Preparation method of graphene coating capable of resisting acid medium corrosion in fuel cell

A technology for acidic media and fuel cells, which is applied to fuel cell parts, fuel cells, metal material coating processes, etc., can solve the problems of difficult to meet the conductive coating, high cost of nickel-based alloys, and difficult surface treatment, etc., to achieve Improve the density, reduce the contact resistance, good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

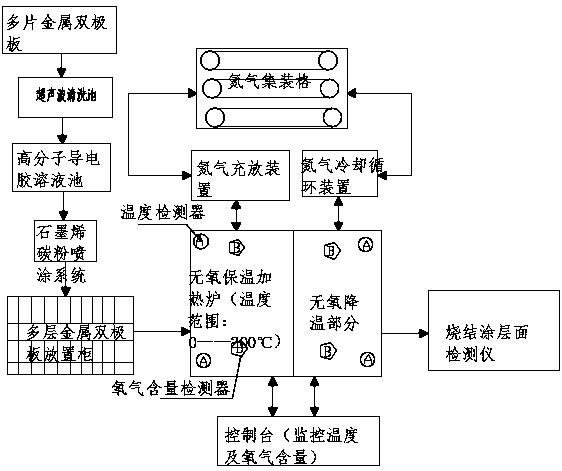

[0078] Such as figure 1 Shown, a kind of graphene coating preparation method of anti-acid medium corrosion in fuel cell, comprises

[0079] L1. Metal bipolar plate substrate polishing. Specifically, the metal bipolar plate substrate is sequentially polished with sandpaper and nylon so that the surface roughness of the metal bipolar plate substrate is not greater than 0.5 μm. This application only needs to be polished with sandpaper and nylon, and the pretreatment operation is very simple. save time and energy.

[0080] L2. Put the polished metal bipolar plate substrate into the ultrasonic cleaning tank for cleaning. Specifically, the polished metal bipolar plate substrate is placed in an ultrasonic cleaning pool filled with acetone and alcohol for cleaning for 15 minutes.

[0081] L3. Put the ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com