Patents

Literature

40results about How to "Improve coating stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

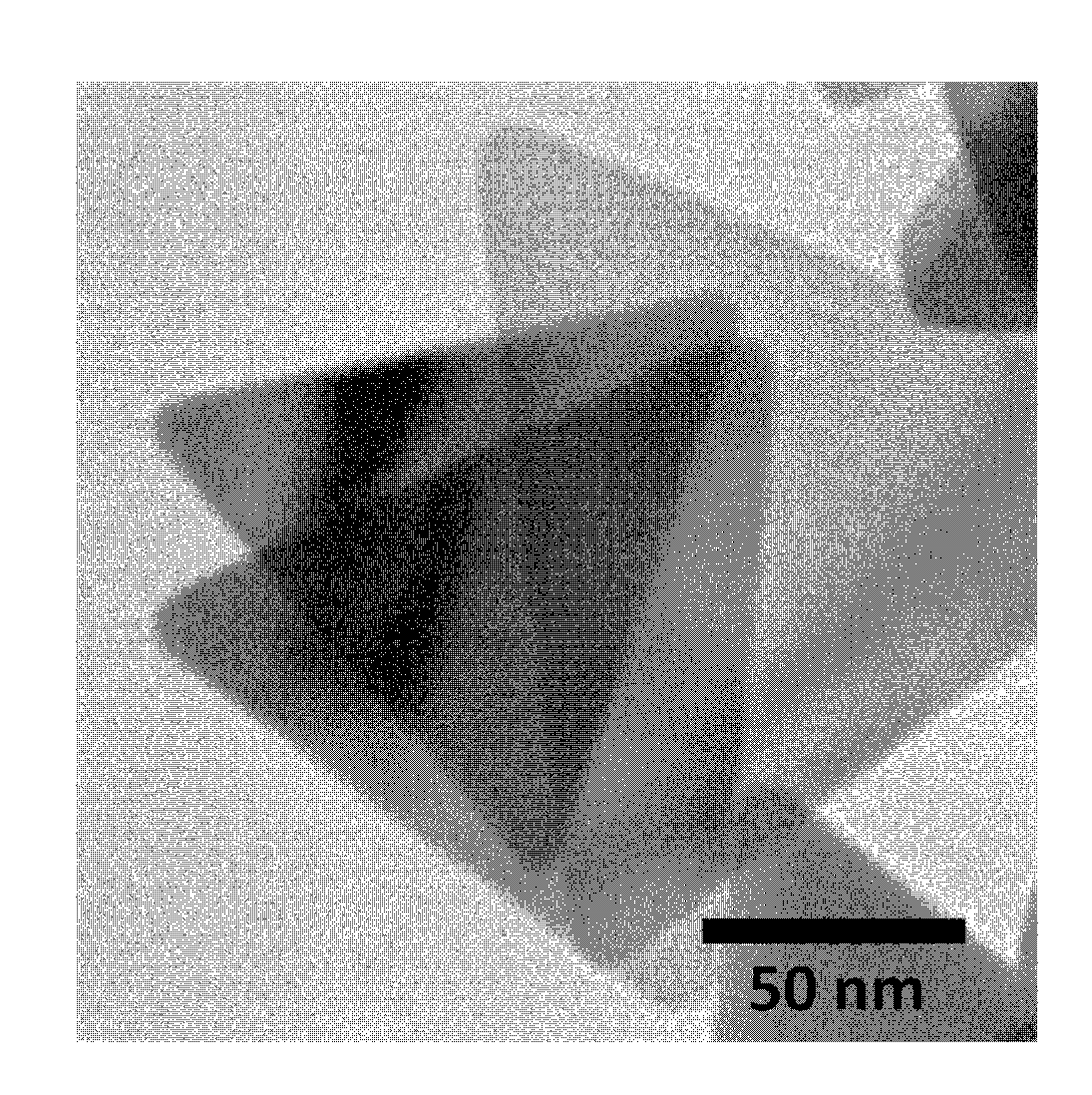

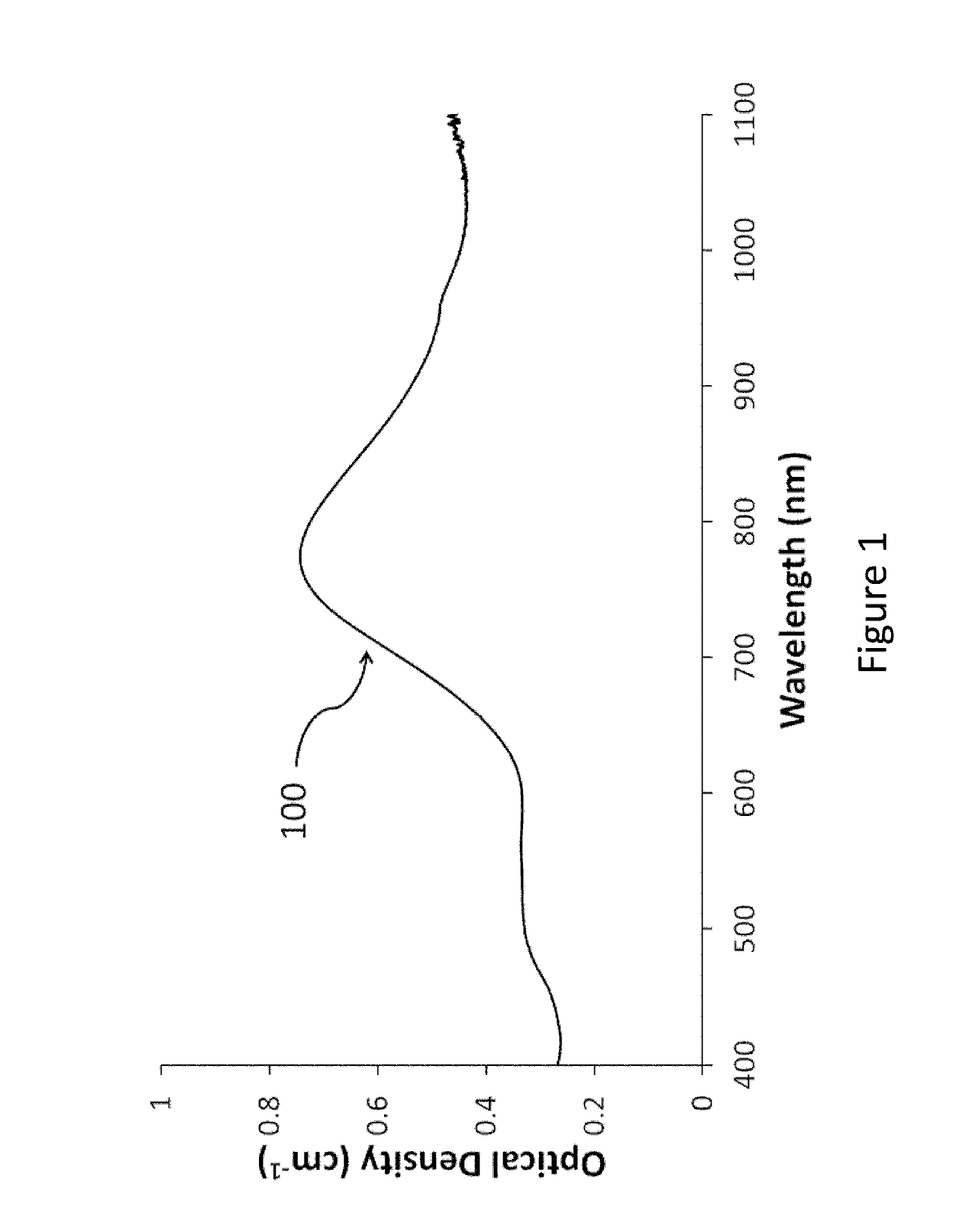

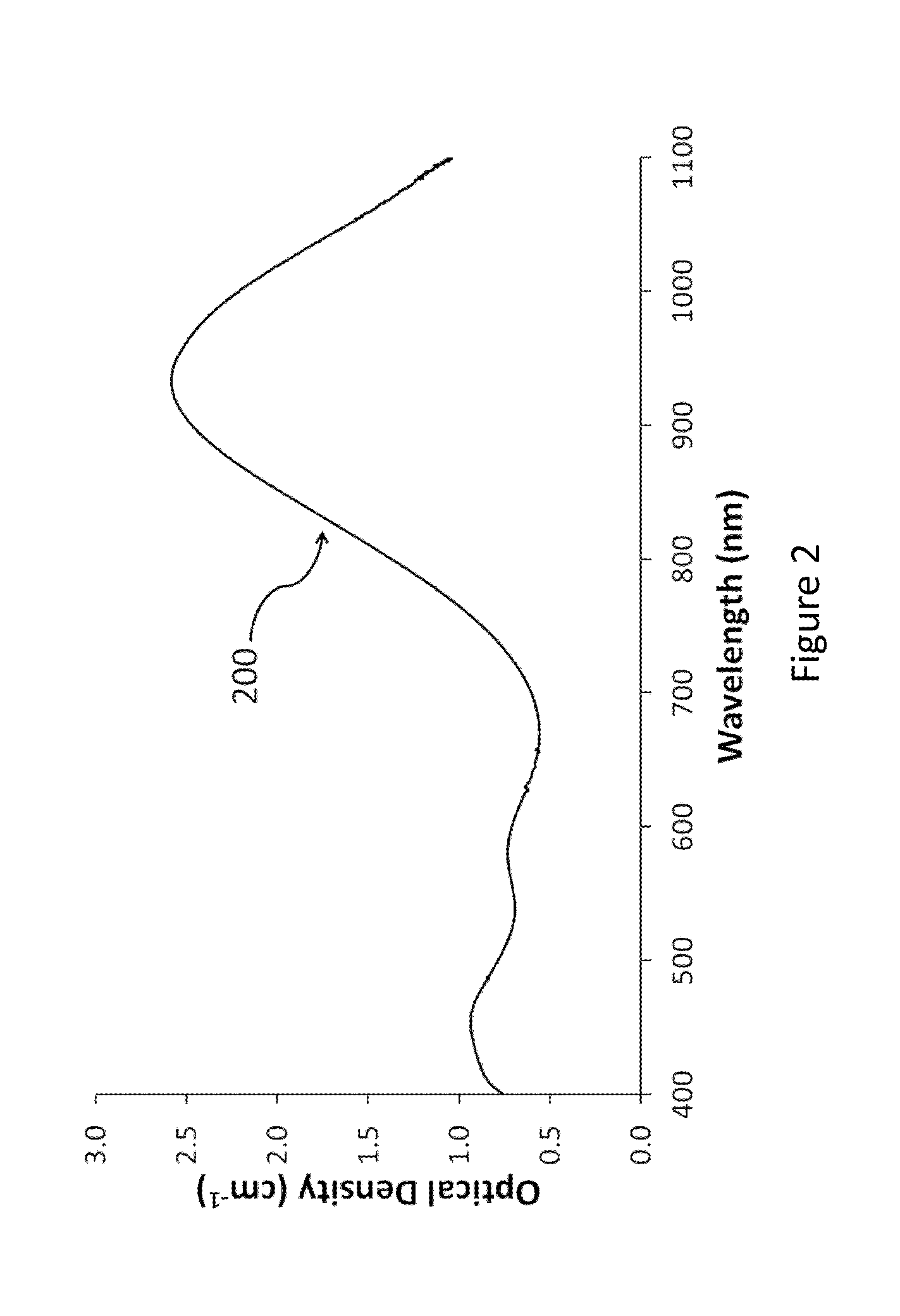

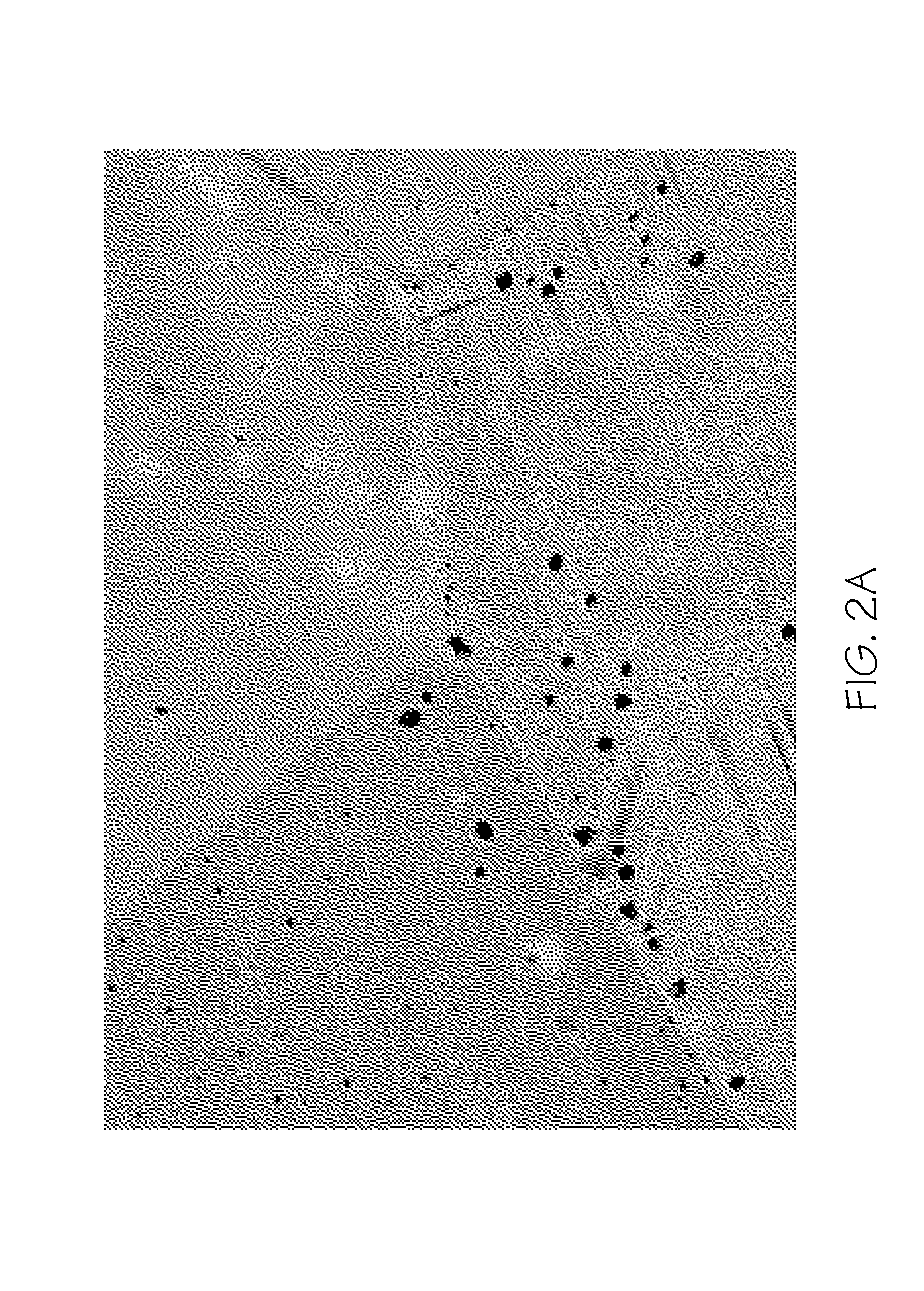

Silver nanoplate compositions and methods

ActiveUS20150225599A1Reduce degradationHigh optical densityAntibacterial agentsAntimycoticsNanoparticlePlatelet

Embodiments of the present invention relate to methods for preparing high optical density solutions of nanoparticle, such as nanoplates, silver nanoplates or silver platelet nanoparticles, and to the solutions and substrates prepared by the methods. The process can include the addition of stabilizing agents (e.g., chemical or biological agents bound or otherwise linked to the nanoparticle surface) that stabilize the nanoparticle before, during, and / or after concentration, thereby allowing for the production of a stable, high optical density solution of silver nanoplates. The process can also include increasing the concentration of silver nanoplates within the solution, and thus increasing the solution optical density.

Owner:CORONADO AESTHETICS LLC +1

Method for preparing corrosion inhibition waterborne aluminum pigment

InactiveCN105482514AImprove stabilityGood sustained release effectPigment flushingPigment treatment with organosilicon compoundsContact reactionsElution

The invention discloses a method for preparing a corrosion inhibition waterborne aluminum pigment. The method comprises the following steps: a step (1) of aluminum powder surface elution treatment; a step (2) of surface hydroxylation treatment; and a step (3) of mixing coating treatment. The method for preparing the corrosion inhibition waterborne aluminum pigment is simple and convenient to operate and easy to implement. According to the method, through aluminum powder surface elution treatment, hydroxylation treatment, slow release treatment and coating treatment, the coating stability of the aluminum pigment surface is improved effectively, the aluminum pigment is prevented from being in contact reaction with water or an air medium, the slow release performance of the aluminum pigment is improved remarkably, and the prepared aluminum pigment is high in stability, good in glossiness and wide in application prospect.

Owner:常熟市环虹化工颜料厂

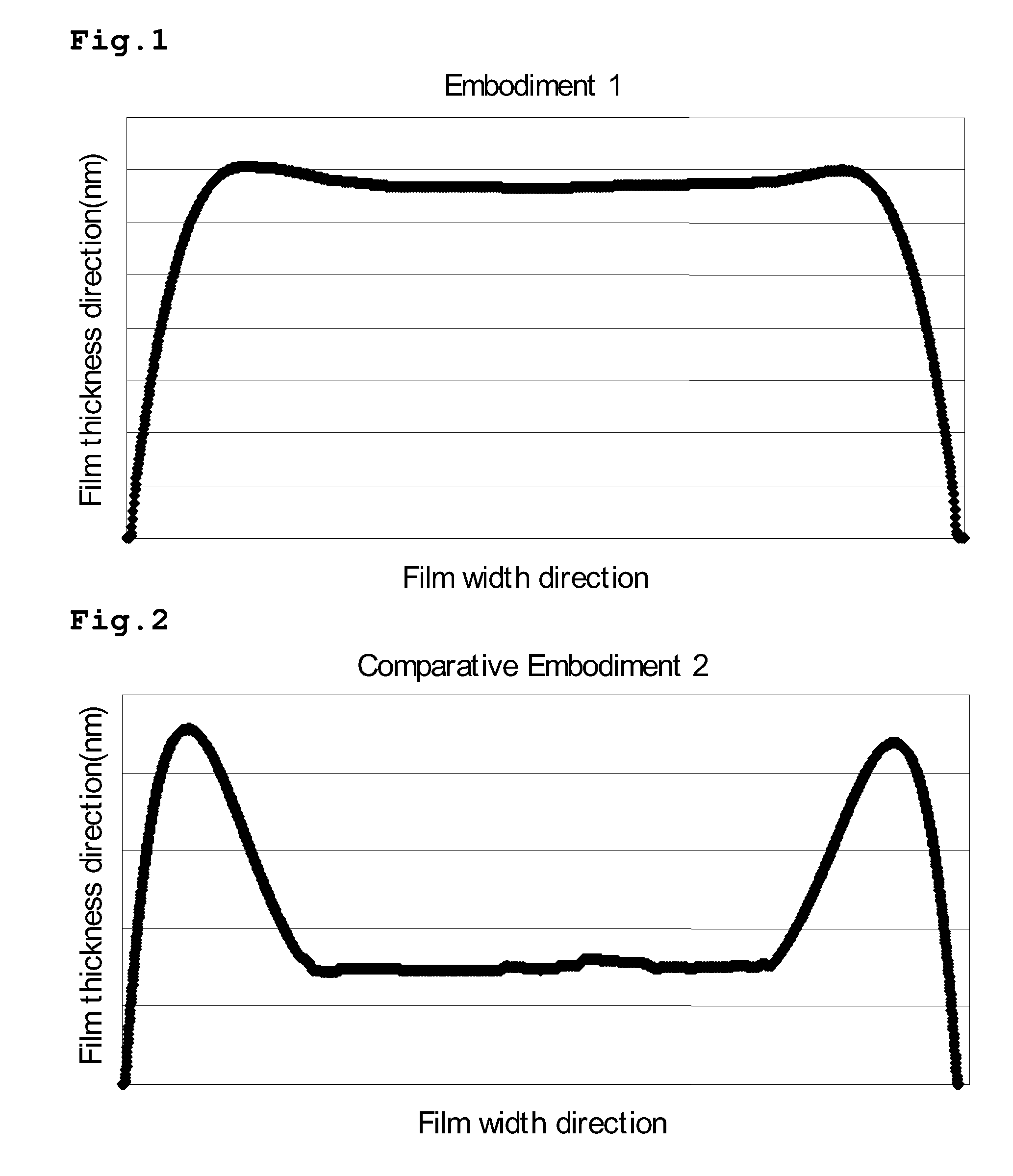

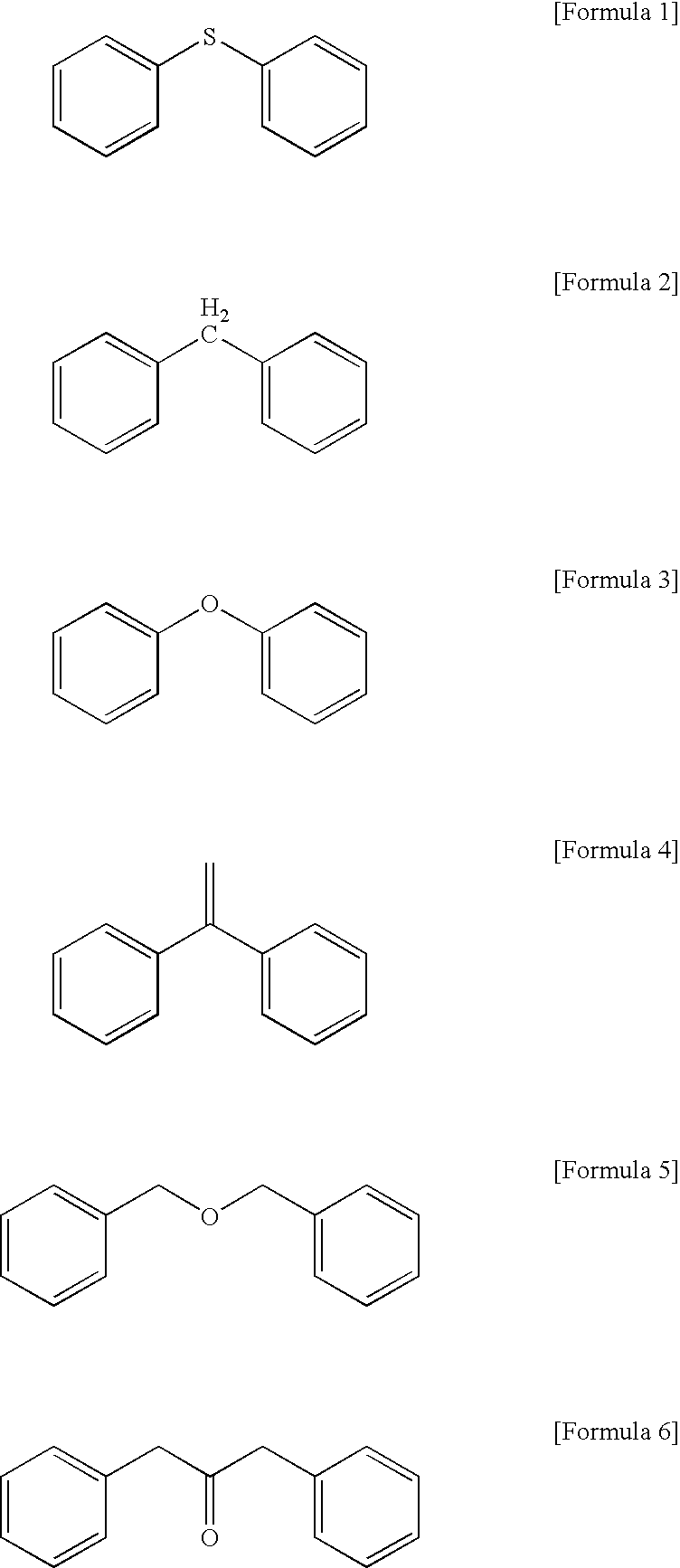

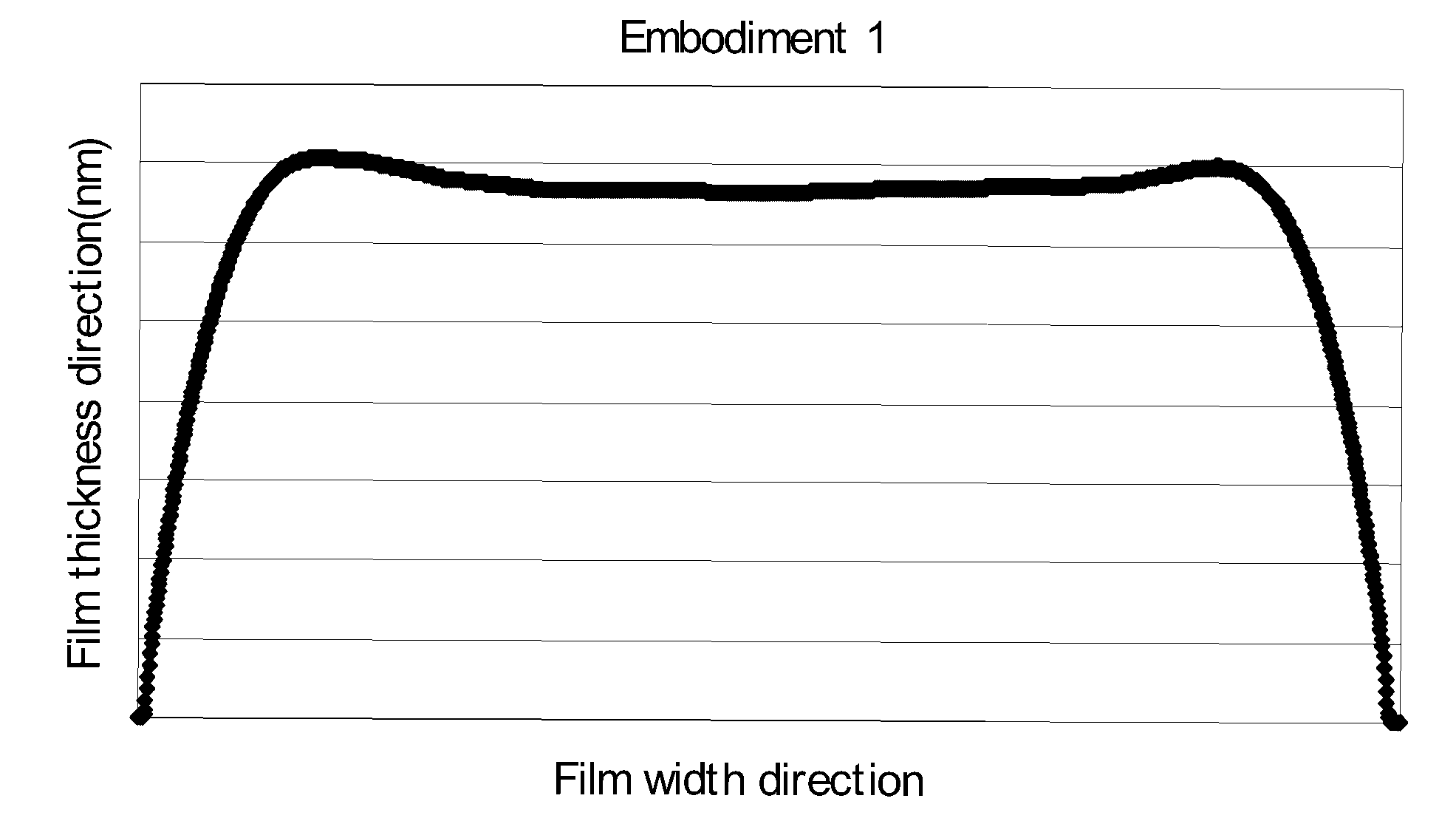

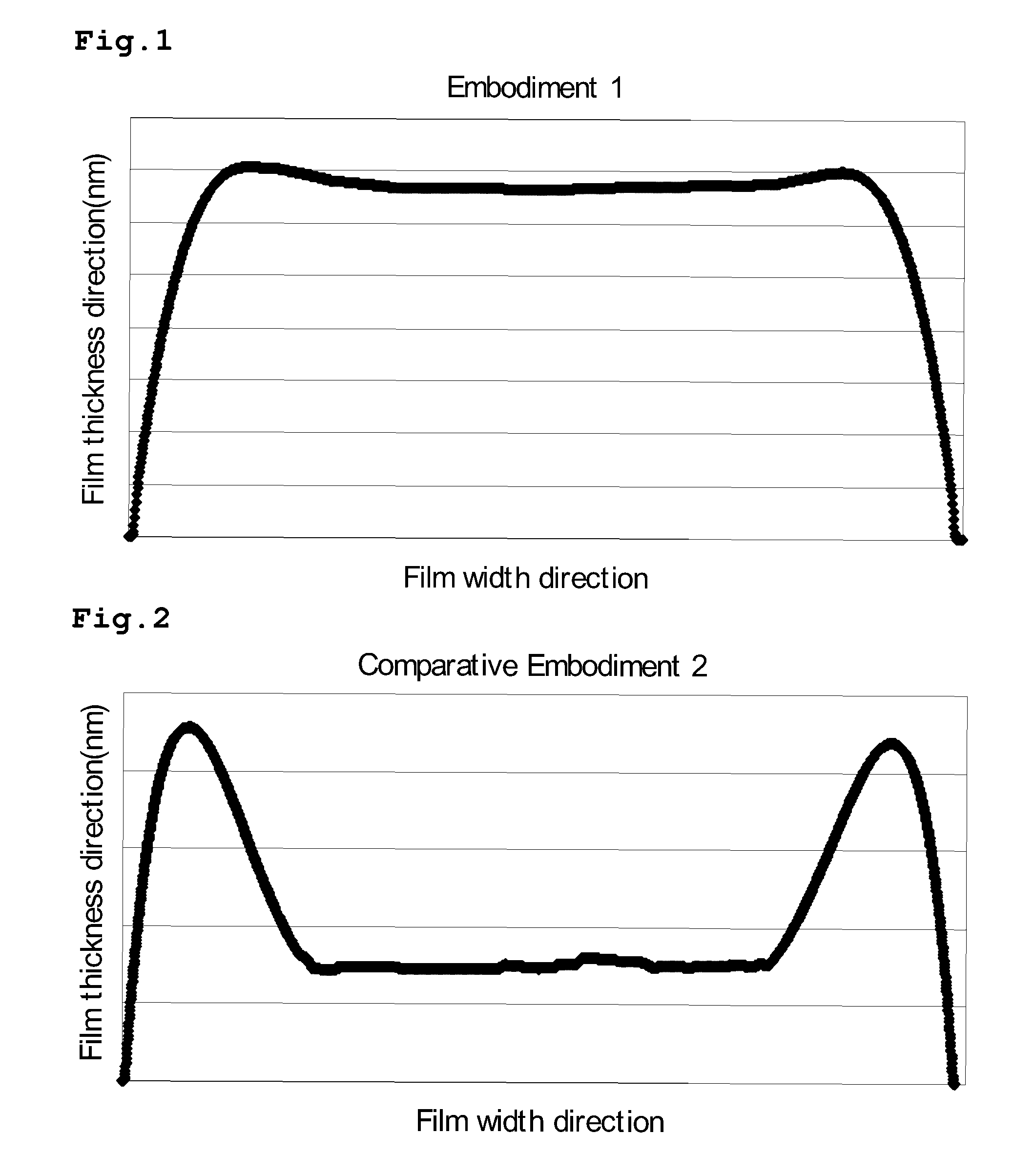

Coating Liquid, Film Production Method, Production Method of Functional Device, and Functional Device

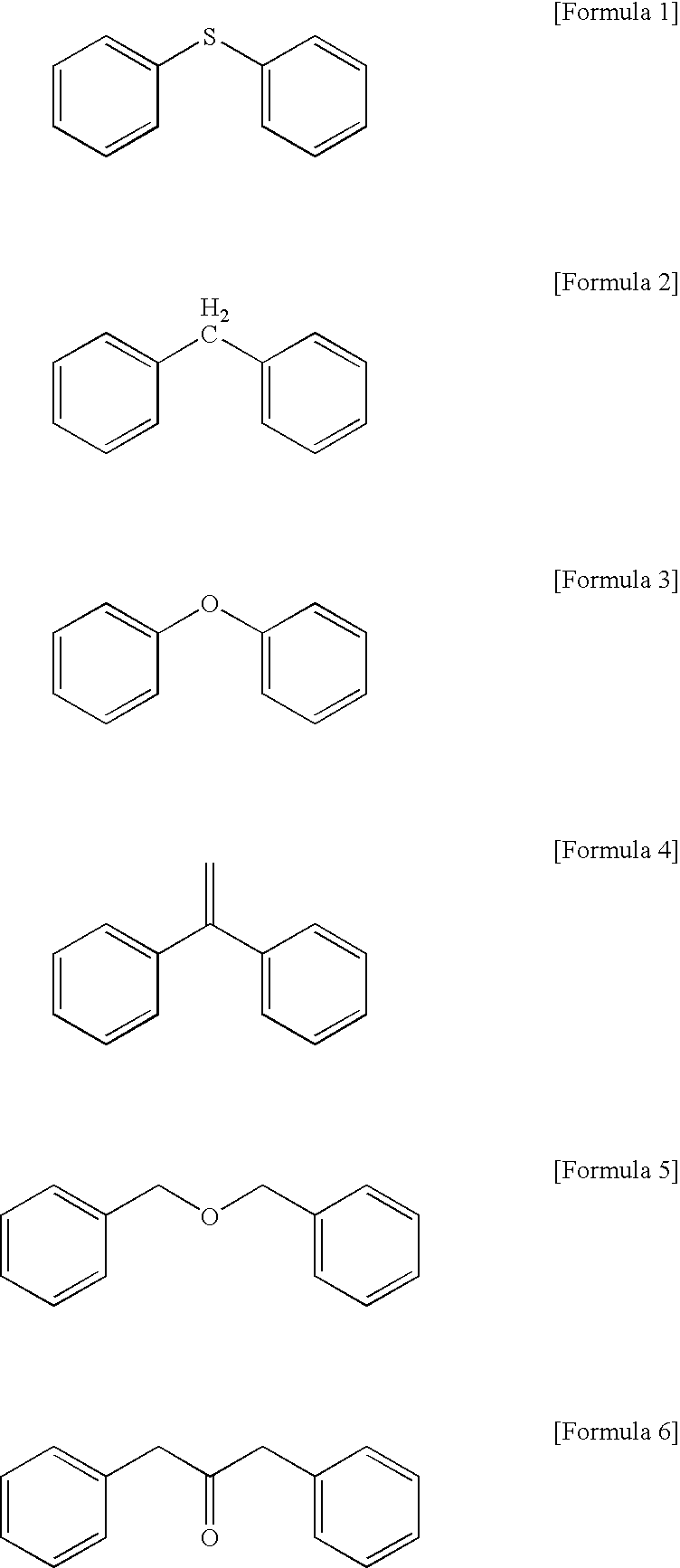

InactiveUS20080038488A1Excellent in stability and coating propertySuppress mutationLiquid crystal compositionsOptical filtersDiphenylmethaneDiphenyl ether

The present invention provides a coating liquid which is excellent in stabilities and capable of being stably ejected by an ejection equipment and suppressing variation in film thickness inside a film or between films, in application for various uses, a film production method, a production method of a functional device, and a functional device, using the coating liquid. The present invention is a coating liquid comprising a mixed solvent and a functional material, wherein the mixed solvent comprises a first solvent constituted by a compound having two or more aromatic rings such as diphenyl sulfide, diphenylmethane, diphenyl ether, and a symmetric structure and another solvent constituted by a compound having an aromatic ring such as xylene, and a proportion by volume of the another solvent is 90% or less in the mixed solvent.

Owner:SHARP KK

Process for producing powder coating composition and powder coating composition obtained by the production process

InactiveUS20060173098A1Improve coating stabilityPowdery paintsGranulation by powder suspensionPolyresinPowder coating

Owner:HOSOKAWA POWDER TECH RES INST

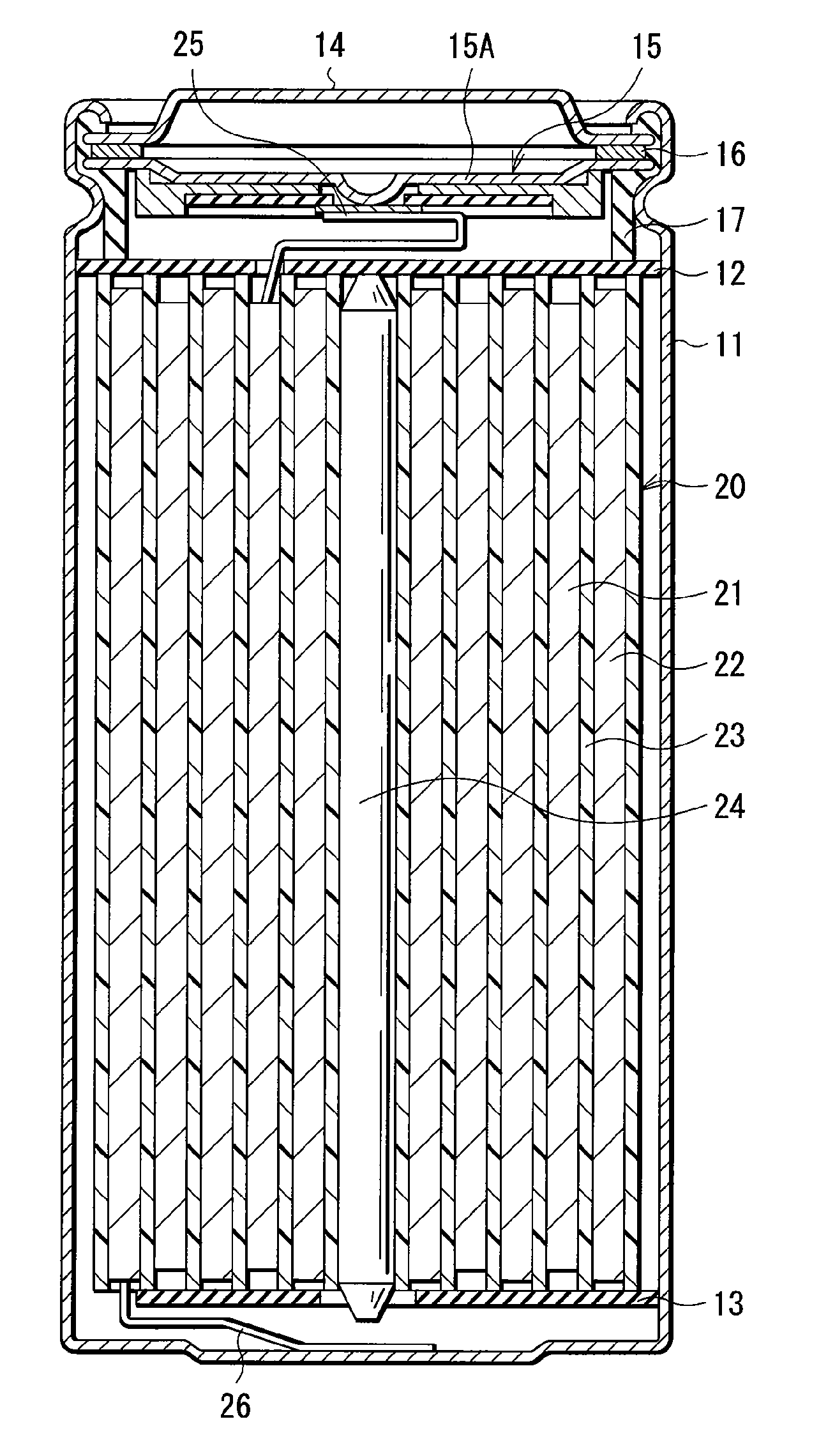

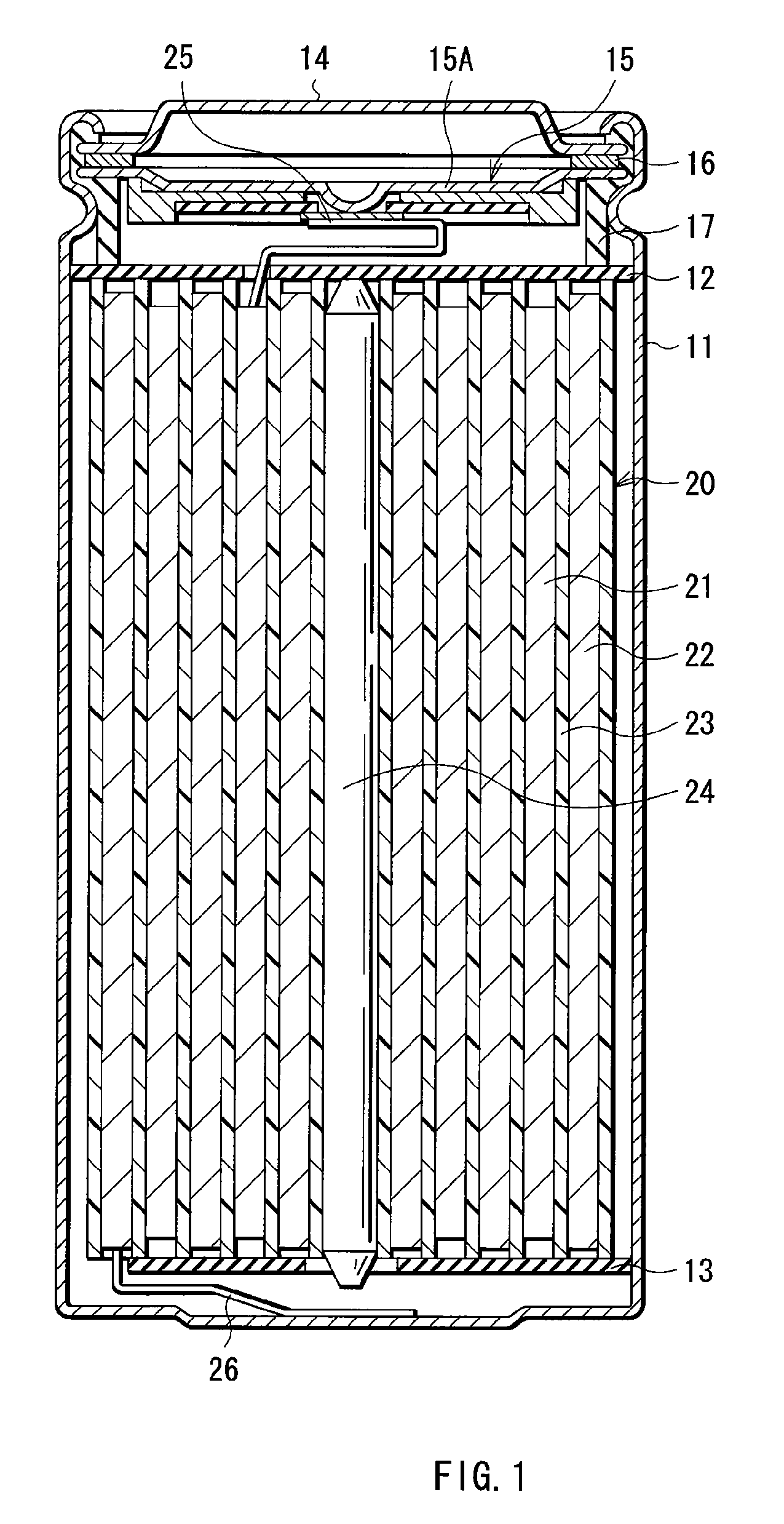

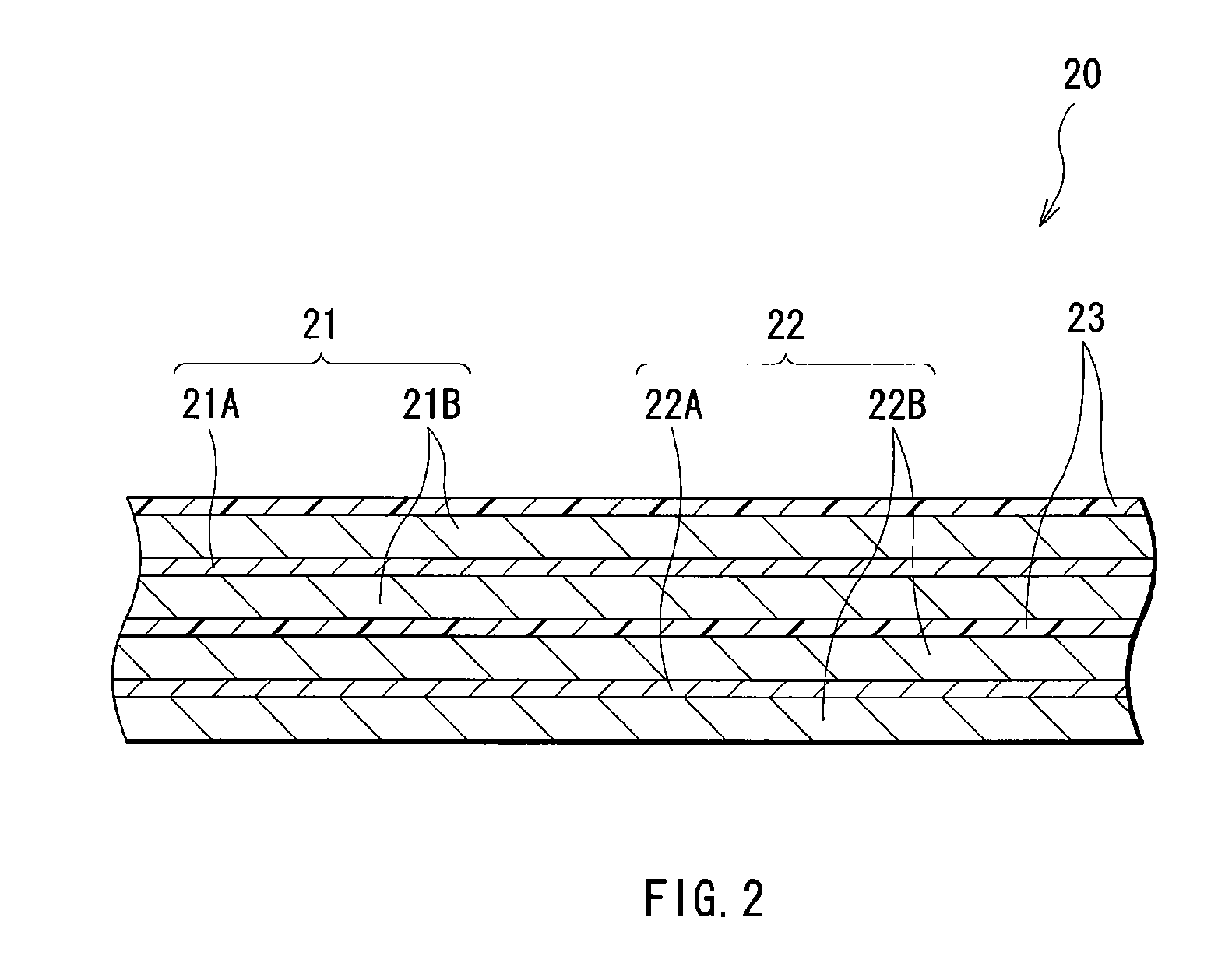

Battery

InactiveUS20060222958A1Improve coating stabilityGood chemical stabilityOrganic electrolyte cellsActive material electrodesChemical stabilityCathode

A battery capable of improving high temperature characteristics is provided. An electrolytic solution is impregnated in a separator. The electrolytic solution contains an imide salt expressed by LiN(CnF2n+1SO2)(CmF2m+1SO2) (n and m are respectively an integer number from 1 to 4, and a different value from each other). Thereby, a coat stable even at high temperatures can be formed on the surface of a cathode or an anode, and chemical stability of the electrolytic solution at high temperatures can be improved. LiPF6 is preferably mixed in the electrolytic solution.

Owner:SONY CORP

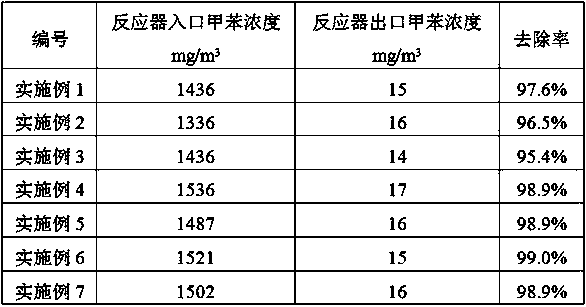

Manganese-copper based composite oxide doped rare earth element catalyst for catalyzing VOCs as well as preparation method and application of catalyst

ActiveCN108325536AHigh activityExpensive to fixGas treatmentHeterogenous catalyst chemical elementsRare-earth elementComposite oxide

The invention provides a manganese-copper based composite oxide doped rare earth element catalyst for catalyzing volatile organic compounds (VOCs) as well as a preparation method and application of the catalyst. The catalyst disclosed by the invention adopts a high-pore-volume cordierite honeycomb ceramic material as a carrier, and the carrier is sequentially coated with a first metal oxide coating layer, a second metal oxide coating layer and a third metal oxide coating layer from the inside to the outside, wherein the first metal oxide coating layer is active aluminum oxide, the second metaloxide coating layer is a hafnium-lanthanum-cerium oxide, and the third metal oxide coating layer is a manganese-copper based oxide. The catalyst provided by the invention adopts a non-precious metalinstead of a precious metal; and the catalyst provided by the invention has uniformly-dispersed coating layers, binding force between an active component and a matrix is strong, the coating layers arenot easy to fall or crack, and the catalyst can maintain higher activity under high-speed airflow and thermal shock, has stable activity when being used repeatedly, strong catalytic activity to the VOCs, a simple preparation process and low costs, and is suitable for large-scale production.

Owner:普利飞尔环保科技(上海)有限公司

Household socket and flame-retardant treatment process thereof

InactiveCN107868577AHigh affinityPrevent flocculationFireproof paintsContact member cases/bases manufactureEpoxyEmulsion

The invention discloses a household socket. The household socket comprises a socket box, wherein an insertion surface butted with a plug is arranged on the socket box; a cover body is also arranged onthe socket box; a protection layer is arranged on the inner wall of the cover body. The protection layer is prepared from the following components in parts by mass: 20-30 parts of organosilicone modified epoxy resin, 10-15 parts of a polyvinyl acetate emulsion, 0-15 parts of a plasticizer, 2-4 parts of a flame retardant, 5-8 parts of diatomite, 1-3 parts of pigments and fillers, 5-7 parts of a silane coupling agent, 4-6 parts of a curing agent, 0.5-1 part of a flame-retardant synergist, 0.1-0.5 part of an antioxidant and 0.2-0.4 part of composite rare earth. The flame-retardant treatment process is simple and is easy to operate; the treated socket has extremely high flame resistance; the service life of the socket is prolonged; and the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

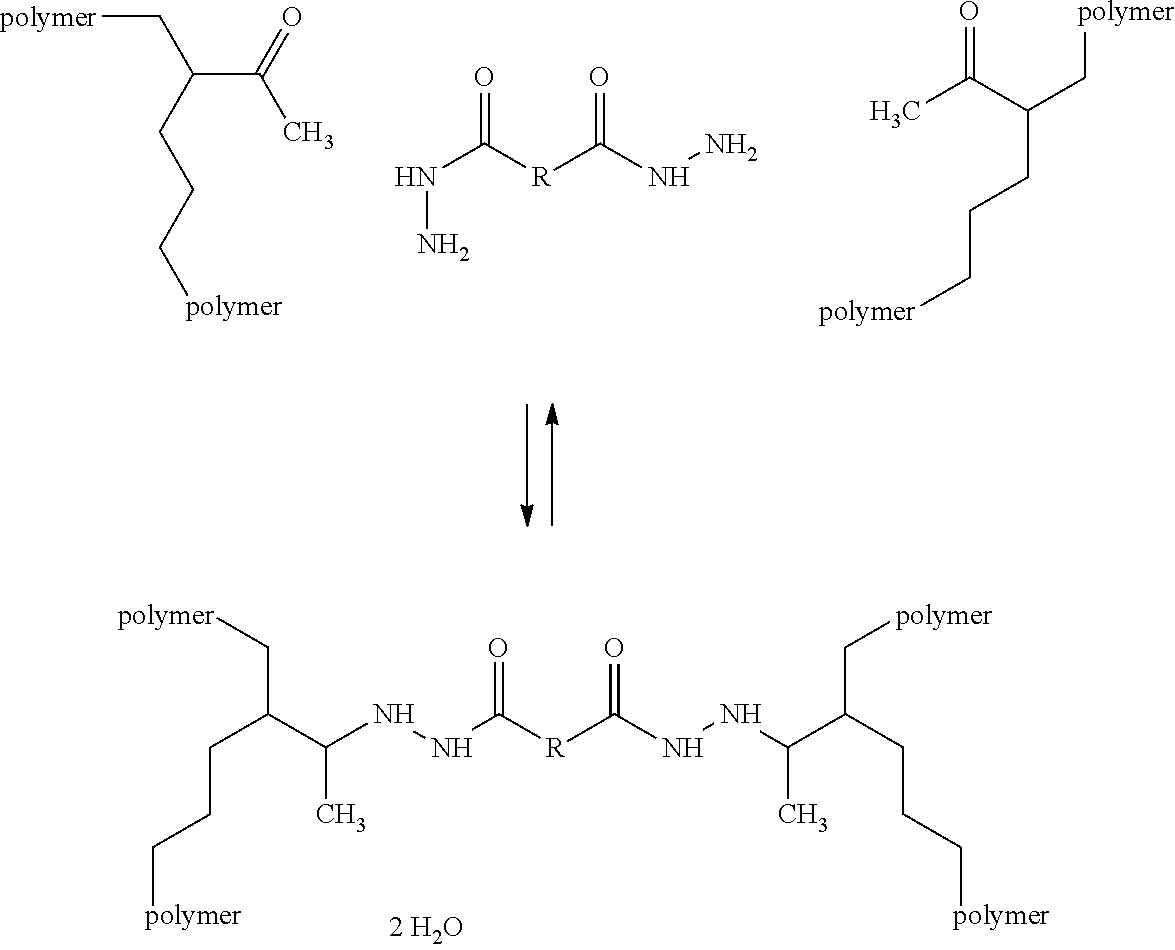

Aqueous coating composition and preparation thereof

ActiveUS20110124795A1Good lookingSimple structureThixotropic paintsPolyurea/polyurethane coatingsEtherPolyurea

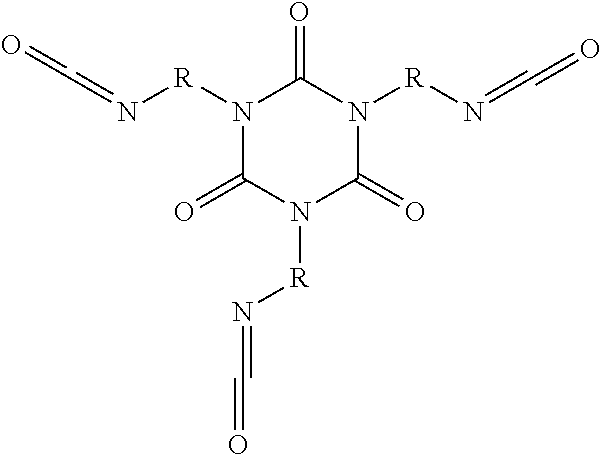

A process for the preparation of a thixotropic aqueous coating composition comprising the steps of: i) providing an aqueous dispersion of a binder system comprising carbonyl and hydrazide functional groups for crosslinking; and ii) reacting in the aqueous dispersion, an ether amine with a tris(isocyanate) isocyanurate to form a polyurea sag control agent.

Owner:ALLNEX NETHERLANDS BV

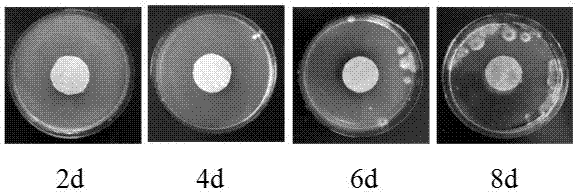

Sustained-release mildewproof/antibacterial and self-cleaning bifunctional casein-based nanometer microcapsule coating material and preparation method thereof

ActiveCN106883756AUniform size distributionNatural biocompatibilityAntifouling/underwater paintsPaints with biocidesOrganic solventAnti bacteria

The invention relates to a sustained-release mildewproof / antibacterial and self-cleaning bifunctional casein-based nanometer microcapsule coating material and a preparation method thereof. The preparation method comprises the following steps: adding casein powder into a weak acid solution, performing stirring dissolution and cooling to obtain a solution A, adding a mildewproof agent or antibacterial agent, polymeric micelles, tetrabutyl orthotitanate and a coupling agent into an organic solvent, performing stirring dissolution and cooling to obtain a solution B, and slowly adding the solution B into the solution A for continuous stirring, so as to obtain a target product. According to the material and the preparation method thereof, a mildewproof agent or antibacterial agent coated polymer-based inorganic composite nanometer microcapsule is prepared by adopting casein as a substrate, introducing the mildewproof agent or the antibacterial agent into a core layer and introducing an inorganic nanometer shell layer in a precursor hydrolysis manner, and is nanometer-scale, uniform in size distribution and controllable in size; the inorganic nanometer shell layer is nanometer titanium dioxide, and a coating self-cleaning effect can be achieved under ultraviolet irradiation, so that the material has mildewproof / antibacterial and self-cleaning bifunctionality.

Owner:SHAANXI UNIV OF SCI & TECH

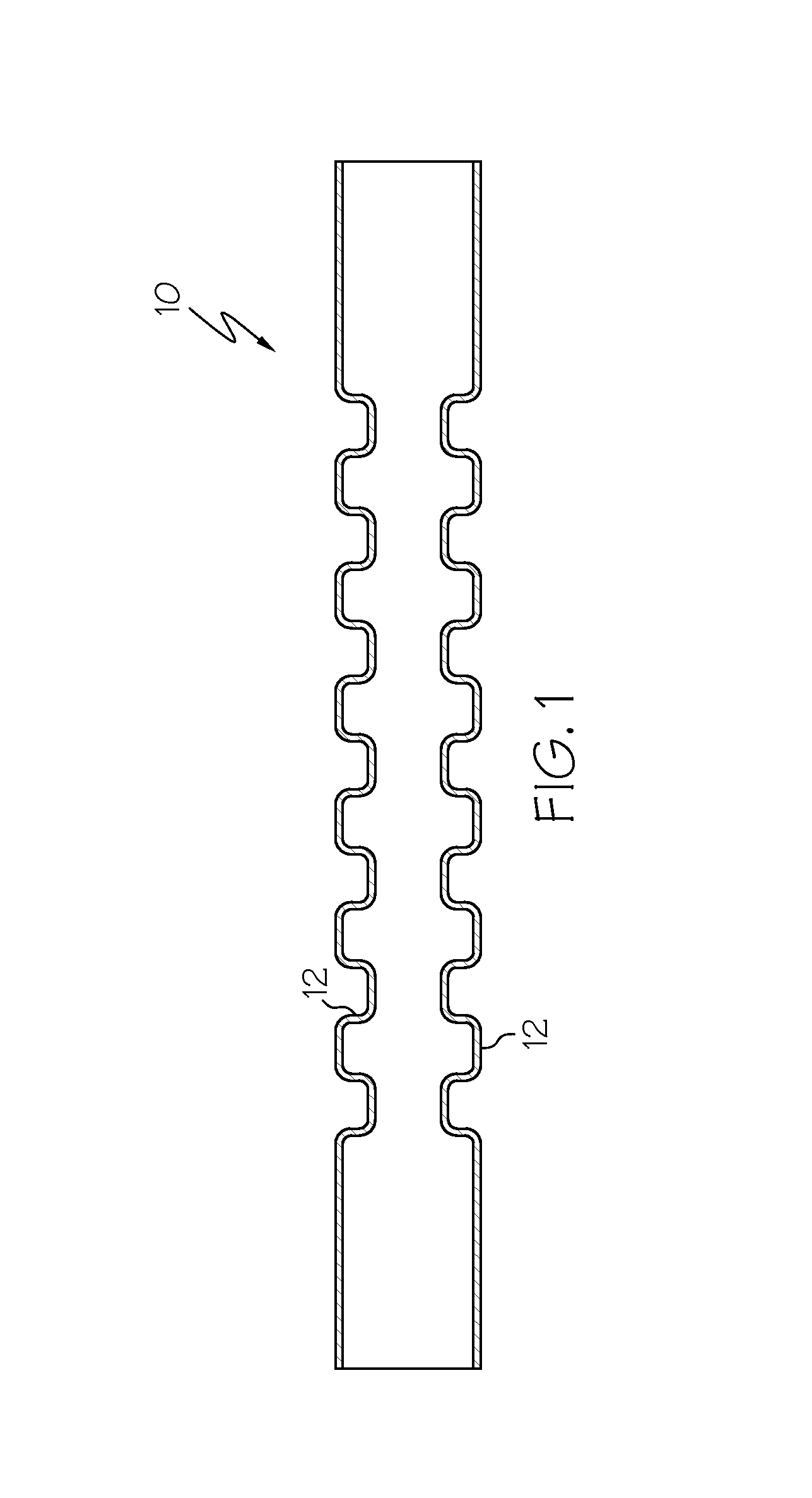

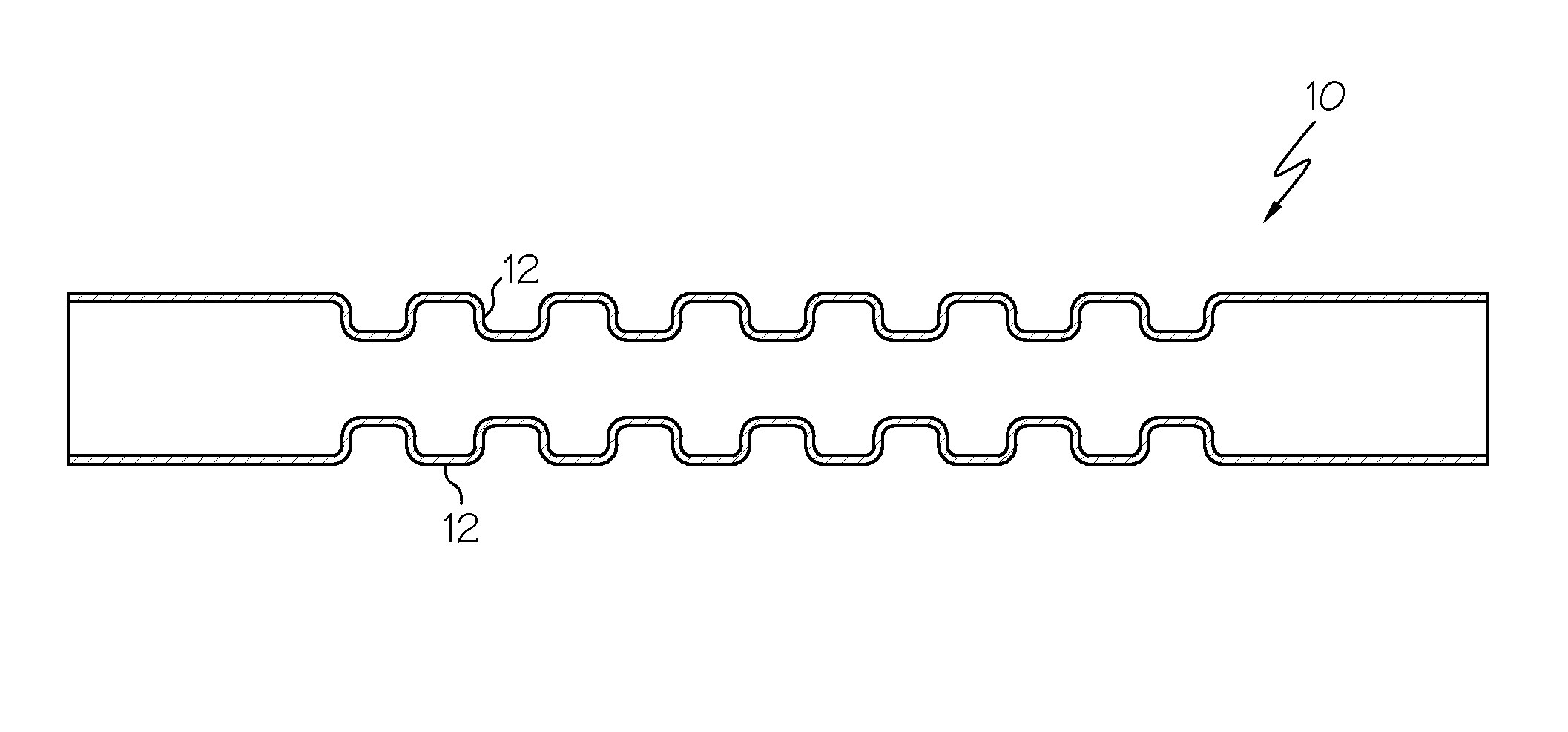

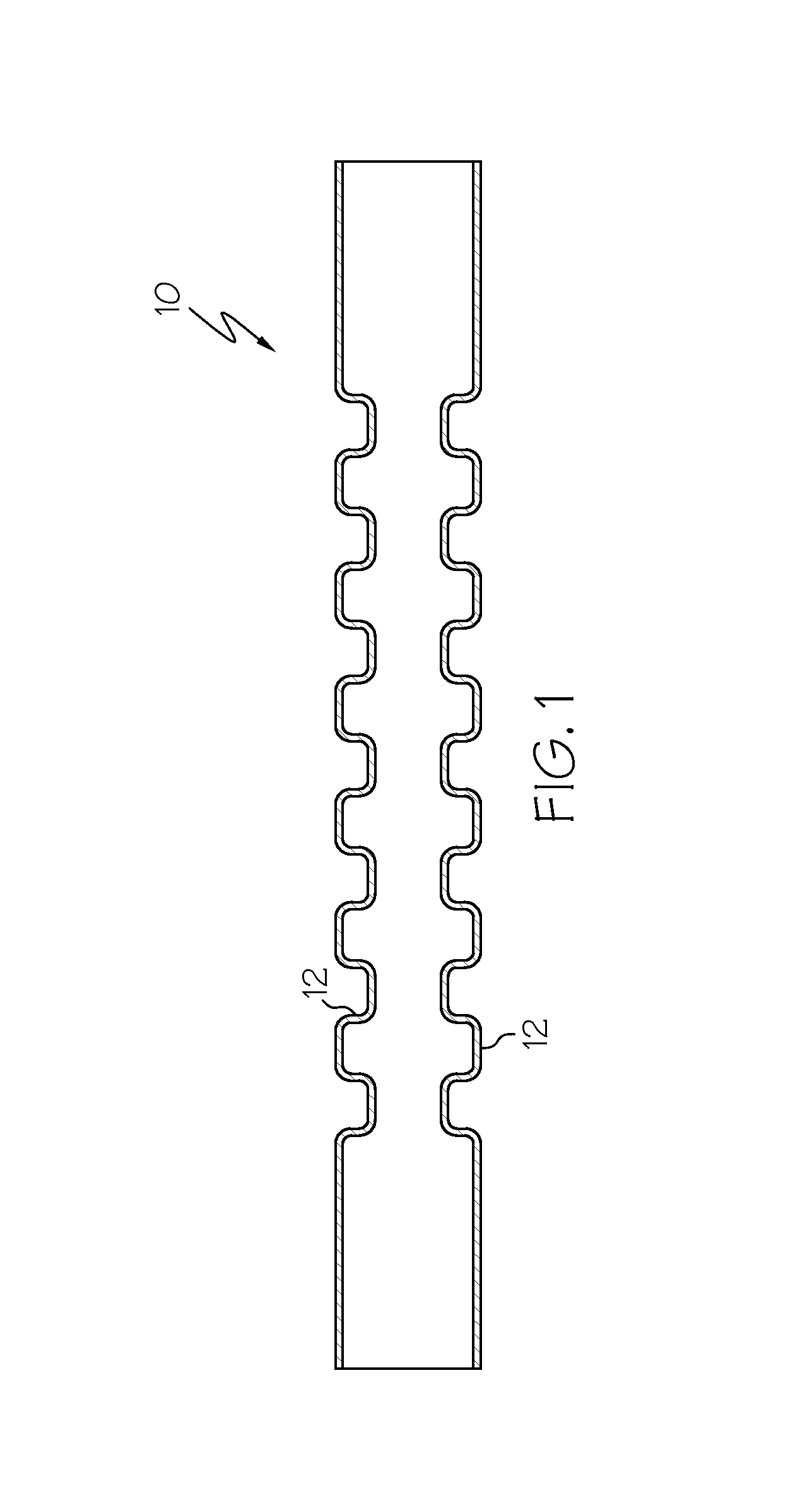

Method of depositing durable thin gold coating on fuel cell bipolar plates

ActiveUS8778562B2Increased durabilityReduce porosityElectrolytic coatingsElectrode carriers/collectorsPorosityFuel cells

A method of depositing a thin gold coating on bipolar plate substrates for use in fuel cells includes depositing a gold coating onto at least one surface of the bipolar plate substrate followed by annealing the gold coating at a temperature between about 200° C. to 500° C. The annealed gold coating has a reduced porosity in comparison with a coating which has not been annealed, and provides improved corrosion resistance to the underlying metal comprising the bipolar plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Coating liquid, film production method, production method of functional device, and functional device

InactiveUS7807741B2Excellent in stability and coating propertySuppress mutationLiquid surface applicatorsOrganic chemistryDiphenylmethaneDiphenyl ether

The present invention provides a coating liquid which is excellent in stabilities and capable of being stably ejected by an ejection equipment and suppressing variation in film thickness inside a film or between films, in application for various uses, a film production method, a production method of a functional device, and a functional device, using the coating liquid. The present invention is a coating liquid comprising a mixed solvent and a functional material, wherein the mixed solvent comprises a first solvent constituted by a compound having two or more aromatic rings such as diphenyl sulfide, diphenylmethane, diphenyl ether, and a symmetric structure and another solvent constituted by a compound having an aromatic ring such as xylene, and a proportion by volume of the another solvent is 90% or less in the mixed solvent.

Owner:SHARP KK

Method of depositing durable thin gold coating on fuel cell bipolar plates

ActiveUS20130330654A1Increased durabilityReduce porosityMaterial nanotechnologyElectrolytic coatingsPorosityFuel cells

A method of depositing a thin gold coating on bipolar plate substrates for use in fuel cells includes depositing a gold coating onto at least one surface of the bipolar plate substrate followed by annealing the gold coating at a temperature between about 200° C. to 500° C. The annealed gold coating has a reduced porosity in comparison with a coating which has not been annealed, and provides improved corrosion resistance to the underlying metal comprising the bipolar plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Binder solution for anode, active material slurry for anode comprising the binder solution, anode using the slurry and electrochemical device comprising the anode

ActiveUS9515321B2Increased durabilityImprove life characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumCross-link

The present disclosure relates to a binder solution for an anode, comprising a thermally cross-linkable polymer binder that is cross-linked by heat, and a solvent for dissolving the thermally cross-linkable polymer binder, and exhibiting a concentration of hydrogen ions corresponding to pH 2.5 to pH 4.5; an active material slurry for an anode, comprising the binder solution; an anode using the slurry; and an electrochemical device comprising the anode. The binder solution for an anode according to one aspect of the present disclosure can relieve the volume expansion of an anode active material by the intercalation and disintercalation of lithium during cycles of electrochemical devices to improve the durability of an anode active material layer, thereby enhancing the life characteristics of the electrochemical devices, and also can provide good dispersibility to the active material slurry for an anode, thereby improving the coating stability of an anode active material layer.

Owner:LG ENERGY SOLUTION LTD

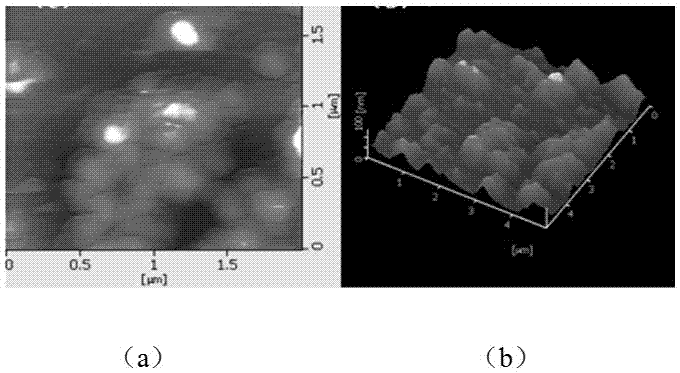

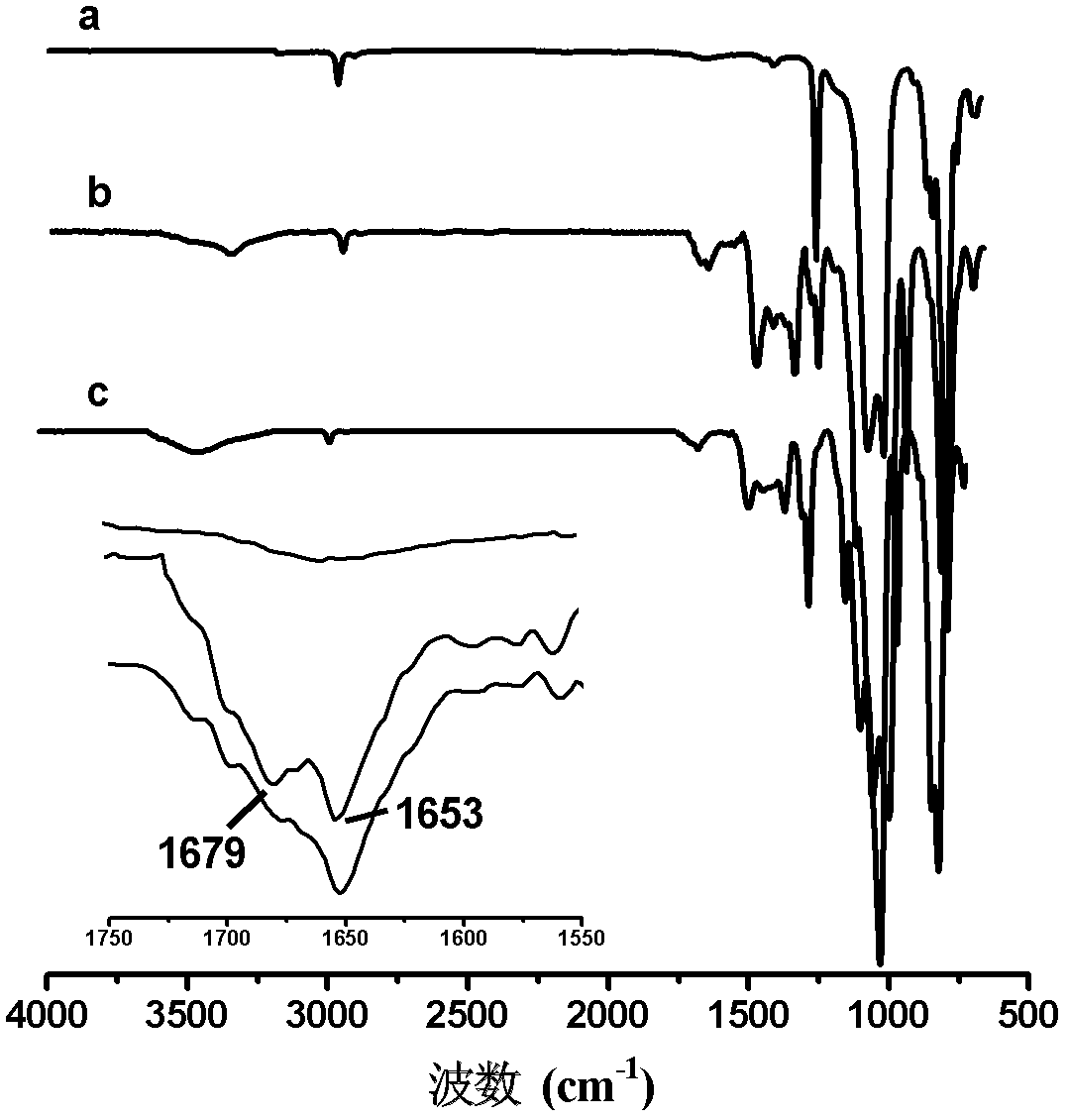

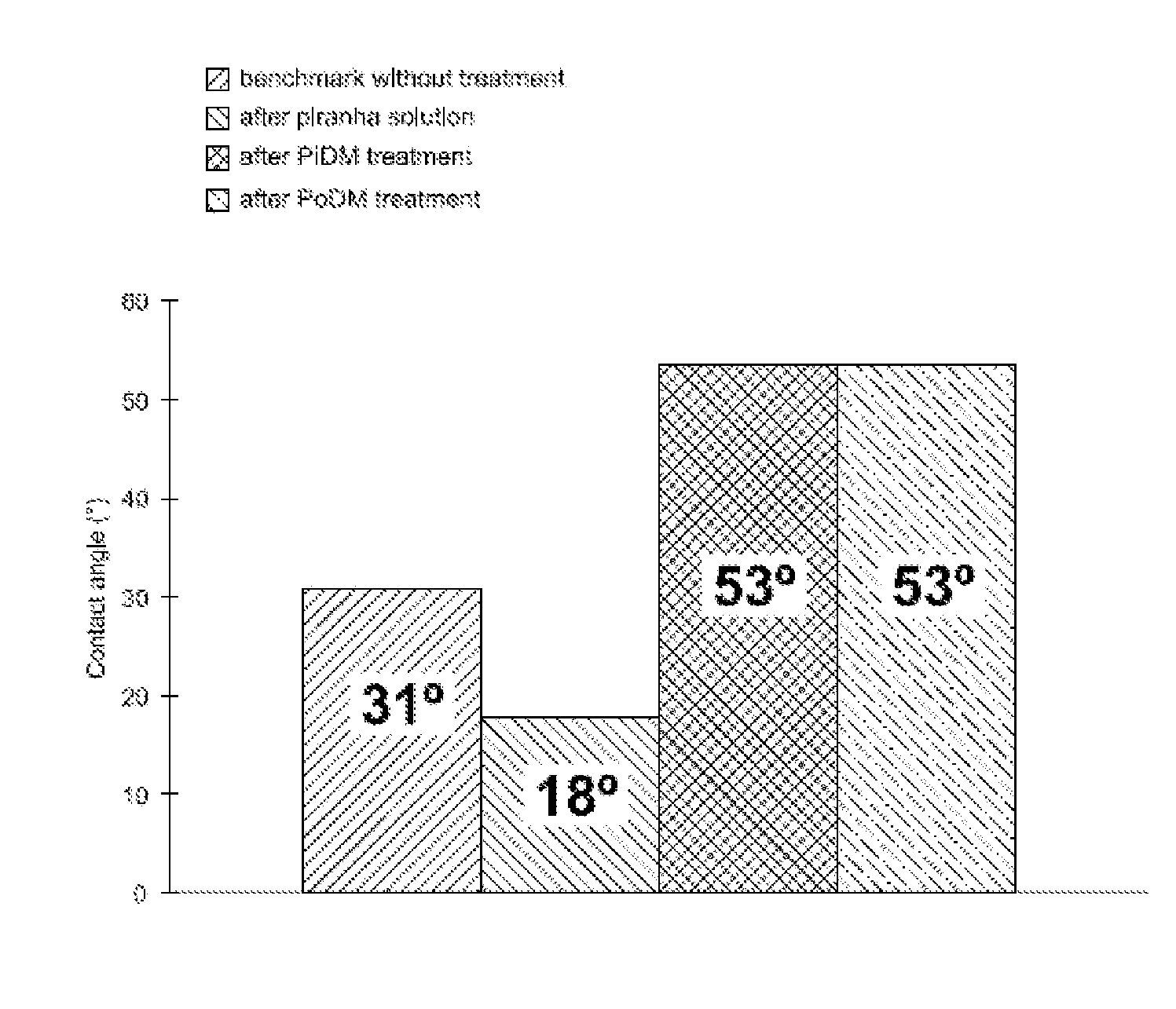

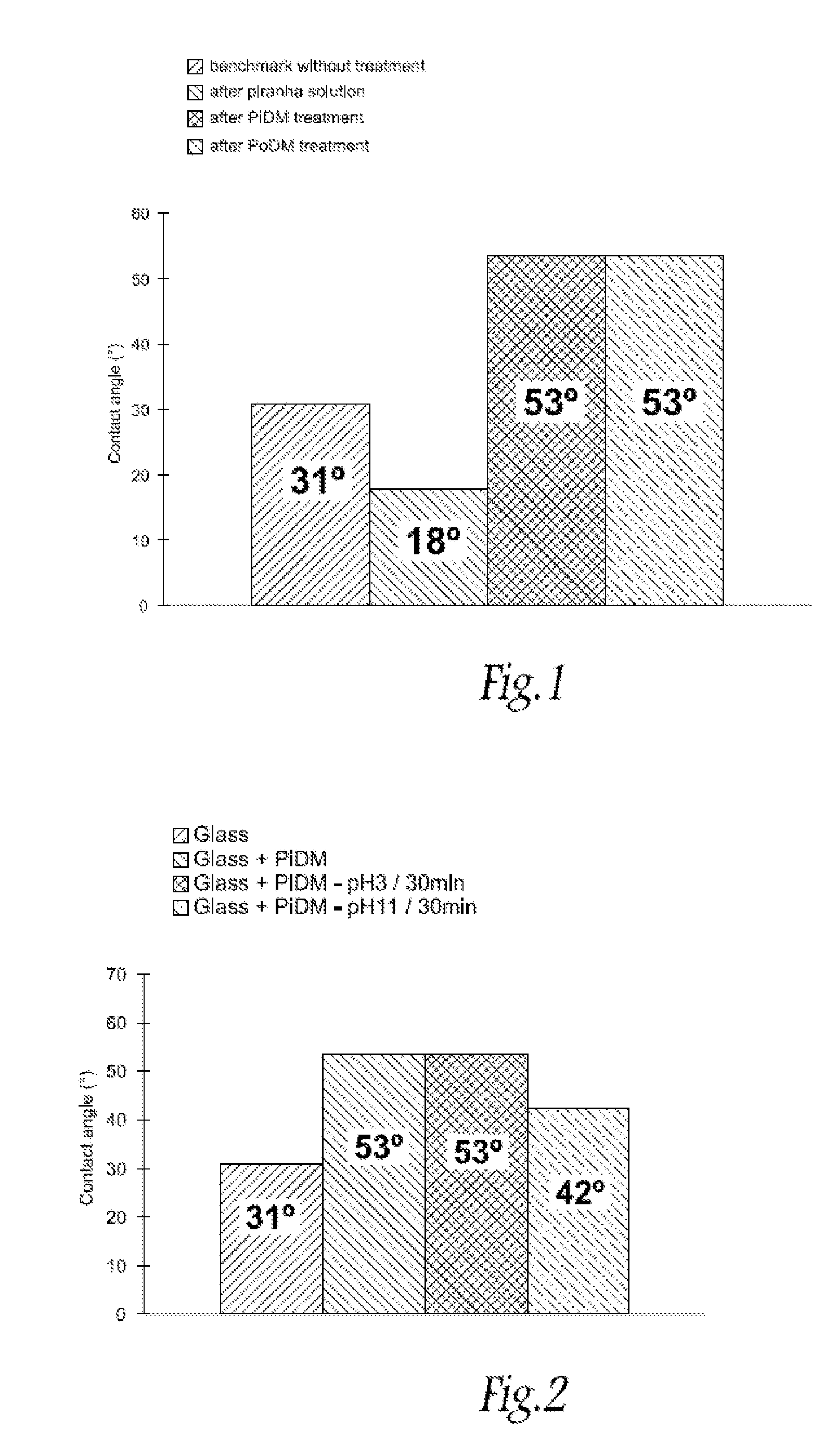

Polydimethylsiloxane surface modification method based on hydrophobin/methylcellulose

InactiveCN103772728AImprove coating stabilityImprove surface hydrophilicityAntifouling/underwater paintsPaints with biocidesMethyl cellulosePolydimethylsiloxane

The invention discloses a polydimethylsiloxane surface modification method based on hydrophobin / methylcellulose. The hydrophobin SC3 and the methylcellulose are used as the surface modifier to be physically adsorbed onto the surface of a micropassage of the polydimethylsiloxane to form an amphipathic monomolecular film, then a chip passage is heated, so that the structure conversion of the hydrophobin SC3 can be induced by the methylcellulose, and a stable amphipathic monomolecular film is formed on the surface of the micropassage of the polydimethylsiloxane. By adopting the method, the coating stability of the polydimethylsiloxane can be improved, the surface hydrophily of the passage can be improved, the non-specificity adsorption of the protein on the surface of the micropassage can be effectively prevented, the antipollution capacity of the surface of the polydimethylsiloxane can be improved, and the high-efficiency reproducibility and separation of an analyzed substance can be realized.

Owner:SHAANXI NORMAL UNIV

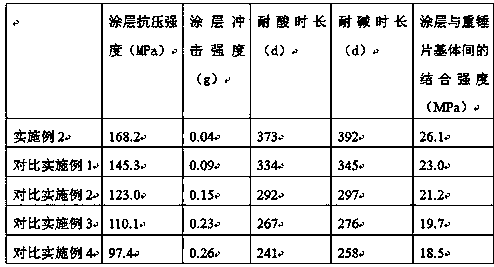

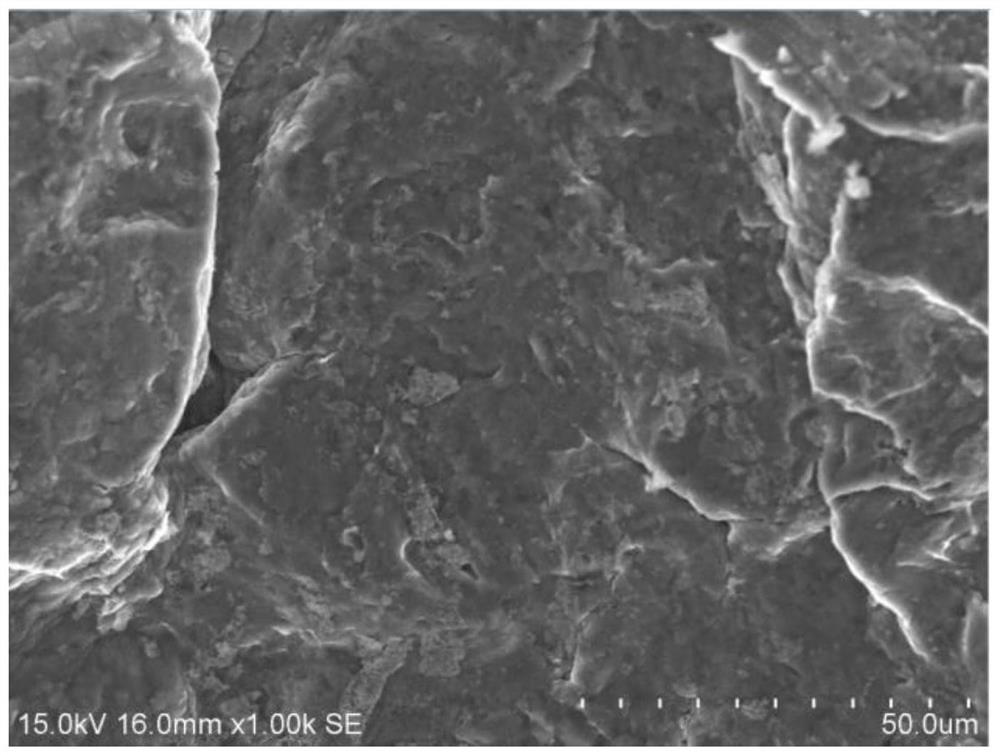

Surface enhancement treatment method for heavy hammer sheet

InactiveCN110605226AImprove the use effect and lifeIncrease roughnessPretreated surfacesAnti-corrosive paintsPlasma treatmentSurface finishing

The invention discloses a surface enhancement treatment method for a heavy hammer sheet. The method comprises the following steps of (1) surface cleaning treatment; (2) shot blasting treatment; (3) surface plasma treatment; and (4) coating spraying and covering treatment. According to the surface enhancement treatment method for the heavy hammer sheet, the surface enhancement treatment method forthe heavy hammer sheet is simple in overall process and easy to popularize and apply, the treated heavy hammer sheet has the advantages that the mechanical property is good, the corrosion resistance is high, the anti-aging capability is strong, the coating stability is high, and the comprehensive service life is remarkably prolonged.

Owner:安徽省含山县兴建铸造厂

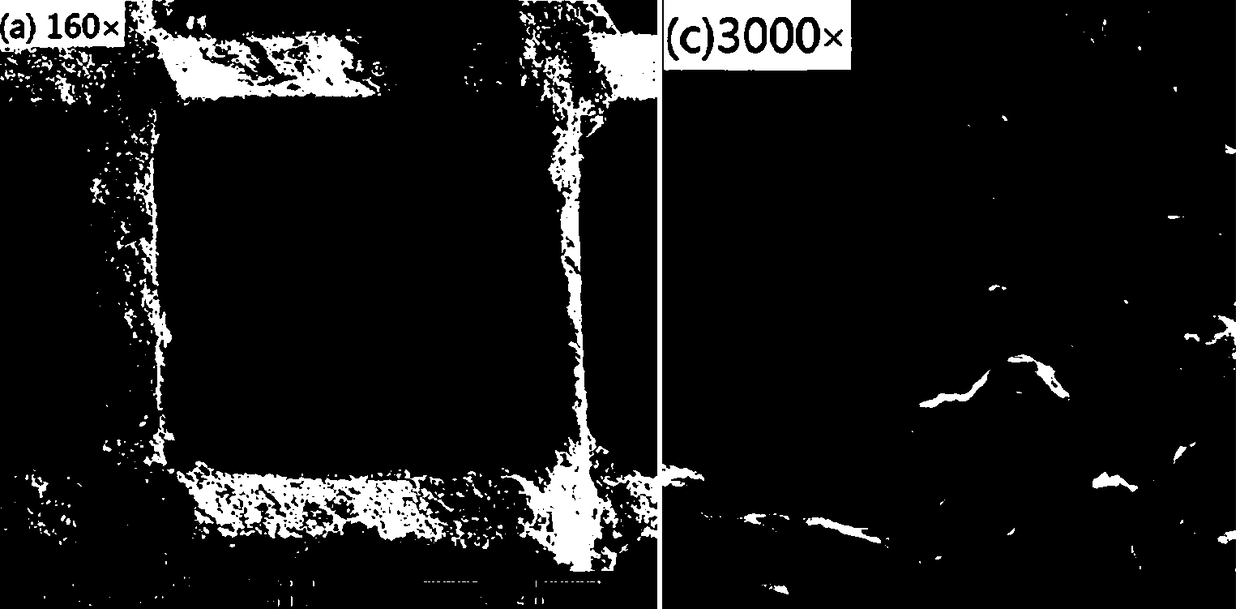

Magnetic recording medium and method of manufacturing same

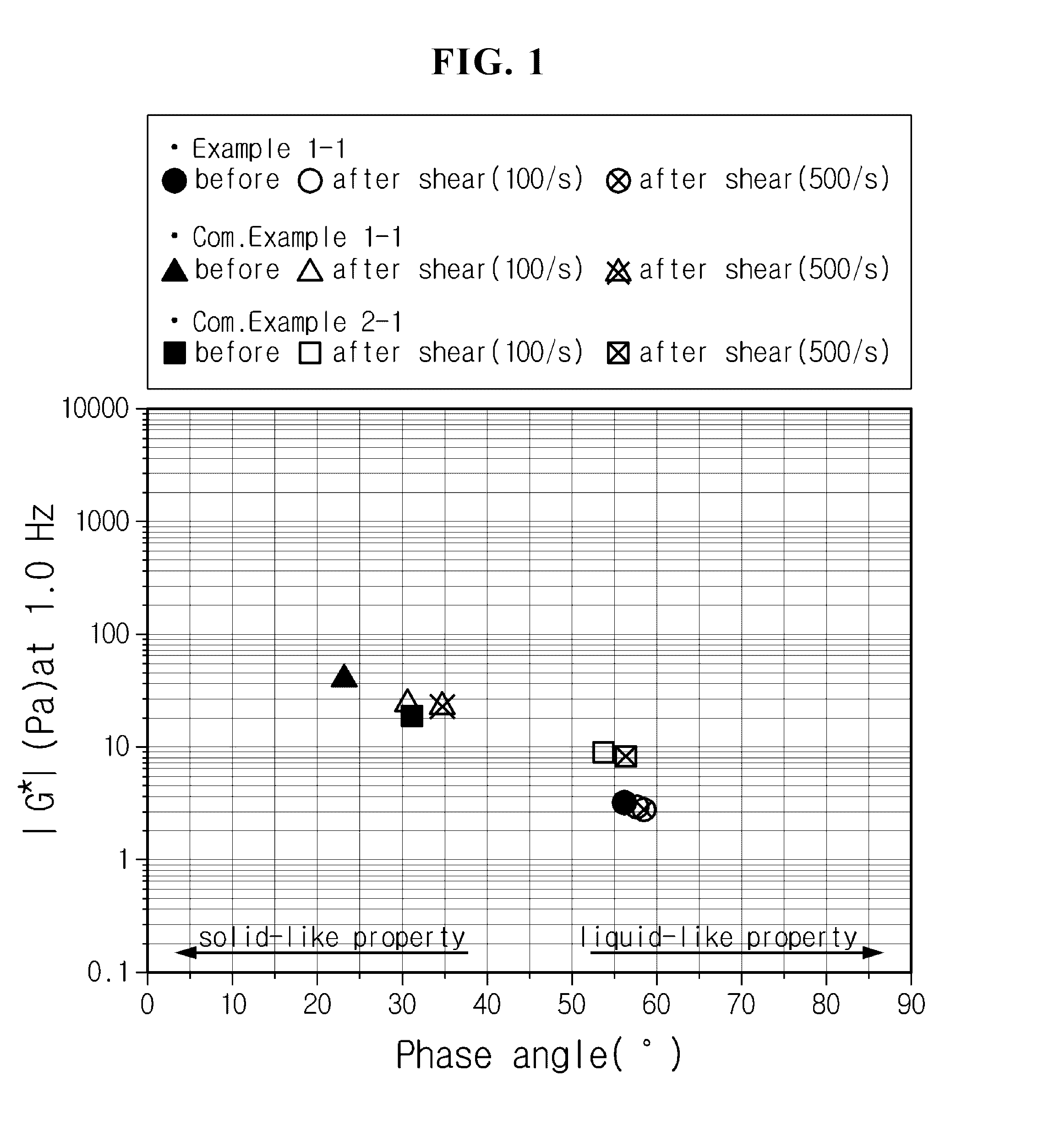

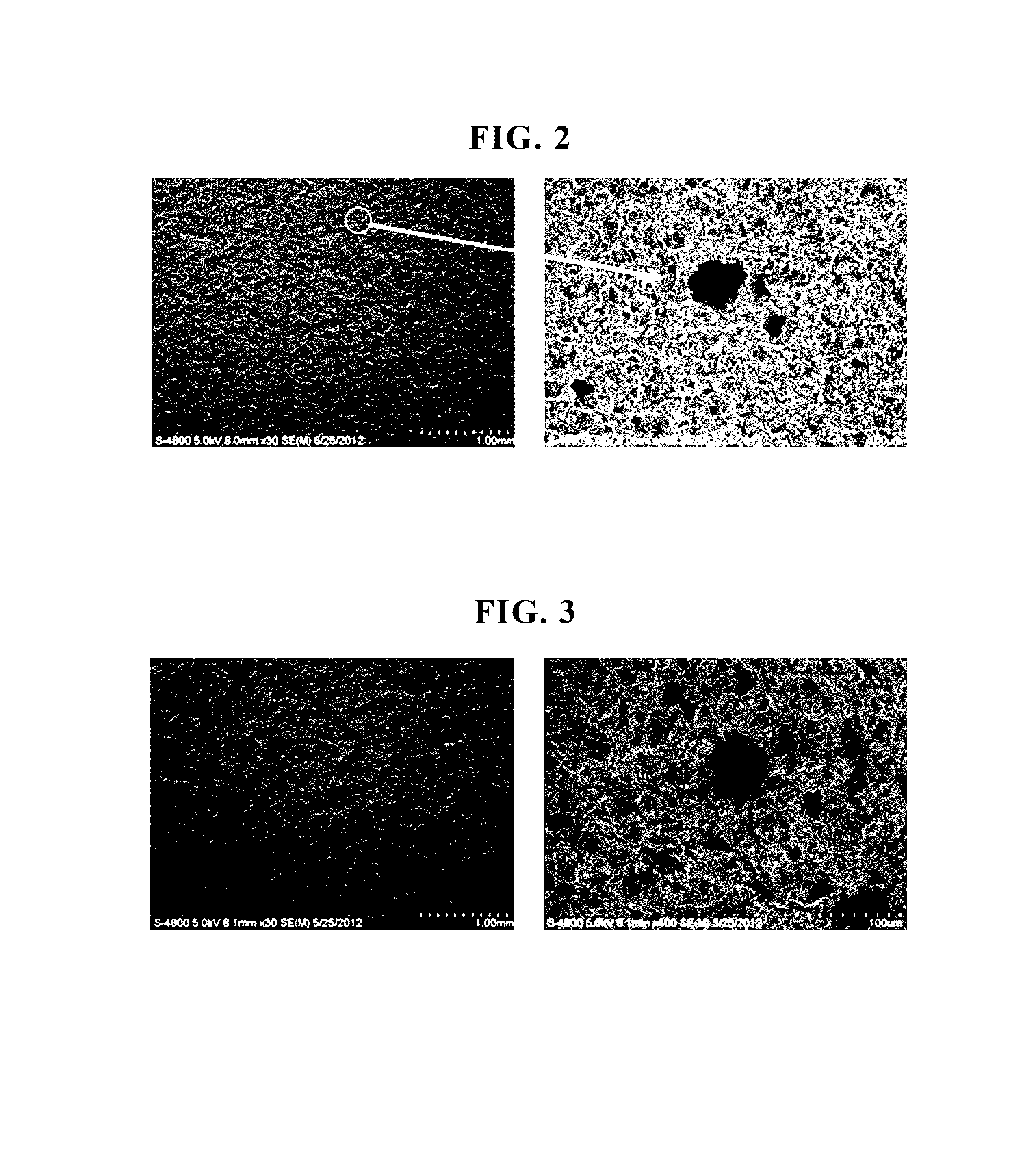

InactiveUS20020037436A1Good dispersionImprove coating stabilityMagnetic materials for record carriersLayered productsSolid componentParticulates

Enclosed is a magnetic recording medium obtained by sequentially providing on a flexible nonmagnetic support a nonmagnetic layer comprising a nonmagnetic powder and a binder and a magnetic layer comprising a ferromagnetic powder and a binder. The thickness of the magnetic layer is 0.01-0.1 mum and the ratio of the exposed area of nonmagnetic power on the surface of the magnetic layer is not greater than 10 percent. A method of manufacturing a magnetic recording medium comprising coating a nonmagnetic layer coating liquid on a flexible nonmagnetic support and applying a magnetic layer coating liquid on the coated layer while the coated layer is still wet. The ratio of the exposed area of nonmagnetic power on the surface of the magnetic layer is not greater than 10 percent; the nonmagnetic layer coating liquid has a yield stress of not less than 100 muN / cm2 or 10 dyne / cm2 and the solid component concentration of the magnetic layer coating liquid is greater than the solid component concentration of the nonmagnetic layer coating liquid. A particulate magnetic recording medium having a magnetic layer of not greater than 0.1 mum, good production properties, and good electromagnetic characteristics when used with MR heads is provided.

Owner:FUJIFILM CORP

Method for modifying polydimethylsiloxane by hydrophobic coating self-assembly by using ion complementary peptide

InactiveCN104497334AImprove adsorption capacityInhibition of non-specific adsorptionLaboratory glasswaresCoatingsAnalyteDodecyl-beta-D-maltoside

The invention discloses a method for modifying polydimethylsiloxane by hydrophobic coating self-assembly by using an ion complementary peptide, which comprises the following steps: by using an ion complementary peptide EAR16-II or ion complementary peptide EAR16-II, methyl cellulose and dodecyl-beta-D-maltoside as a surface modifier, carrying out physical adsorption to perform self-assembly on the polydimethylsiloxane microchannel surface so as to form a stable hydrophobic film; and in the presence of saccharide derivatives, changing the configuration of the EAR16-II to form the more stable beta-folding self-assembled hydrophobic film. The method can effectively inhibit the non-specific adsorption of the protein to the microchannel surface, enhances the surface anti-pollution capacity and biological compatibility of the polydimethylsiloxane, and implements high-efficiency recurrent separation of the analyte.

Owner:SHAANXI NORMAL UNIV

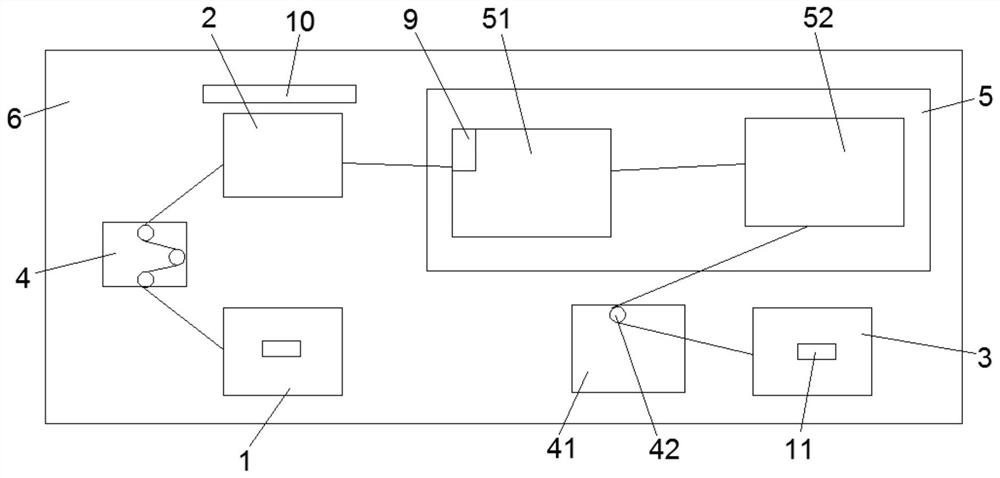

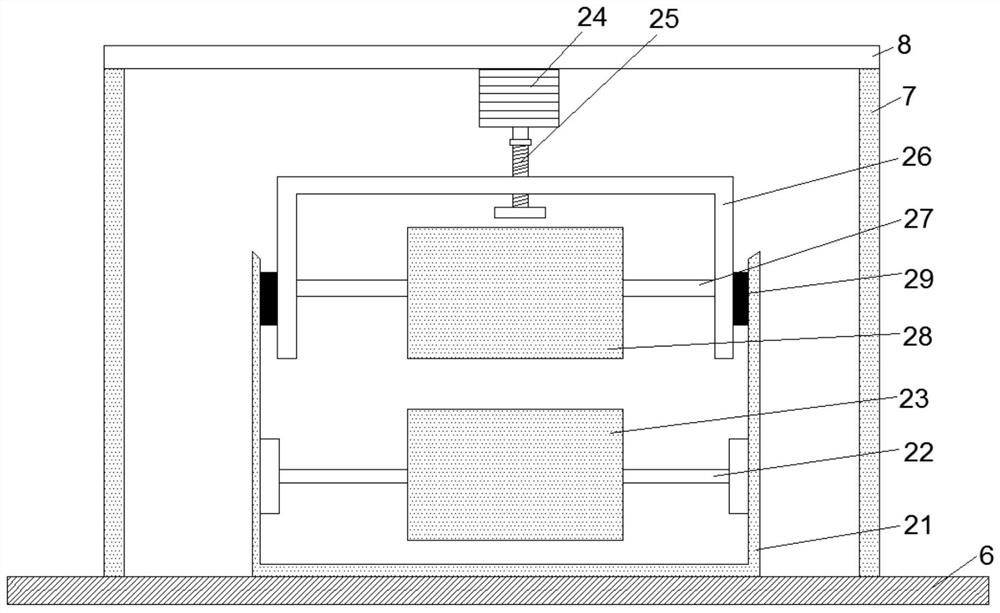

Multifunctional coating machine

PendingCN112517315AWide range of applicationsImprove stabilityLiquid surface applicatorsCoatingsPhysicsPaper sheet

The invention discloses a multifunctional coating machine. The multifunctional coating machine comprises an unwinding device, a coating device and a winding device which are sequentially arranged, traction devices are arranged between the unwinding device and the coating device and between the coating device and the winding device, and a drying device is further arranged between the coating deviceand the winding device. The drying device comprises a preheating oven and a drying box which are arranged in sequence. The coating device comprises a trough, first rotating shafts are installed at the positions, close to the bottom, of the inner walls of the two sides of the trough through bearings, liquid feeding rollers sleeve the first rotating shafts, the trough is arranged on a workbench, alifting block is arranged on a lead screw, a second rotating shaft is arranged in the middle of the lifting block, and a pressing roller sleeves the second rotating shaft. Moving rails are arranged atthe positions, close to the lifting block, in the two sides of the trough, limiting plates are arranged on the two sides of the lifting block, and the limiting plates can move in the moving rails. The multifunctional coating machine is simple in structure and good in gluing effect and can be suitable for coating of paper with different thicknesses, and meanwhile the rate of finished products canbe increased through the arranged drying device.

Owner:江苏精屯机电设备有限公司

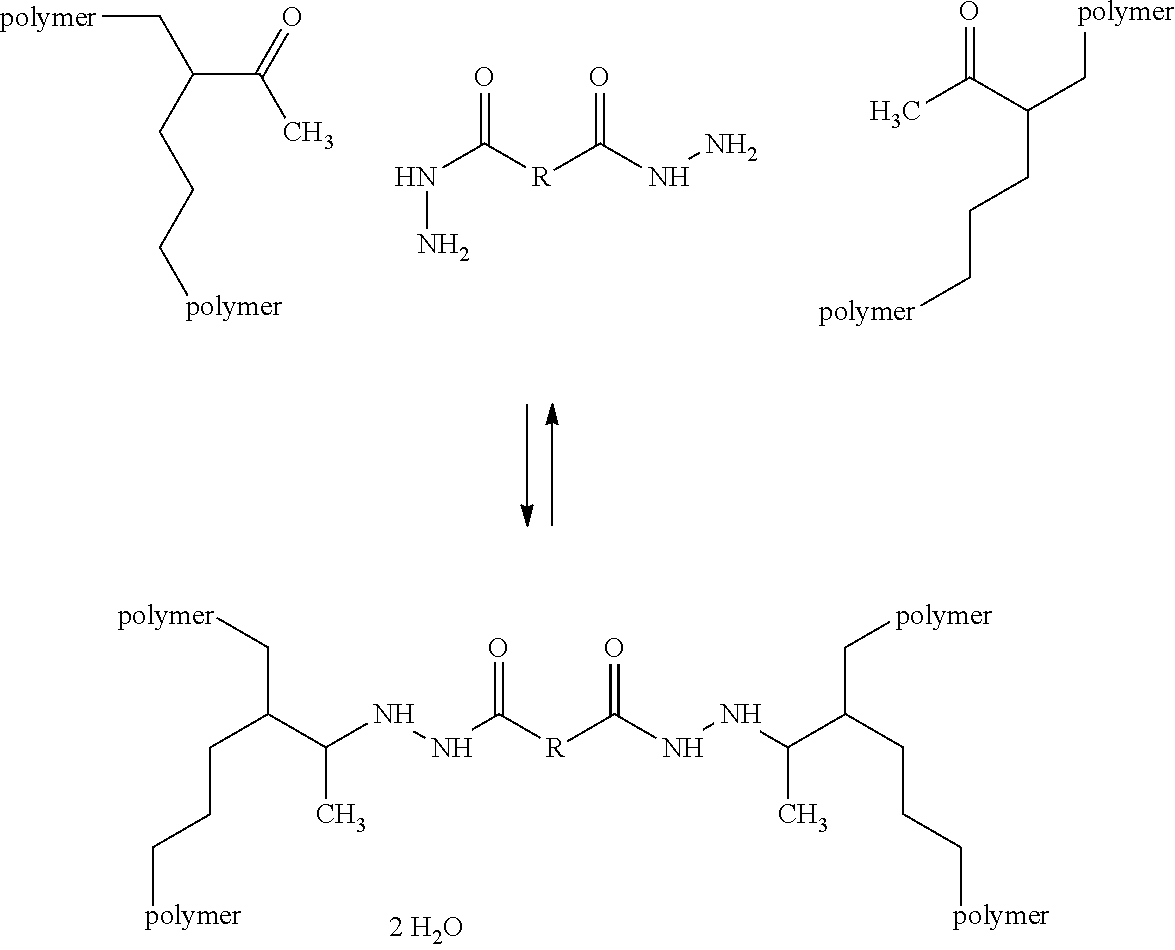

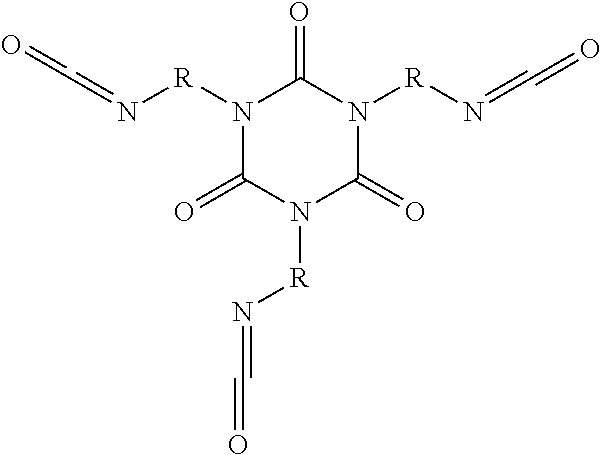

Aqueous coating composition and preparation thereof

ActiveUS9023942B2Good lookingSimple structureThixotropic paintsPolyurea/polyurethane coatingsEtherPolyurea

A process for the preparation of a thixotropic aqueous coating composition comprising the steps of: i) providing an aqueous dispersion of a binder system comprising carbonyl and hydrazide functional groups for crosslinking; and ii) reacting in the aqueous dispersion, an ether amine with a tris(isocyanate) isocyanurate to form a polyurea sag control agent.

Owner:ALLNEX NETHERLANDS BV

Lithium-ion secondary battery

ActiveUS20170237121A1Improve coating stabilityImprove stabilityCell electrodesSecondary cellsLithiumOxide coating

A lithium-ion secondary battery of the present invention includes a cathode including an electrode material having electrode active material particles and an oxide coat and a carbonaceous film which coat surfaces of the electrode active material particles, an anode including a carbon-based active material, and an electrolytic solution, and the electrolytic solution does not substantially include additives for stabilizing a coat formed on a surface of the anode.

Owner:SUMITOMO METAL MINING CO LTD

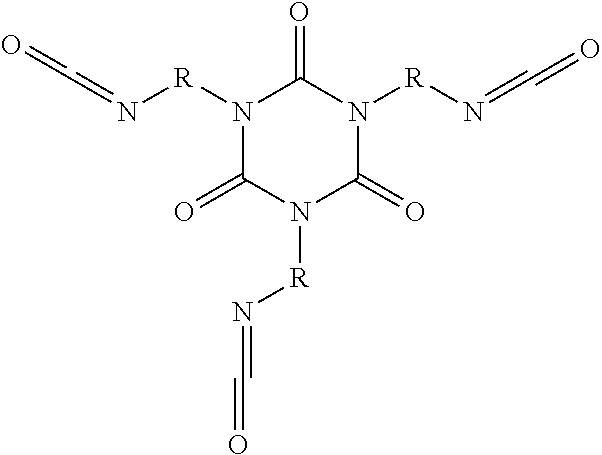

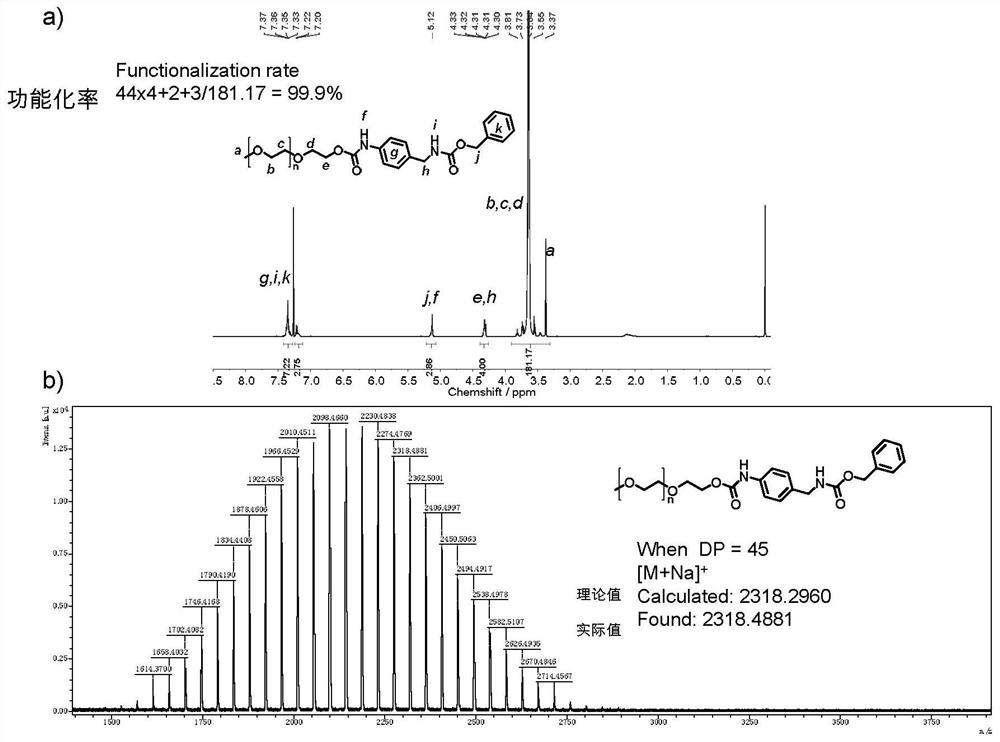

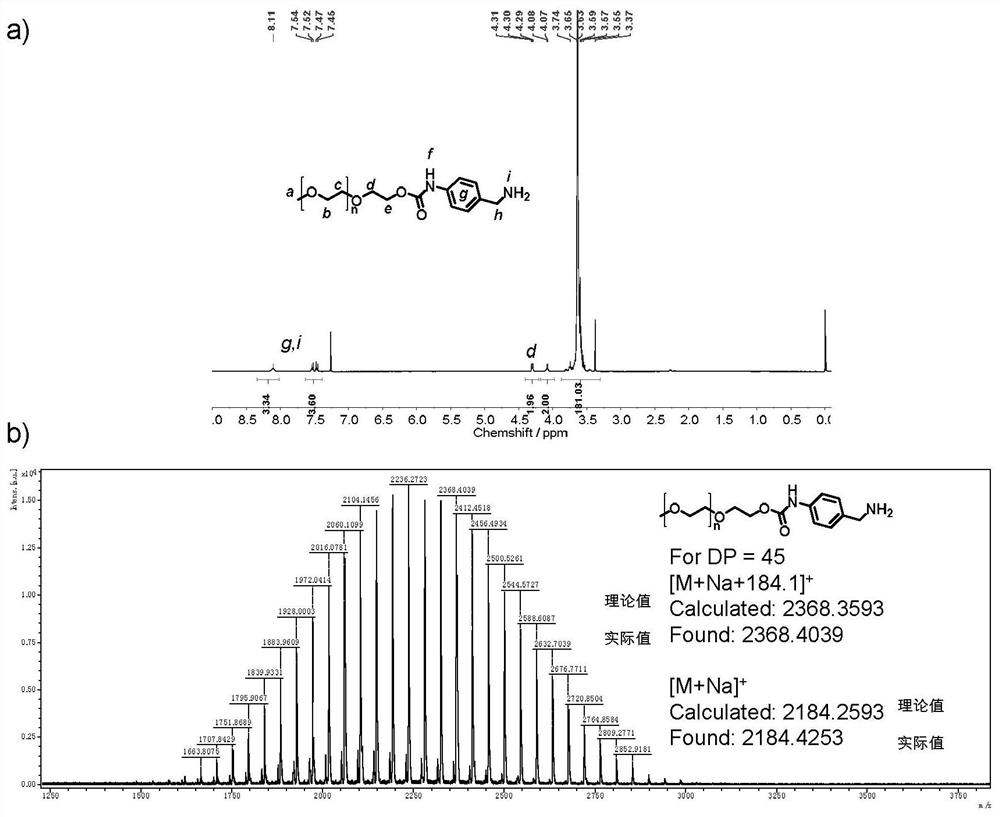

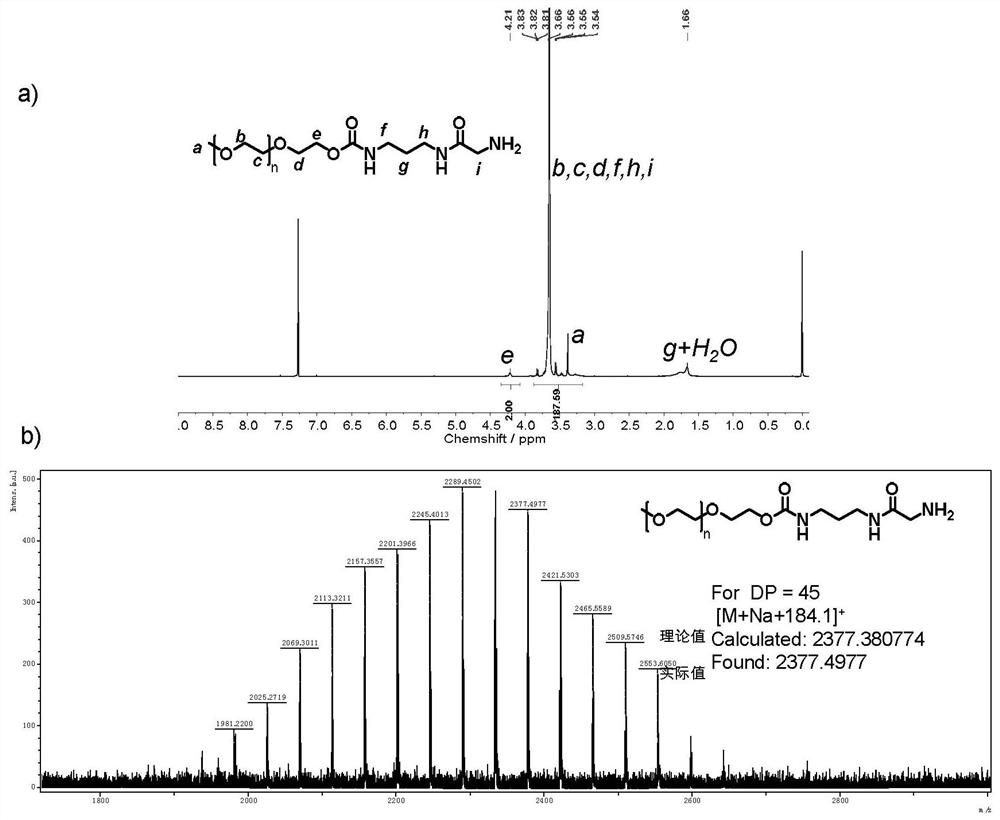

Hydroxyl compound terminal modified functional group and method for modifying hydroxyl compound by using hydroxyl compound terminal modified functional group

PendingCN113831265AImprove the modification rateImprove stabilityCarbamic acid derivatives preparationOrganic compound preparationPolymer sciencePolyethylene terephthalate glycol

The invention provides a hydroxyl compound terminal modified functional group and a method for modifying a hydroxyl compound by using the hydroxyl compound terminal modified functional group. Specifically, the modified functional group is a functional group molecule containing acyl azide or a functional group molecule containing isocyanate converted from the functional group molecule. The modified functional group reacts with terminal hydroxyl groups of polyethylene glycol (PEG), polylactic acid (PLA), polycaprolactone (PCL), polycarbonate (PC) or polyethylene glycol terephthalate (PET) compounds with various topological structures, and a terminal functionalized product containing stable carbamate connection is obtained. Compared with hydroxyl esterification or etherification modification which is mostly researched at present, the method disclosed by the invention is thorough in reaction, short in reaction time and high in functionalization rate, the functionalization rate is greater than 99%, and the obtained functionalized product is high in stability.

Owner:UNIV OF SCI & TECH OF CHINA

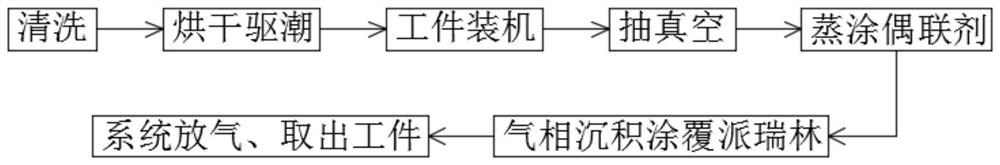

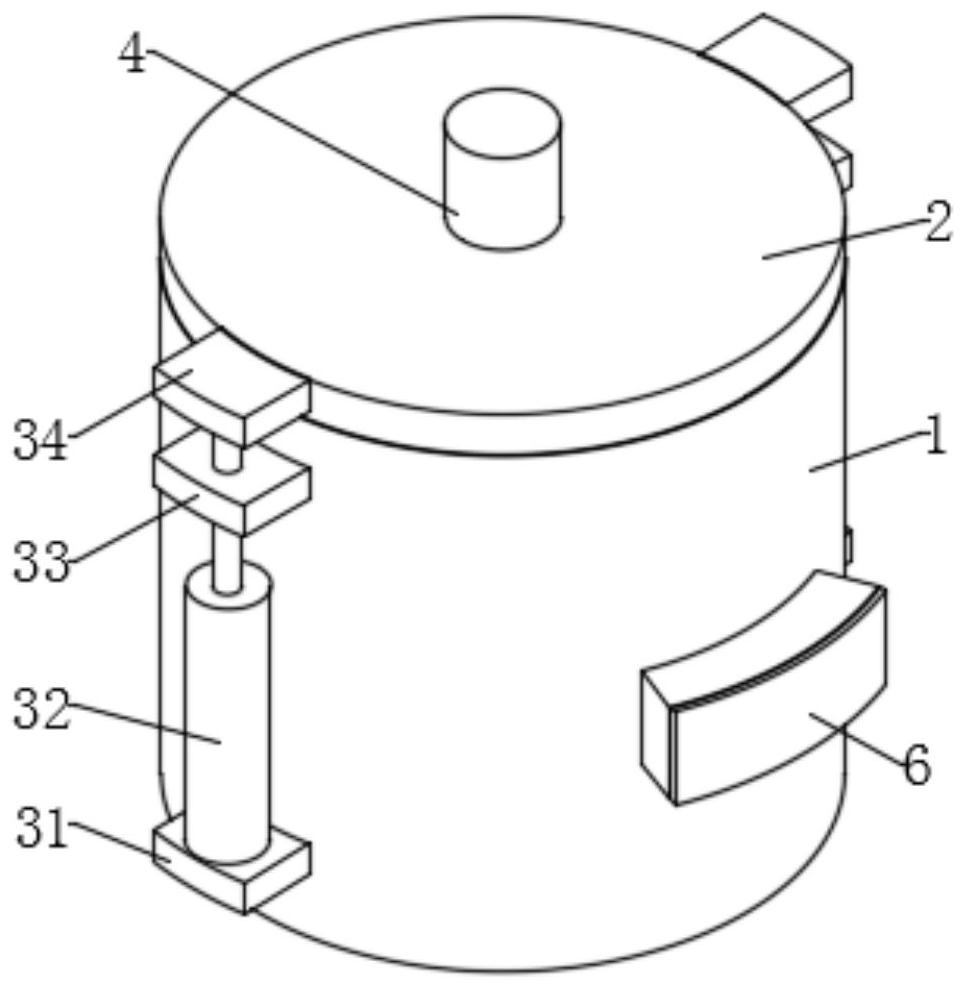

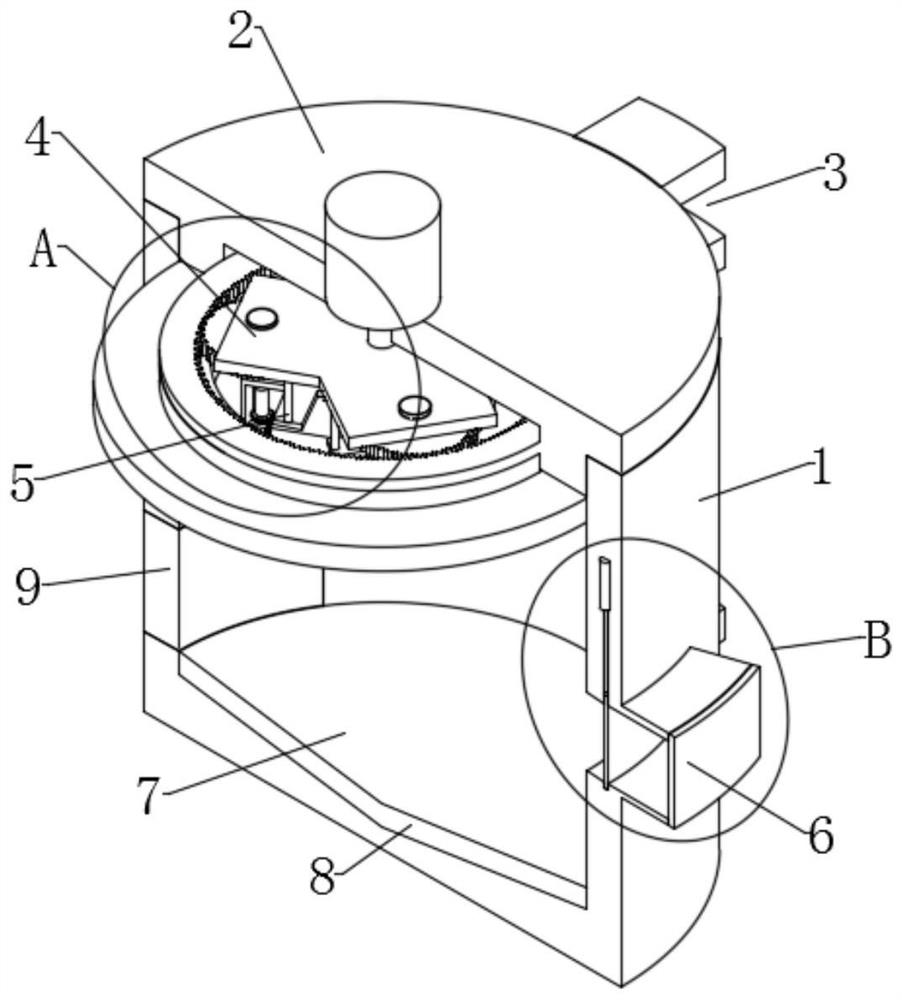

Process for improving adhesive force of coating layer

ActiveCN114260155AImprove adhesionEvenly distributedLiquid surface applicatorsCoatingsParylene coatingClean water

The invention discloses a process for improving the adhesive force of a coating layer, belongs to the technical field of vapor deposition, and aims to solve the problems that the existing parylene coating layer is low in adhesive force and easy to fall off due to non-uniform adhesion of a coupling agent in the early stage and non-uniform thickness of the coating layer during vapor deposition. Putting the workpiece into a drying oven, and drying and cleaning water vapor adsorbed on the surface of the workpiece; putting the workpiece into an evaporation reaction tank of a coating machine; sealing the reaction tank, vacuumizing to adsorb the silane coupling agent through the sponge, putting the sponge into the reaction tank, and carrying out coupling agent evaporation coating according to the requirements of a coating machine; adding parylene into the reaction tank, and carrying out vapor deposition to coat parylene according to the requirements of a coating machine; deflating the system and taking out the workpiece. The silane coupling agent is adsorbed through the sponge, the distribution area is increased, steam is evenly distributed in the reaction tank cavity, the coupling agent is evenly coated on the surface of a workpiece in an evaporation mode, then parylene is coated in a vapor deposition mode, and the adhesive force of a coating layer is improved.

Owner:SHENZHEN SHANHELE TECH DEV

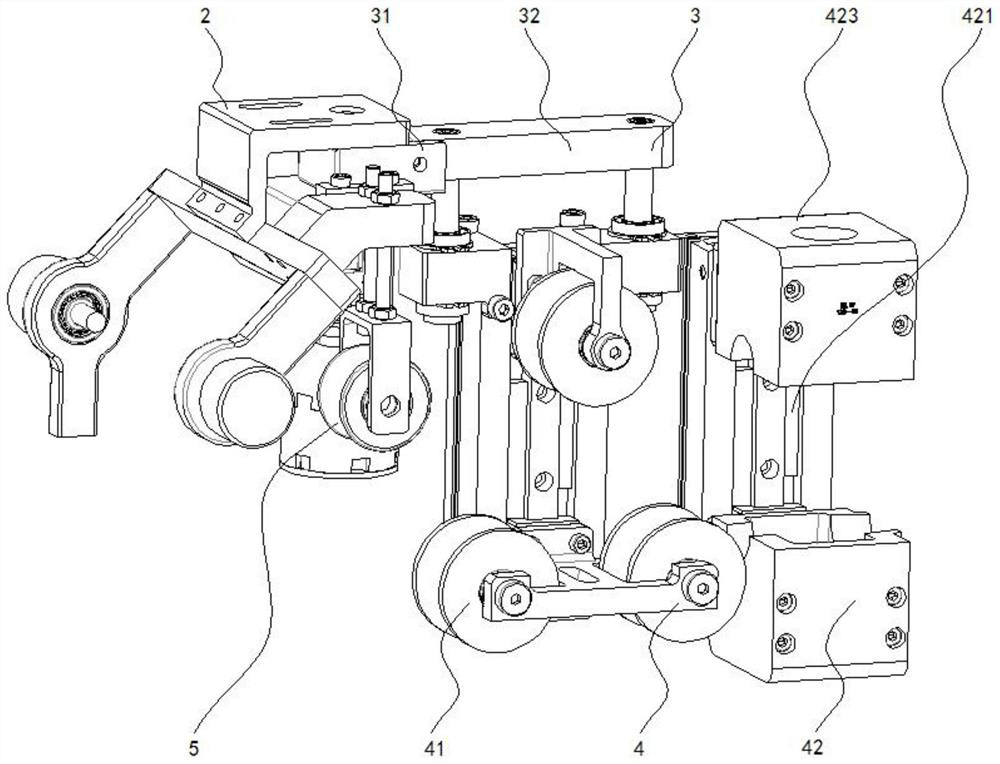

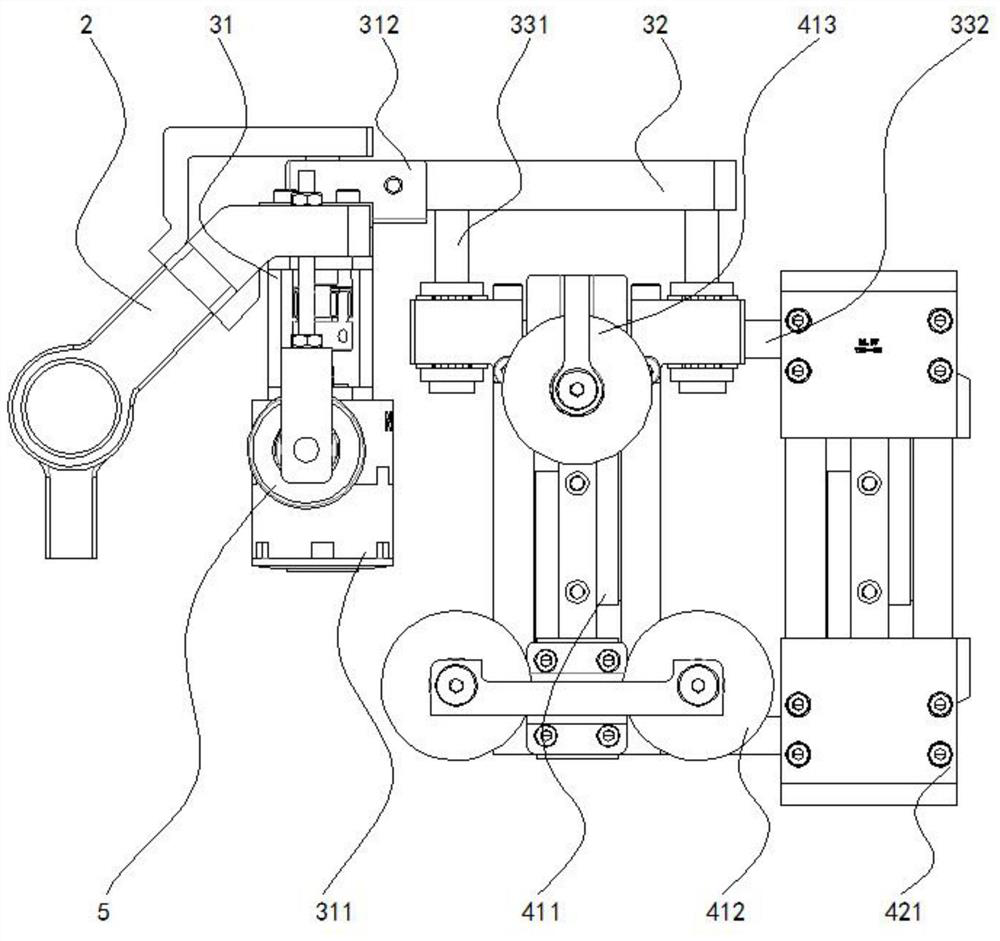

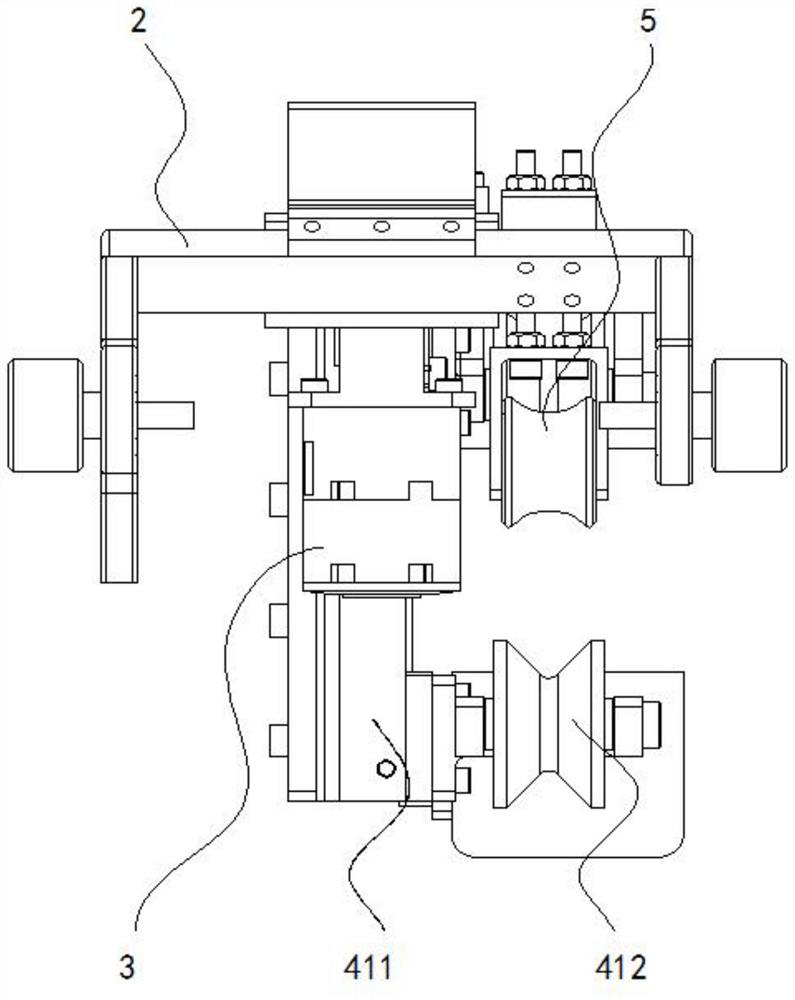

Self-adaptive angle adjusting coating device for cable coating and use method of self-adaptive angle adjusting coating device

PendingCN113953141AAvoid repositioning situationsQuick breakLiquid surface applicatorsCoatingsVertical planeMechanical engineering

The invention provides a self-adaptive angle adjustment coating device for cable coating, which comprises a walking mechanism suspended on the outer wall of a cable, and further comprises a rotating arm, a connecting assembly and a gluing mechanism, the rotating arm is arranged on the walking mechanism, and the rotating arm rotates in a vertical plane parallel to the cable; and the connecting assembly is arranged on the side, away from the walking mechanism, of the rotating arm and drives the gluing mechanism to rotate in the extending direction of the rotating arm or drives the gluing mechanism to rotate in the vertical plane parallel to the cable. According to the self-adaptive angle adjustment coating device for cable coating, the movable part and the sliding assembly are driven by the first servo motor to horizontally rotate along the cable, the sliding assembly drives the gluing mechanism to deflect relative to the horizontal plane of the cable, and the gluing mechanism can be conveniently and rapidly separated from the cable or get close to the cable; and the situation that the position of the walking mechanism needs to be adjusted again due to the fact that obstacles exist on the outer wall of the cable is avoided, and therefore the coating efficiency of the coating device is improved.

Owner:武汉露能科技有限公司

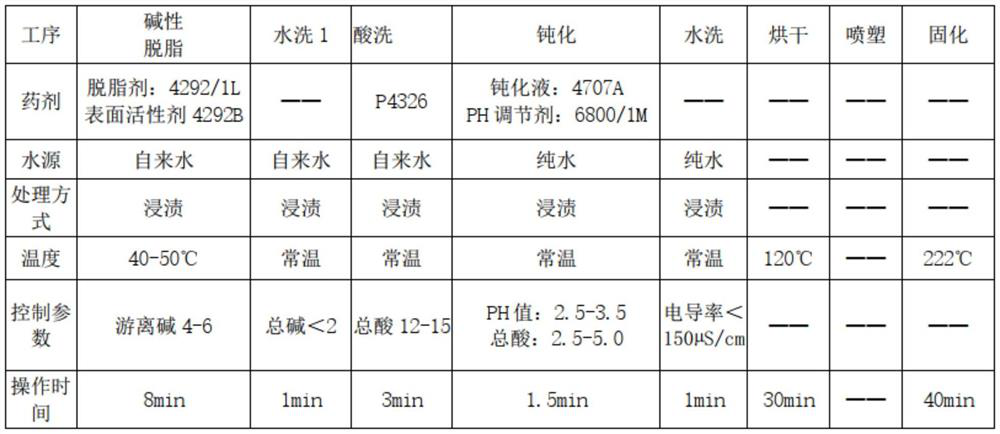

Plastic spraying process for cast aluminum alloy component

InactiveCN113145428AEasy to loosenImprove coating stabilityPretreated surfacesMetallic material coating processesSpray coatingHeat conservation

The invention discloses a plastic spraying process for a cast aluminum alloy component. The plastic spraying process comprises the steps that shot blasting treatment, acid degreasing treatment, cleaning, passivating treatment, cleaning, drying and heat preservation treatment, plastic spraying treatment and curing treatment are sequentially carried out on the cast aluminum alloy component. According to the process, the technical problem that a plastic spraying coating on the surface of a cast aluminum alloy is prone to loosening and falling off in the machining or carving process is solved, the stability of the coating of the cast aluminum alloy component treated through the method is greatly improved, and the machining performance of the cast aluminum alloy component is remarkably improved.

Owner:重庆福泰涂装技术有限公司

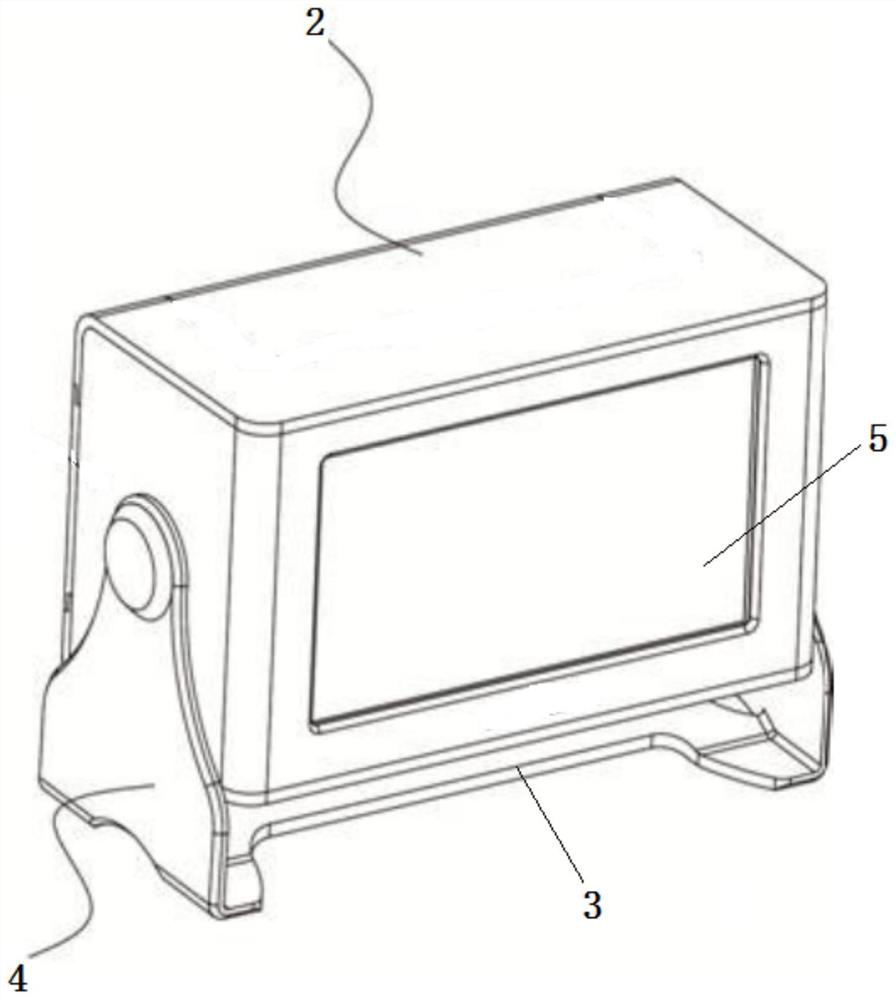

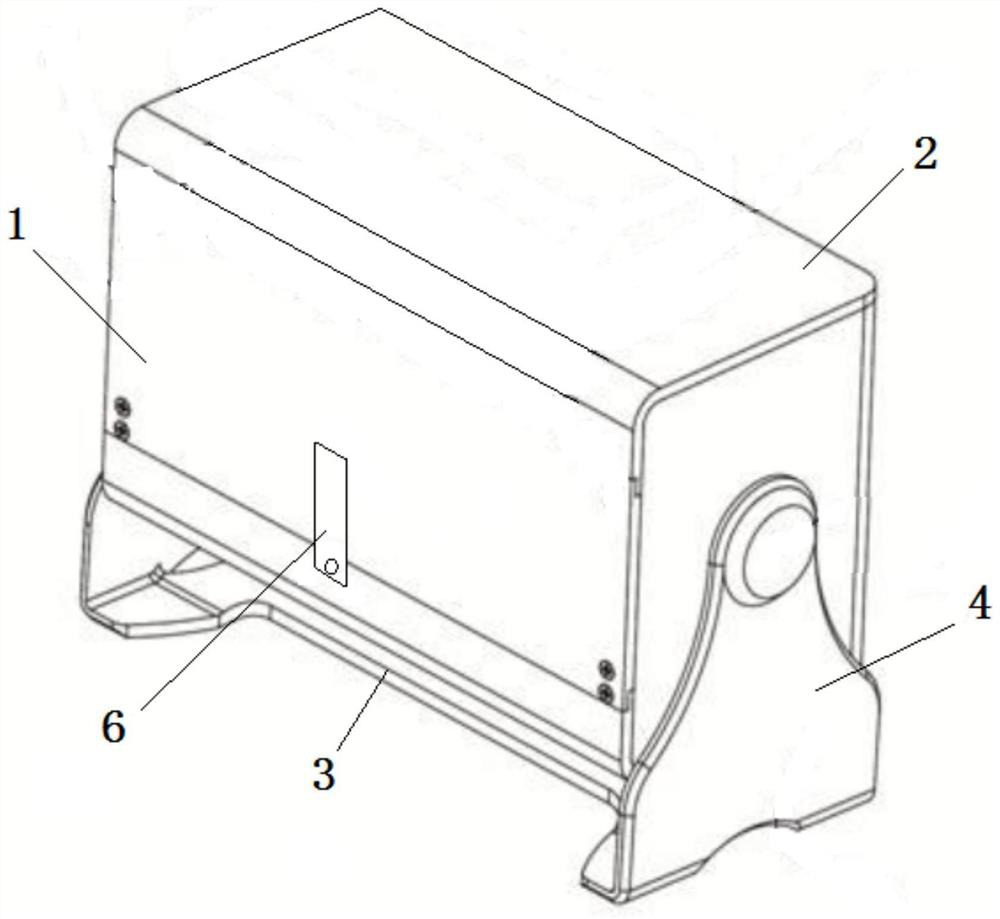

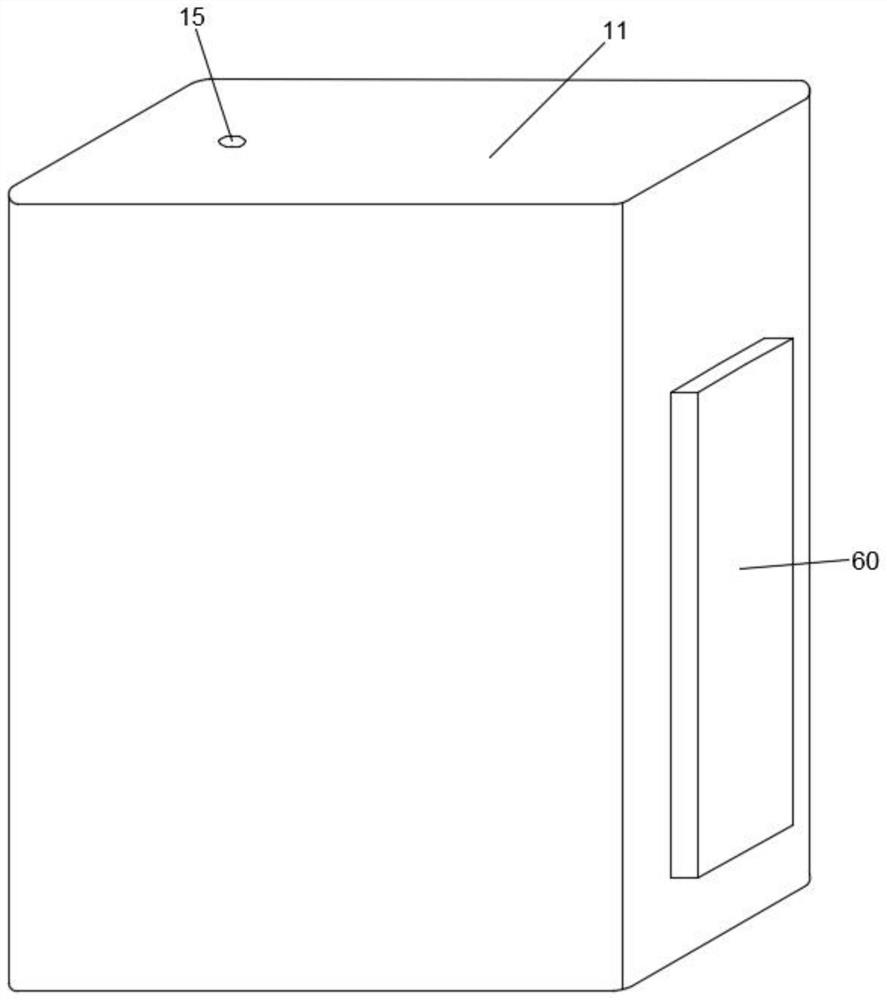

Weather resistance detection instrument

InactiveCN112251104AEasy to placeEasy to install and disassembleFireproof paintsAnti-corrosive paintsWeather resistanceStructural engineering

The invention discloses a weather resistance detection instrument. The weather resistance detection instrument comprises an instrument main body and a support; the support is arranged at the bottom end of the instrument main body; and a protective layer is arranged on the surface of the instrument main body. The support comprises an installation groove, a support bottom plate and connecting arms;the two sides of the support bottom plate are symmetrically provided with the connecting arms; and the two connecting arms are arranged on the two sides of the installation groove; the instrument mainbody is arranged in the installation groove; a transparent observation window is arranged on one side of the installation groove; the other side of the installation groove is of an opening structure;a fixing block is arranged at the lower end of the opening structure of the installation groove. The weather resistance detection instrument is simple in structure, adjustable, good in adaptability and good in weather resistance, and the service life of the weather resistance detection instrument is prolonged.

Owner:南京鹏安智慧科技有限公司

Magnetic recording medium and method of manufacturing same

InactiveUS6558772B2Improve featuresMaintain good propertiesMagnetic materials for record carriersLayered productsSolid componentParticulates

Enclosed is a magnetic recording medium obtained by sequentially providing on a flexible nonmagnetic support a nonmagnetic layer comprising a nonmagnetic powder and a binder and a magnetic layer comprising a ferromagnetic powder and a binder. The thickness of the magnetic layer is 0.01-0.1 mum and the ratio of the exposed area of nonmagnetic power on the surface of the magnetic layer is not greater than 10 percent. A method of manufacturing a magnetic recording medium comprising coating a nonmagnetic layer coating liquid on a flexible nonmagnetic support and applying a magnetic layer coating liquid on the coated layer while the coated layer is still wet. The ratio of the exposed area of nonmagnetic power on the surface of the magnetic layer is not greater than 10 percent; the nonmagnetic layer coating liquid has a yield stress of not less than 100 muN / cm2 or 10 dyne / cm2 and the solid component concentration of the magnetic layer coating liquid is greater than the solid component concentration of the nonmagnetic layer coating liquid. A particulate magnetic recording medium having a magnetic layer of not greater than 0.1 mum, good production properties, and good electromagnetic characteristics when used with MR heads is provided.

Owner:FUJIFILM CORP

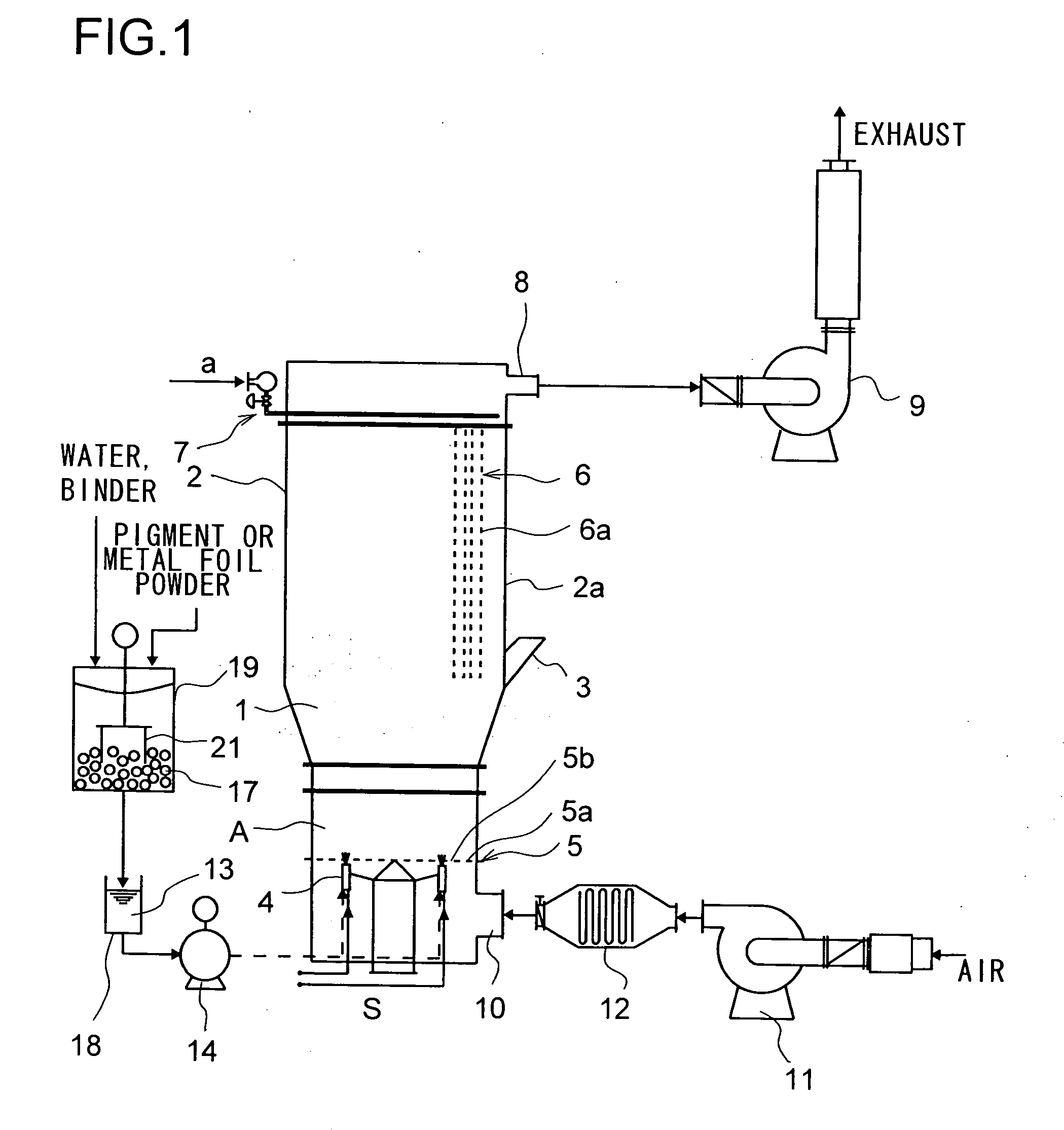

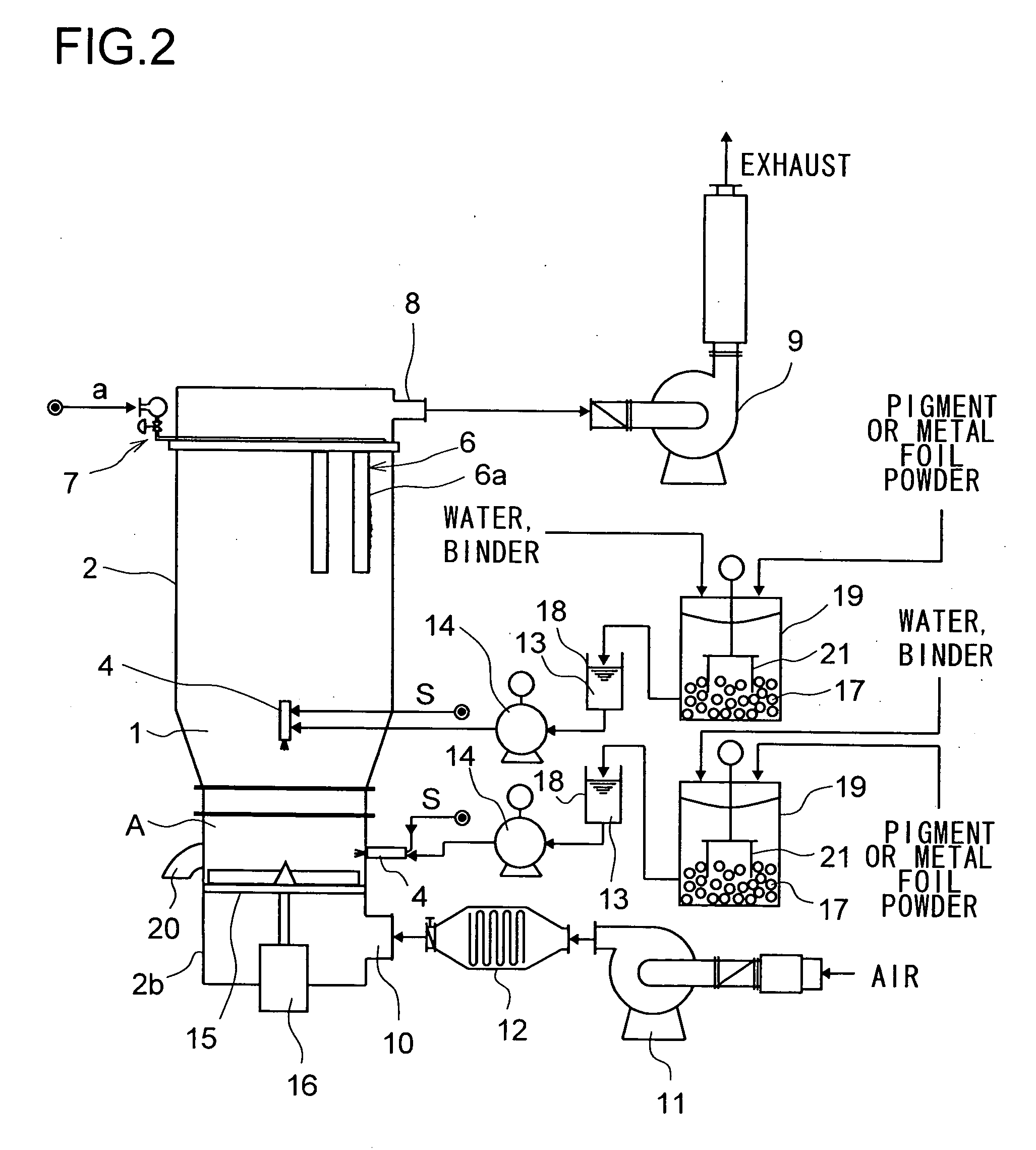

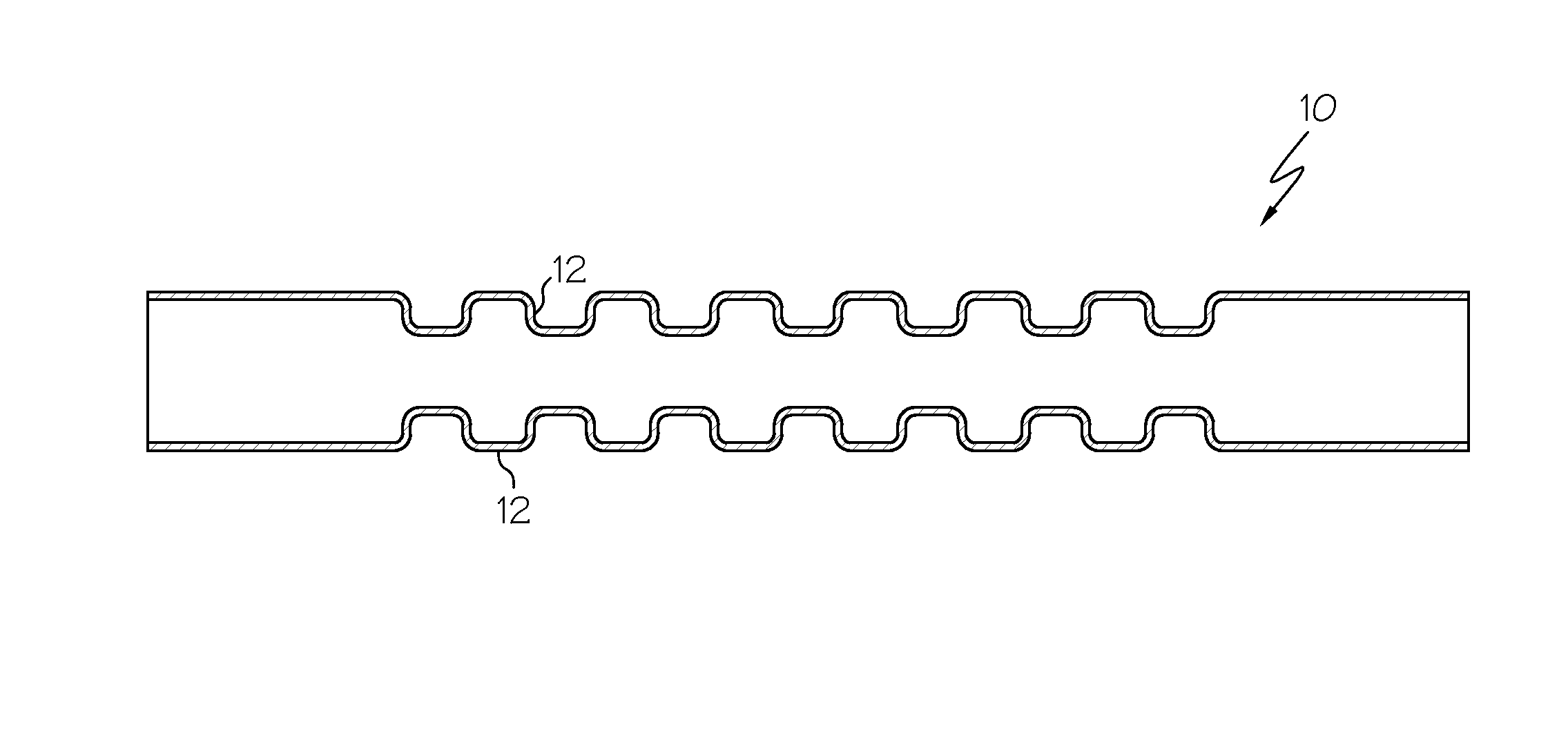

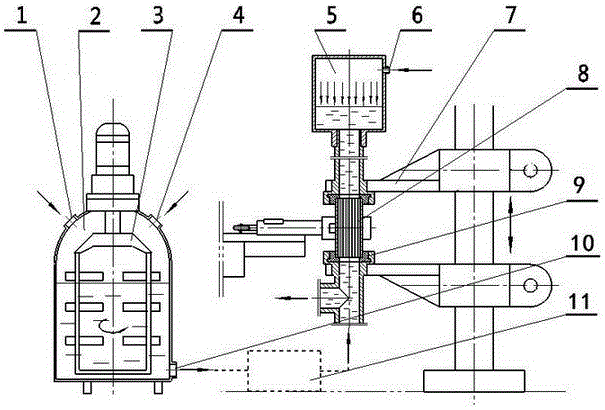

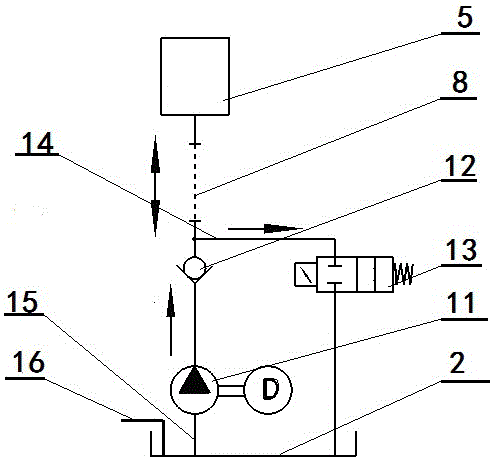

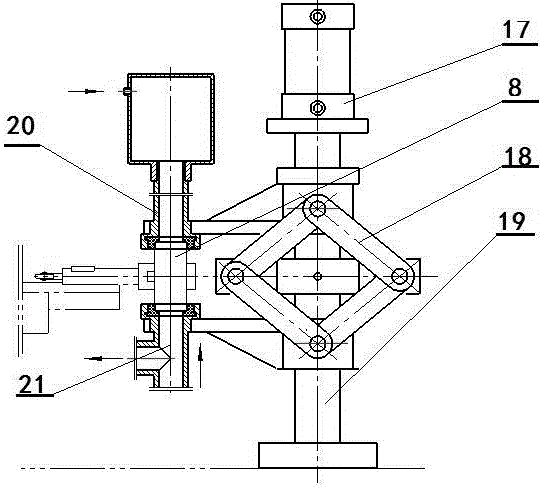

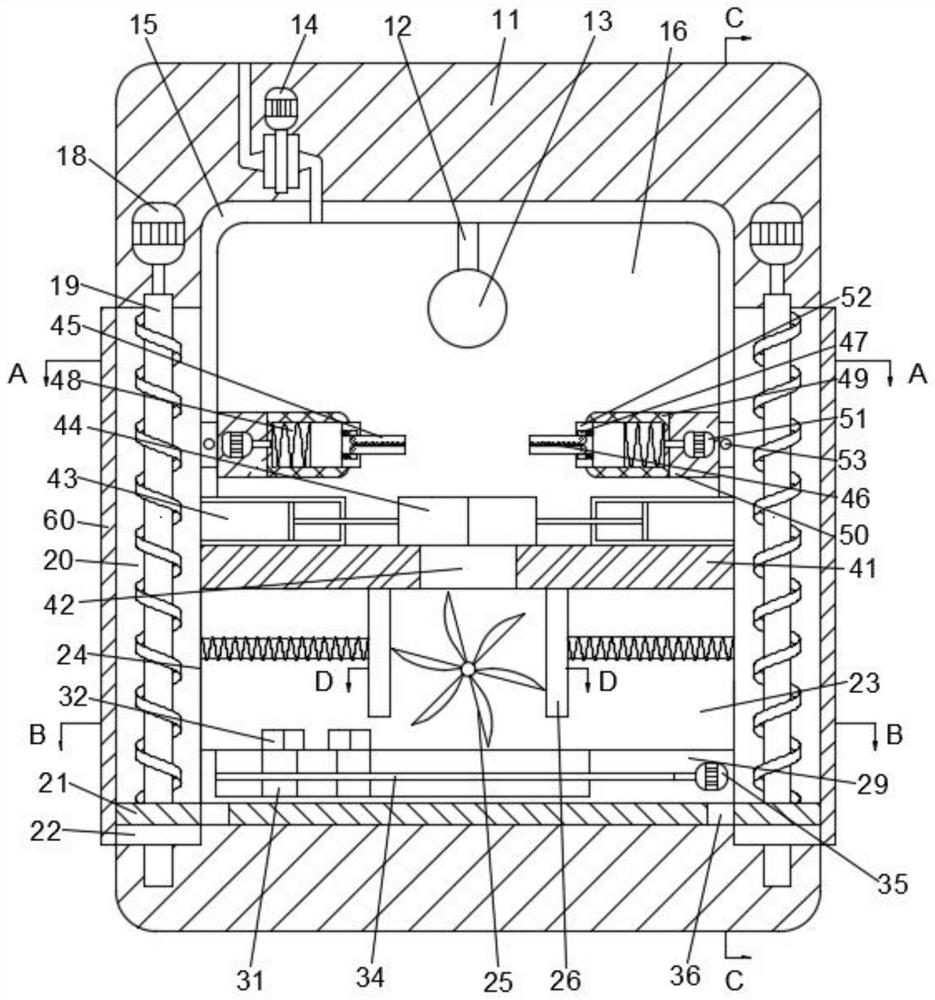

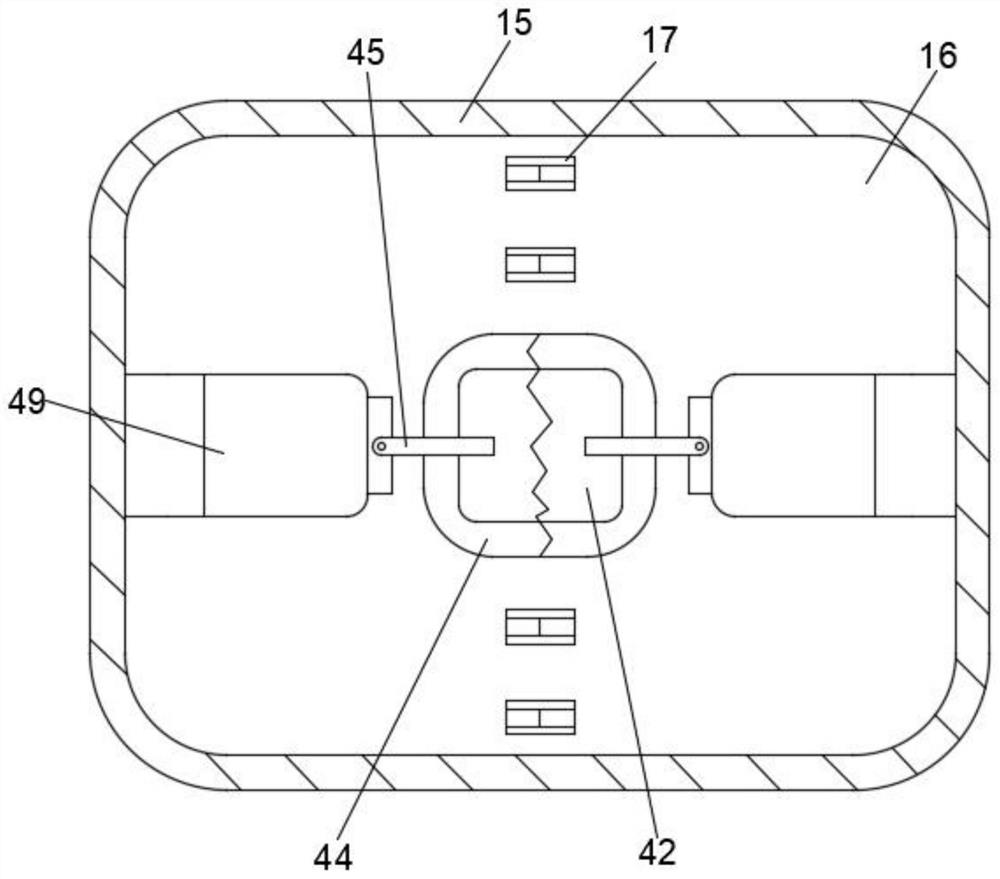

A catalyst automatic coating device for honeycomb exhaust pipe

ActiveCN103752465BGuaranteed uniformityAccurate settingLiquid surface applicatorsCoatingsControl systemAgricultural engineering

The invention discloses an automatic coating device of a honeycomb exhaust pipe catalyst. The automatic coating device is composed of a material storage system, a pressure control system and a rapid interface device; the material storage system is mainly composed of a storage cabin and a stirrer; the pressure control system is mainly composed of a quantitative injection pump, a discharging pipe, a one-way valve, an electromagnetic valve, a backflow pipe and a pressure-retaining cabin; and the rapid interface device is mainly composed of a rapid joint mechanism, a double-upright-post frame, a stress-applying lever system, a sealing base assembly and a cylinder. By means of application of the automatic coating device of the honeycomb exhaust pipe catalyst disclosed by the invention, constancy and homogeneity of the coating amounts of coatings are ensured; the product quality accords with enterprise standard requirements; the labour intensity of first-line operators is greatly lightened; and the production efficiency is effectively increased.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for making an arrangement consisting of a cast part and a cast-in component

InactiveUS20140102659A1Increased shear strengthAvoid high material consumptionElectrolytic coatingsCylindersMetallic materialsCasting mold

A method for making an arrangement consisting of a cast part and a cast-in component composed of a metallic material. The cast-in component is composed of a metallic material that has a galvanically applied nickel layer. The layer is applied by positioning the cast-in component in an electrolyte bath and applying the coating on at least part of the surface of the component. The cast-in component is then positioned in a casting mold and a cast part is casted around the cast-in part.

Owner:MAHLE INT GMBH

Efficient glass coating system

PendingCN114262161AStable transformationEfficient conversionVacuum evaporation coatingSputtering coatingCoating systemEngineering

The invention discloses an efficient glass coating system which comprises a main box body and is characterized in that a vacuum cavity is formed in the main box body, a sealing body is fixedly arranged on the upper side of the vacuum cavity, a top plate is fixedly arranged at the lower end of the sealing body, a communicating cavity is formed in the top plate, and symmetrical glass frames are fixedly arranged on the upper end face of the top plate front and back; the left wall and the right wall of the vacuum cavity are provided with rotating bodies capable of moving up and down and back and forth, the rotating bodies can clamp a fixed workpiece to a designated position to be placed, the upper end face of the top plate is provided with a sealing block capable of moving left and right, the two ends of the sealing block are fixedly connected with propellers, and the distance between the propellers on the two sides is the symmetric center. A drying cavity is formed in the main box body and located below the top plate, a blade is fixedly arranged at the center of the rear wall of the drying cavity, symmetrical isolation plates are arranged on the left side and the right side of the blade, the isolation plates on the two sides are fixedly connected with the top plate, and two lifting cavities which are symmetrical left and right are formed in the main box body.

Owner:余晴

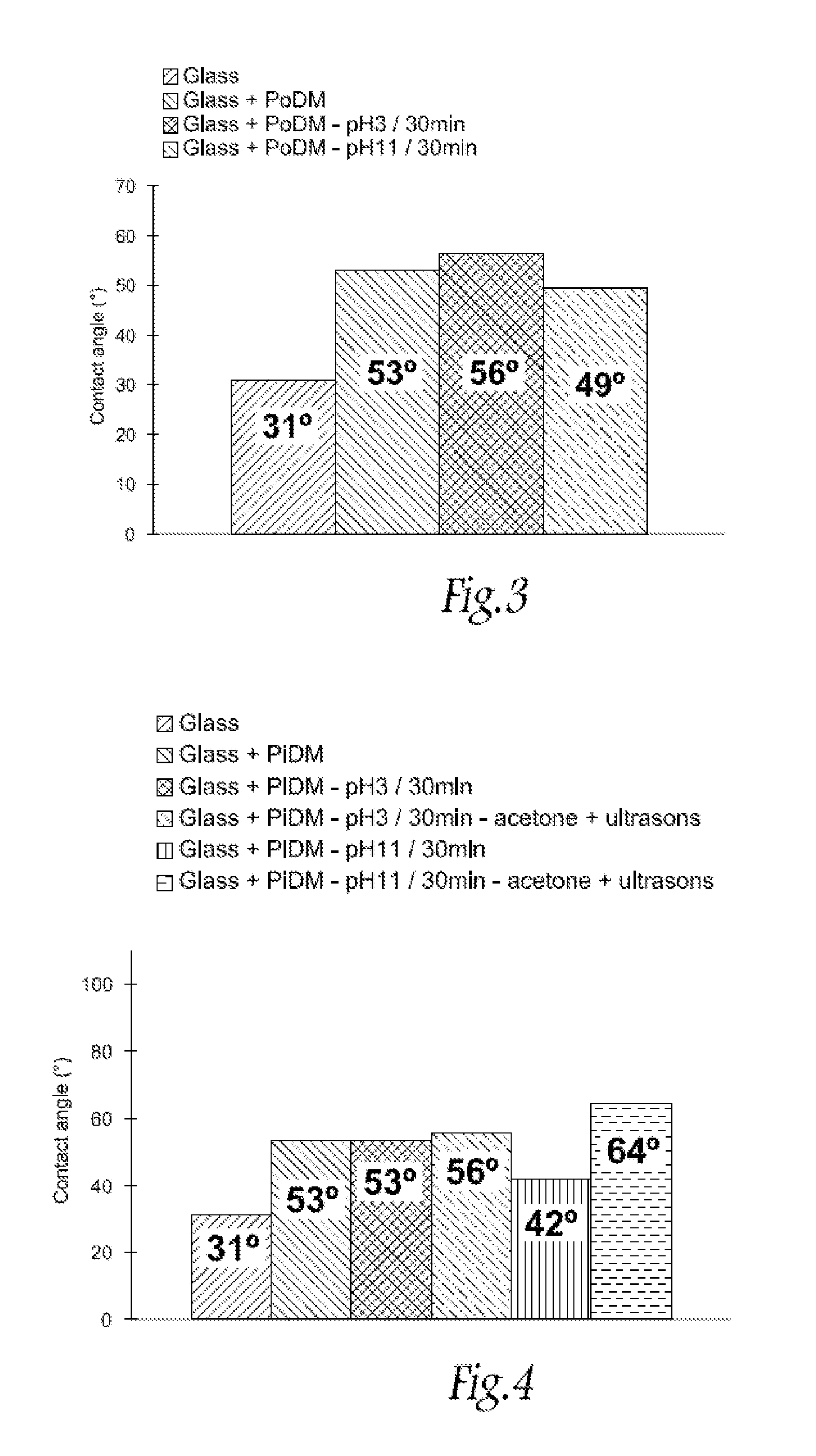

Method of coating an inorganic substrate with a stable organic layer

InactiveUS9217085B2Increased durabilityImprove coating stabilityGroup 5/15 element organic compoundsCoatingsOrganic layerMetal

A method for coating a metallic or inorganic substrate is described, such as metal or glass supports, with an organic layer comprising conjugated diene phosphinate or phosphonate compounds.

Owner:SOLVAY (CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com