A photothermal evaporation surface and its preparation and application

A technology of evaporating surface and photothermal, which is applied in the field of solar photothermal utilization, can solve the problems of being unsuitable for large-scale industrial applications, consuming too many nanoparticles, and unstable performance, so as to achieve industrial application, high photothermal conversion efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

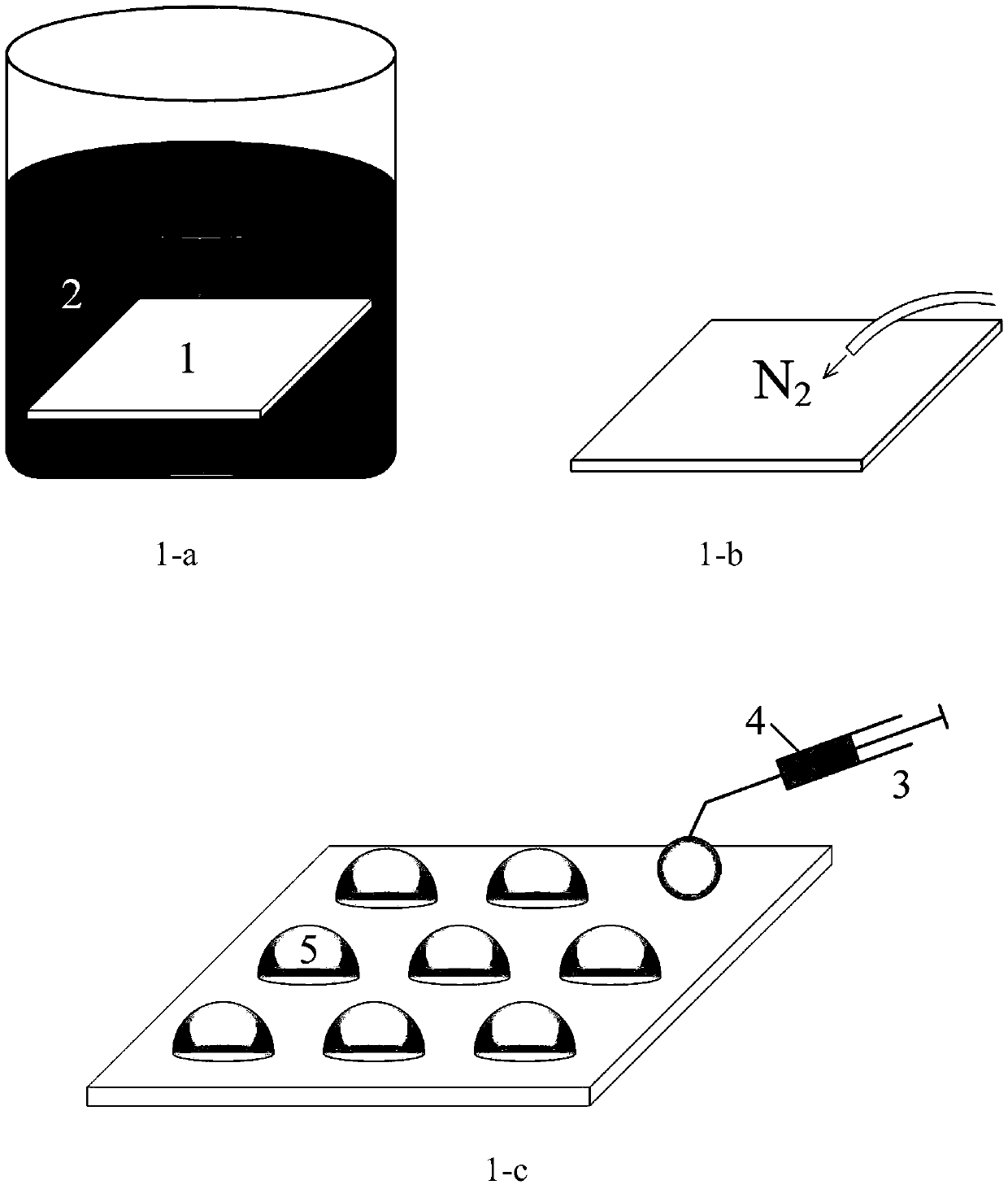

[0048] Prepare the high-efficiency photothermal evaporation surface according to the following method:

[0049] The surface of the substrate is made of quartz glass, with a length of 200 mm, a width of 200 mm, and a thickness of 2 mm. The quartz glass surface is polished, and the surface roughness is at the sub-micron level. Wash with acetone, absolute ethanol, and deionized water in an ultrasonic cleaning machine to remove organic dirt on the surface, and dry it with nitrogen for use.

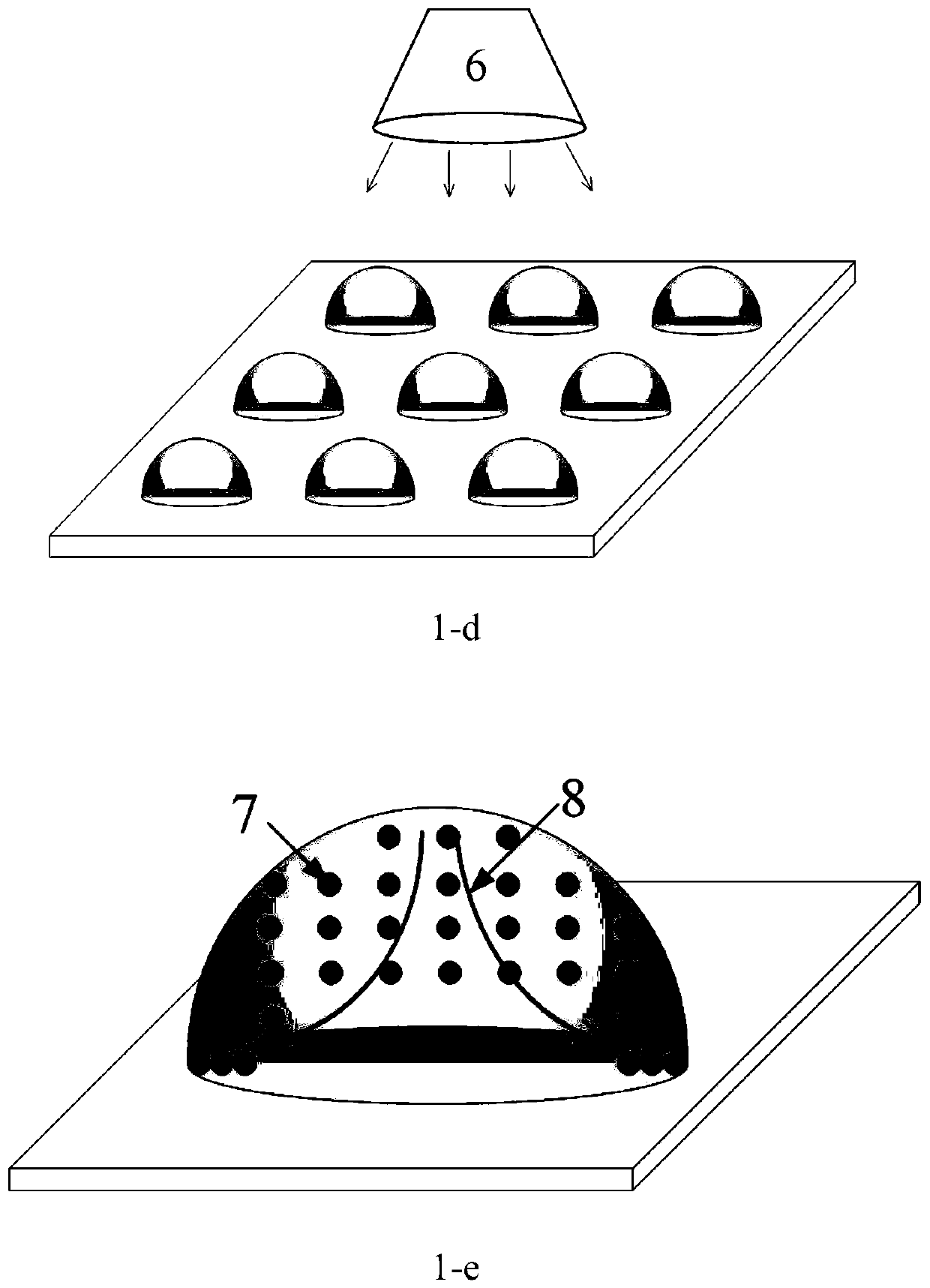

[0050] The nanofluid selects gold nanofluid, the concentration is 10μg / mL, and the diameter of the gold nanoparticle is 18nm. The nanofluid is loaded into the micro-droplet generator and fixed on the coordinate table, and the coordinate table is moved by the controller to generate droplets at the designated position. The droplet volume generated by the micro droplet generator is 2 μL, the contact angle of the droplet on the substrate surface is 81°, and the contact surface diameter is 2.1 mm. Pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com