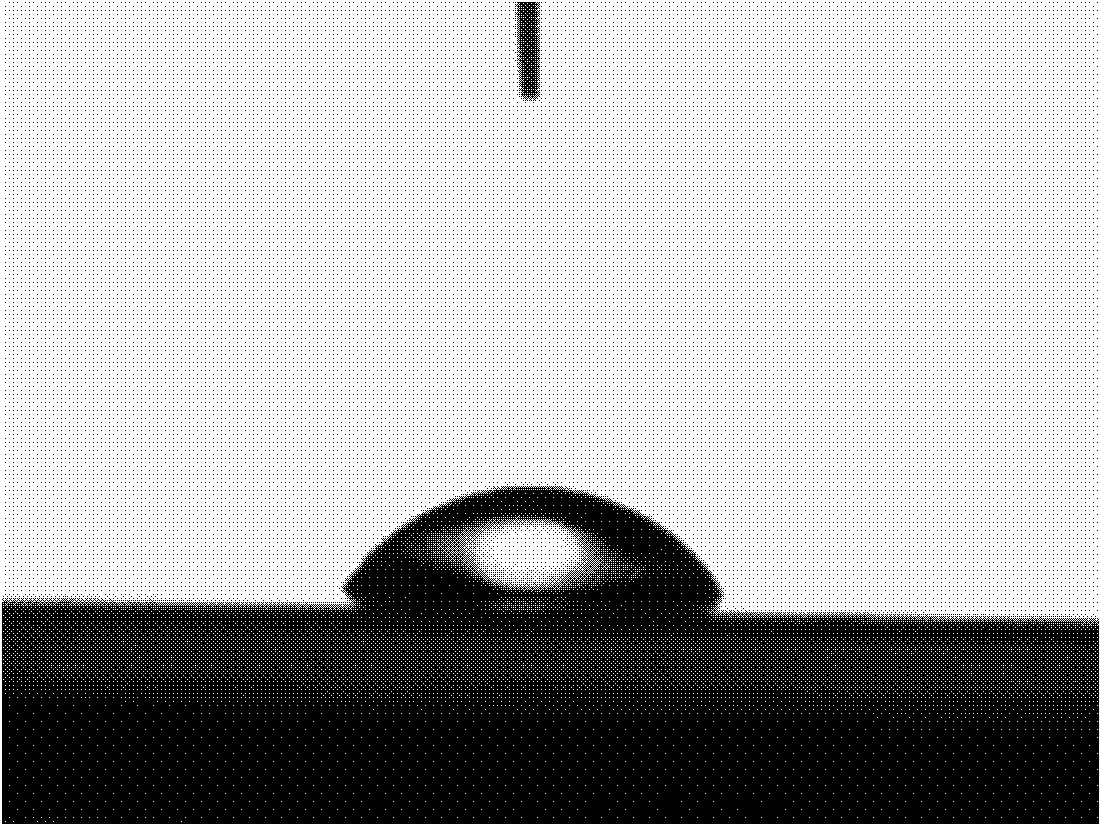

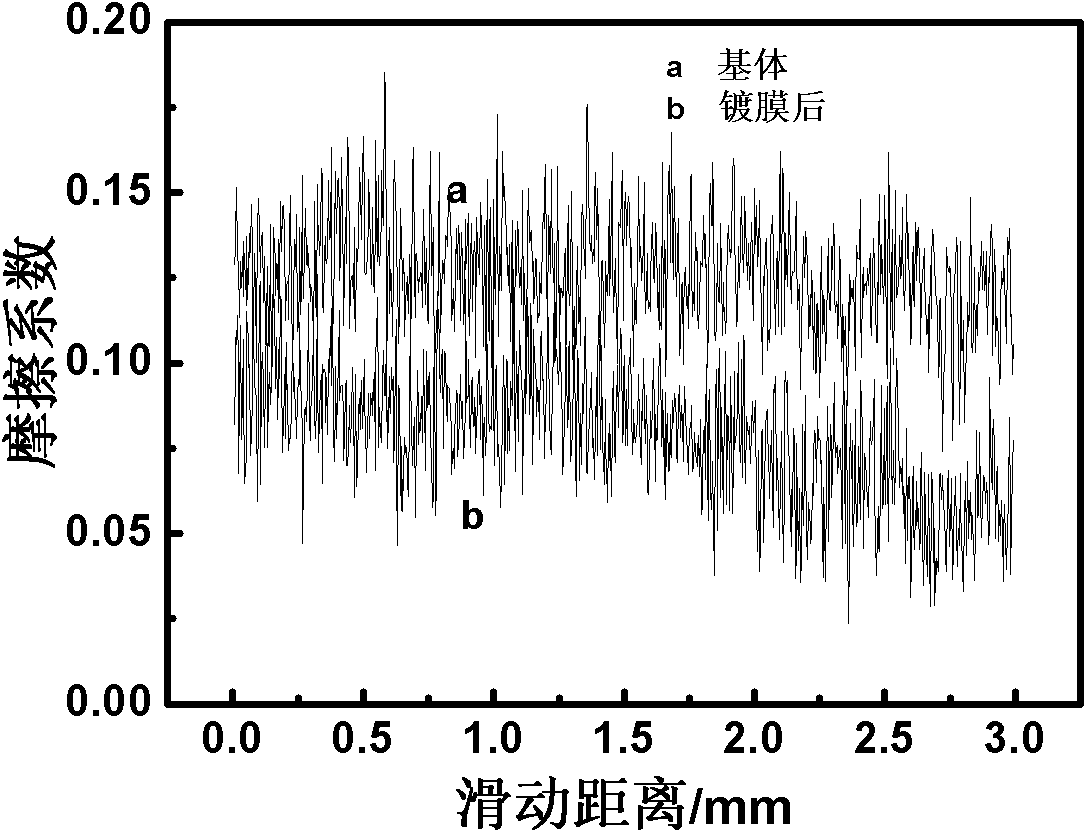

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, the MB8 magnesium alloy material with a size of 50×30×2 (mm) was selected as the base material, and a nano-organic film with hydrophobic, friction-reducing and anti-adhesion properties was prepared on the surface of the MB8 magnesium alloy material by cyclic voltammetry. First use 360#, 800#, 1200#, 1500#, 2000# sandpaper to grind the MB8 magnesium alloy workpiece, and put it in acetone solution for ultrasonic cleaning for 15 minutes to remove oil stains, take it out and dry it with cold air for later use.

[0041] The preparation of nano organic film comprises the following steps and process conditions:

[0042] (1) Preparation of coating electrolyte solution

[0043]

[0044] Select the one containing the above shown containing R 1 for alkyl and R 2 The water-soluble triazazine organic compound salt of aryl functional group is 8mmol / l, the alkaline supporting electrolytic salt is 0.2mol / l potassium hydroxide, and the electrolyte solution for orga...

Embodiment 2

[0049] In this embodiment, an industrial pure aluminum material with a size of 50×30×0.3 (mm) is selected as the base material, and a nano-organic film with hydrophobic, anti-friction and anti-adhesion properties is prepared on the surface of the industrial pure aluminum material by constant current method. First use 1500#, 2000# sandpaper to polish the pure aluminum sample, and put it in acetone solution for ultrasonic cleaning for 15 minutes to remove oil stains, take out the cold air and dry it for later use;

[0050] The preparation of nano organic film comprises the following steps and process conditions:

[0051] (1) Preparation of coating electrolyte solution

[0052]

[0053] Select the one containing the above shown containing R 1 for other classes and R 2 5 mmol / l of water-soluble triazazine organic compound salt of alkenyl functional group, 0.15 mol / l of sodium borate as alkaline supporting electrolytic salt, and an electrolyte solution for organic coating is pre...

Embodiment 3

[0058] In this embodiment, the H80 copper alloy material with a size of 50×30×2 (mm) is selected as the base material, and a nano-organic film with hydrophobic, friction-reducing and anti-adhesion properties is prepared on the surface of the H80 copper alloy material by a constant potential method. First use 360#, 800#, 1200#, 1500#, 2000# sandpaper to polish the copper alloy sample, and put it in acetone solution for ultrasonic cleaning for 15 minutes to remove oil stains, take out the cold air and dry it for later use;

[0059] The preparation of nano organic film comprises the following steps and process conditions:

[0060] (1) Preparation of coating electrolyte solution

[0061]

[0062] Select the one containing the above shown containing R 1 for alkenyl and R 2 The water-soluble triazazine organic compound salt of alkyl functional group is 3mmol / l, the alkaline supporting electrolytic salt is 1mol / l sodium bicarbonate, and the electrolyte solution for organic coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com