Unconventional reservoir multi-scale fusion method based on digital core technology

A multi-scale fusion, digital core technology, applied in the field of exploration, can solve the problems that the core model cannot express the strong heterogeneity tight sandstone shale reservoir, the model memory cannot integrate nano-sized pores, and the core model storage capacity is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

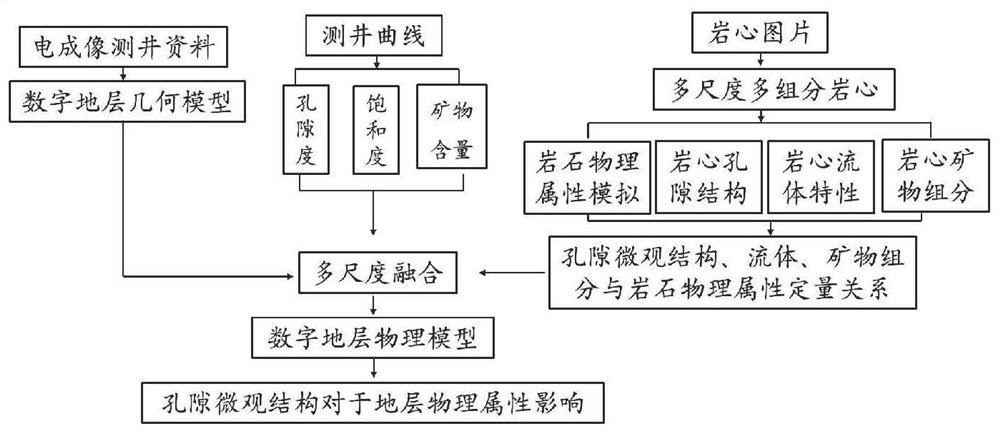

[0081] Taking the multi-scale fusion technology based on digital core technology in the 2305m-2350m depth section of the HG tight sandstone reservoir in an example well in an oilfield in China as an example, figure 1 It is a flow chart of multi-scale fusion technology for unconventional reservoirs based on digital core technology. The multi-scale fusion technology based on digital core technology specifically includes the following steps:

[0082] Step 1: Construct an initial physical model of a tight sandstone 3D digital formation based on electrical imaging logging data and logging curve data;

[0083] Step 1.1: Obtain stratum occurrence information based on electrical imaging data;

[0084] Step 1.2: According to the three porosities (neutron CNL, density DEN and acoustic AC), deep and shallow dual lateral (RLLd, RLLs) resistivity and lithology logging curves (spontaneous potential SP, natural gamma GR), obtain Porosity (POR), saturation and shale content (Vsh), such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com