Patents

Literature

86 results about "Composite microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-dip galvanized steel sheet and production thereof

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

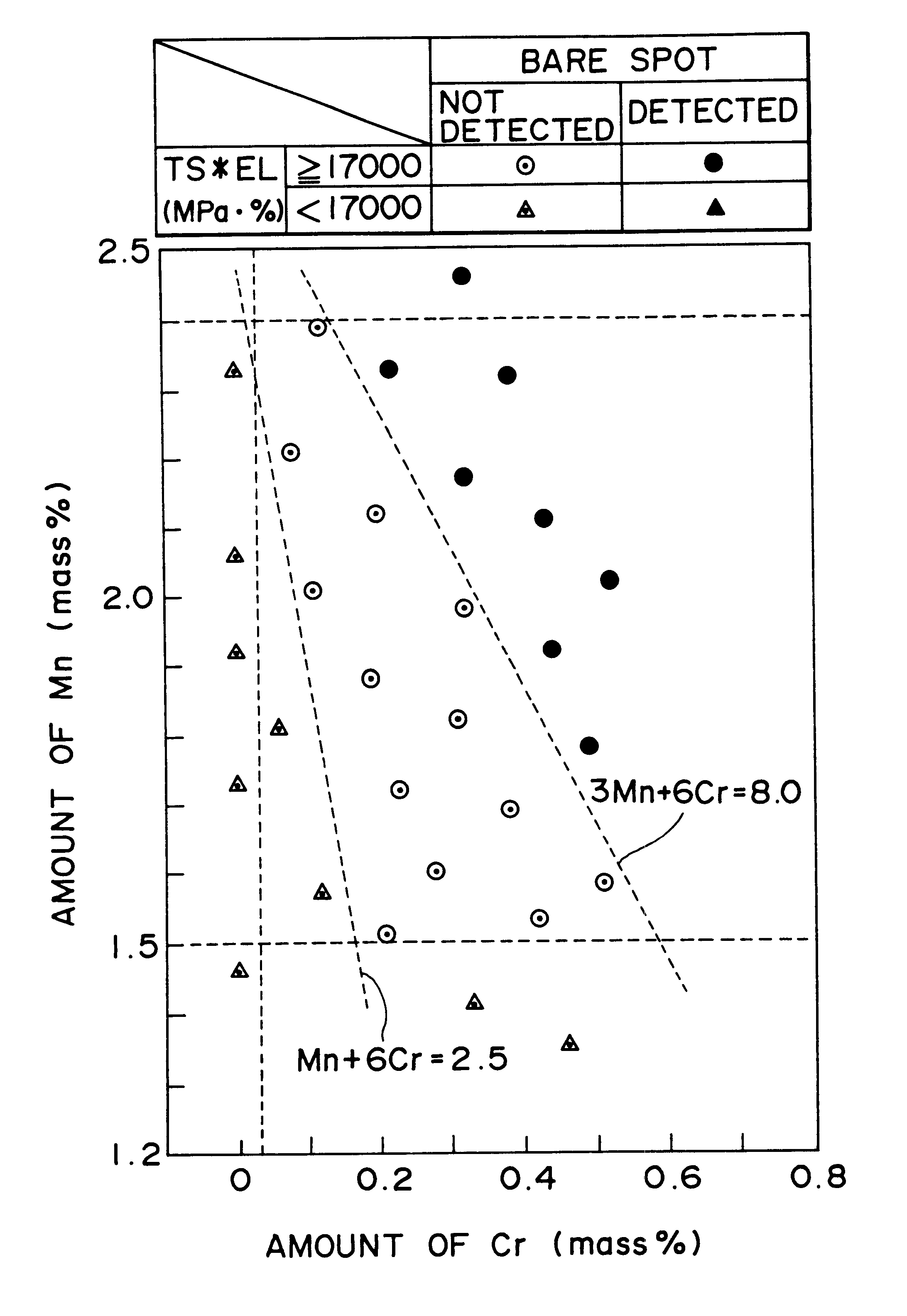

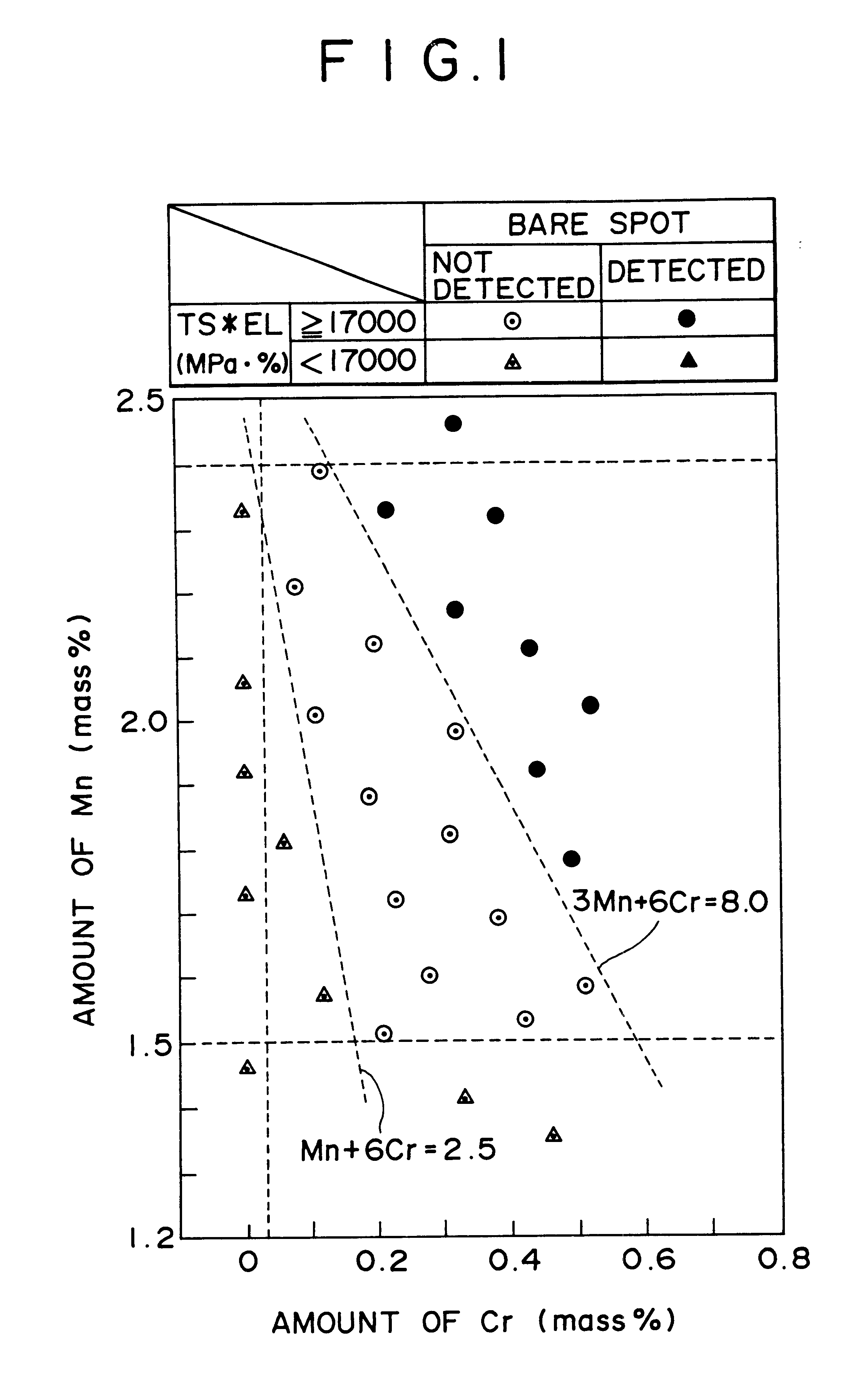

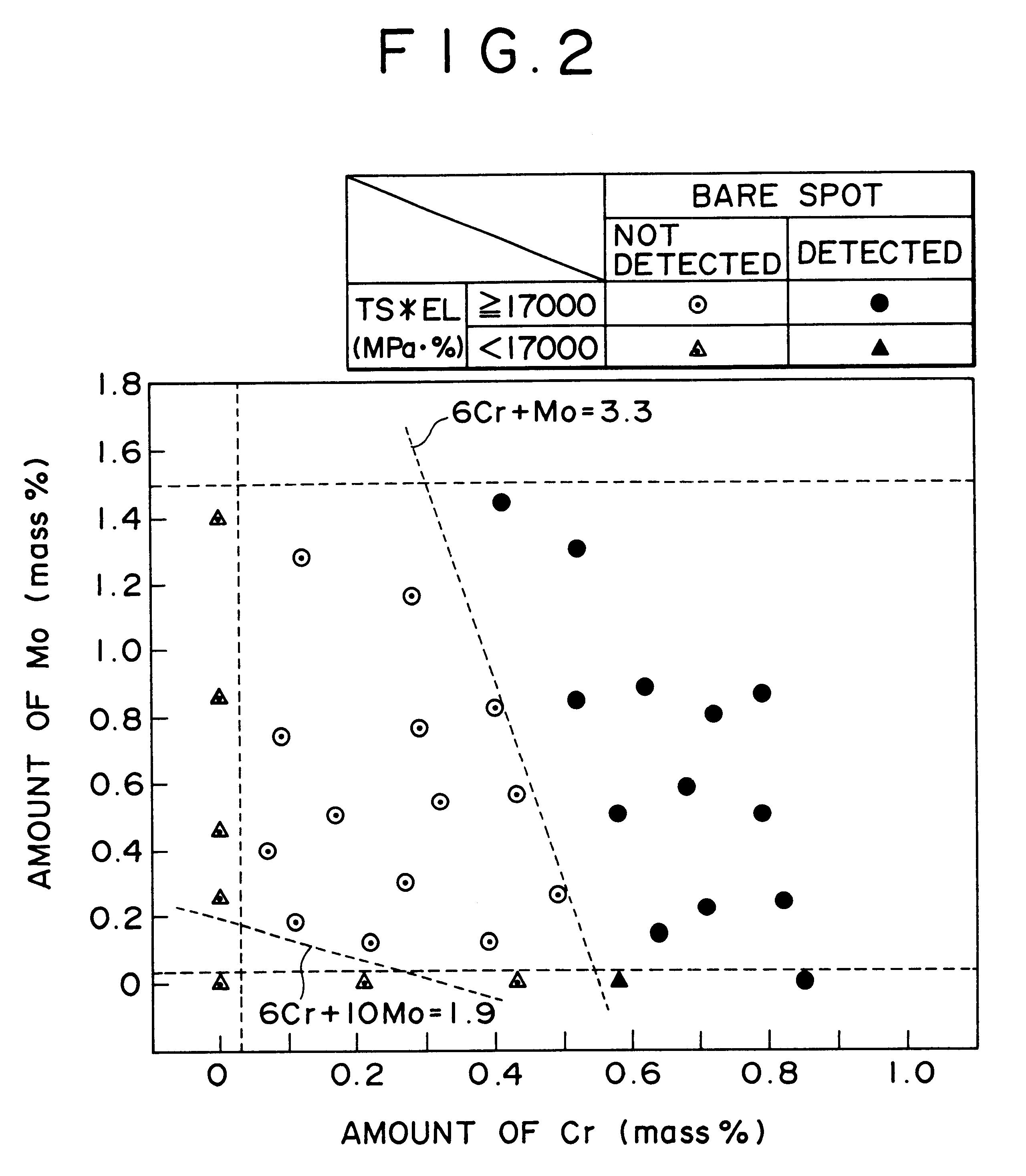

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

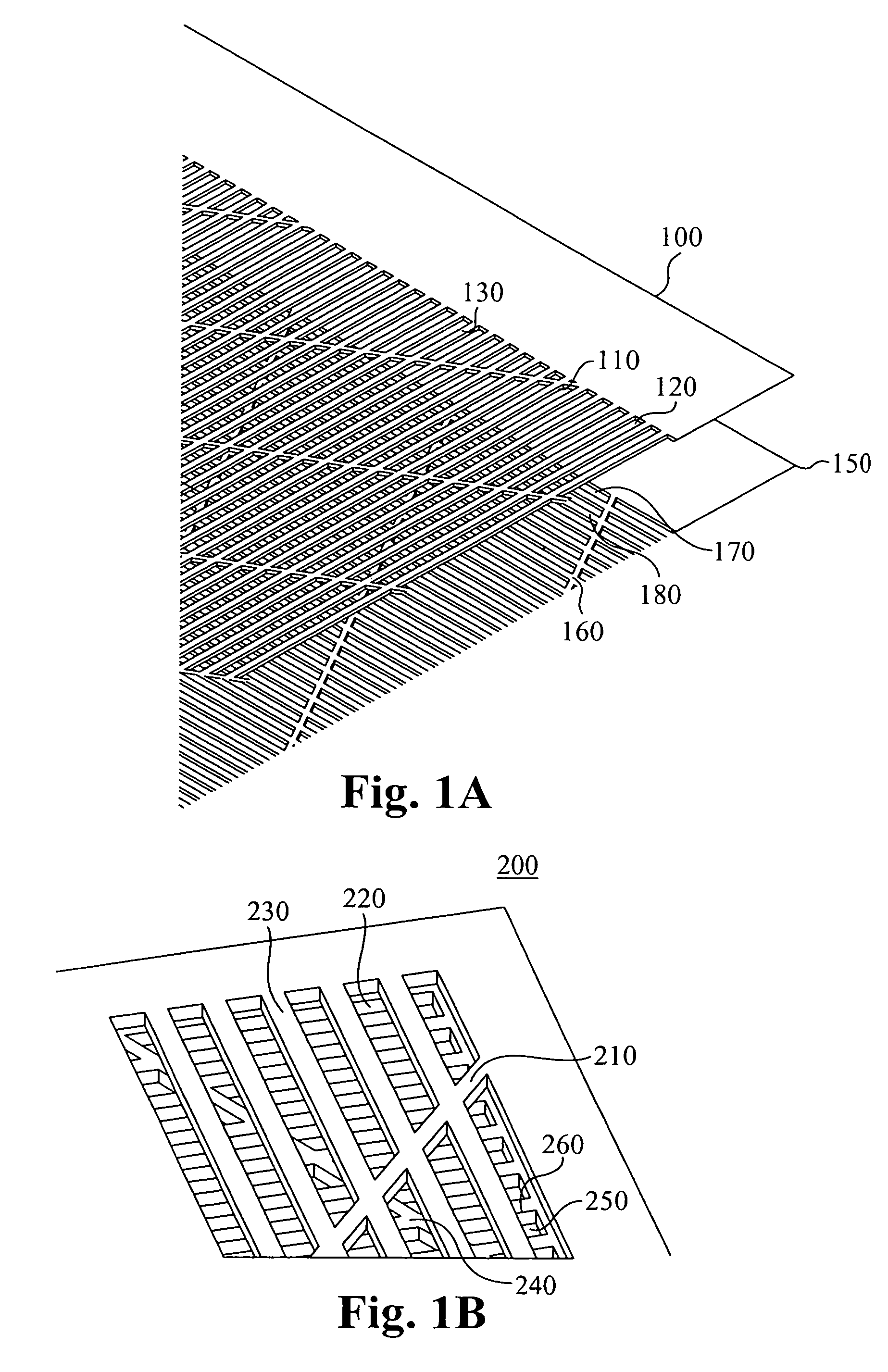

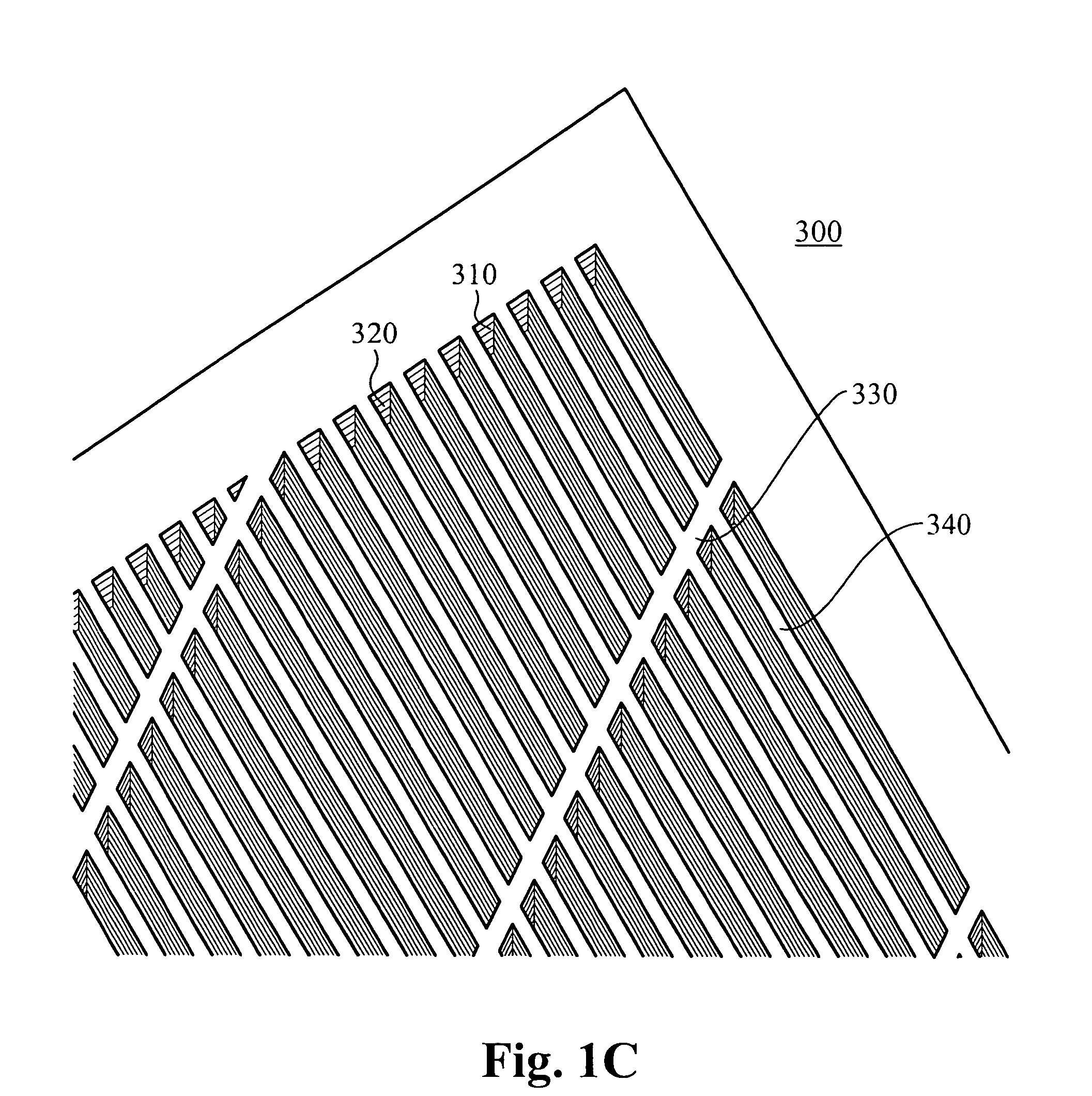

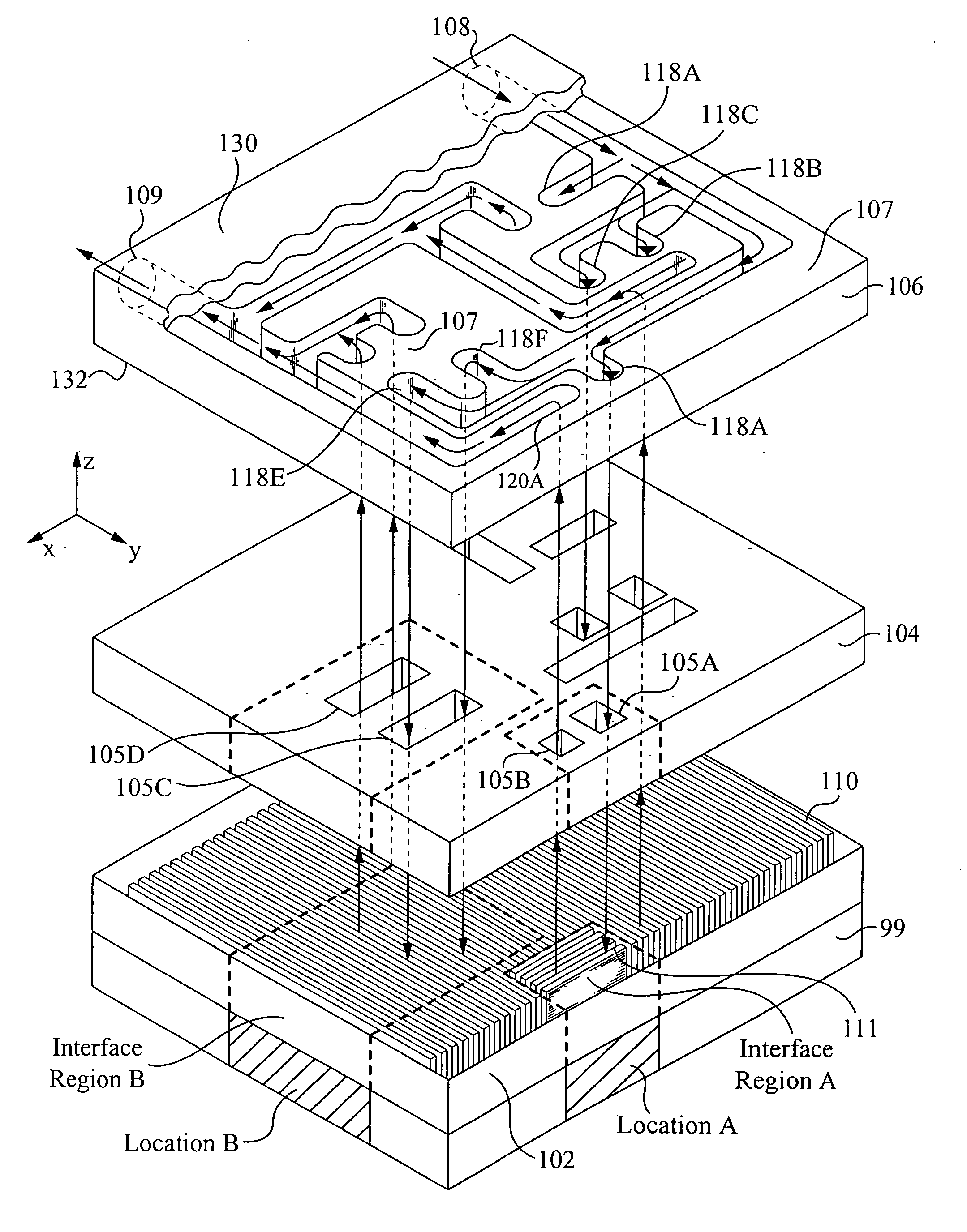

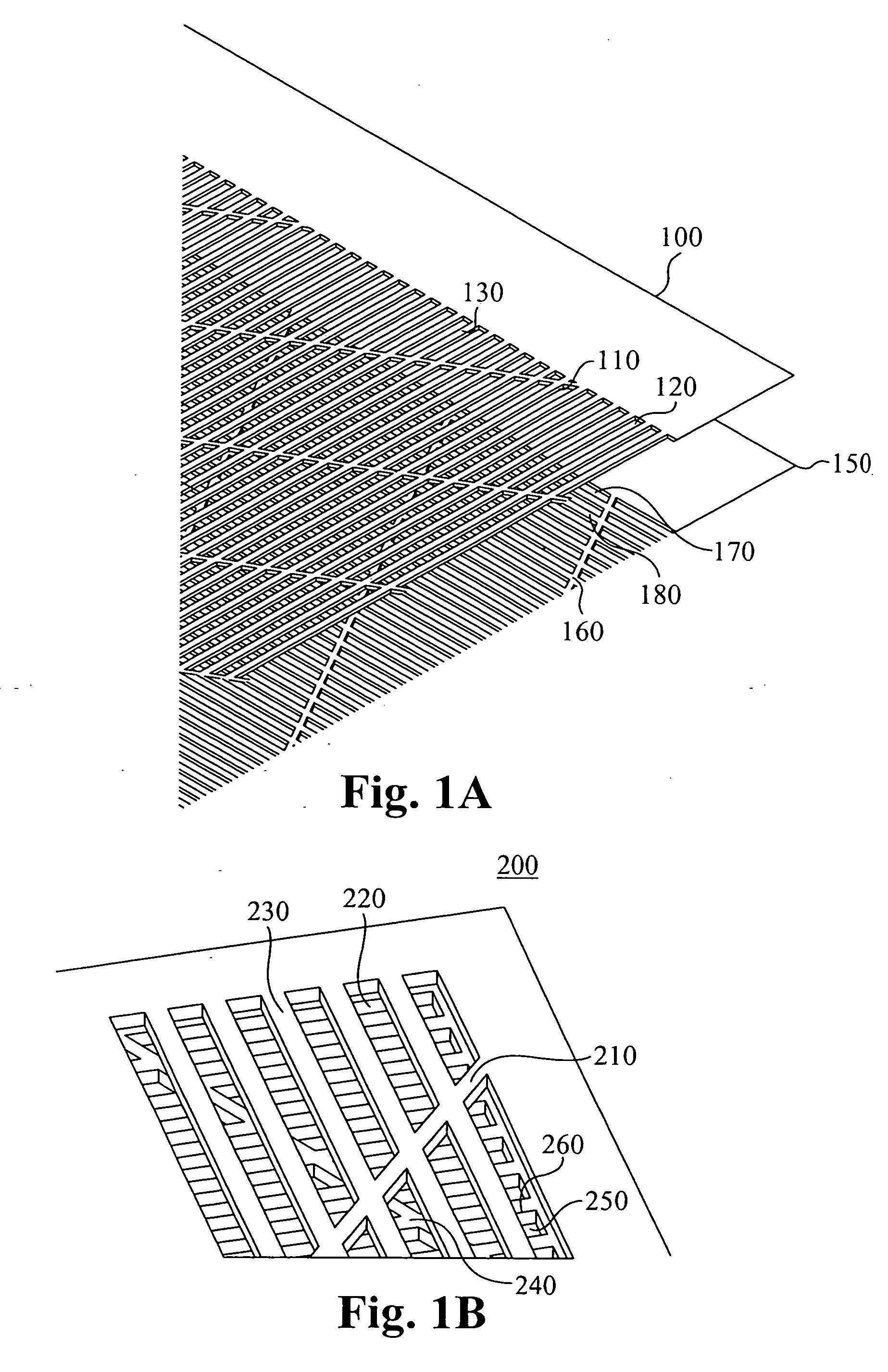

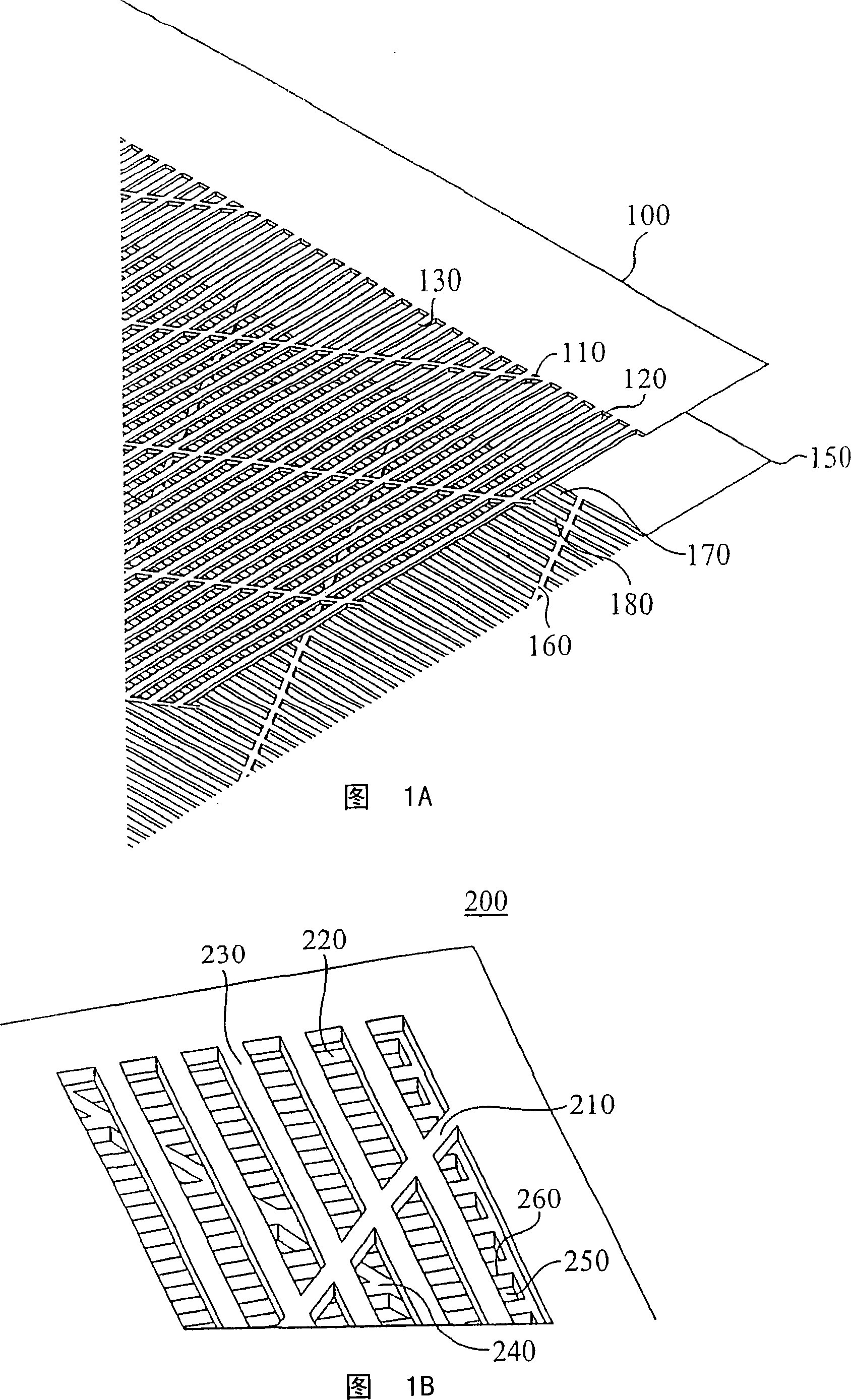

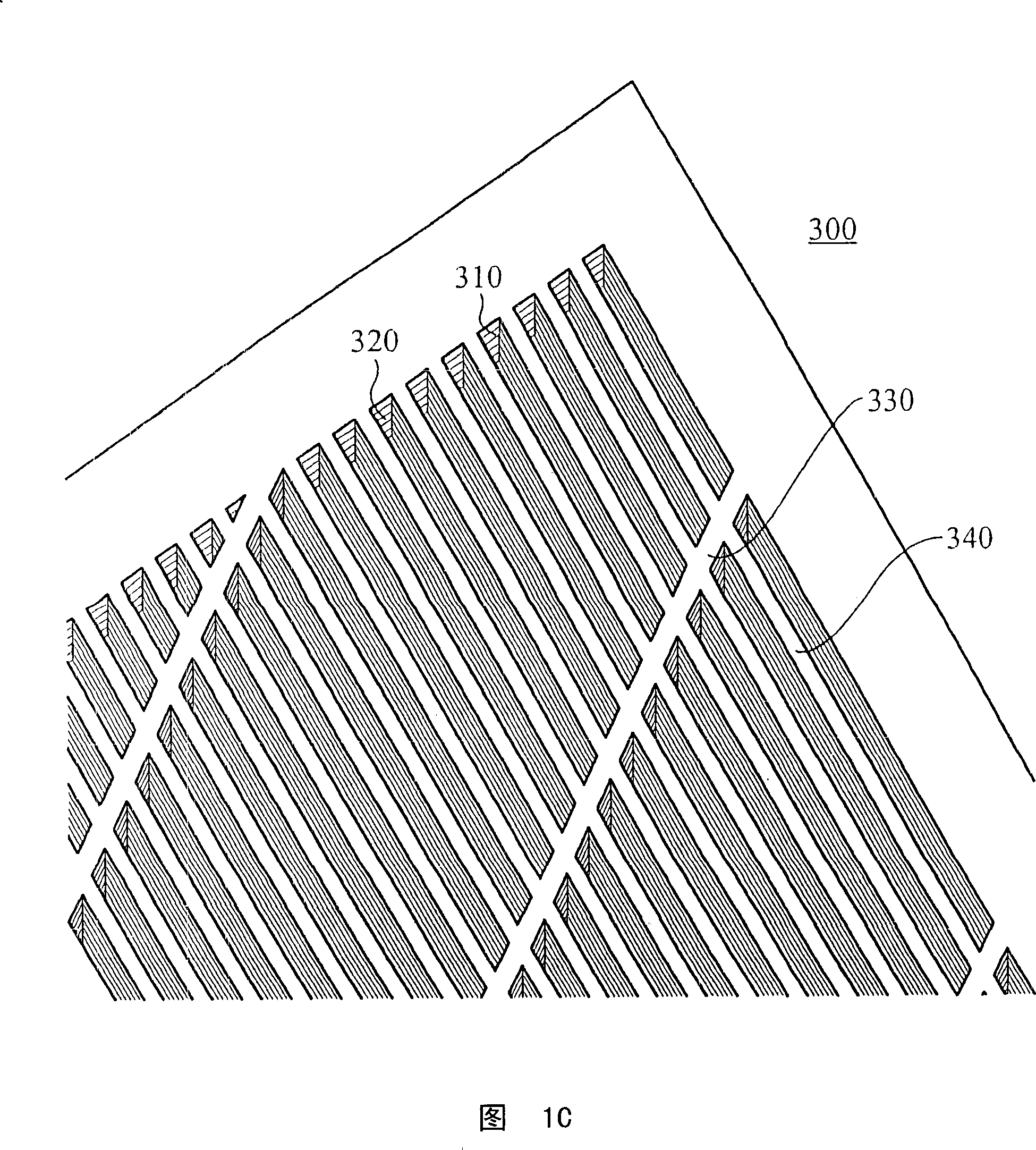

Method of fabricating high surface to volume ratio structures and their integration in microheat exchangers for liquid cooling system

Owner:VERTIV CORP

Fabrication of high surface to volume ratio structures and their integration in microheat exchangers for liquid cooling systems

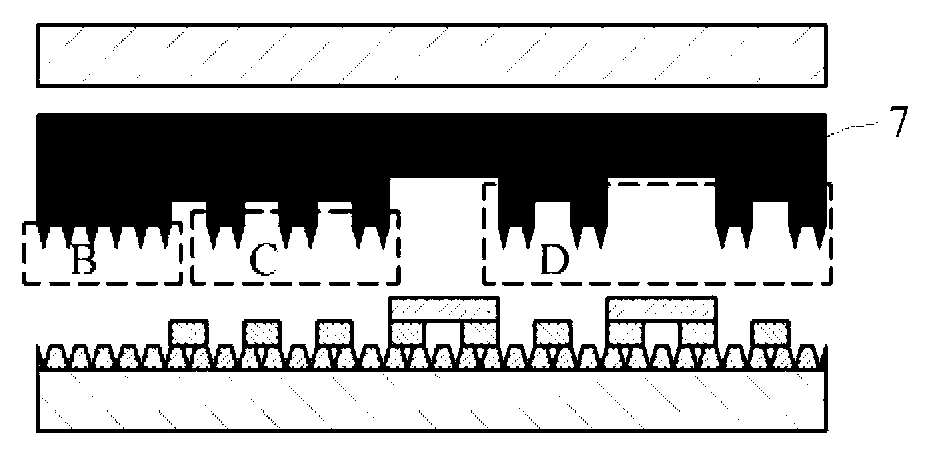

ActiveUS20080210405A1Good mechanical bondExcellent thermal bondingSemiconductor/solid-state device detailsMetal-working apparatusEtchingIt integration

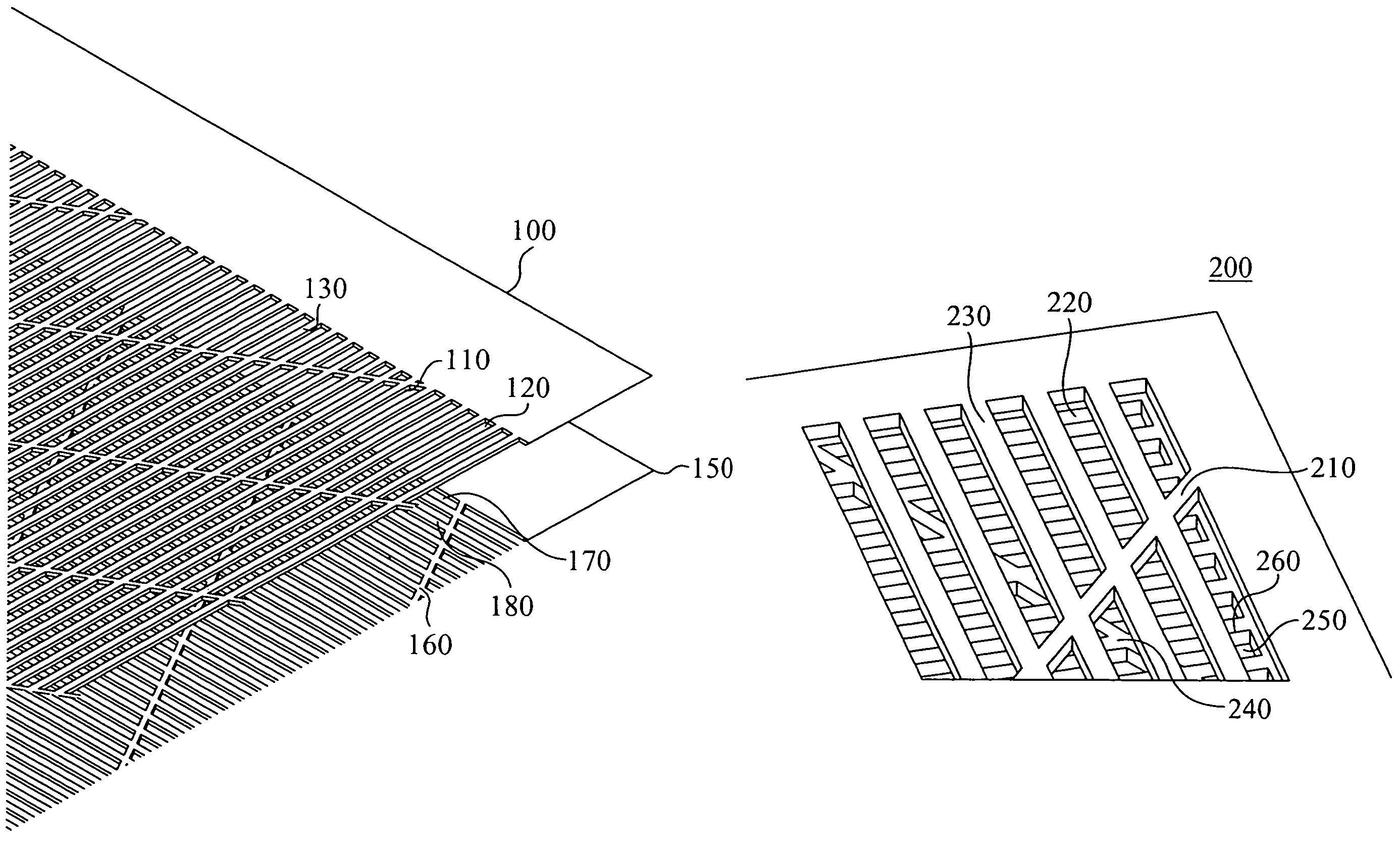

An structure and method of manufacturing a microstructure for use in a heat exchanger is disclosed. The heat exchanger comprises a manifold layer and an microstructured region. The manifold layer comprises a structure to deliver fluid to the microstructured region. The microstructured region is formed from multiple windowed layers formed from heat conductive layers through which a plurality of microscaled apertures have been formed by a wet etching process. The plurality of windowed layers are then coupled together to form a composite microstructure.

Owner:VERTIV CORP

Preparation method and application of super-hydrophobic and adhesion-adjustable surface with micro-nano composite structure

The invention relates to a preparation method for a super-hydrophobic and adhesion-adjustable surface with a micro-nano composite structure. The preparation method comprises the following steps: a, preparing a dual-level composite microstructure template according to wetting characteristics needed by a product surface; b, preparing a solution from a hydrophilic / hydrophobic nanoparticle and absolute ethyl alcohol according to adhesion characteristics needed by the product surface, immersing the dual-level composite microstructure template into the solution, carrying out ultrasonic dispersion, then taking the treated microstructure template out and drying the treated microstructure template so as to obtain a three-level micro-nano composite structure template; c, fixing the obtained template on the surface of a die cavity, injecting high-molecular melt into the cavity by using an injection machine, carrying out pressure maintaining and then carrying out cooling and molding; and d, separating a molded high-molecular product from an injection die by using a demolding apparatus. The hydrophilic / hydrophobic nanoparticle is adhered on the surface or embedded into the surface layer of the dual-level composite microstructure on the surface of the molded high-molecular product, and the molded high-molecular product surface has the characteristics of super-hydrophobicity and adjustable adhesion and can realize flexible switching between a lotus leaf effect and a petal effect.

Owner:SOUTH CHINA UNIV OF TECH

High Strength Dual Phase Steel With Low Yield Ratio, High Toughness and Superior Weldability

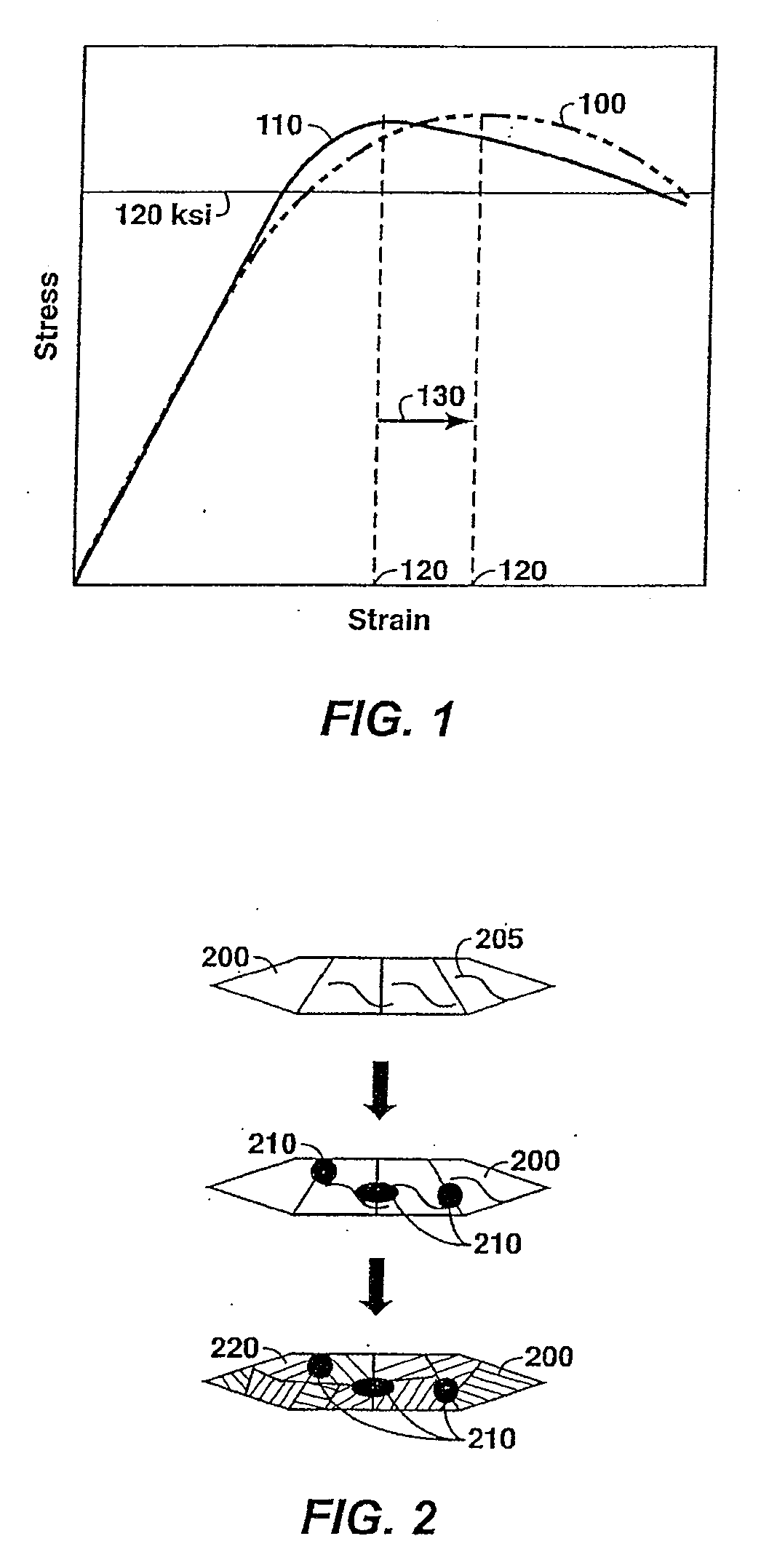

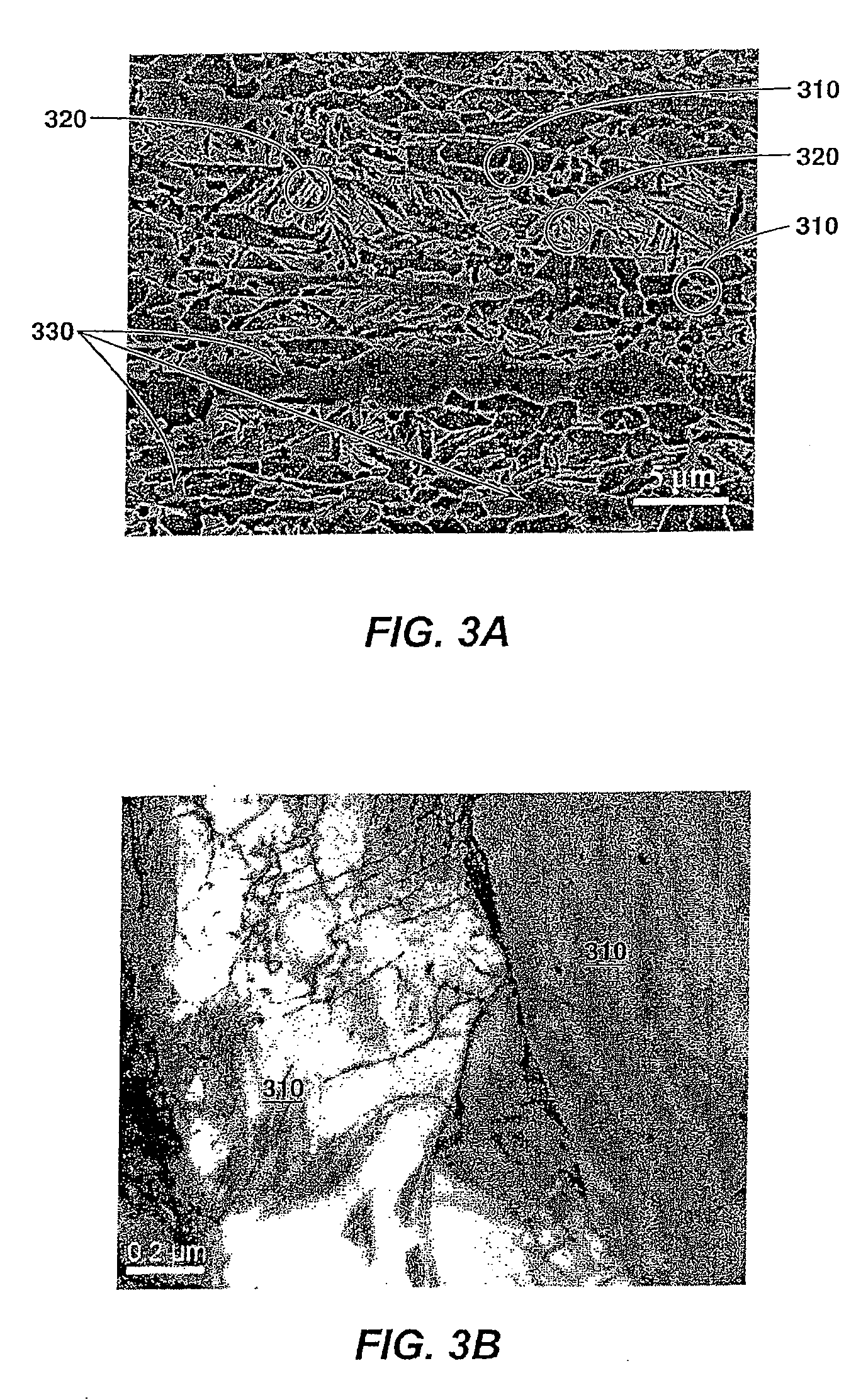

A dual phase, high strength steel having a composite microstructure of soft and hard phases providing a low yield ratio, high strain capacity, superior weldability, and high toughness is provided. The dual phase steel includes from about 10% by volume to about 60% by volume of a first phase or constituent consisting essentially of fine-grained ferrite. The first phase has a ferrite mean grain size of about 5 microns or less. The dual phase steel further includes from about 40% by volume to about 90% by volume of a second phase or constituent comprising fine-grained martensite, fine-grained lower bainite, fine-grained granular bainite, fine-grained degenerate upper bainite, or any mixture thereof. Methods for making the same are also provided.

Owner:NIPPON STEEL CORP

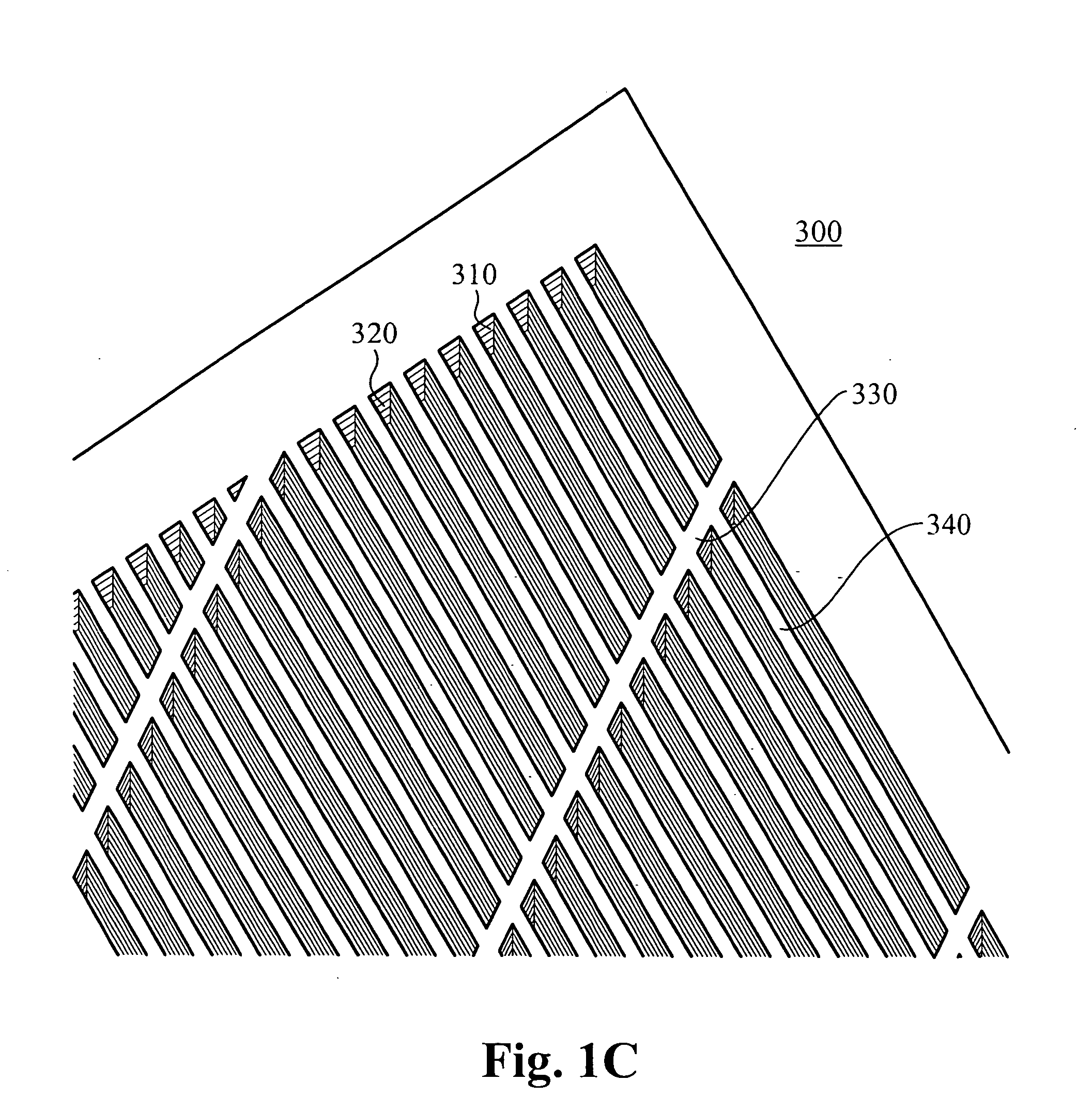

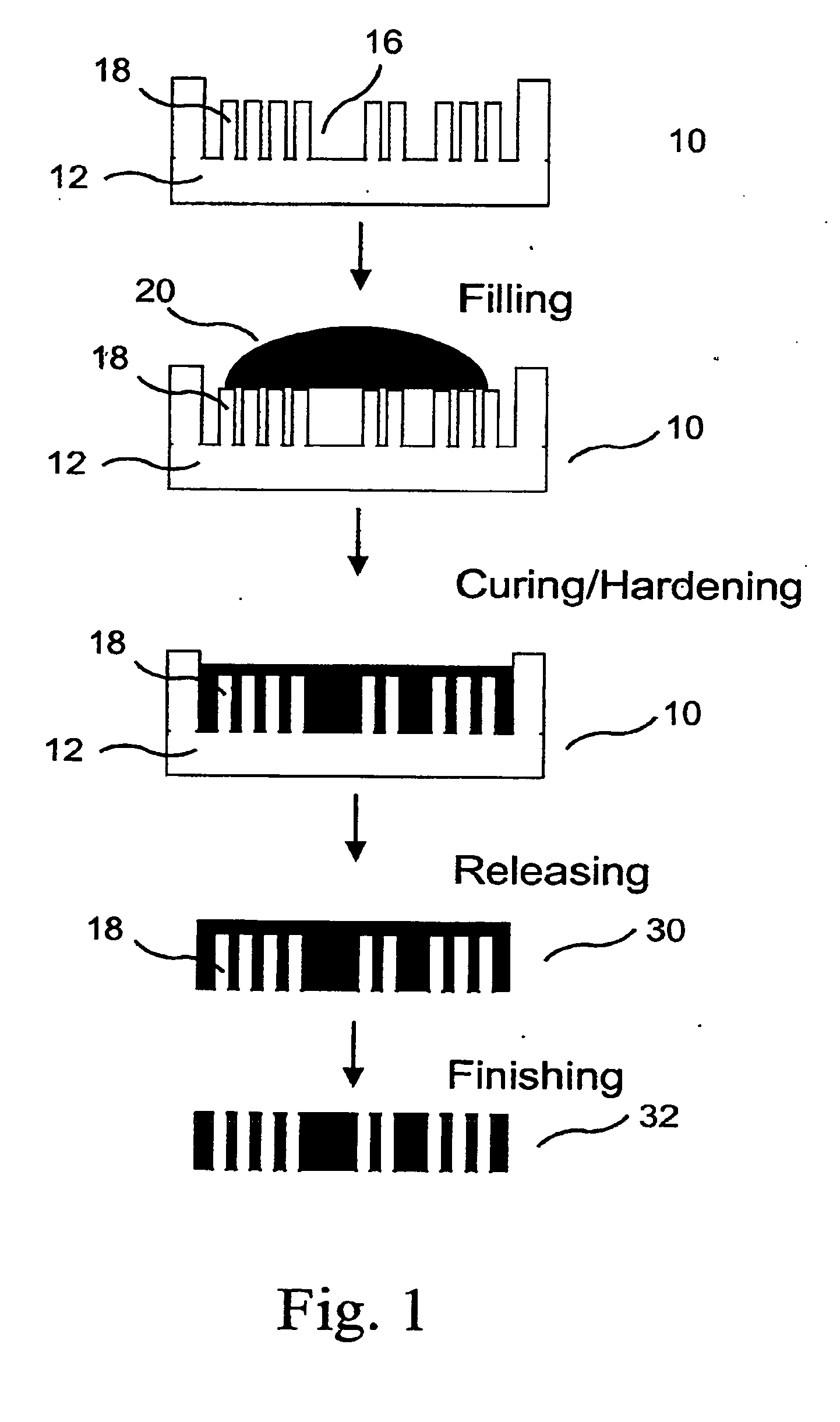

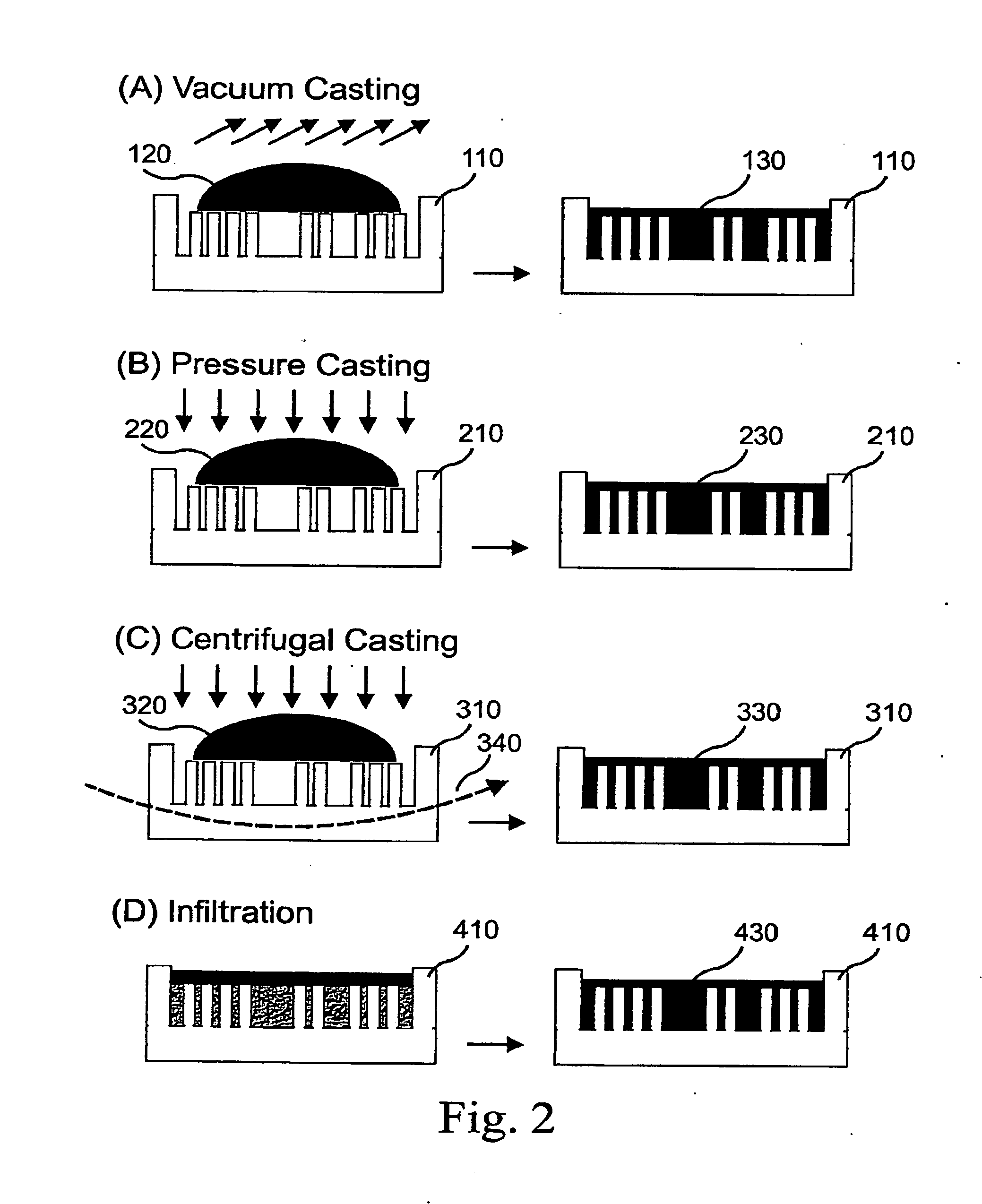

High Aspect Ratio Microstructures and Method for Fabricating High Aspect Ratio Microstructures From Powder Composites

InactiveUS20100276829A1High aspect ratioImprove accuracyTransportation and packagingMetal-working apparatusAlloyAnti-scatter grid

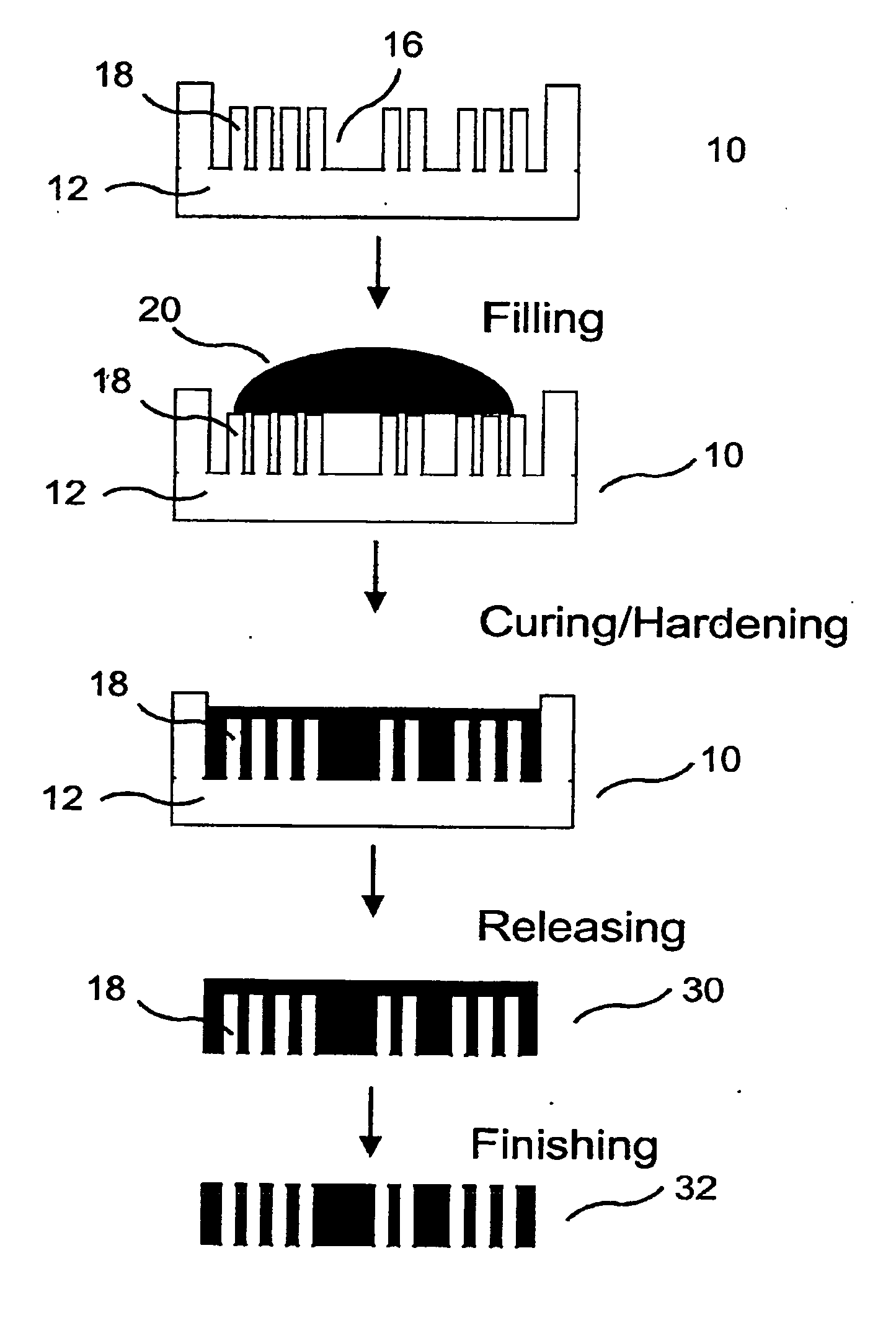

Methods to fabricate high aspect ratio powder composite microstructures is provided by filling a molding composition containing a powdered material and a binder into a patterned mold, and releasing the cured composite microstructures from the mold. An alternate method is by filling a mix of powdered dense metals and low-melt alloys into a patterned mold, and releasing the melted and solidified composite microstructures from the mold. The mold is derived from lithographically defined parent mold. One example of the application is in the field of x-ray anti-scatter grids and nuclear collimators.

Owner:CREATV MICROTECH

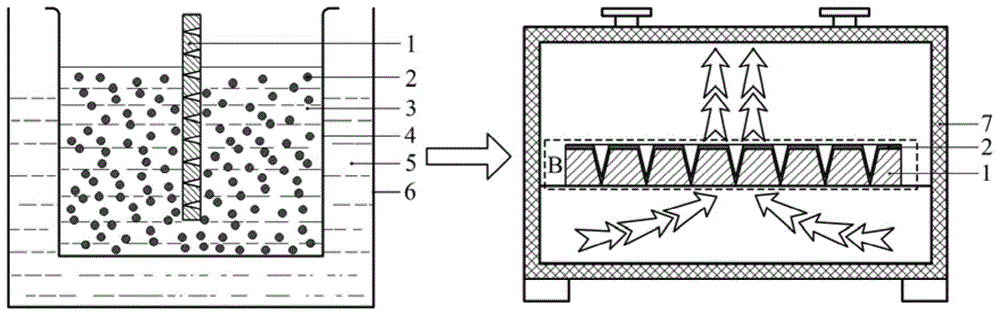

Preparation method and application of super hydrophobic surface with composite microstructure

ActiveCN103101147AReduce processGuaranteed continuityCoatingsInjection molding machineMaterials science

The invention relates to a preparation method of a super hydrophobic surface with a composite microstructure. The preparation method comprises the following steps of: a, manufacturing a composite microstructure moldboard with more than two scale micro features according to the wetting features required by a product surface, and fixing the composite microstructure moldboard on the surface of an injection molding die cavity; b, utilizing the injection molding machine to inject a macromolecule fusant in the injection molding die cavity, carrying out pressure maintaining on the fusant through the one-way or bi-directional compression of the volume of the die cavity or the axial movement of the screw rod of the injection molding machine, and subsequently cooling and shaping; and c, isolating a macromolecule product and an injection mold through a stripper apparatus, and obtaining the super hydrophobic surface. According to the preparation method, the composite microstructure on an accurate copying moldboard, the microstructure surface and macromolecule products with various functions are obtained, and the preparation method belongs to the technical field for preparing the hydrophobic surface.

Owner:SOUTH CHINA UNIV OF TECH

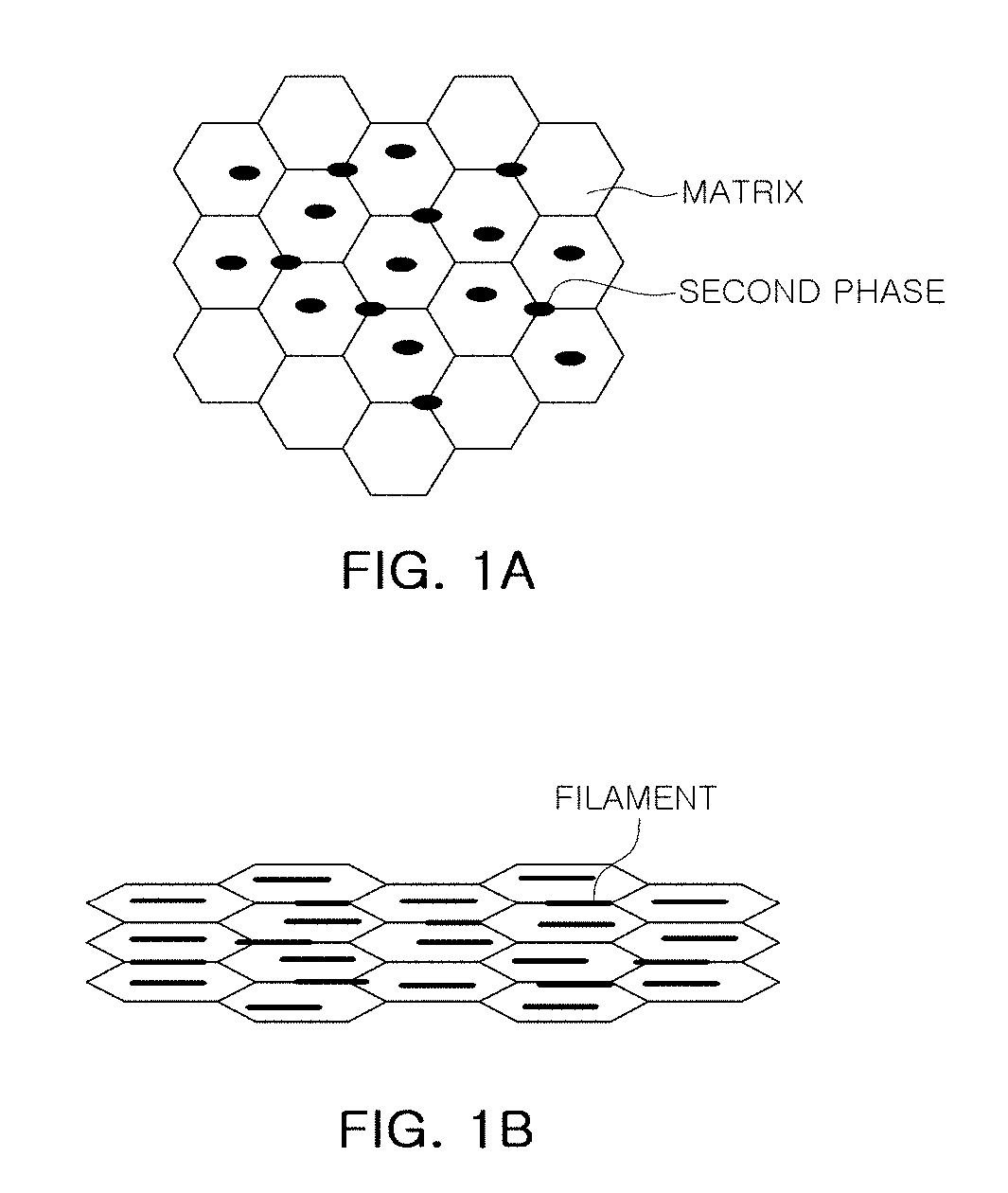

High Entropy Alloy Having Composite Microstructure and Method of Manufacturing the Same

ActiveUS20170275745A1High strengthImprove ductilityThin material handlingHigh entropy alloysHigh intensity

A metallic alloy, more particularly, a high-entropy alloy with a composite structure exhibits high strength and good ductility, and is used as a component material in electromagnetic, chemical, shipbuilding, machinery, and other applications, and in extreme environments, and the like.

Owner:THE IND & ACADEMIC COOP IN CHUNGNAM NAT UNIV (IAC)

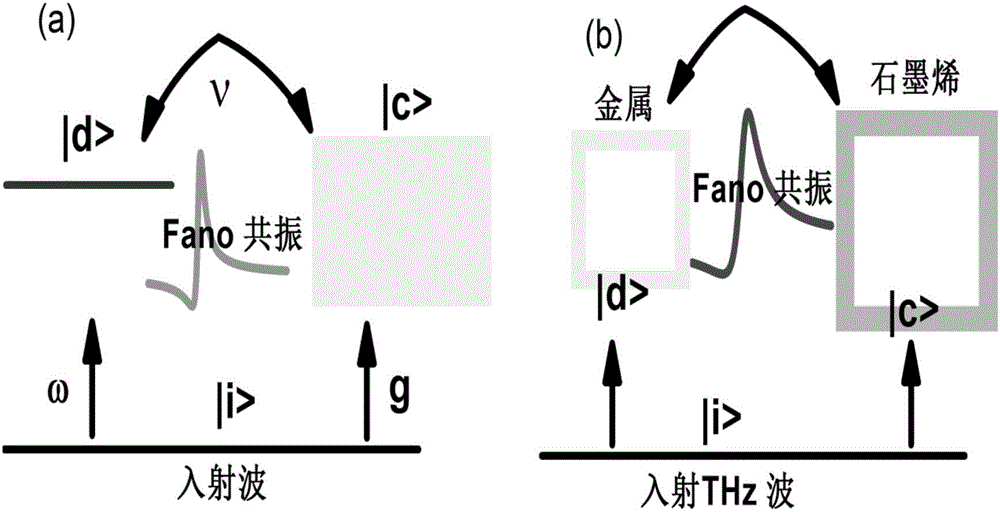

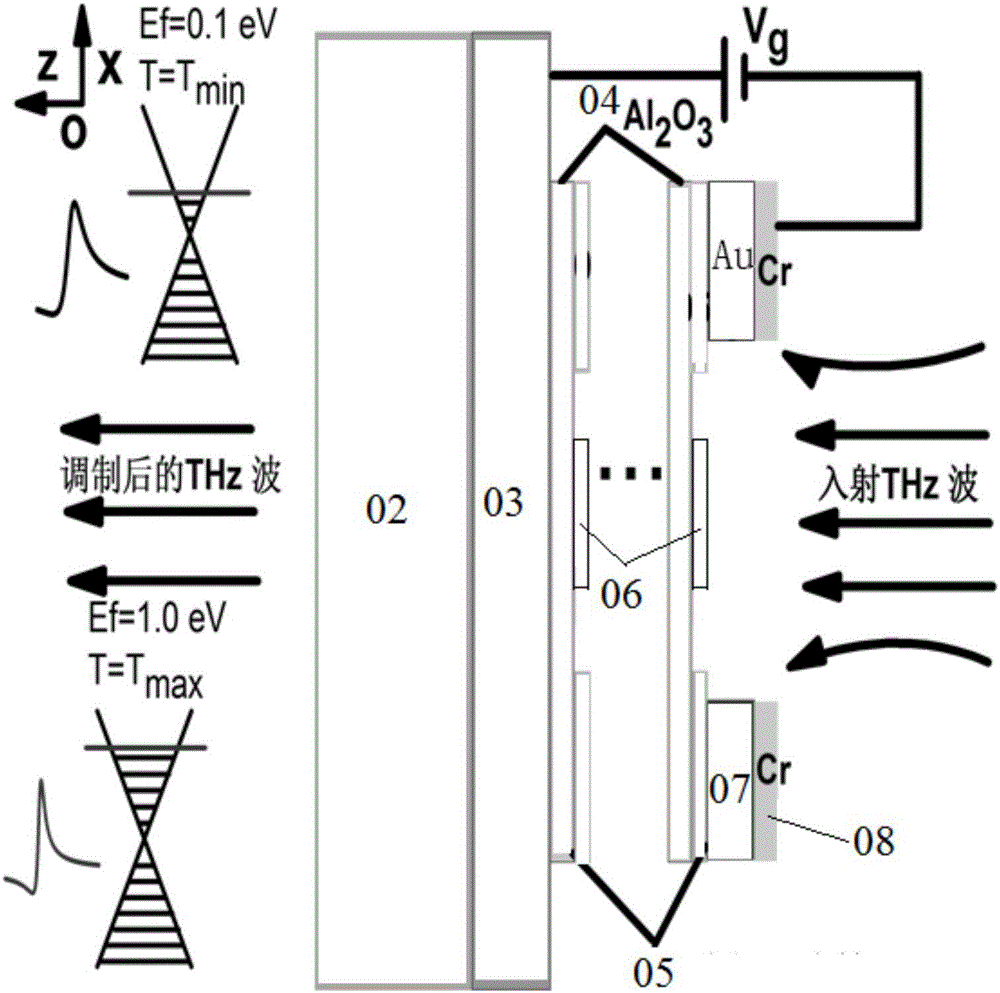

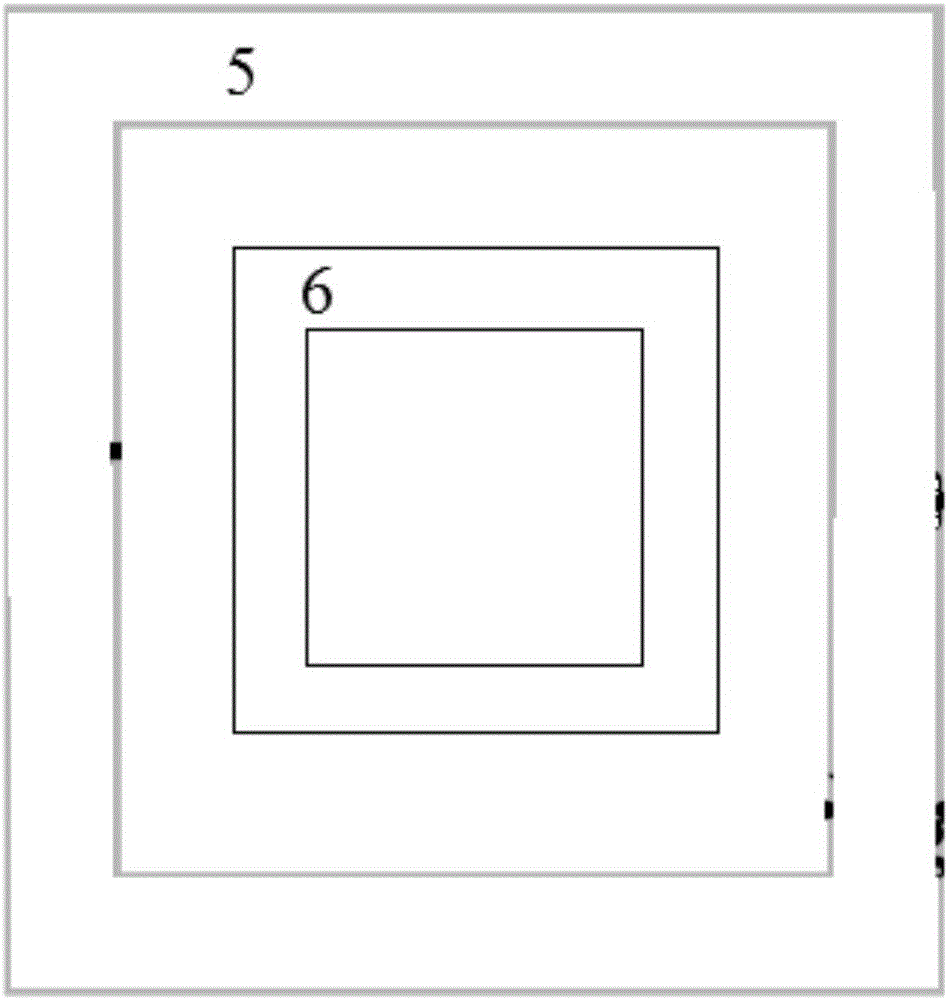

THz modulator based on graphene-metal composite microstructure and preparation thereof

ActiveCN106449381AChanging the Fermi levelGreat modulation depthSemiconductor/solid-state device manufacturingNon-linear opticsMetal microstructureCvd graphene

The invention relates to a THz modulator based on graphene-metal composite microstructure and preparation thereof. The THz modulator includes: a polymer flexible substrate layer; a doped semi-conductor epitaxial layer; a A1203 insulating-active region structure composite layer which grows on the doped semiconductor epitaxial layer and is composed by superposing at least one A1203 insulating-active region sub-structure which includes an A1203 insulating layer which is disposed therebelow and a graphene microstructure layer and a metal microstructure layer which grow on the A1203 insulating layer, the metal microstructure layer being disposed inside the graphene microstructure layer and is arranged spaced from the graphene microstructure layer to form the active sub-region structure of the THz; a metal layer which is vapor plated on one active sub-structure in the uppermost and processed to form a metal top electrode. Compared with prior art, according to the invention, the THz modulator can effectively regulate THz waves, has high quality factor, excellent adjustability and great modulation depth, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

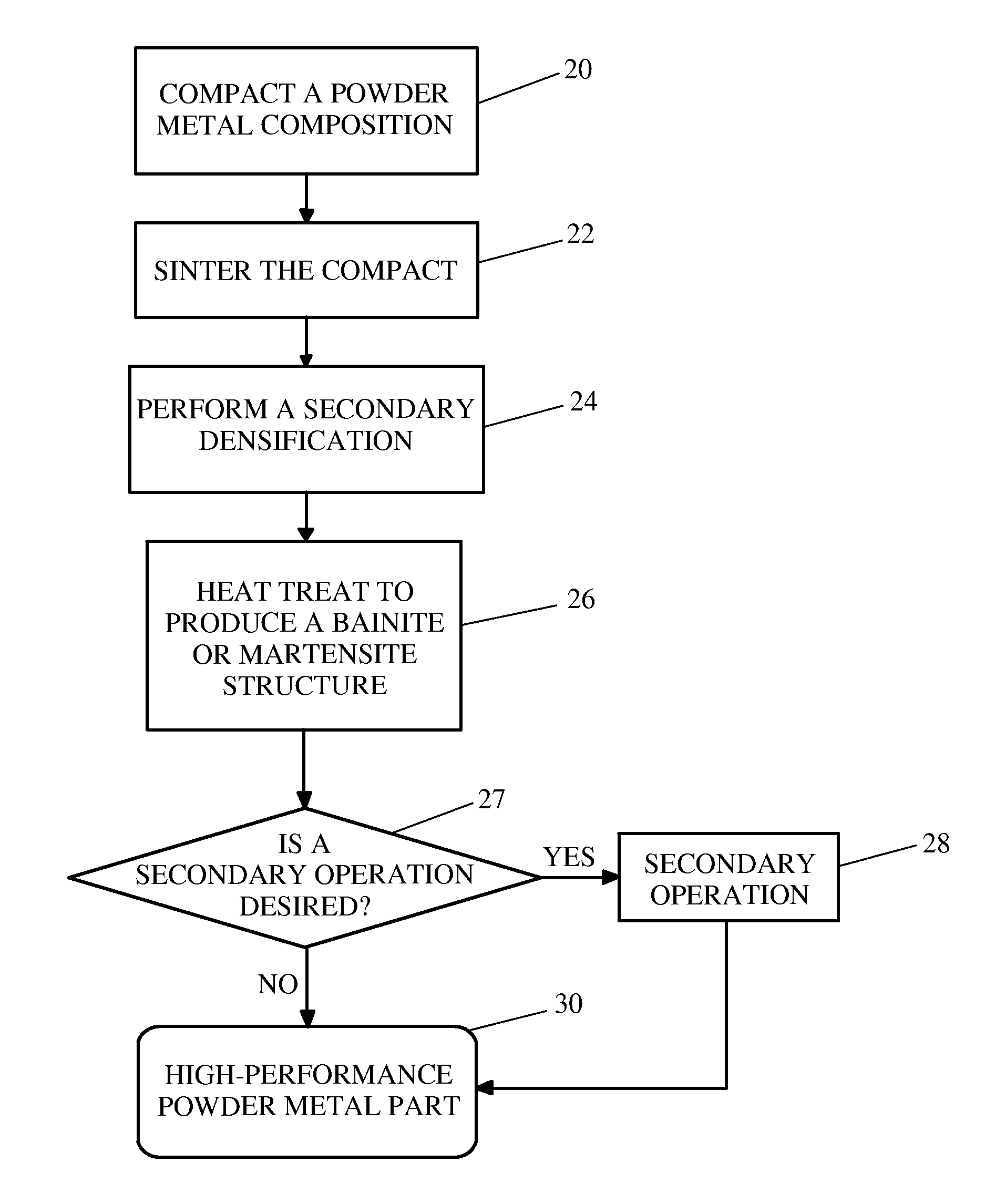

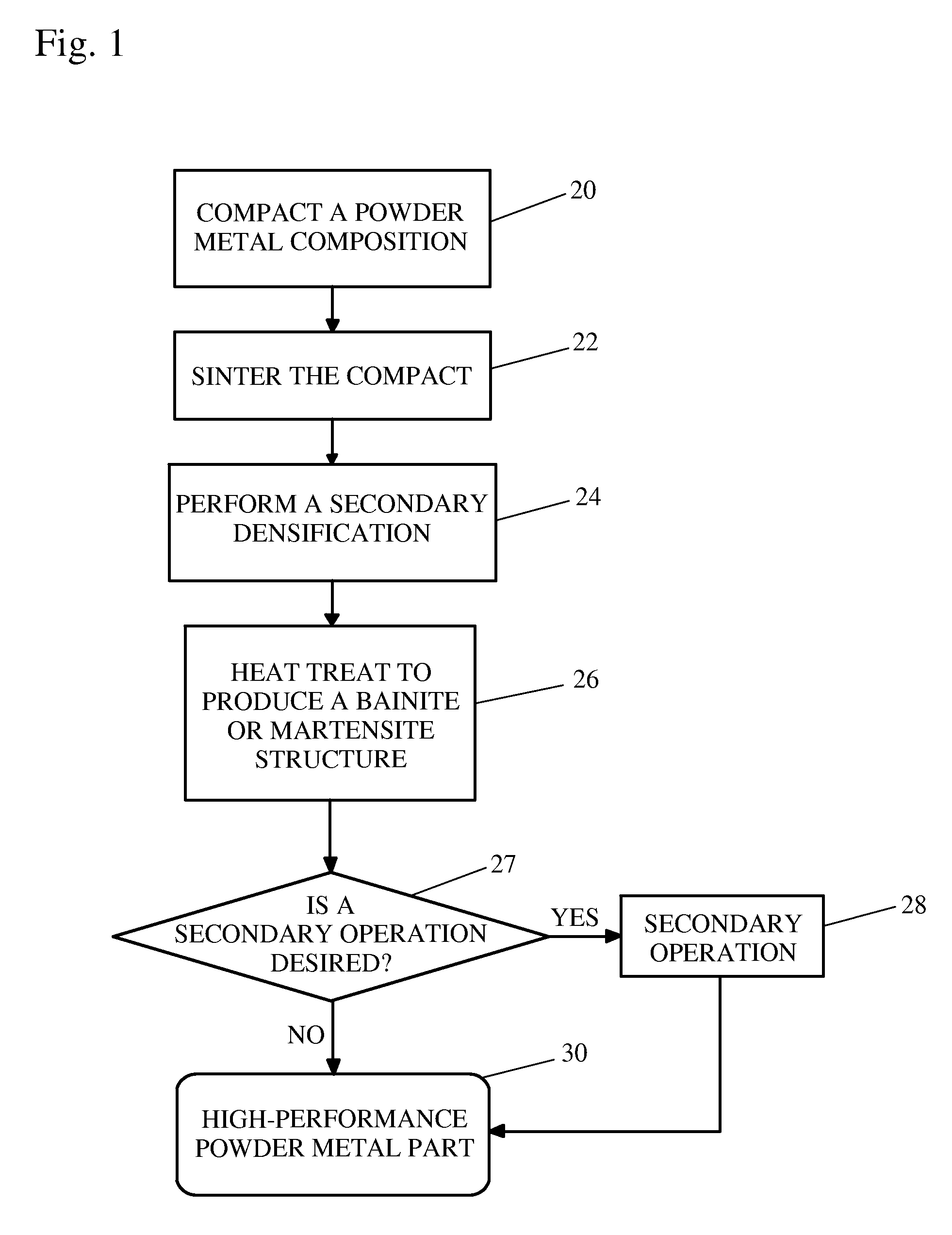

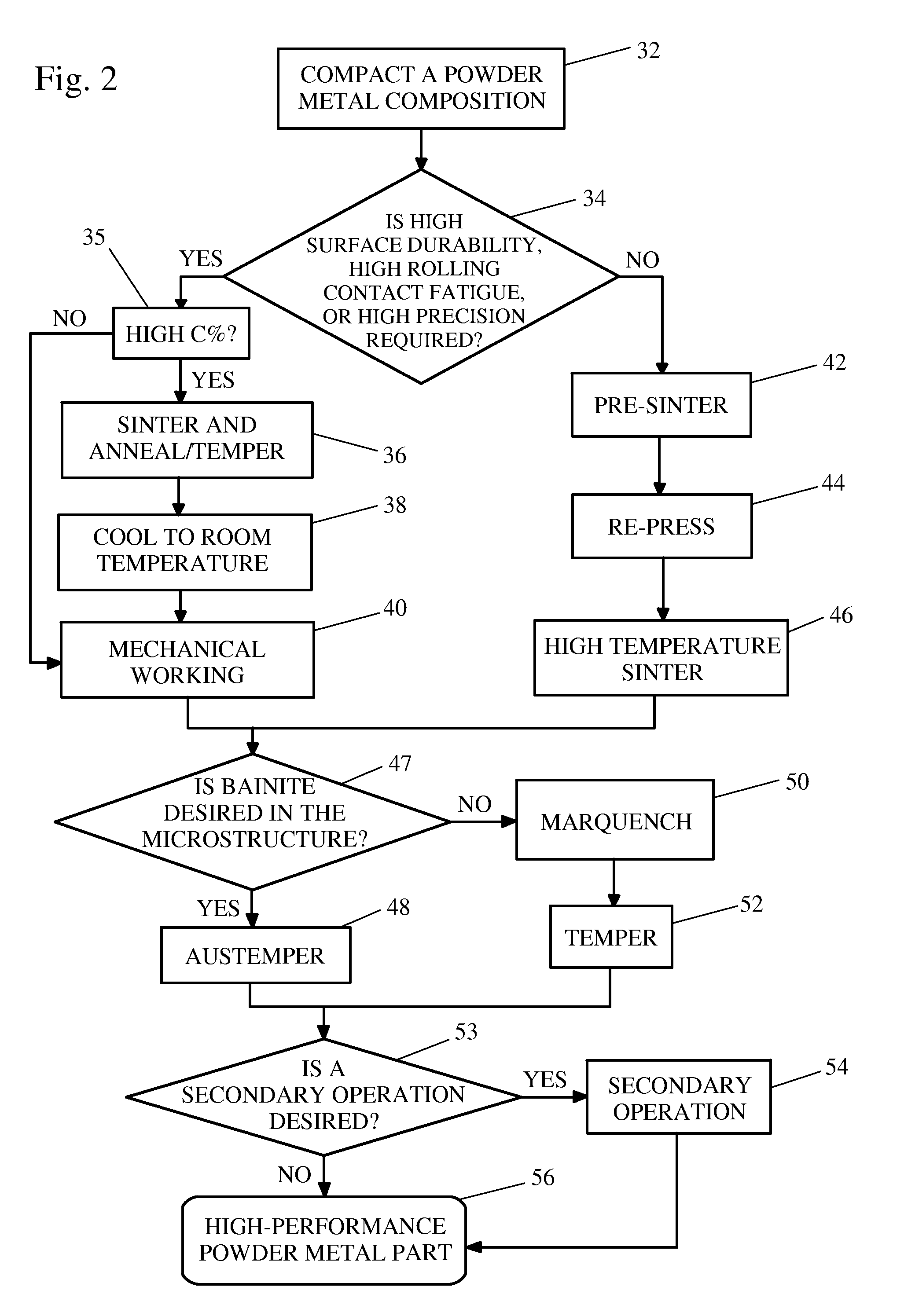

Austempering/marquenching powder metal parts

InactiveUS20060182648A1High densityImprove performanceTransportation and packagingMetal-working apparatusHeat treatedParticulate material

A powder metal part is made by compaction at room temperature or an elevated temperature followed by sintering, a secondary densification, heat treating, and optional secondary operations. The particulate materials preferably include iron, 0-2.0 wt % copper, 0.15-0.9 wt % carbon, 0.5-2.0 wt % molybdenum, 0.5-4.5 wt % nickel, 0-4.0 wt % chromium, and 0-1.5 wt % silicon. At least one secondary densification is applied to the part after compaction and pre-sinter / sinters steps to achieve medium to high density. The secondary densification is part of a double-press double-sinter (DPDS) or is a mechanical working depending on the application requirements. The powder metal is heat treated by austempering or marquenching followed by tempering. A unique composite microstructure is achieved from austempering by controlling the powder chemistry and the holding time at an elevated temperature. The combination of a secondary densification and austempering or marquenching produces a high performance powder metal part for demanding applications.

Owner:BORGWARNER INC

Nano-porous aerogel/fiber composite super thermal insulation material and preparation method thereof

The invention discloses a nano-porous aerogel / fiber composite super thermal insulation material and a preparation method thereof. The aerogel / fiber composite super thermal insulation material comprises silicon dioxide aerogel, alumina micro powder, zirconium oxide fibers and opacifying agent of titanium dioxide. The preparation method comprises that organic solvent, cross-linking agents and organic monomers make up pre-mixed solution according to a certain proportion, the silicon dioxide aerogel, the alumina micro powder, the zirconium oxide fibers, pore-forming agents, suspending agents and the titanium dioxide make up slurry through a ball milling process according to a certain proportion, then a certain amount of initiating agents and a certain amount of catalytic agents are dropwise added into the slurry through vacuum bubble removal, composite material in-situ solidification is achieved through a gel injection moulding process, and then demoulding, vacuum drying and degreasing glue discharging are conducted. The nano-porous aerogel / fiber composite super thermal insulation material has a nano-porous / reinforced fiber composite microstructure, the heat conductivity is 0.040-0.046W*m<-1>*K<-1> (298K), and the flexure strength is as high as 12-14MPa. Preparation processes are simple, industrialized application is easily achieved on a large scale, and the nano-porous aerogel / fiber composite super thermal insulation material is suitable for thermal protection of aerospace, military affairs and severe rugged environments.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

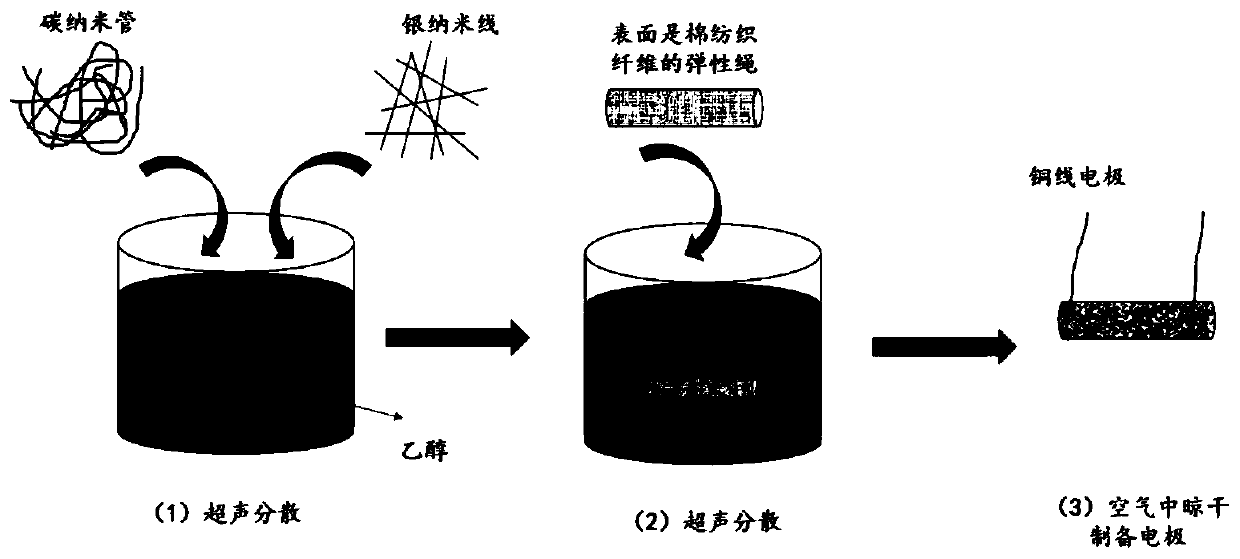

Flexible stress sensor with composite microstructure and preparation method thereof

InactiveCN110361119AImprove stabilityHigh sensitivityMaterial nanotechnologyForce measurementTextile fiberSolvent

The invention discloses a flexible stress sensor with a composite microstructure and a preparation method thereof, and belongs to the field of sensors. The method comprises the following steps: two one-dimensional nanomaterials are dispersed in solvents such as ethanol and isopropyl alcohol and stirred and then ultrasonically performed for half an hour, and the process is repeated until the nanomaterials are uniformly dispersed; step 2, an elastic rope is immersed into the dispersion liquid of the conductive nanomaterial of the step 1 and stirred and then ultrasonically performed for 2 hours so that the conductive nanomaterial can adhere to the textile fiber on the surface of the elastic rope sufficiently; and step 3, the elastic rope is taken out to be dried in the air and a metal wire isrespectively connected on the two ends of the elastic rope as a lead-out electrode. The characteristics of large stretchable range, good stability, high sensitivity and rapid response of one-dimensional conductive nanometer material of the textile microstructure substrate are integrated, and the prepared flexible stress sensor has excellent comprehensive performance and high sensitivity and highstretchability.

Owner:NANJING UNIV

Nano-porous aerogel/fiber composite super thermal insulation material and preparation method thereof

The invention discloses a nano-porous aerogel / fiber composite super thermal insulation material and a preparation method thereof. The aerogel / fiber composite super thermal insulation material comprises silicon dioxide aerogel, alumina micro powder, zirconium oxide fibers and opacifying agent of titanium dioxide. The preparation method comprises that organic solvent, cross-linking agents and organic monomers make up pre-mixed solution according to a certain proportion, the silicon dioxide aerogel, the alumina micro powder, the zirconium oxide fibers, pore-forming agents, suspending agents and the titanium dioxide make up slurry through a ball milling process according to a certain proportion, then a certain amount of initiating agents and a certain amount of catalytic agents are dropwise added into the slurry through vacuum bubble removal, composite material in-situ solidification is achieved through a gel injection moulding process, and then demoulding, vacuum drying and degreasing glue discharging are conducted. The nano-porous aerogel / fiber composite super thermal insulation material has a nano-porous / reinforced fiber composite microstructure, the heat conductivity is 0.040-0.046W*m<-1>*K<-1> (298K), and the flexure strength is as high as 12-14MPa. Preparation processes are simple, industrialized application is easily achieved on a large scale, and the nano-porous aerogel / fiber composite super thermal insulation material is suitable for thermal protection of aerospace, military affairs and severe rugged environments.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

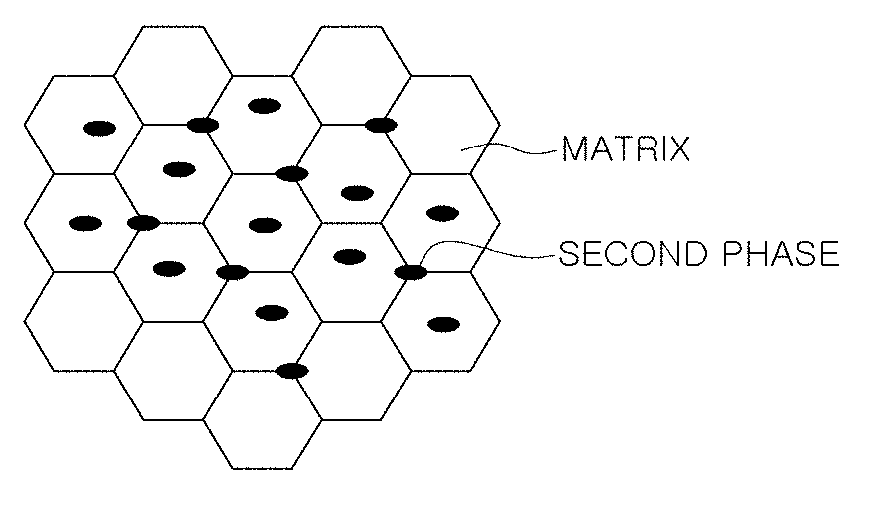

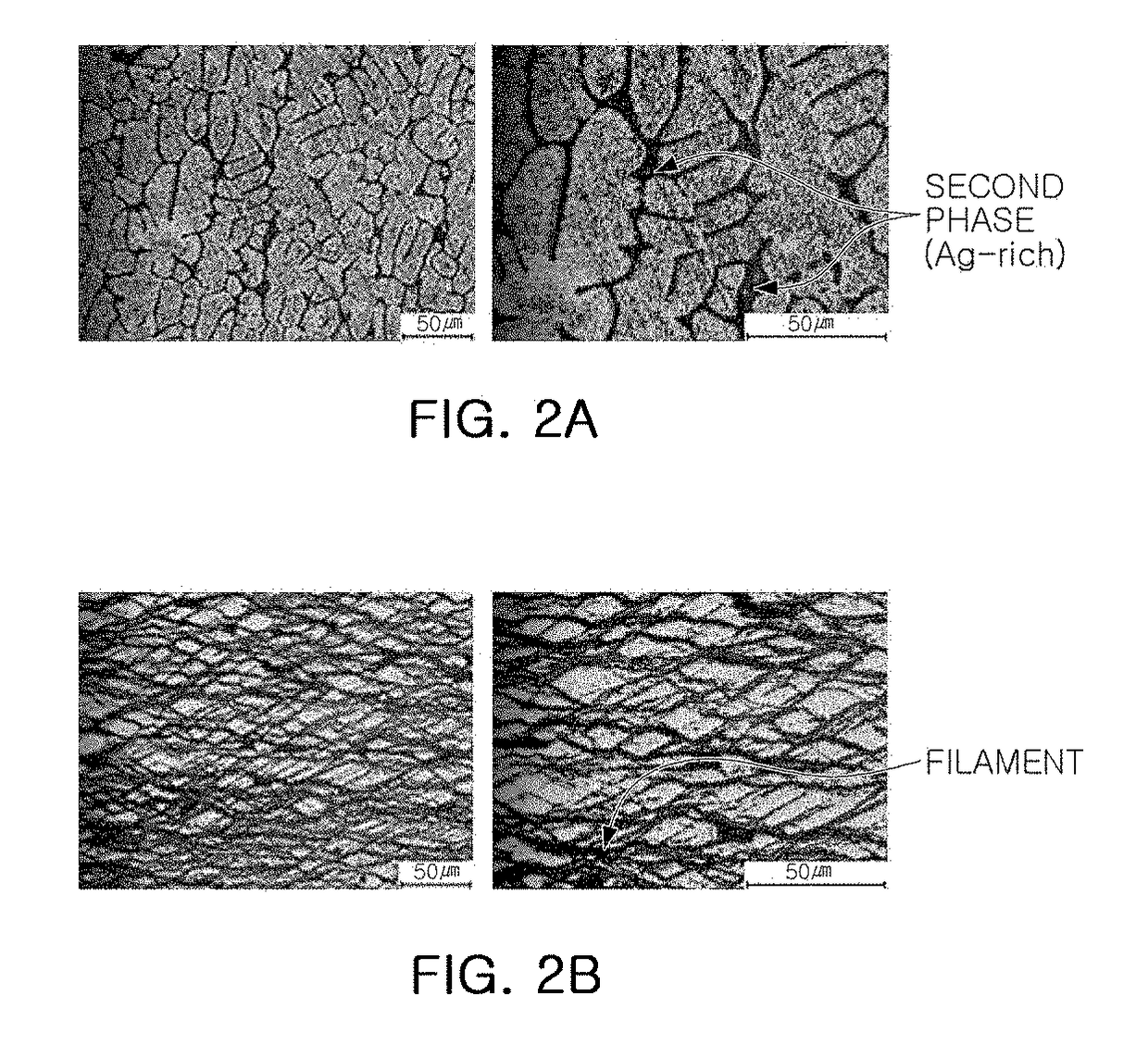

Wrought magnesium alloy having excellent formability and method of producing same

Disclosed is a wrought magnesium alloy having excellent strength and extrusion or rolling formability, and a method of producing the same. The wrought magnesium alloy comprises 0.1 - 1.5 at% group IIIa, 1.0 - 4.0 at% group IIIb, 0.35 at% or less of one selected from the group consisting of groups IIa, IVa, VIIa, IVb, and a mixture thereof, 1.0 at% or less of group IIb, and a balance of Mg and unavoidable impurities and thus has a second phase composite microstructure. The wrought magnesium alloy of the present invention has high strength, toughness, and formability in addition to the electromagnetic wave shield ability of magnesium. Accordingly, the wrought magnesium alloy is a material useful to portable electronic goods, such as notebook personal computers, mobile phones, digital cameras, camcorders, CD players, PDA, or MP3 players, automotive parts, such as engine room hoods, oil pans, or inner panel of door, or structural parts for airplane.

Owner:PRIMOMETAL CO LTD

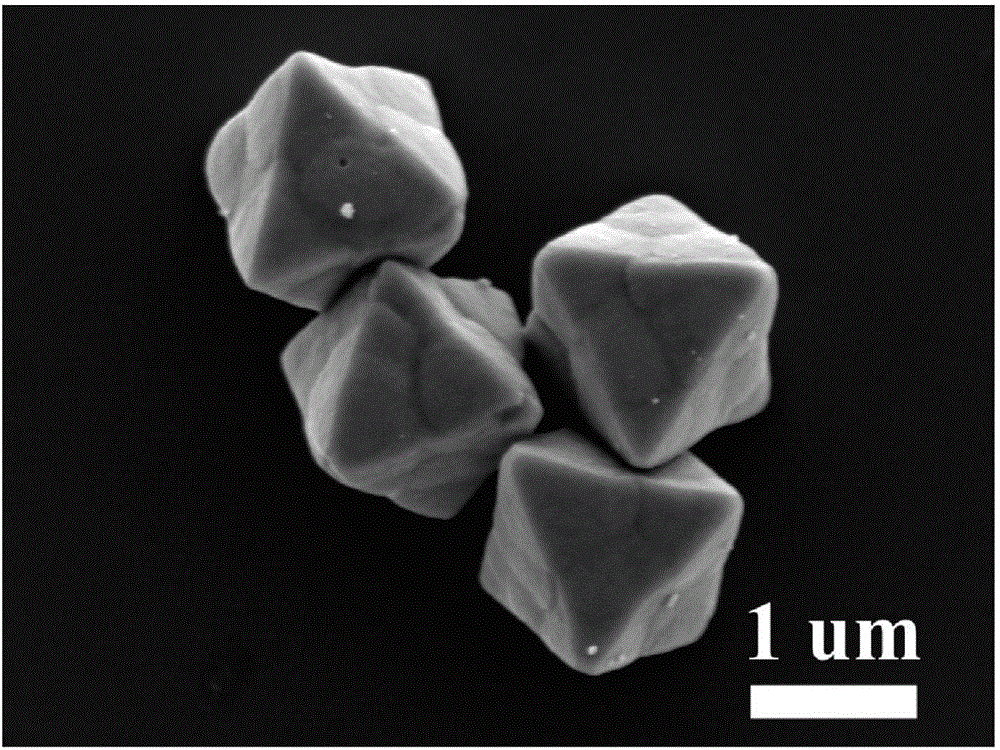

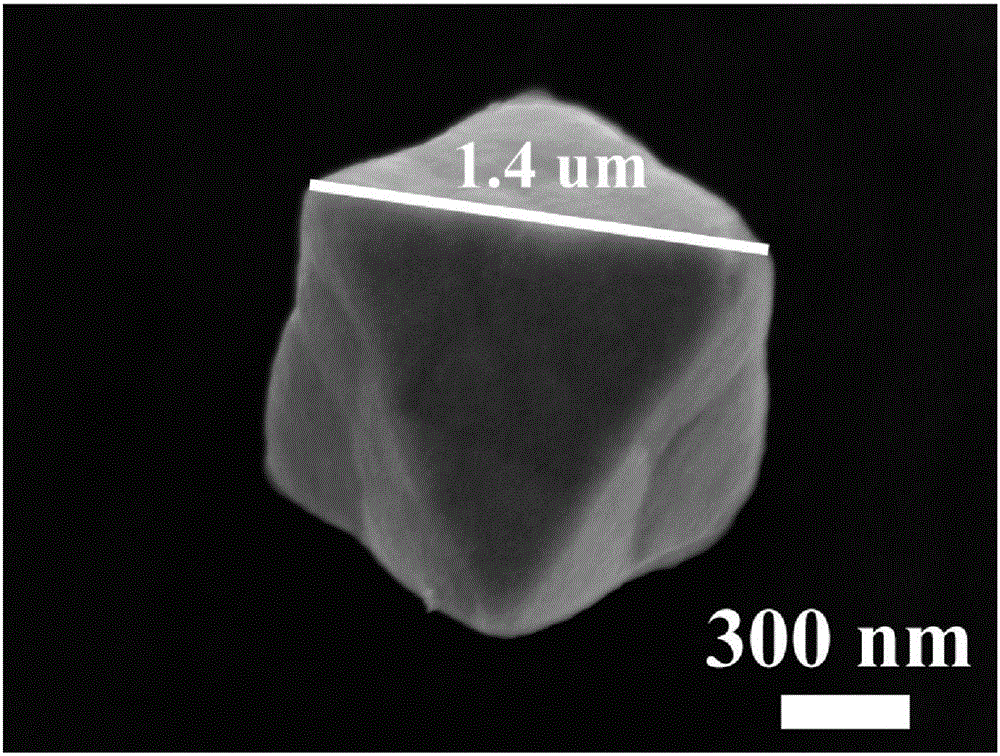

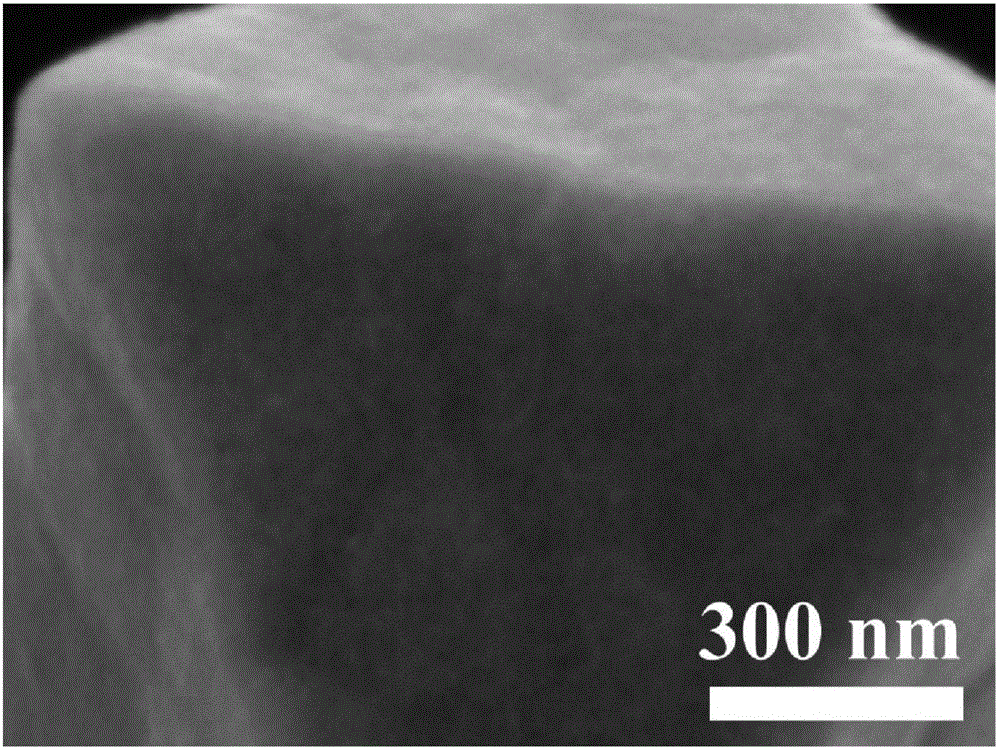

Cu2O-Au composite microparticle surface enhanced Raman scattering active substrate and production method thereof

ActiveCN105866098ANarrow particle size distributionThe preparation process is simple and controllableRaman scatteringSurface energyComposite microstructure

The invention provides a Cu2O-Au composite microstructure surface enhanced Raman scattering active substrate and a production method thereof. The method comprises the following steps: chelating citrate ions and copper ions, shaping with polyvinylpyrrolidone, and carrying out a reaction under water bath conditions with glucose as a reducing agent to generate Cu2O octahedral crystals; and dispersing the Cu2O octahedral crystals in water, adding a AuCl<4><-> solution, reducing AuCl<4><-> by the Cu2O octahedral crystals to form Au nanoparticles, and carrying out Au nanoparticle in situ deposition on the surface of octahedral Cu2O to reduce the surface energy of a system and generate Cu2O-Au composite microparticles. A Cu2O-Au composite microstructure is designed and synthesized to develop the surface enhanced Raman scattering activity of a semiconductor Cu2O, and local surface plasma resonance of Au aggregate and strong electromagnetic field generated in an interface due to charge transfer between Cu2O and Au are used to improve the surface enhanced Raman scattering activity of the Cu2O-Au composite microstructure.

Owner:JILIN NORMAL UNIV

Detection method of damage of one-way silicon carbide fiber toughening silicon carbide ceramic matrix composite in oxidation environment

ActiveCN103093063ALow resolutionOvercome costsSpecial data processing applicationsElement modelElement analysis

The invention discloses a detection method of damage of one-way silicon carbide fiber toughening silicon carbide ceramic matrix composite in oxidation environment and aims to solve the technical problem that the prior detection method of damage of the one-way silicon carbide (SiC) / SiC composite is bad in accuracy. The technical scheme is that an oxidizing reaction kinetics equation is applied to calculate the thickness of oxidation loss of a carbon interface in the composite material microstructure oxidation process and acquire a geometric model under different oxidation times of the composite microstructure; a finite element model of the composite microstructure after being oxidized is built to conduct finite element calculation of microcosmic stress; and maximum stress strength criterions are adopted to detect damage conditions of materials. The detection method of damage of the one-way silicon carbide fiber toughening silicon carbide ceramic matrix composite in the oxidation environment is simple and high-efficiency from the molding process to the calculation process, overcomes the defects that the prior experimental method is high in cost and long in time consumption, acquires the microcosmic stress in the microstructure of the composite after being oxidized with the help of the strong finite element analysis function of ANSYS; improves accuracy of damage analysis of the one-way SiC / SiC composite and solves the problem that the mesomechanics model is low in accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Polyether-ether-ketone based wear-resistant composite material and preparation method thereof

The invention provides a polyether-ether-ketone based wear-resistant composite material and a preparation method thereof, and relates to the technical field of production of a functional composite material. Polyether-ether-ketone based wear-resistant composite granules are prepared by mixing modified graphene nanometer microsheets, polyether-ether-ketone and polytetrafluoroethylene (PTFE), puttingthe mixture into a double-screw extruding machine, performing melt mixing and performing extrusion granulation. According to the polyether-ether-ketone (PEEK) based wear-resistant composite material,a PTFE phase which takes on an 'island' structure in a PEEK matrix as well as nanosheet-shaped graphene microsheets which are dispersed in the matrix uniformly form the surface of a dense nanometer composite transfer membrane consisting of PEEK-PTFE-graphene in the friction process, so that excellent wear resistance is achieved; meanwhile, due to the 'sea island' structure appearance and the nanometer composite microstructure, the composite material has excellent mechanical properties, particularly toughness.

Owner:扬州市维纳复合材料科技有限公司

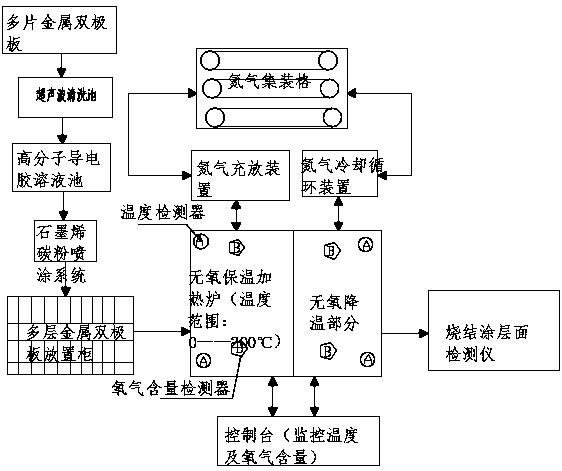

Preparation method of graphene coating capable of resisting acid medium corrosion in fuel cell

ActiveCN111446461AQuick Spray OperationEfficient Spray OperationMetallic material coating processesCollectors/separatorsGraphene coatingFuel cells

The invention relates to the technical field of material surface treatment, and in particular relates to a preparation method of a graphene coating capable of resisting acid medium corrosion in a fuelcell. The preparation method comprises the steps of L1 polishing a metal bipolar plate substrate; L2 placing the polished metal bipolar plate substrate into an ultrasonic cleaning pool to be cleaned;L3 placing the metal bipolar plate substrate subjected to ultrasonic cleaning on a substrate rotating stand, and introducing argon to perform glow discharge cleaning on the surface of the metal bipolar plate substrate; L4 gluing the metal bipolar plate substrate subjected to glow discharge cleaning through a polymer conductive adhesive solution pool; L5 evenly adsorbing graphene powder to the surface of the metal bipolar plate substrate through a graphene carbon powder spraying system; and L6 placing the metal bipolar plate substrate with the graphene powder layer in a multi-layer polar plateplacing cabinet. According to the method, a multi-layer composite microstructure and a large number of amorphous structures are formed on the surface of the metal bipolar plate substrate, so that thedensity of the coating is improved, a corrosive medium can be prevented from immersing into the coating, and the corrosion resistance of the coating is greatly improved.

Owner:ZHEJIANG HAROG TECH CO LTD

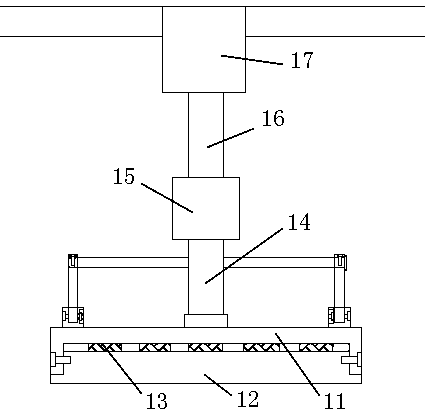

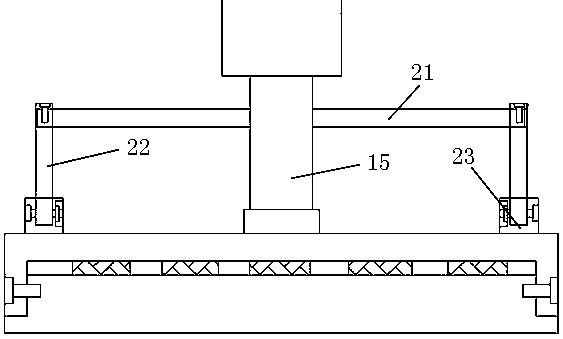

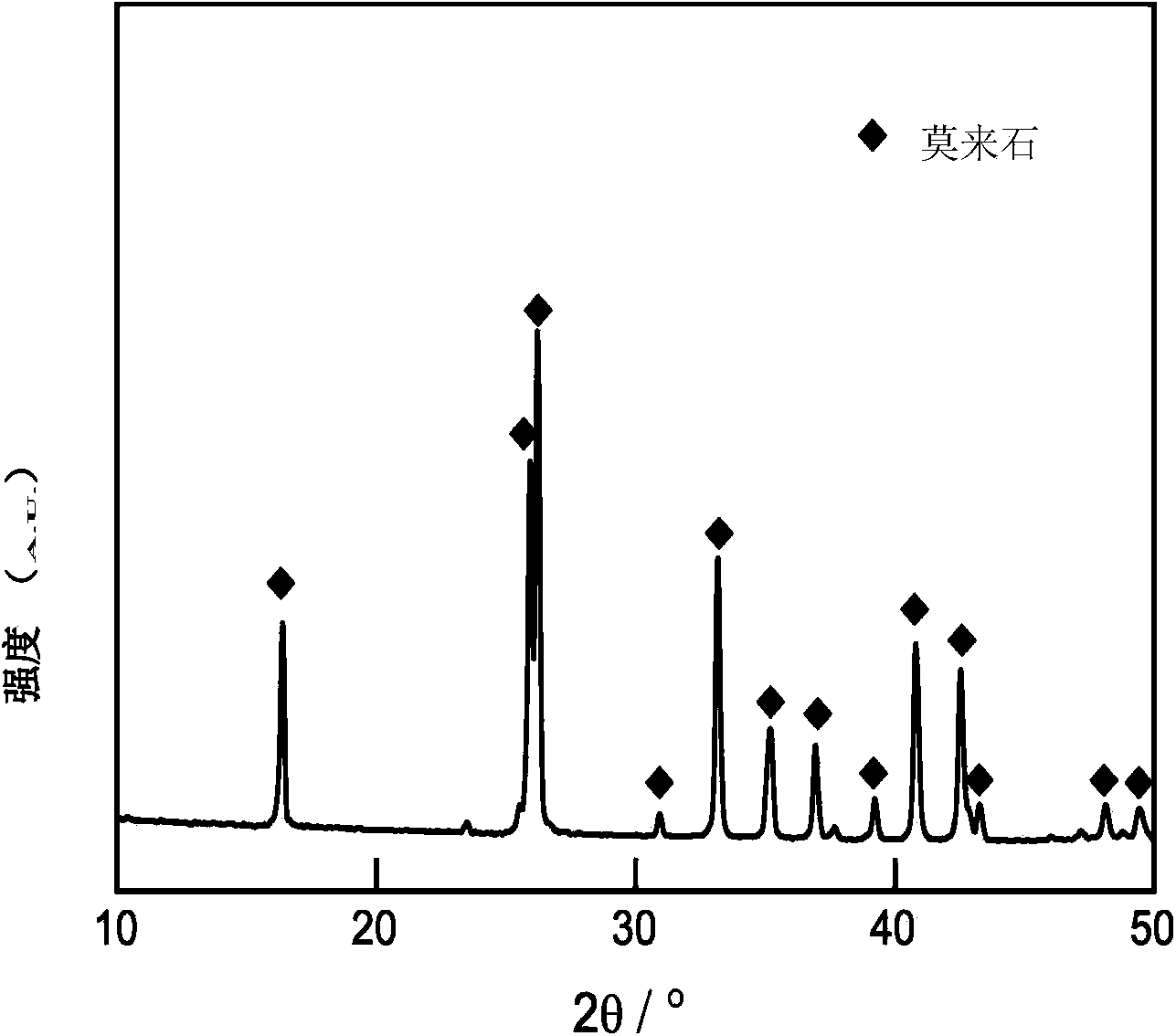

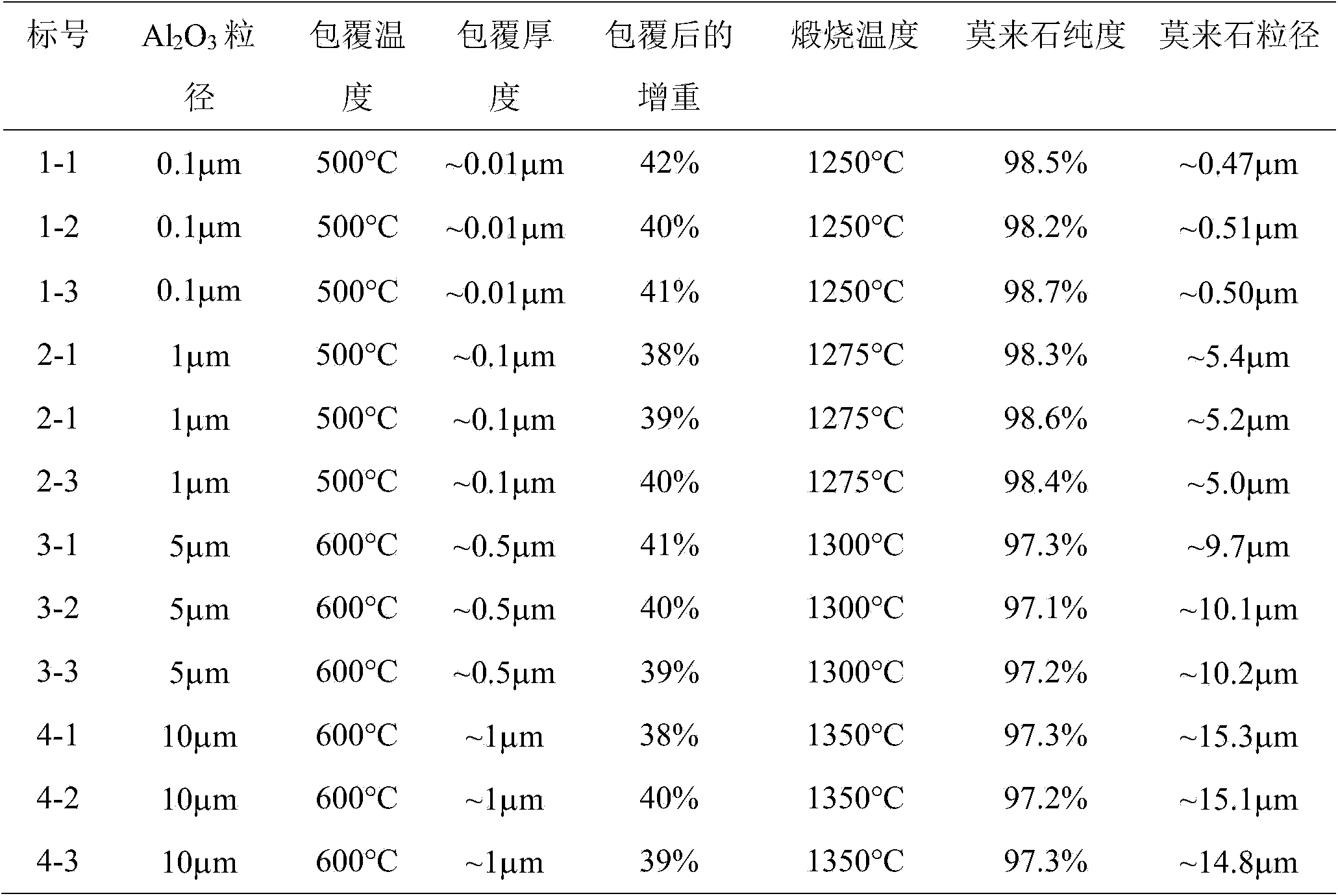

Preparation method of mullite ceramic powder

InactiveCN104016668ASolve processing problemsHigh structural thermal stabilityMetallurgyHeat stability

The invention discloses a preparation method of mullite ceramic powder. The method comprises the following steps: wrapping a SiO2 nano layer composite microstructure on the surface of Al2O3 powder to prepare mullite powder, wherein the average grain size of initial powder Al2O3 powder is 0.1-10 microns; by taking TEOS with purity being over 99% as a raw material of SiO2, wrapping SiO2 on the surface of Al2O3 powder at 500-600 DEG C; and finally, sintering at 1250-1350 DEG C. The mullite powder prepared by the method provided by the invention has purity being over 97%, and has uniform grain size and the components. According to the user demand, the mullite powder with different grain sizes is produced and synthesized with low cost by selecting different Al2O3 powder. The method has the advantages of good repeatability and the like, and is simple to operate and easy to industrialize, and the prepared mullite powder structure is high in heat stability, low in cost, uniform in grain size distribution and suitable for commercial application on a large scale.

Owner:HOHAI UNIV

Process for Production of a Carboxylic Acid/Diol Mixture Suitable for Use in Polyester Production

Disclosed is a wrought magnesium alloy having excellent strength and extrusion or rolling formability, and a method of producing the same. The wrought magnesium alloy comprises 0.1-1.5 at % group IIIa, 1.0-4.0 at % group IIIb, 0.35 at % or less of one selected from the group consisting of groups IIa, IVa, VIIa, IVb, and a mixture thereof, 1.0 at % or less of group IIb, and a balance of Mg and unavoidable impurities and thus has a second phase composite microstructure. The wrought magnesium alloy of the present invention has high strength, toughness, and formability in addition to the electromagnetic wave shield ability of magnesium. Accordingly, the wrought magnesium alloy is a material useful to portable electronic goods, such as notebook personal computers, mobile phones, digital cameras, camcorders, CD players, PDA, or MP3 players, automotive parts, such as engine room hoods, oil pans, or inner panel of door, or structural parts for airplane.

Owner:PRIMOMETAL CO LTD

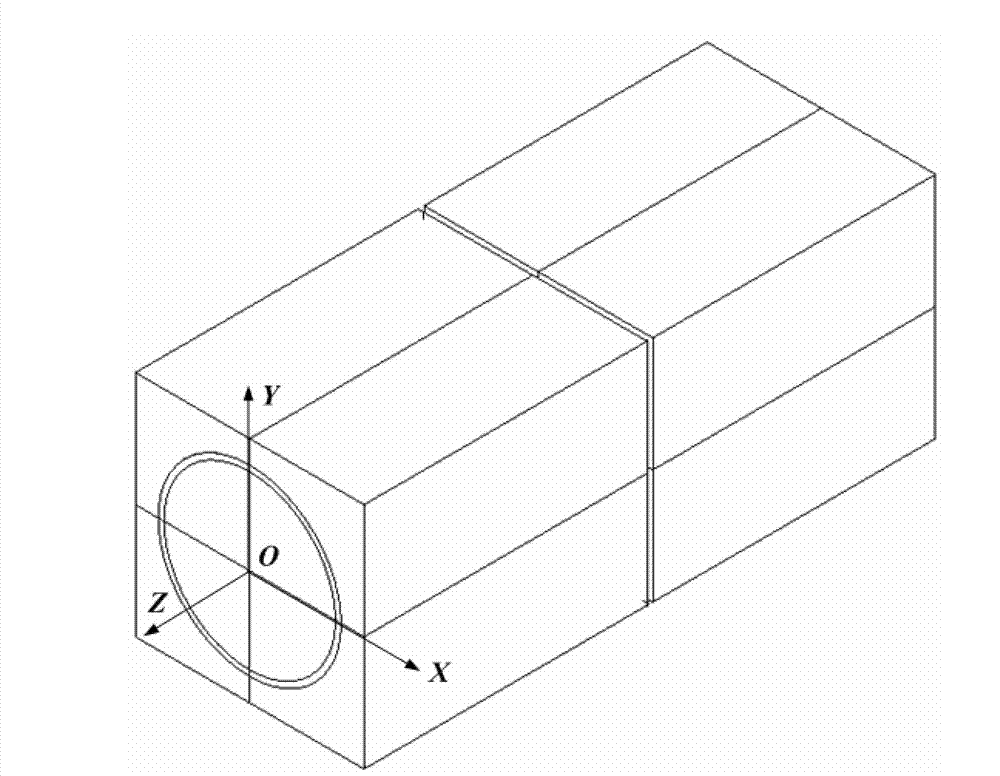

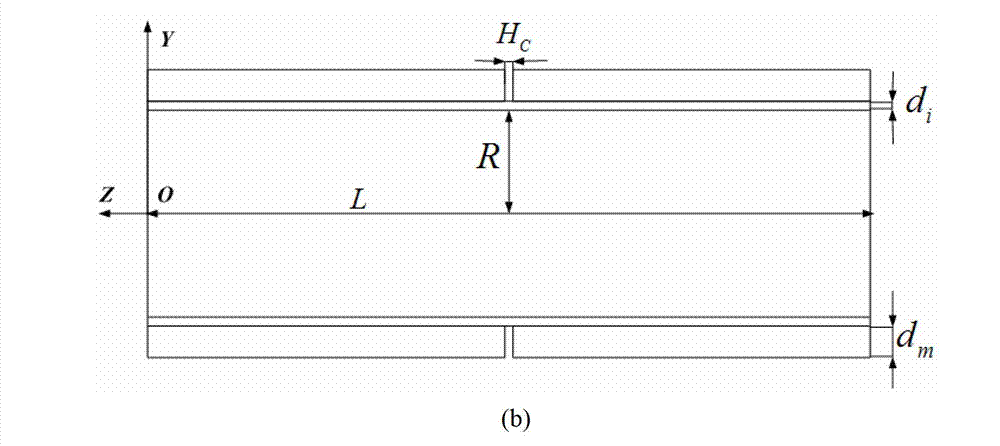

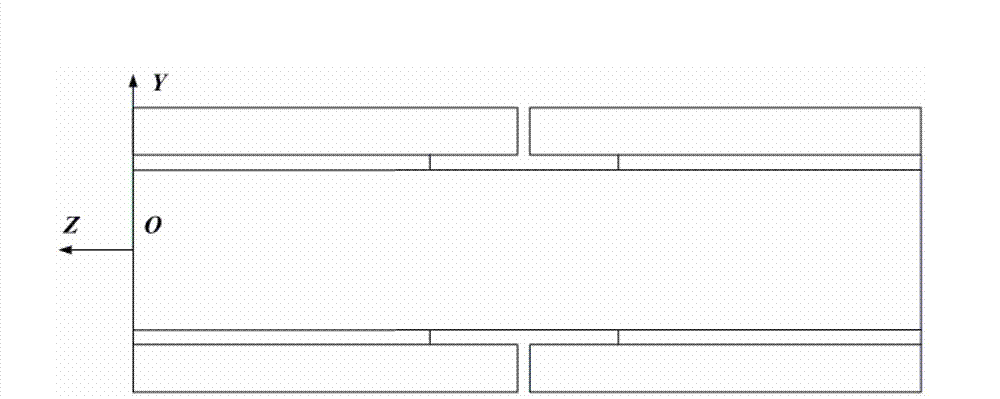

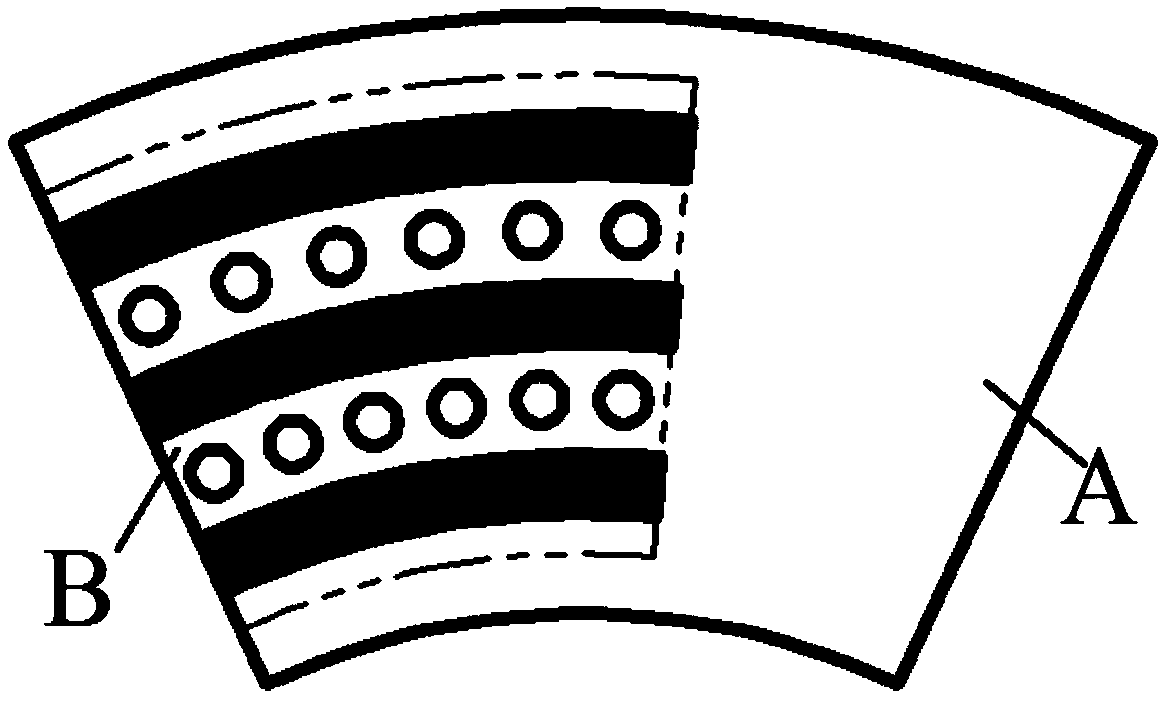

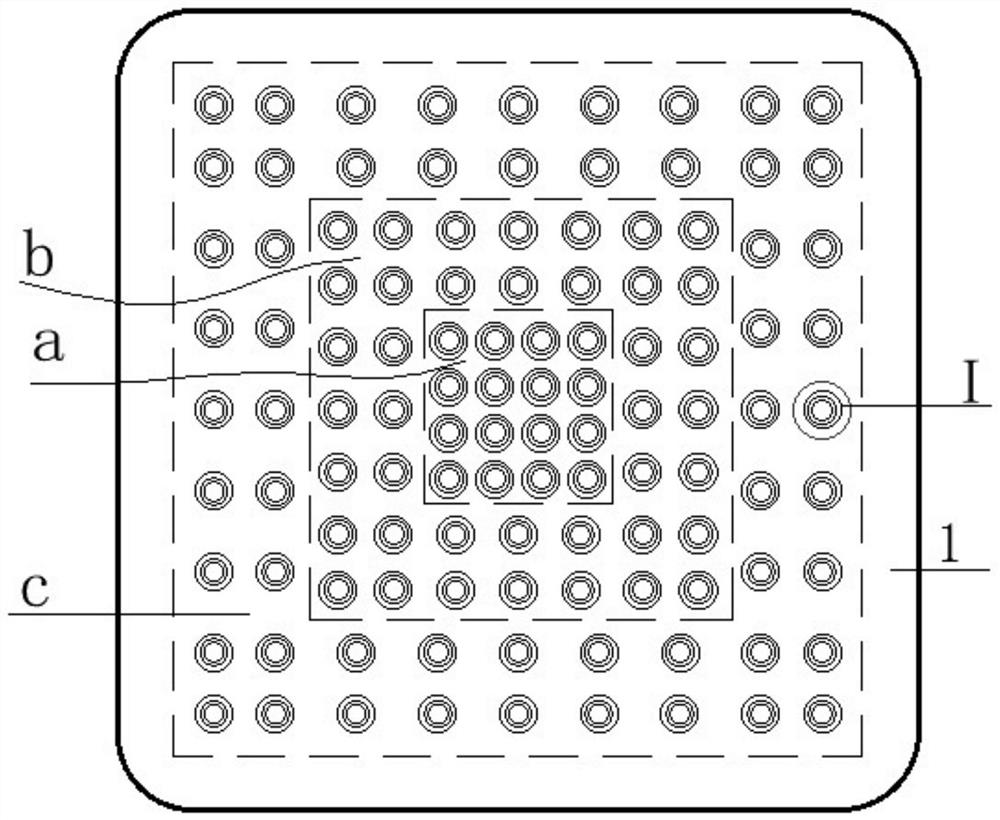

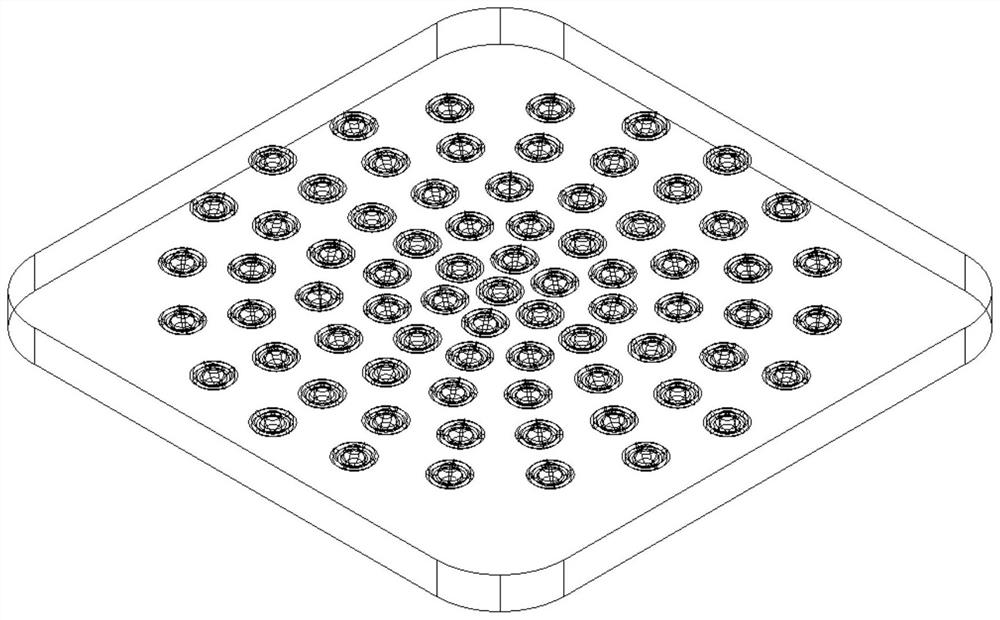

Composite microstructure plane and sector-shaped broken tile thrust bearing and processing method thereof

ActiveCN109538626AEnhanced hydrodynamic lubrication effectSimple designSliding contact bearingsLaser beam welding apparatusThrust bearingLubrication

The invention provides a composite microstructure plane and sector-shaped broken tile thrust bearing. Circular-arc-shaped groove structures and micro-pit structures are formed in the surface of a plane and sector-shaped broken tile. The circular-arc-shaped groove structures are radially and uniformly distributed along the sector-shaped broken tile; and the micro-pit structures, which are uniformlydistributed in an array along the peripheral direction of the plane and sector-shaped broken tile, are arranged between the adjacent circular-arc-shaped groove structures. The circular-arc-shaped groove structures and the micro-pit structures are partial structures; and the partial structures are located in an entrance region of the plane and sector-shaped broken tile thrust bearing. According tothe composite microstructure plane and sector-shaped broken tile thrust bearing provided by the invention, a convergent gap is formed on the surface of the plane and sector-shaped broken tile of thethrust bearing and a fluid dynamic pressure lubrication effect of the thrust bearing is improved; and the effect is the same as that of a tilting broken tile thrust bearing or a Rayleigh step thrust bearing.

Owner:JIANGSU UNIV

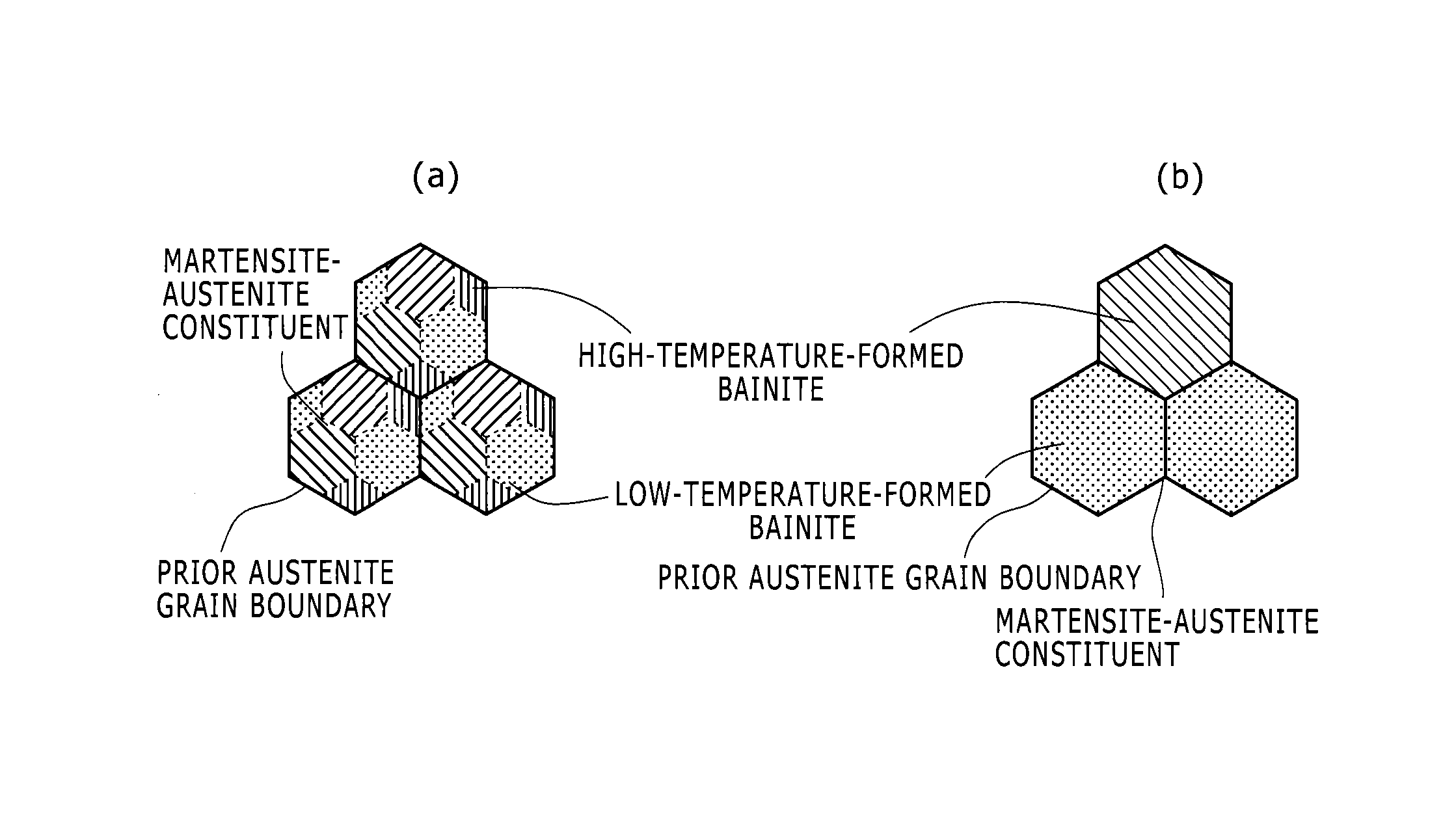

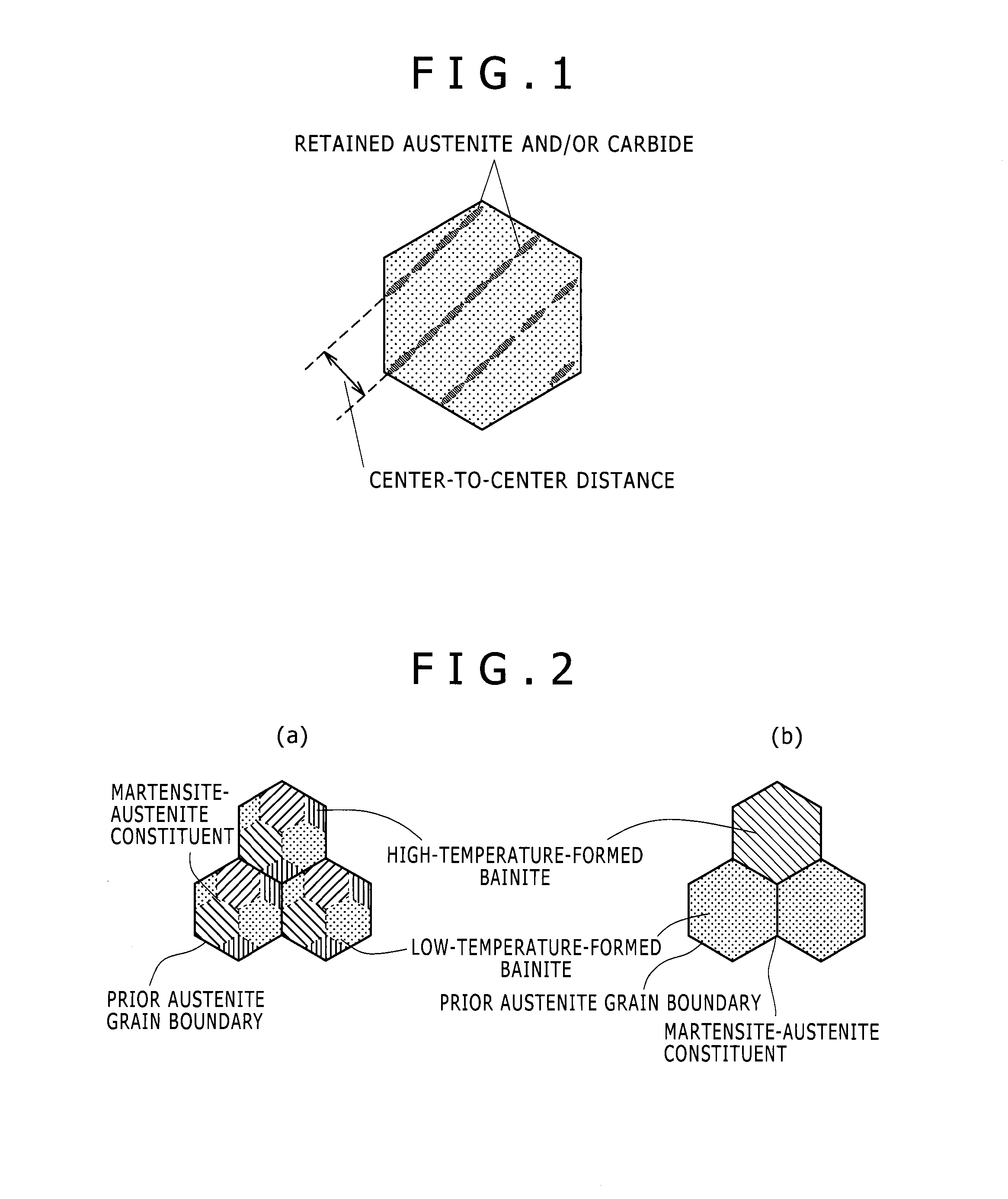

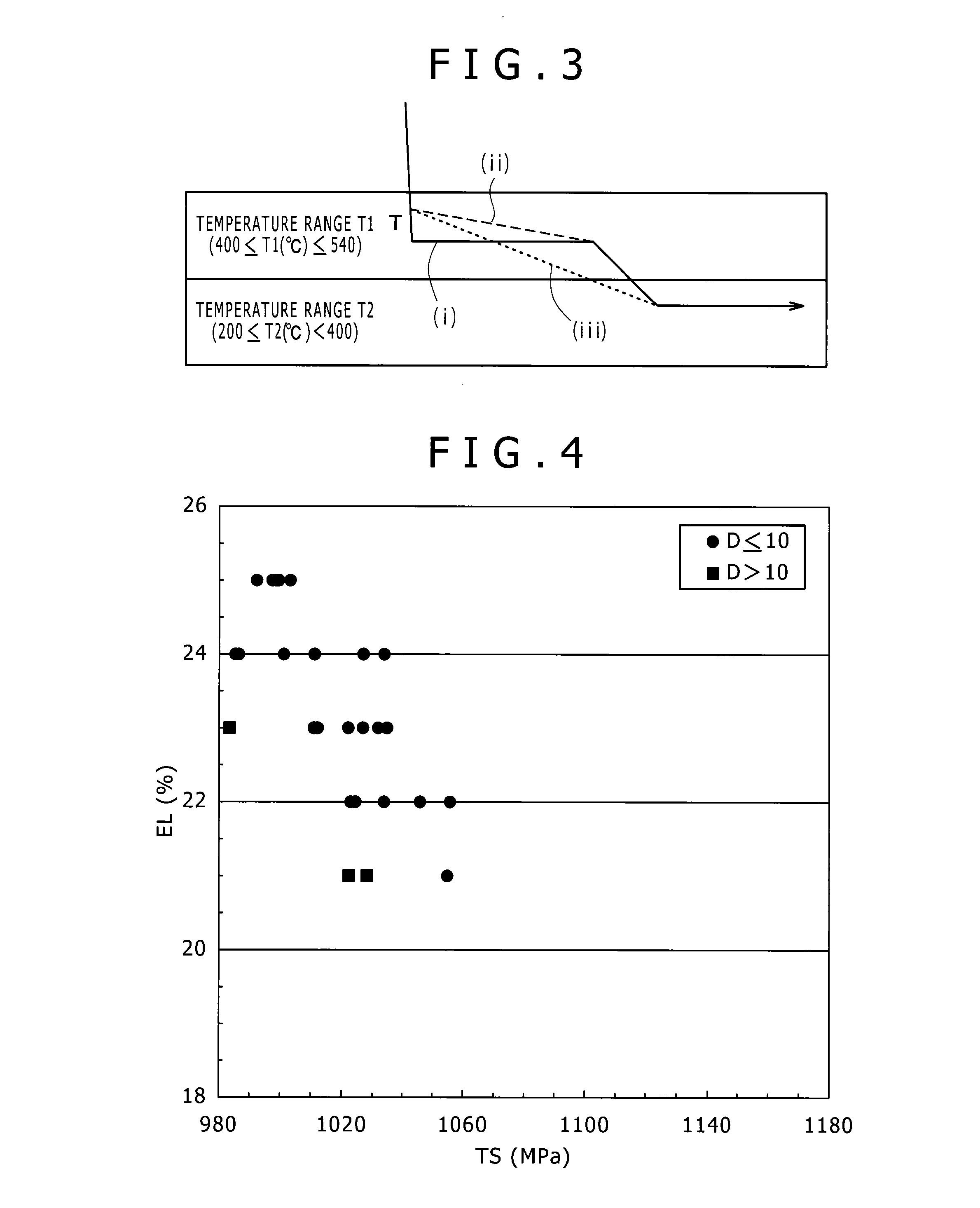

High-strength steel sheet excellent in workability and manufacturing method thereof

InactiveUS20140044988A1Improve machinabilityElongation and local formabilityHot-dipping/immersion processesFurnace typesMicroscopic observationMagnetization

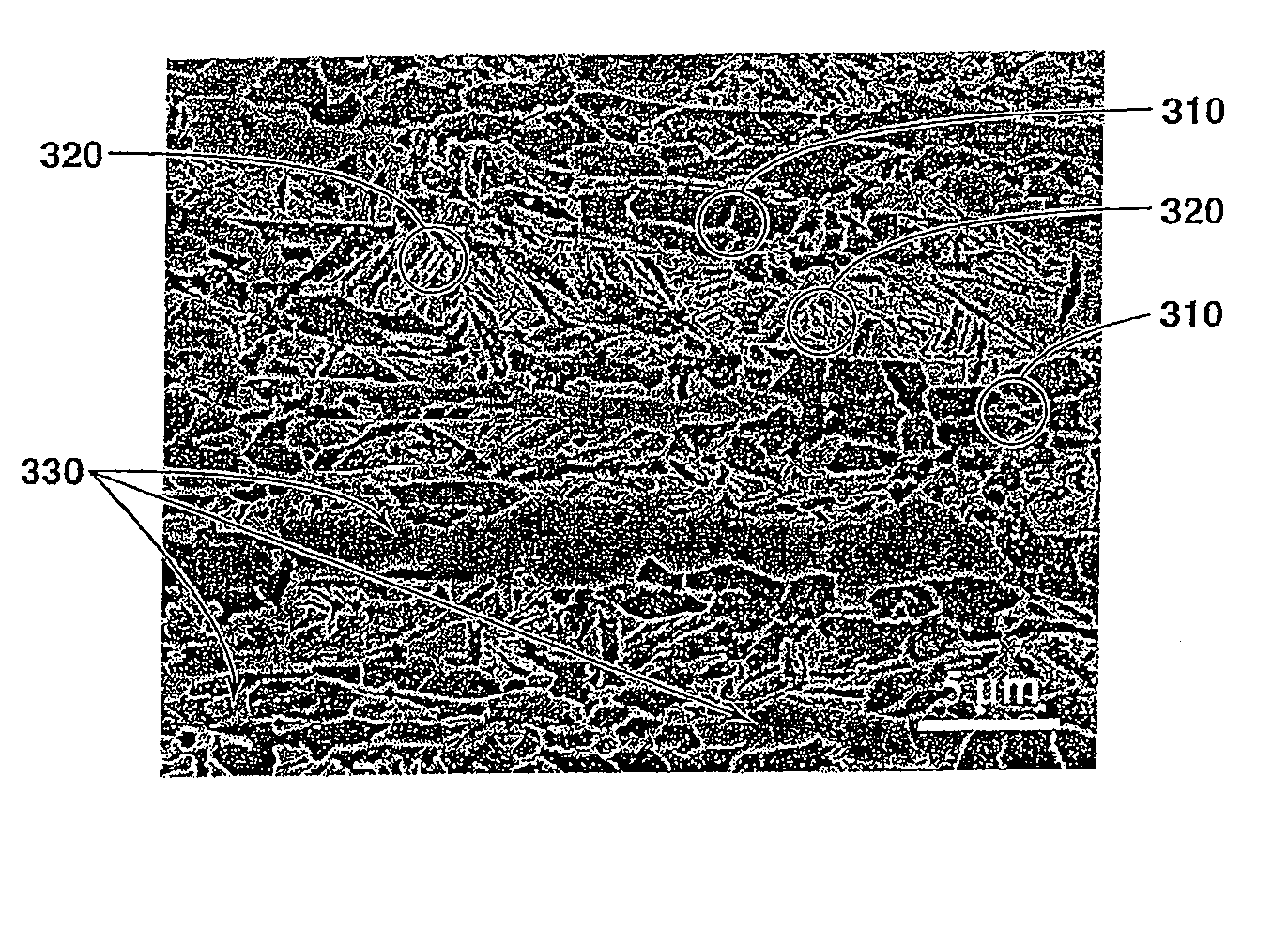

Provided are: a high-strength steel sheet which is improved in both elongation and local formability and thus exhibits excellent workability; and a manufacturing method thereof. The high-strength steel sheet contains C, Si, Mn, Al, P and S with the remainder including iron and unavoidable impurities, and has a metal structure which includes polygonal ferrite, bainite, tempered martensite, and retained austenite. In the metal structure, (1) the bainite has a composite microstructure including both a high-temperature-formed bainite having an average distance between adjacent regions of retained austenite and / or carbide of 1 μm or more and a low-temperature-formed bainite having an average distance between adjacent regions of retained austenite and / or carbide of less than 1 μm each identified upon observation with a scanning electron microscope; and (2) the retained austenite is present in a volume percentage of 5% or more of the entire metal structure as determined by a saturation magnetization measurement.

Owner:KOBE STEEL LTD

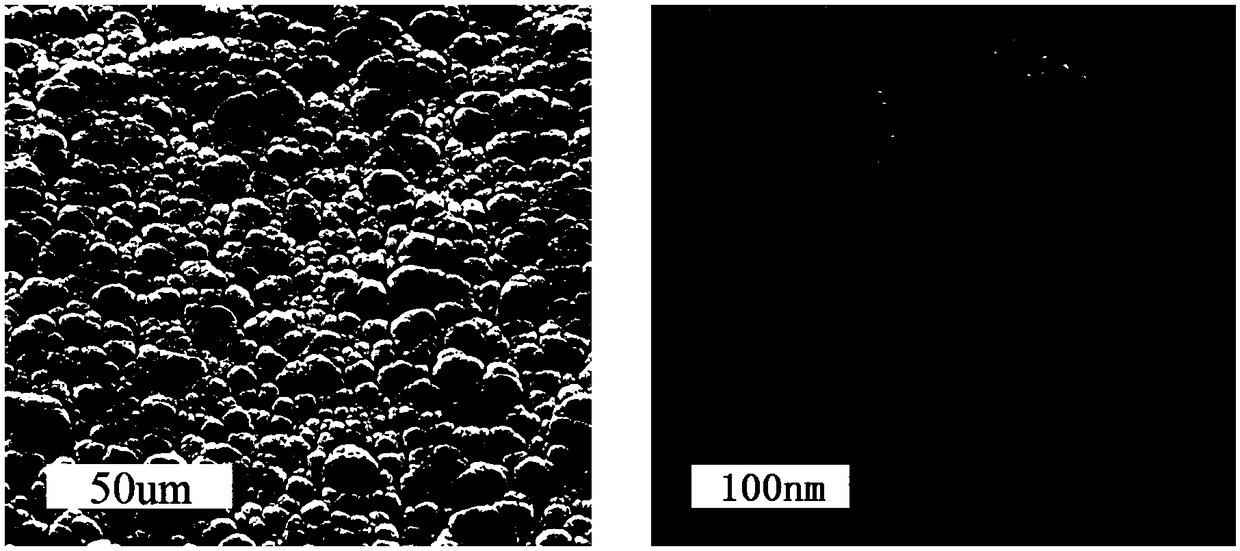

Preparation method and application of biomedical degradable magnesium alloy surface fine grain composite layer

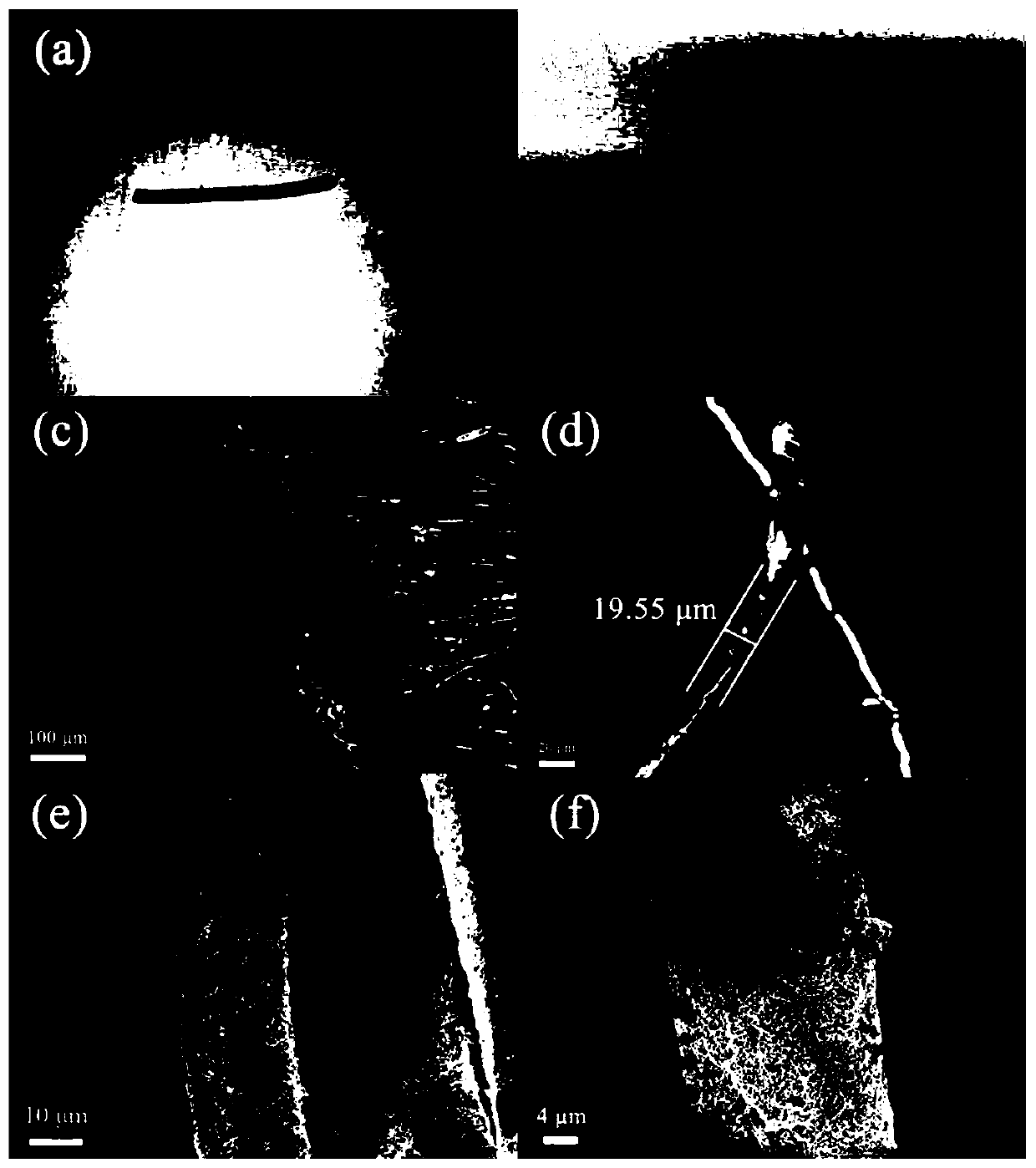

InactiveCN108581392AImprove corrosion resistanceImprove adhesionProsthesisPressure inorganic powder coatingOsseointegrationOsteoblast

The invention discloses a preparation method and application of a biomedical degradable magnesium alloy surface fine grain composite layer. The method comprises the steps that a magnesium alloy substrate is subjected to grinding treatment and chemical cleaning; nanometer hydroxyapatite powder is sprayed to the surface of the magnesium alloy substrate in a cold spray mode, and a nanometer hydroxyapatite coating is obtained; and the surface of the magnesium alloy substrate with the nanometer hydroxyapatite coating is subjected to friction stirring machining, and a nanometer hydroxyapatite-fine grain composite structure is formed on the surface of the magnesium alloy. The method is based on a high-efficiency rapid cold spray coating preparation technique and friction stirring machining technique, a nanometer hydroxyapatite-fine grain composite structure layer is prepared on the surface of the magnesium alloy, the method has the advantages of being reasonable in process, low in cost, highin efficiency, environmentally friendly and the like, the corrosion resistance of the biomedical degradable magnesium alloy can be effectively improved, the excellent cellular affinity and osteogenesis function are achieved, the biomedical function of osteoblasts can regulated, the osseointegration capacity is improved, and the method has broad application prospects in the medical fields such as orthopedic implantation.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Fabrication of high surface to volume ratio structures and their integration in microheat exchangers for liquid cooling systems

An structure and method of manufacturing a microstructure for use in a heat exchanger is disclosed. The heat exchanger comprises a manifold layer and an microstructured region. The manifold layer comprises a structure to deliver fluid to the microstructured region. The microstructured region is formed from multiple windowed layers formed from heat conductive layers through which a plurality of microscaled apertures have been formed by a wet etching process. The plurality of windowed layers are then coupled together to form a composite microstructure.

Owner:COOLIGY INC

Fuel cell proton exchange membrane based on concave-convex composite microstructure

Owner:无锡隆盛新能源科技有限公司

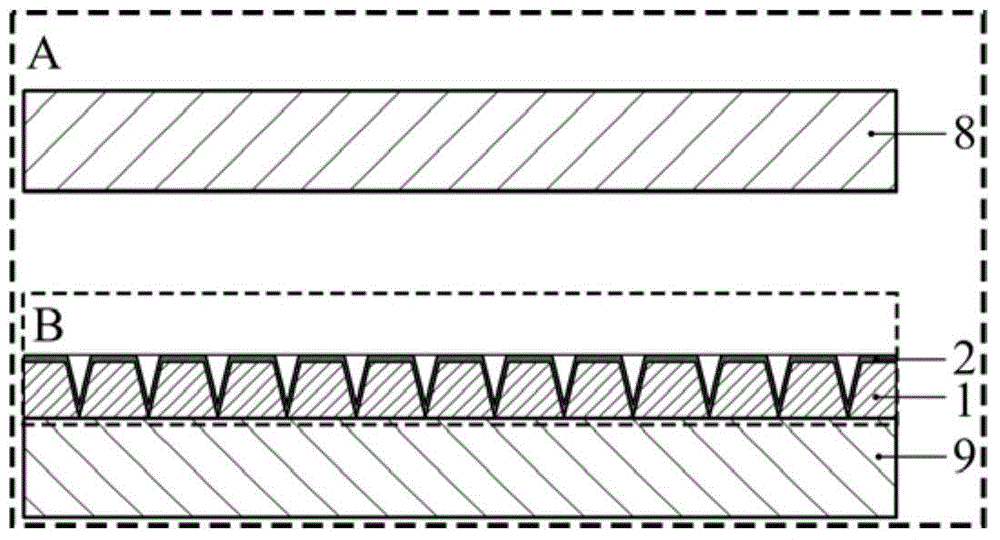

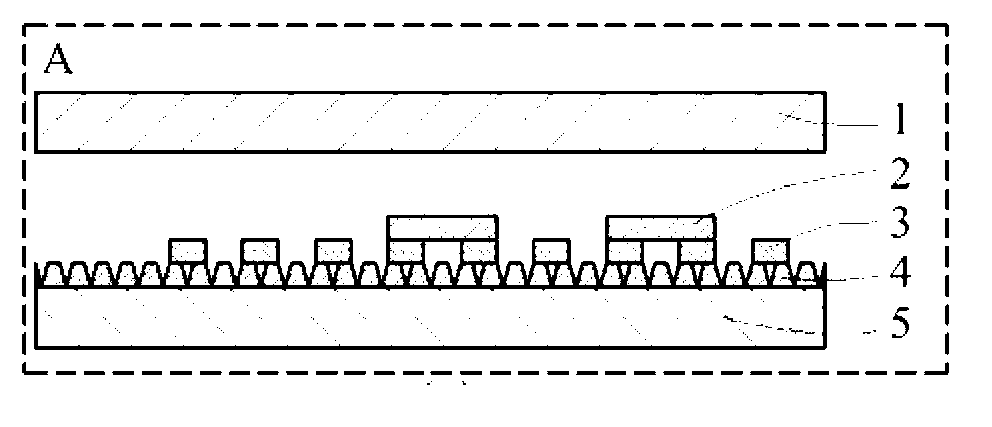

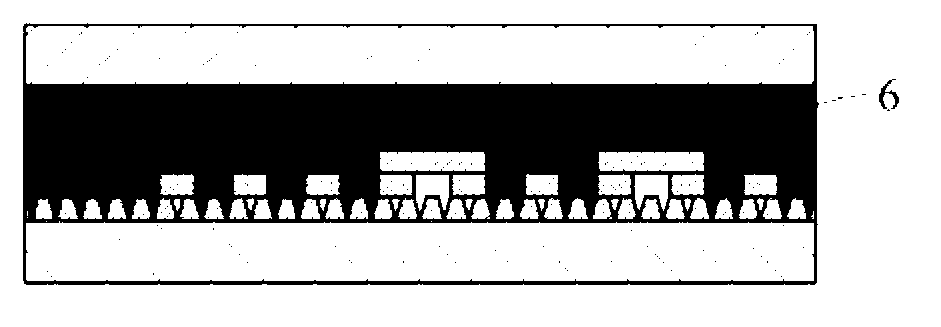

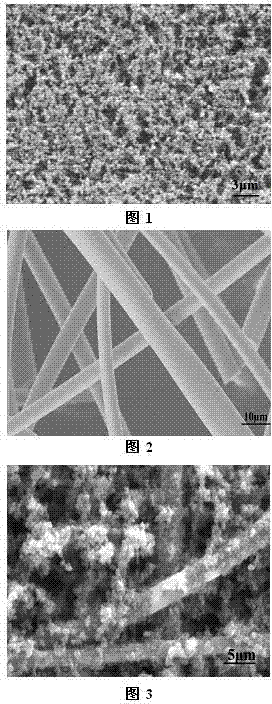

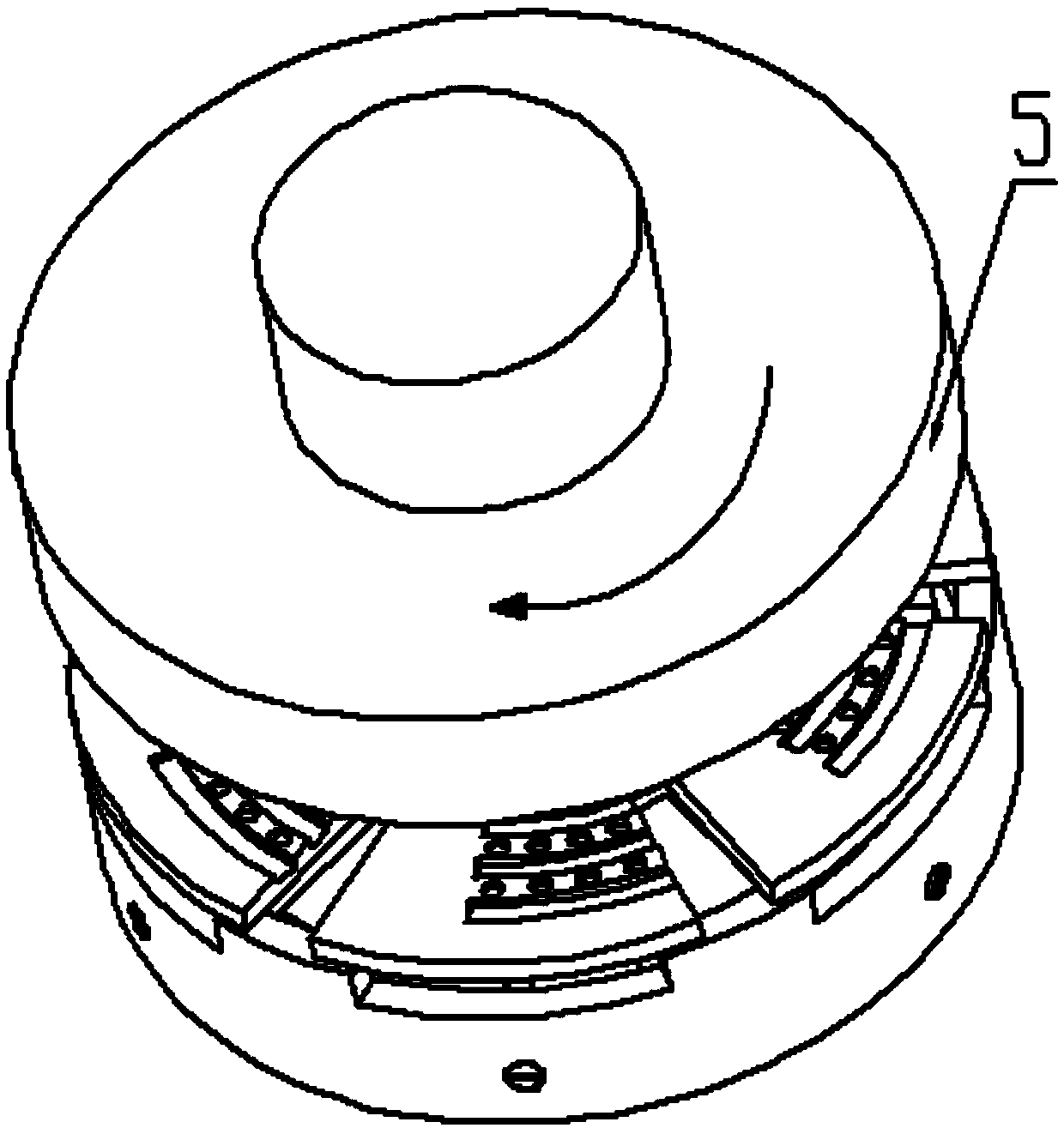

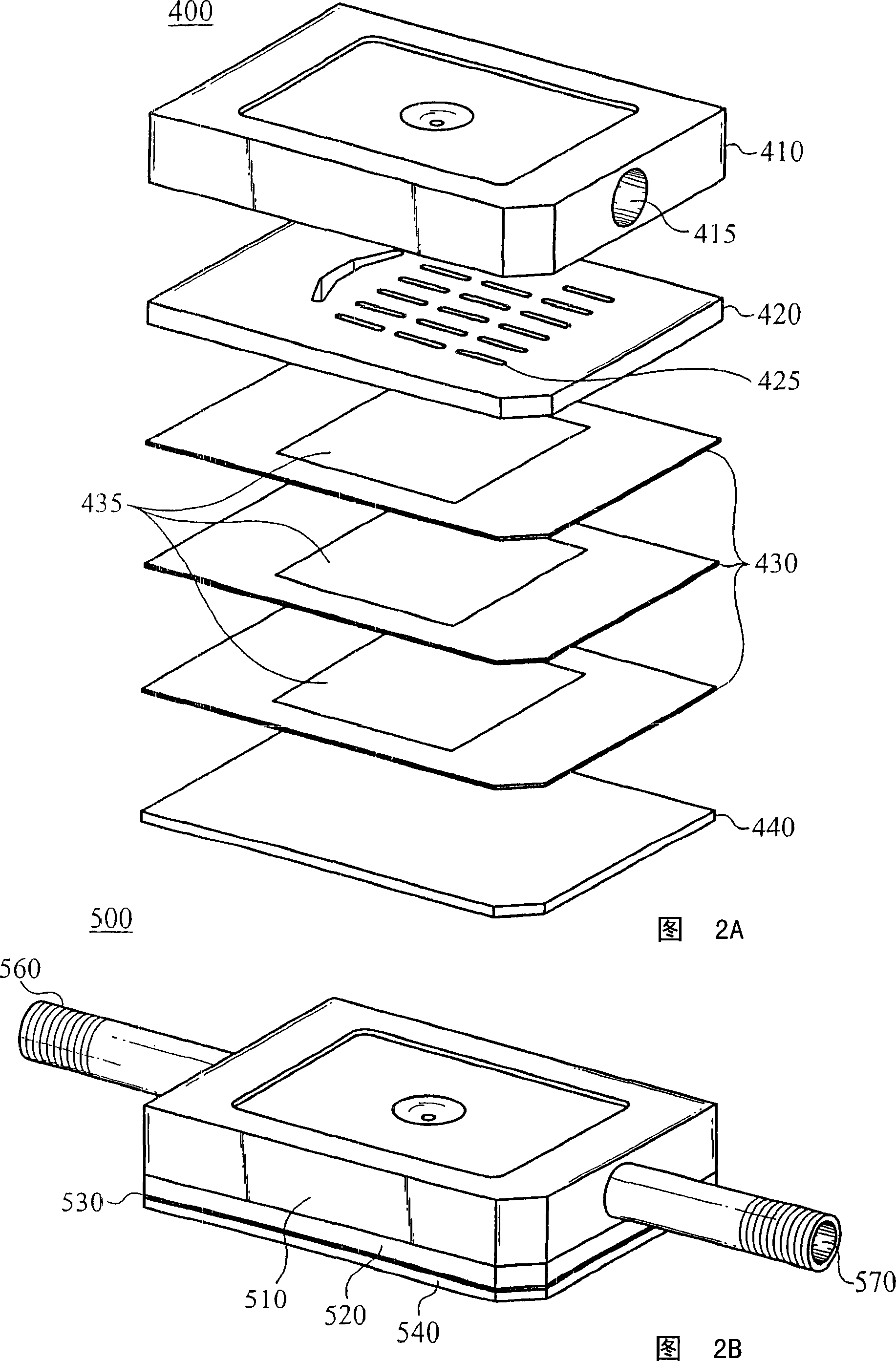

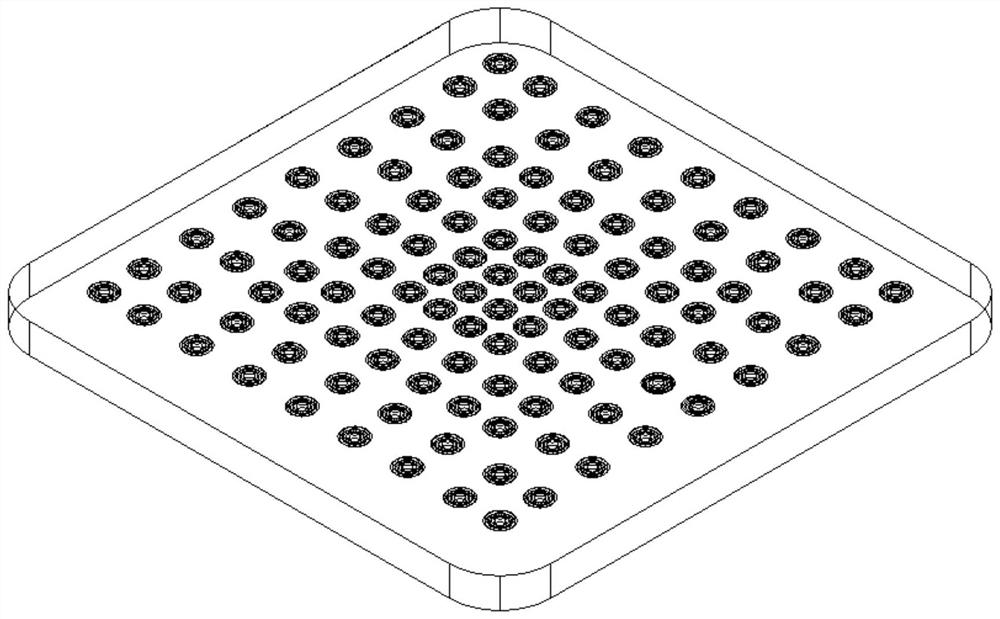

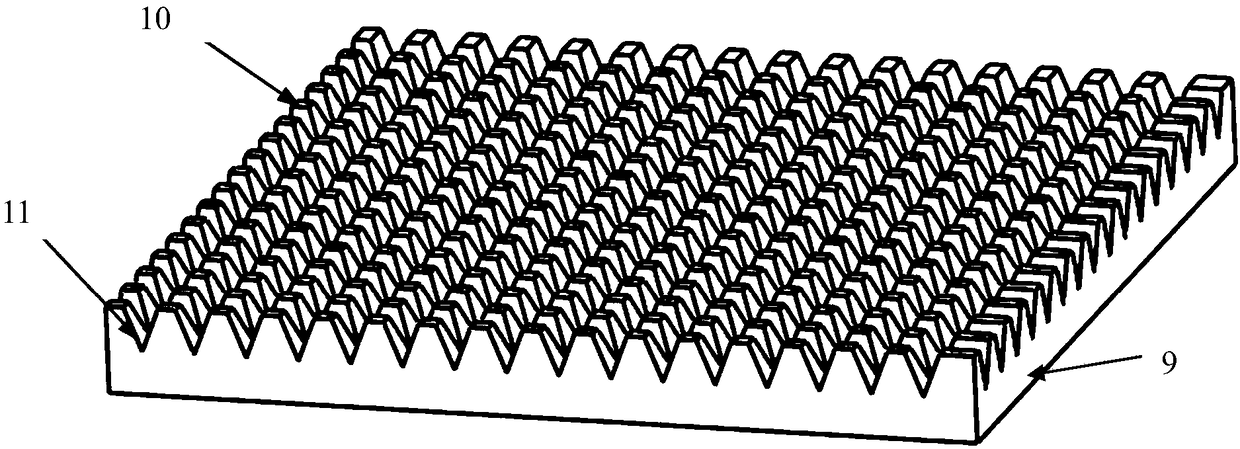

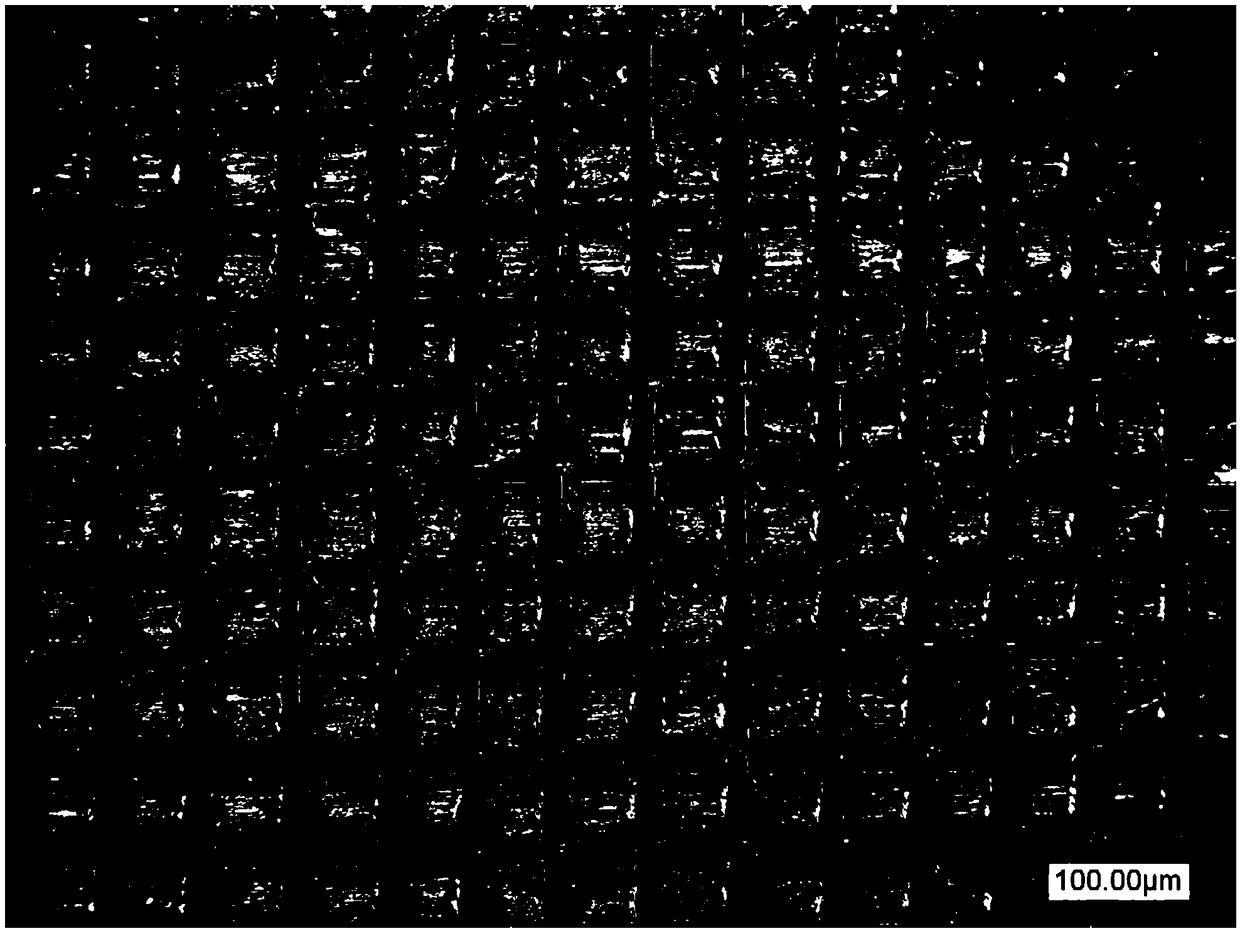

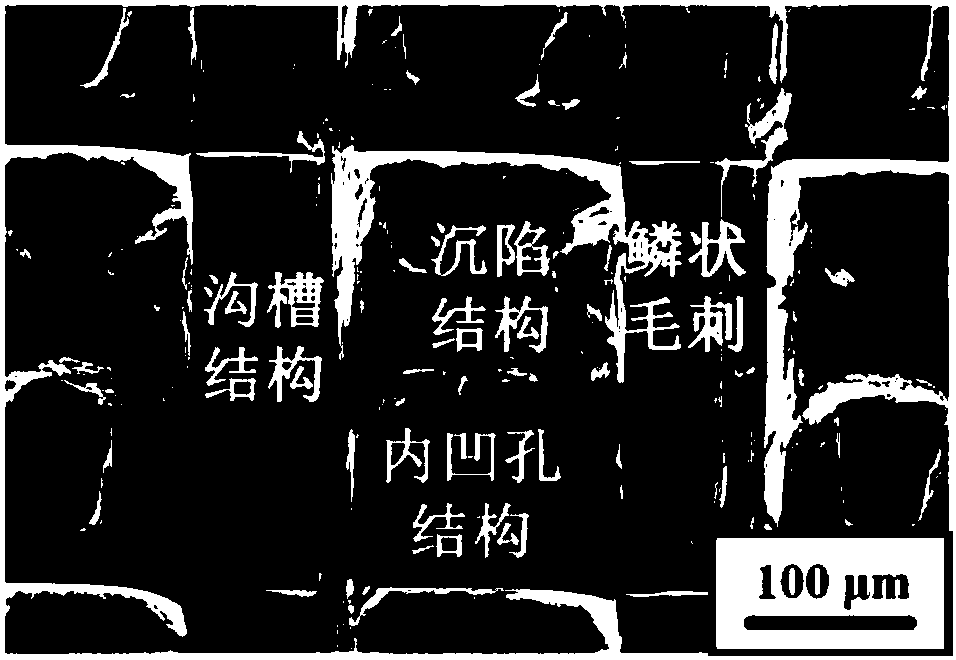

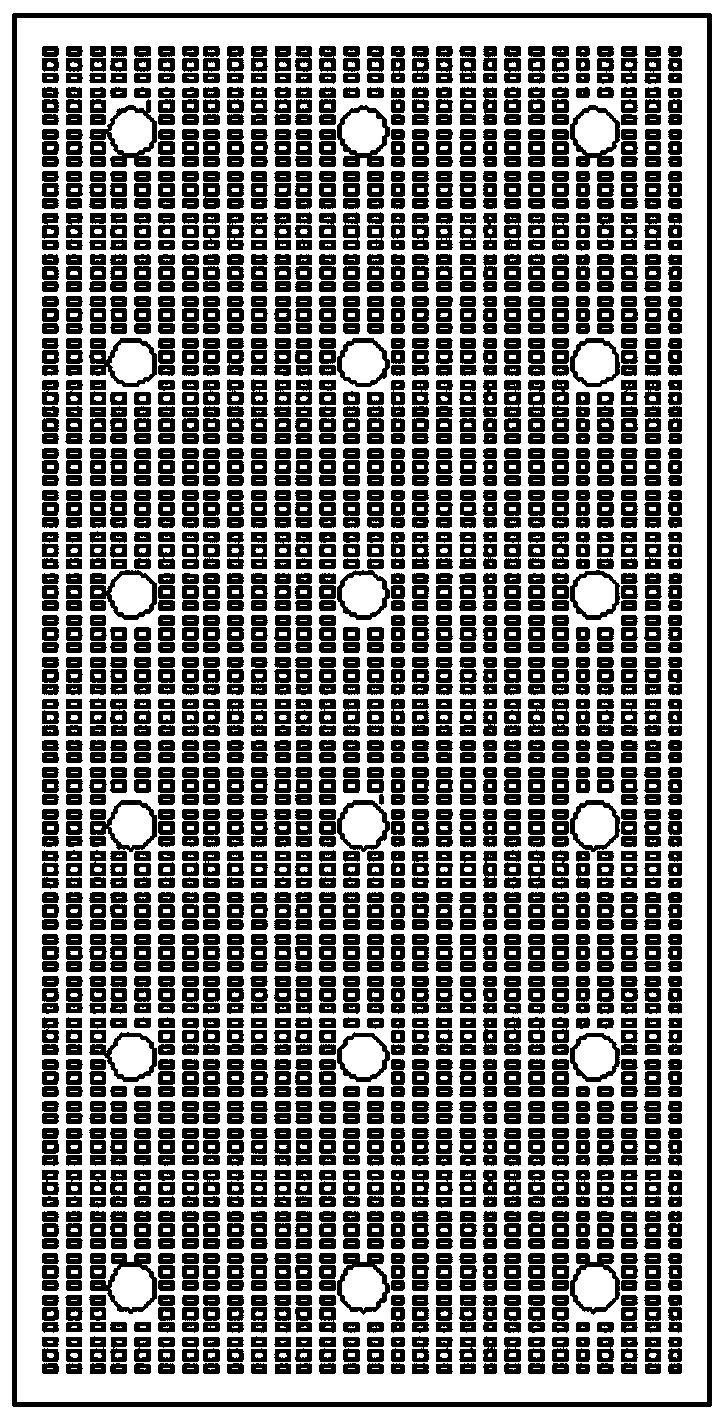

Composite microstructure current collector for lithium ion battery and preparation method of composite microstructure current collector

ActiveCN108428901AImprove bindingHigh reversible capacityElectrode carriers/collectorsSecondary cellsElectrical batterySodium-ion battery

The invention discloses a composite microstructure current collector for a lithium ion battery and a preparation method of the composite microstructure current collector for the lithium ion battery. The composite microstructure current collector comprises a smooth bottom surface and a top surface with a composite microstructure; the top surface comprises a micro-convex table and grooves, and the micro-convex table is surrounded by the grooves; concave holes, scaly burrs and a sinking structure are arranged on the micro-convex table. The preparation method comprises the following steps: (1) designing a cutter and carrying out pretreatment on a copper sheet; (2) cutting a processing surface microstructure by a plow. The composite microstructure current collector for the lithium ion battery,disclosed by the invention, can effectively increase the surface area of the current collector to enhance the contact between active materials and the current collector, and improve the utilization ratio of the active materials and the conductivity of an electrode to increase the capacity of the battery, reduce the impedance of the battery, and improve the rate capability of the battery. The composite microstructures such as the grooves, the concave holes, the scaly burrs, the sinking structure and the like can limit acute volume changes of the active materials during the charging-dischargingprocess of the battery to prolong the service life of the battery and improve electrochemical properties of the reversible capacity, the cycling stability, the coulombic efficiency and the like of thebattery.

Owner:SOUTH CHINA UNIV OF TECH

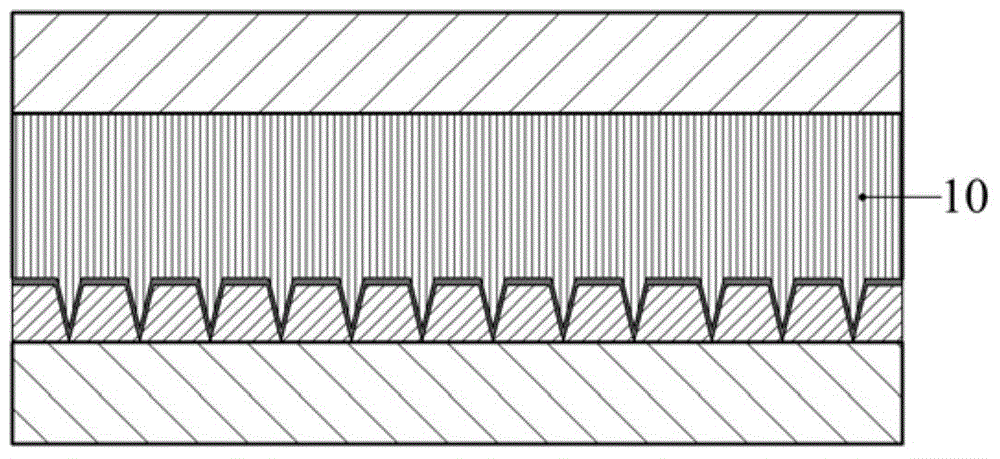

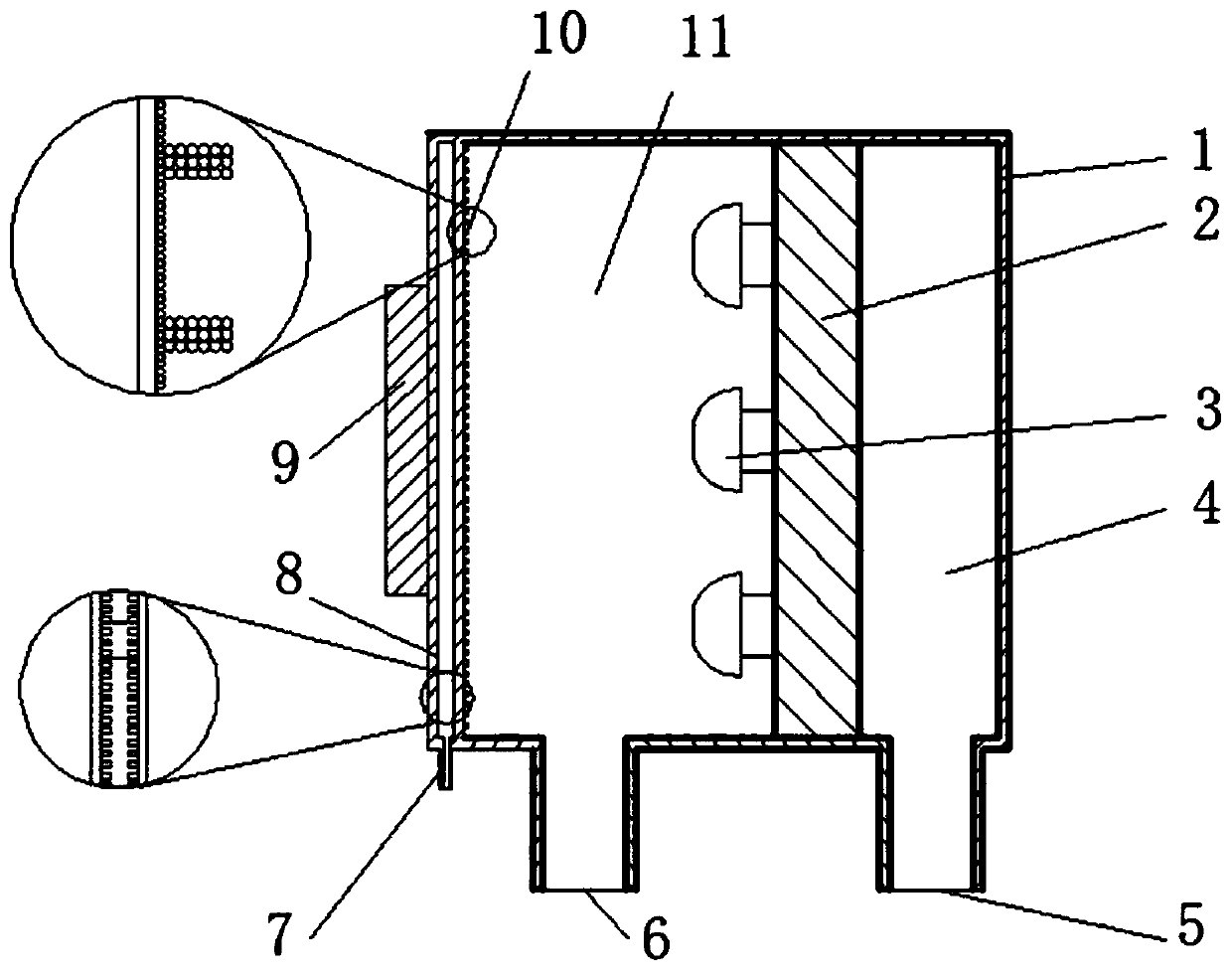

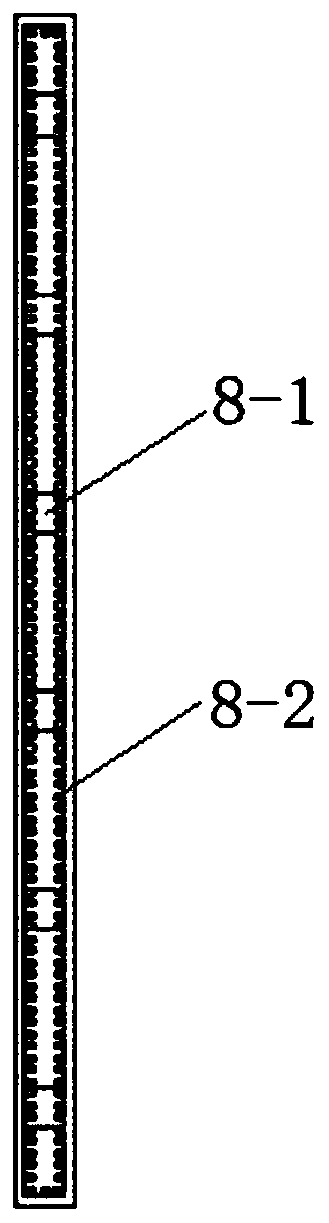

Spray cooling device combining steam cavity and composite microstructure

ActiveCN110381701AImprove cooling effectImprove ductilityCooling/ventilation/heating modificationsVena contracta diameterEnhanced heat transfer

The invention discloses a spray cooling device combining a steam cavity and a composite microstructure. The device comprises a spray chamber, a spray chamber liquid inlet pipe, a spray chamber liquidoutlet pipe and a steam chamber, wherein the spray chamber and the steam chamber are integrally arranged; the spray chamber comprises a spray orifice plate, array nozzles and a composite microstructure which are positioned in the spray chamber; the spray orifice plate divides the spray chamber into a buffer chamber and a spray chamber; the spray chamber liquid inlet pipe is communicated with the buffer chamber; the spray chamber liquid outlet pipe is communicated with the spray chamber, the composite microstructure is arranged on the wall face, opposite to the array nozzle, in the spray chamber, the composite microstructure comprises a bottom layer liquid absorption core arranged on the wall face opposite to the array nozzle and a plurality of rib-shaped liquid absorption cores arranged onthe bottom layer liquid absorption core, and a phase change working medium is sealed in the steam chamber. The steam chamber expands heat generated by a heat source to the spraying wall face with a large area, the heat exchange performance of the wall face is improved through multi-nozzle array spraying, and the two-phase heat exchange capacity of spraying is improved through combination of the steam chamber and a composite microstructure enhanced heat transfer mode.

Owner:NANJING UNIV OF SCI & TECH

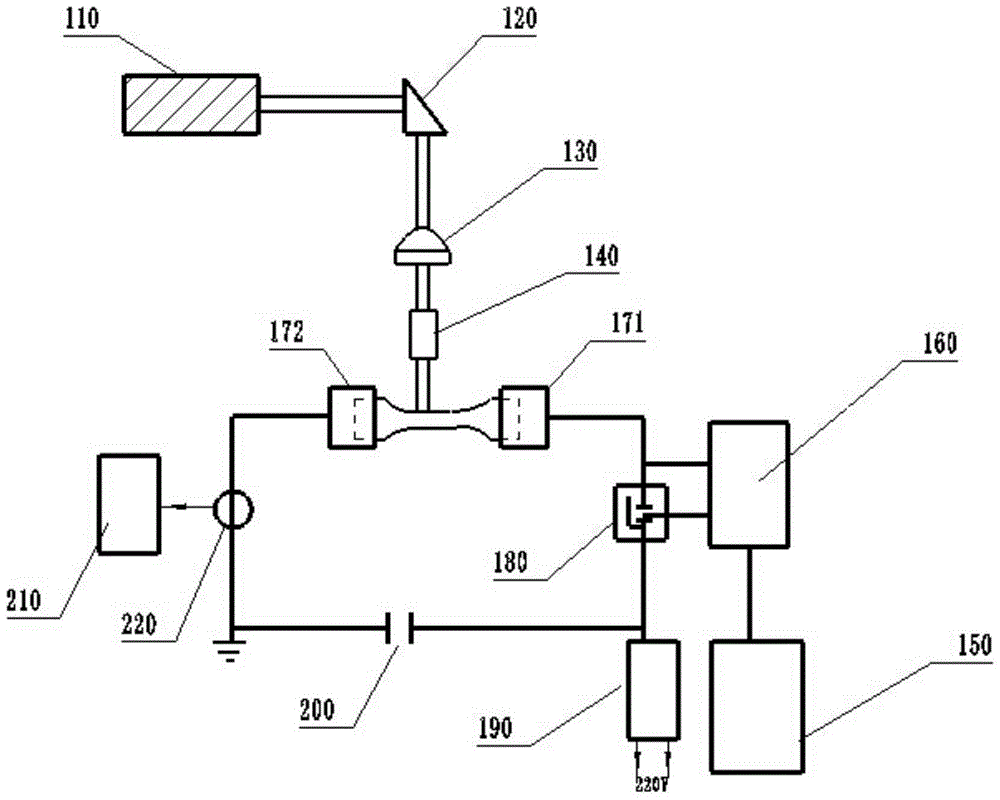

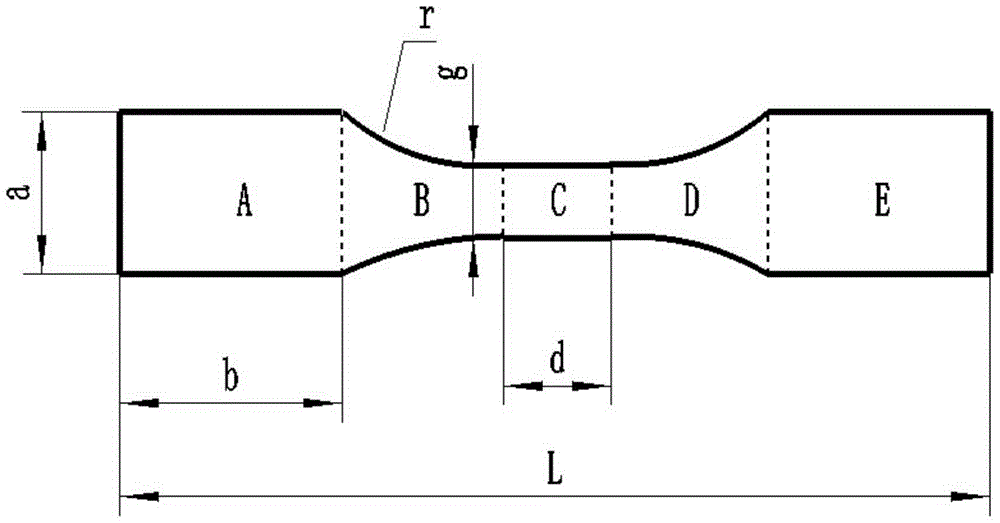

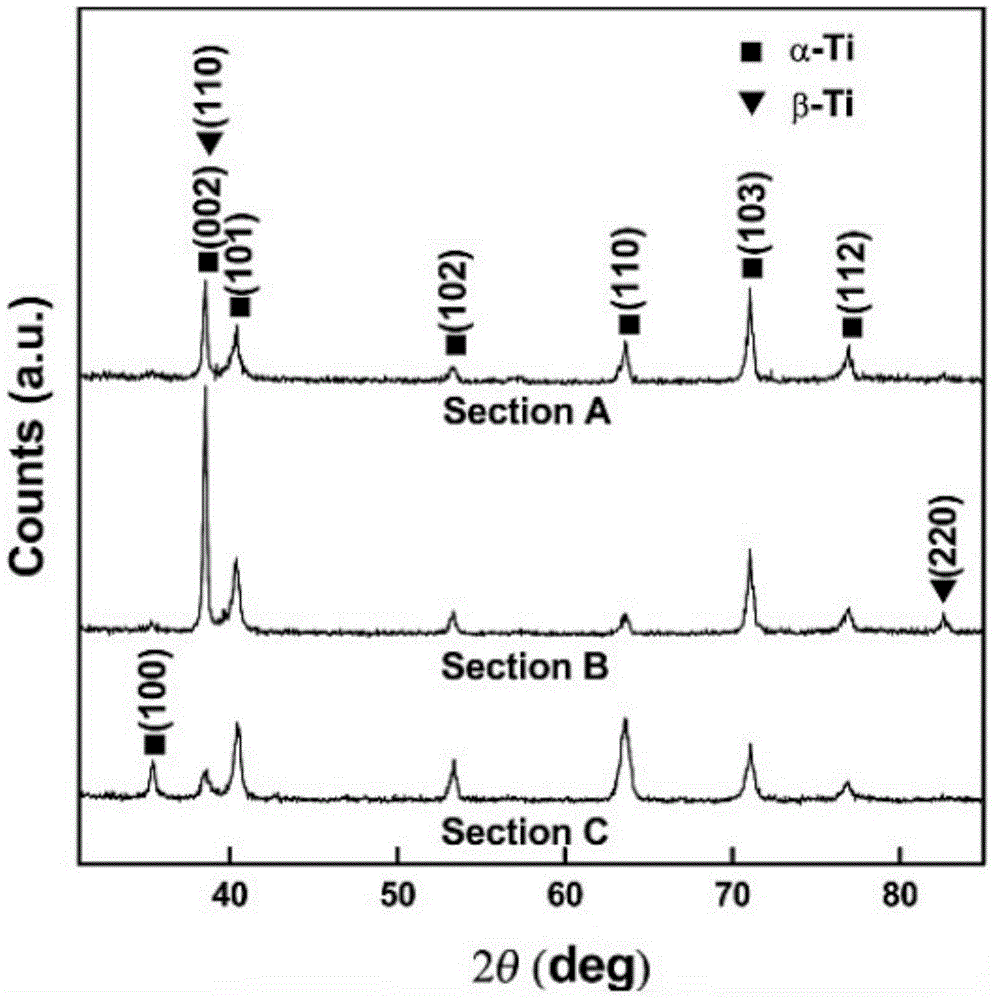

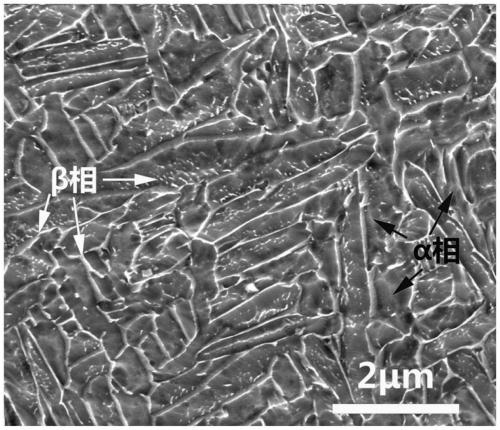

Photoelectric pulse composite processing method of novel composite microstructure of Ti-6Al-4V alloy

The invention provides a photoelectric pulse composite processing method of a novel composite microstructure of Ti-6Al-4V alloy. Optimization design is conducted on an output light path of a pulse laser, and a pulse impact method and a pulse current processing method can be combined and applied, so that the Ti-6Al-4V alloy mechanical property is improved remarkably. The method includes the steps that firstly, and a laser pulse energy impact method is adopted to change the grain structure of the Ti-6Al-4V alloy; secondly, pulse current processing change is conducted to change the grain structure of the Ti-6Al-4V alloy, the pulse current processing process of the Ti-6Al-4V alloy is completed through the pulse current joule heat effect, the electroplastic effect, the magnetic compression effect and the like; and thirdly, the microstructure type of the material is changed, and brand-new mechanical property is obtained. A vacuum annealing method is adopted, and the oxygen content of a processed Ti-6Al-4V alloy sample is lowered effectively, so that the novel composite microstructure of the Ti-6Al-4V alloy reaches the industrial application level, and the method is significant in material non-traditional machining and material science.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

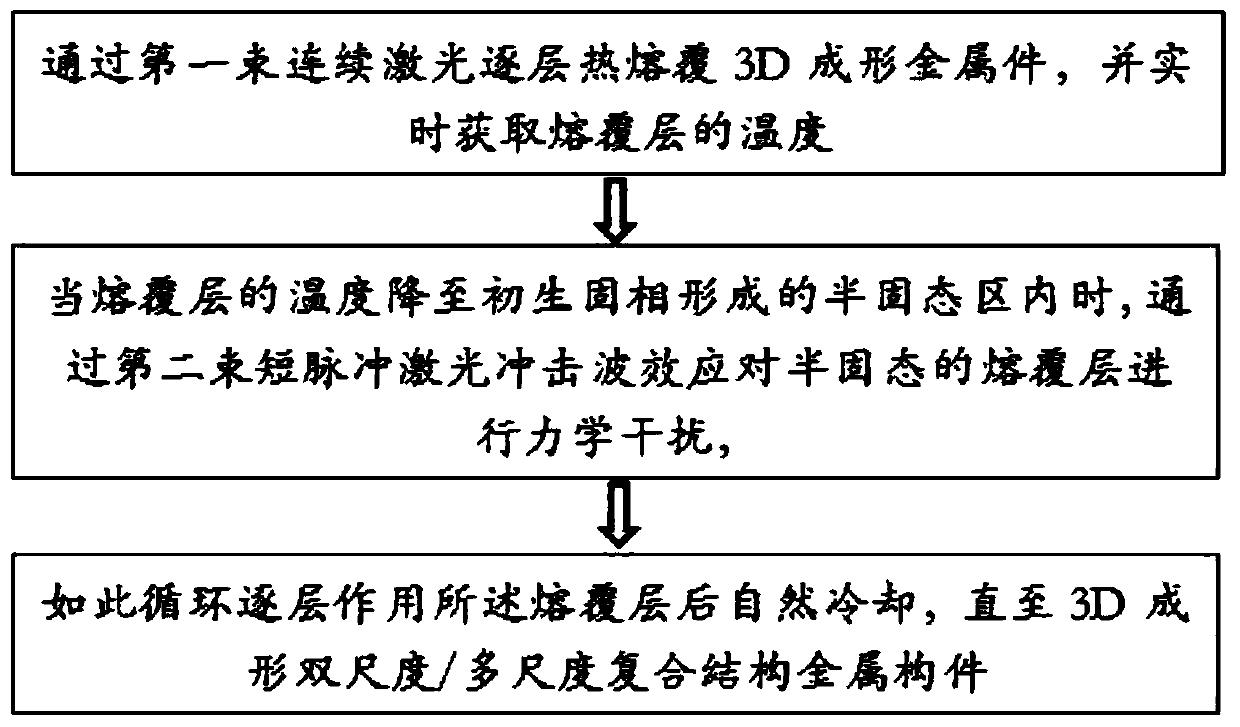

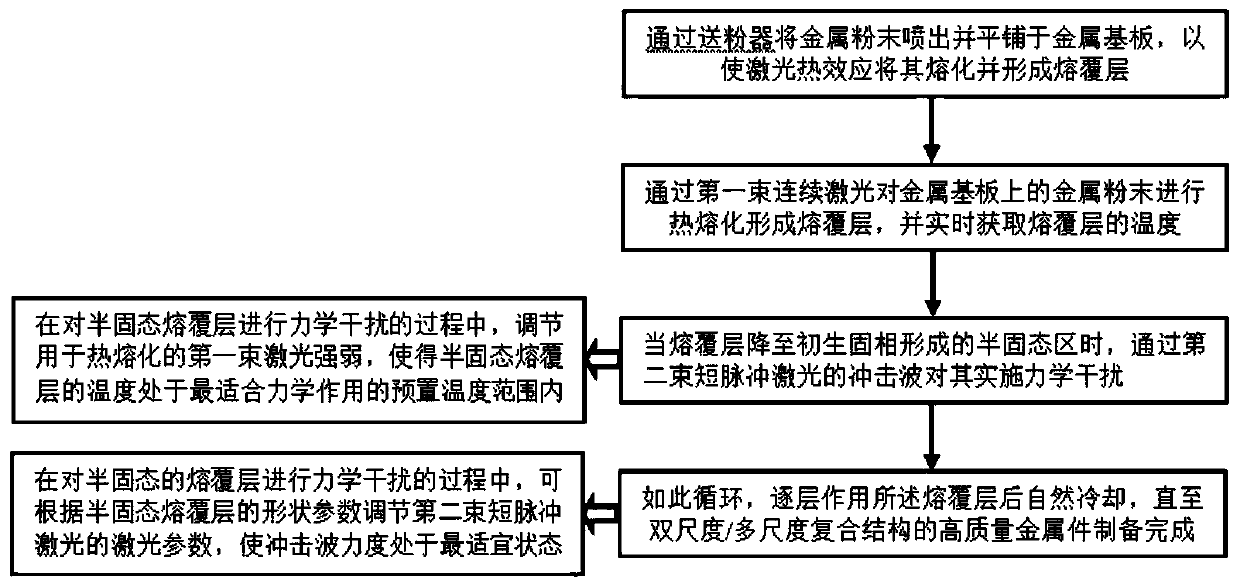

Laser semi-solid processing preparation method of high-strength high-toughness metal material, high-strength high-toughness metal material, and application thereof

PendingCN111471991AImprove performanceImprove internal qualityMetallic material coating processesAviationMacroscopic scale

The invention belongs to the technical field of metal materials, and particularly relates to a laser semi-solid processing preparation method of a high-strength high-toughness metal material, the high-strength high-toughness metal material, and application thereof. The preparation method comprises the steps of (1) hot-cladding a three-dimensional (3D) forming metal piece layer by layer through a first beam of continuous laser, and acquiring the temperature of a cladding layer in real time; (2) when the temperature of the cladding layer is reduced to be within a semi-solid state area formed bya primary solid phase, carrying out mechanical disturbance on the semi-solid-state cladding layer through a shock wave effect of a second beam of short-pulse laser; and (3) circularly acting on the cladding layer layer by layer, and then cooling naturally until 3D forming a dual-scale / multi-scale composite structure metal component. According to the laser semi-solid processing preparation method of the high-strength high-toughness metal material, the high-strength high-toughness metal material, and the application thereof provided by the invention, the metal material with novel composite microstructures such as dual-scale / multi-scale structures of nano-grain, ultra-fine grain and fine grain and an excellent combination property is obtained, and can be widely applied to the fields such as high speed railway, space flight and aviation, military industry and instruments and apparatus, and the effective control on macroscopical deformation and cracking problems of metal pieces is realized.

Owner:GUANGZHOU INST OF RAILWAY TECH

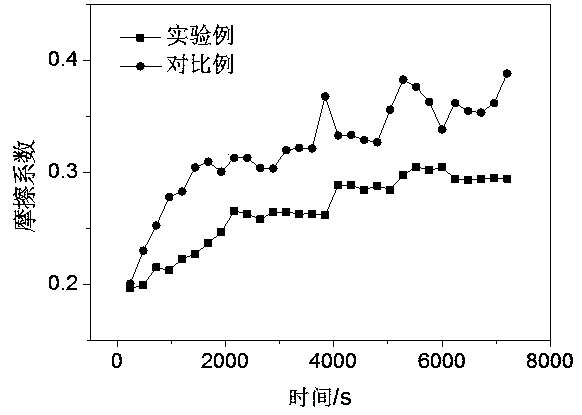

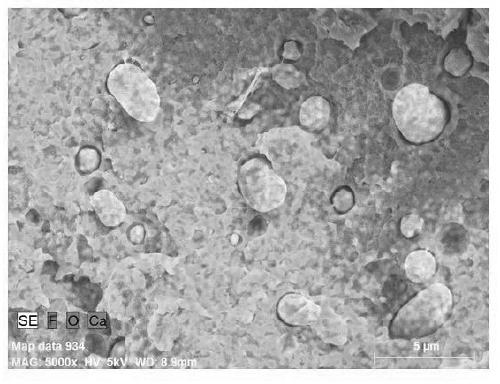

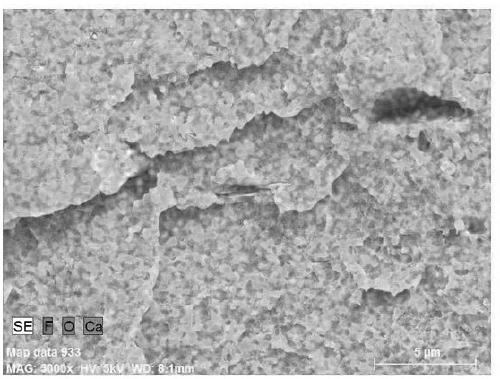

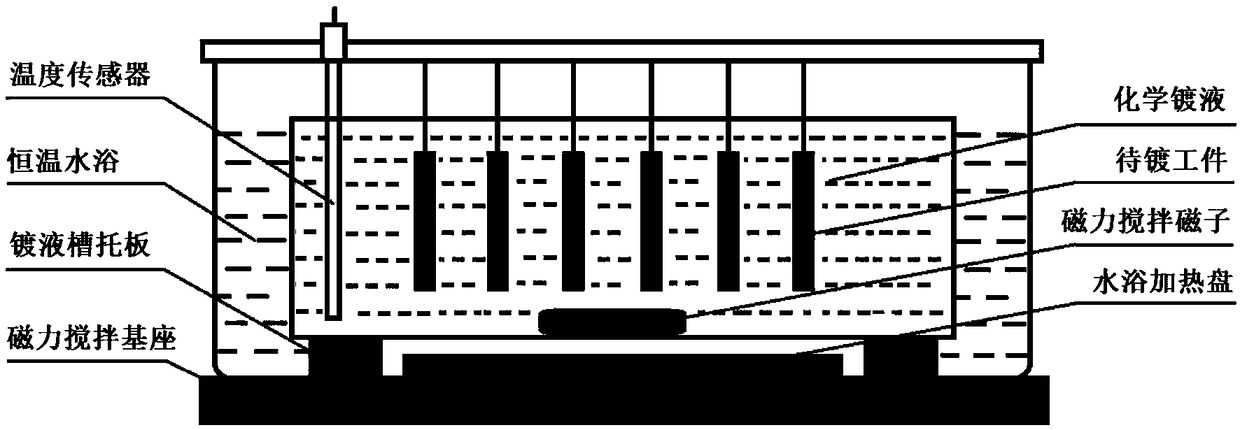

Binary composite structure type nickel boron alloy coating and preparation method and application thereof

ActiveCN108588692AImprove cooling effectReduce coefficient of frictionLiquid/solution decomposition chemical coatingSurface cleaningAlloy coating

The invention discloses a binary composite structure type nickel boron alloy coating and a preparation method and application thereof. The nickel boron alloy coating is provided with a micron and nanobinary composite microstructure, wherein the first-order structure is a micron-level vortex cell type structure unit; a second-order structure is a nano-level villus type structure unit. The preparation method comprises the steps of chemically coating a surface-cleaned workpiece to be coated in a chemical coating solution to obtain a coated workpiece subjected to chemical coating treatment; and thermally processing the surface of the coated workpiece to obtain the binary composite structure type nickel boron alloy coating. The binary composite structure type nickel boron alloy coating is extremely high in heat dissipating performance, high in corrosion resistance, low in friction coefficient, high in adhesive force, hard to peel off, low in cost, simple in processing processes, and free from pollution, and achieves engineering realization; the service performances of spare parts can be effectively improved; the service life is prolonged; and the binary composite structure type nickelboron alloy coating is applicable to the surface reinforcing processing of a rapid cutting tool or a rapid fire weapon.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com