A catalyst automatic coating device for honeycomb exhaust pipe

An automatic coating and exhaust pipe technology, which is applied to the device and coating of the surface coating liquid, can solve the problem that the slurry flow rate and pressure cannot be well controlled, the slurry flow rate and pressure are not easy to be controlled, and the coating Overcoming problems such as quality control is not easy to achieve the effect of shortening production auxiliary time, reducing manpower and raw material consumption, and eliminating the influence of human operation factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

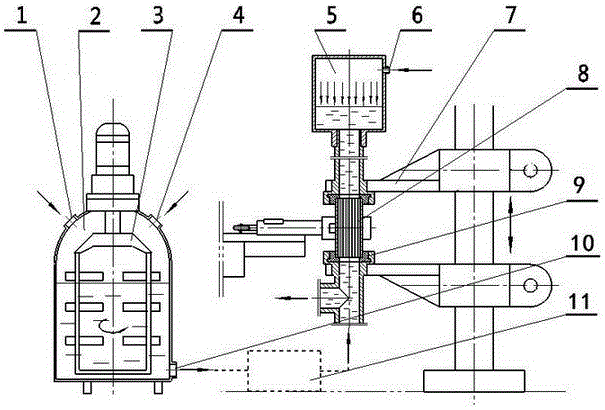

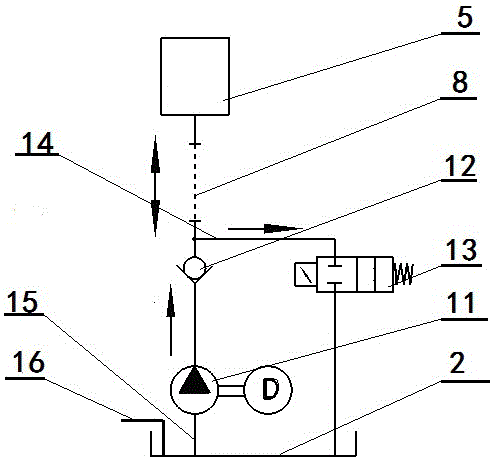

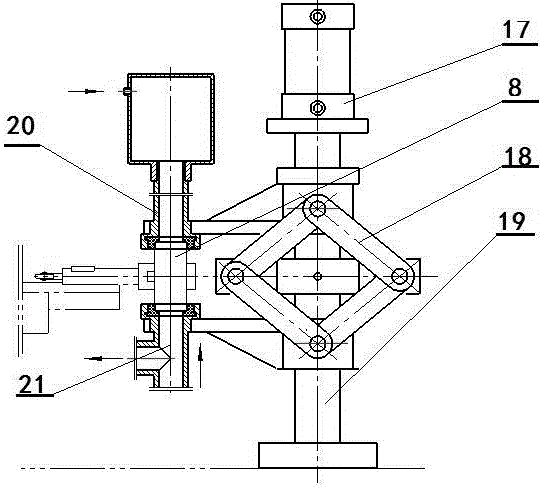

[0022] An automatic catalyst coating device for a honeycomb exhaust pipe, which consists of three parts: a material storage system, a pressure control system and a quick interface device.

[0023] The material storage system is mainly composed of a storage bin 2 and an agitator 3; the storage bin 2 stores the catalyst, and its upper part is provided with a feeding port 4 and a paint return port 1, and the lower part is provided with a discharge port 10, and its material is stainless steel; the material The supplementary pipe 16 is connected to the feeding port 4; the agitator 3 driven by a geared motor is arranged inside the storage bin 2, which ensures the real-time uniformity of the slurry (liquid) fluid and lays the foundation for the stability of the coating process.

[0024] The pressure control system is mainly composed of a quantitative injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com