Multifunctional coating machine

A coating machine and multi-functional technology, applied in the field of coating machines, can solve the problems of product scrapping, high cost of use, long distance, etc., and achieve the effects of improving stability, reducing coating waste, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be further described below in conjunction with the accompanying drawings and specific examples to better understand the invention and can be implemented, but the embodiments are not limited thereto.

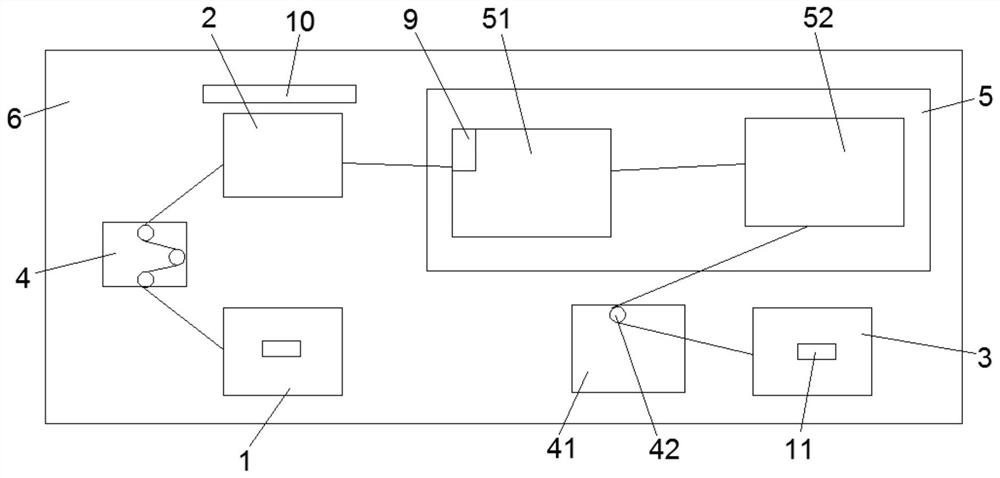

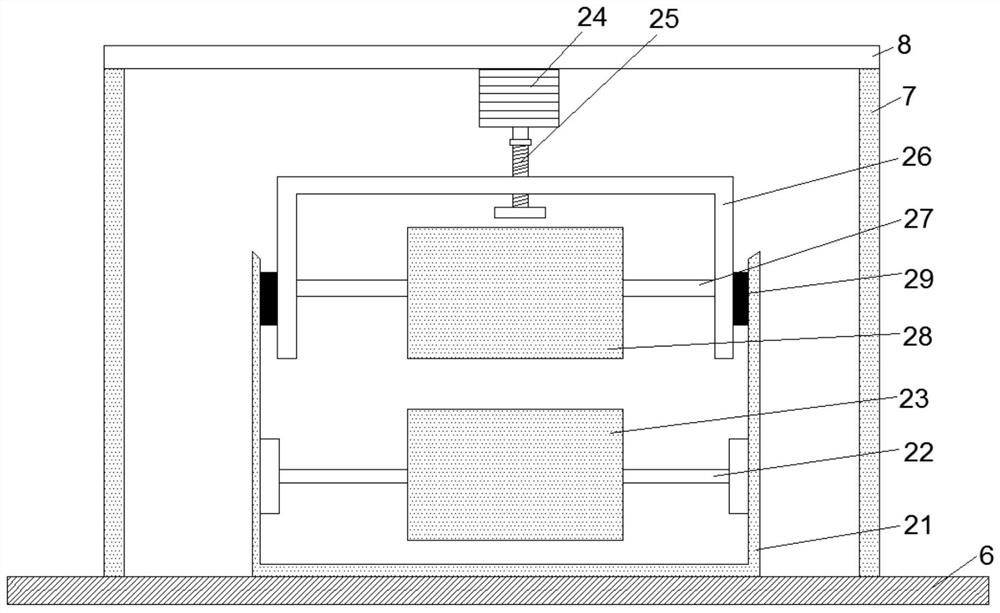

[0020]ReferFigure 1 to 2As shown, an embodiment of a multi-function coater of the present invention includes a discharge device 1, a coating device 2, and a winding device 3, and a coating device 1, and a coating device 2, coating. A traction device 4 is provided between the cloth device 2 and the winding apparatus 3, and the coating device 2 and the winding device 3 are also provided with a drying device 5, and the drying device 5 includes a preheating oven 51 and drying. Box 52; the coating device 2 includes a tank 21, and the inner wall of the binder 21 is adjacent to the bottom, and the first spindle 22 is mounted by the bearing, and the first spindle 22 is provided with an upper liquid roller 23, and the tank 21 is disposed at work. On the table 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com