Manganese-copper based composite oxide doped rare earth element catalyst for catalyzing VOCs as well as preparation method and application of catalyst

A technology of copper-based composite and rare earth elements, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of high cost of precious metal catalysts, catalyst poisoning and deactivation, Eliminate the loss of active components and other issues, to achieve the effect of improving redox performance, increasing activity, and promoting uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

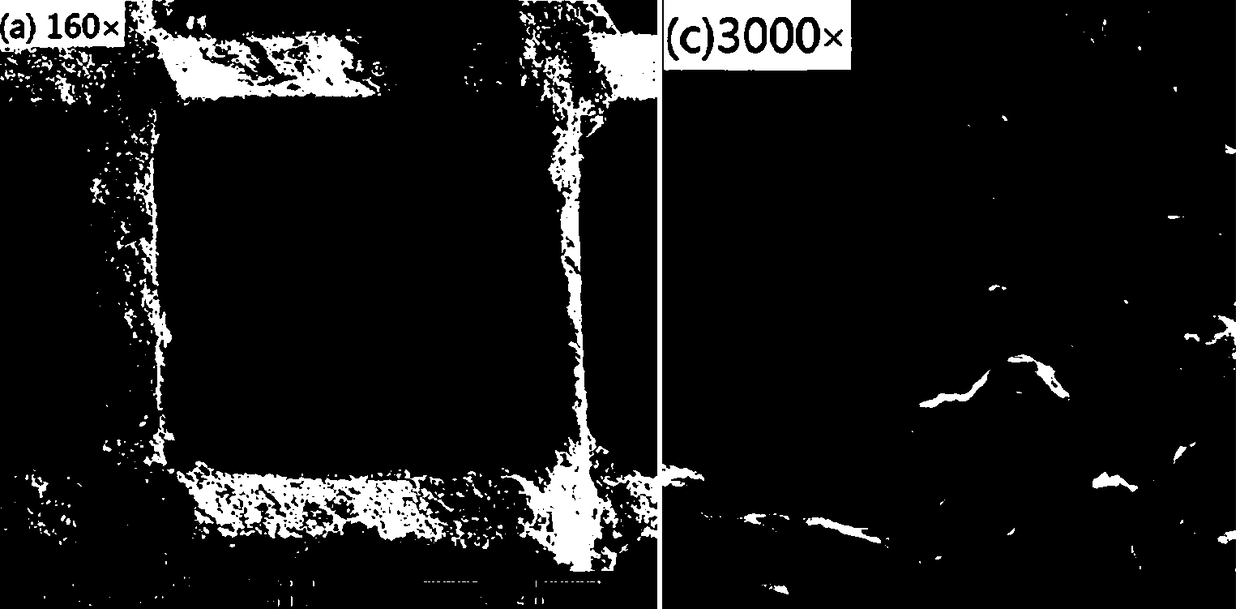

Image

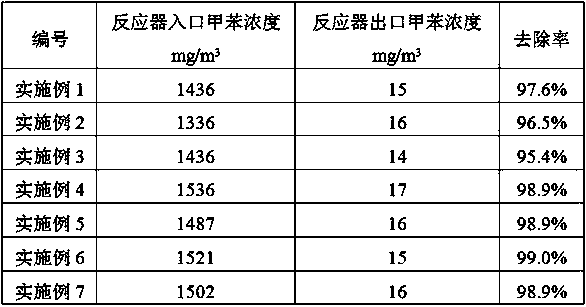

Examples

Embodiment 1

[0035] This example provides a manganese-copper based composite oxide doped rare earth element catalyst, which is prepared by the following method:

[0036] (1) Soak the cordierite honeycomb ceramic matrix in dilute dilute acid with a concentration of 5% for 4 hours for pretreatment, take it out and dry it at 90°C for 6 hours, and set it aside.

[0037] (2) Immerse the cordierite honeycomb ceramic substrate treated in step (1) in the aluminum sol, take it out and blow off the residual liquid, dry it at 90°C for 6 hours, and bake it at 250°C for 2 hours to obtain a honeycomb ceramic coated with alumina coating , the preparation method of the aluminum sol is: mix pseudo-boehmite powder and deionized water in proportion, add urea, stir well at room temperature, add concentrated nitric acid dropwise to adjust the pH of the slurry to 2, and peptize for 60 minutes to obtain stable aluminum sol. Sol, wherein the mass ratio of pseudo-boehmite powder: deionized water: urea is 3:25:1.5....

Embodiment 2

[0041] This example provides a manganese-copper based composite oxide doped rare earth element catalyst, which is prepared by the following method:

[0042] (1) Soak the cordierite honeycomb ceramic matrix in dilute dilute acid with a concentration of 10% for 12h pretreatment, take it out and dry it at 150°C for 1h, and set it aside.

[0043] (2) Immerse the cordierite honeycomb ceramic substrate treated in step (1) in the aluminum sol, take it out and blow off the residual liquid, dry it at 90°C for 6 hours, and bake it at 250°C for 2 hours to obtain a honeycomb ceramic coated with alumina coating , the preparation method of the aluminum sol is: mix pseudo-boehmite powder and deionized water in proportion, add urea, fully stir at room temperature, add concentrated nitric acid dropwise to adjust the pH of the slurry to 5, and peptize for 240 minutes to obtain stable aluminum sol. Sol, wherein the mass ratio of pseudo-boehmite powder: deionized water: urea is 5: 30: 2.5.

[00...

Embodiment 3

[0047] This example provides a manganese-copper based composite oxide doped rare earth element catalyst, which is prepared by the following method:

[0048] (1) Soak the cordierite honeycomb ceramic matrix in dilute dilute acid with a concentration of 8% for 8h pretreatment, take it out and dry it at 90°C for 3h, and set it aside.

[0049] (2) Immerse the cordierite honeycomb ceramic substrate treated in step (1) in the aluminum sol, take it out and blow off the residual liquid, dry it at 90°C for 6 hours, and bake it at 250°C for 2 hours to obtain a honeycomb ceramic coated with alumina coating , the preparation method of the aluminum sol is: mix pseudo-boehmite powder and deionized water in proportion, add urea, fully stir at room temperature, drop concentrated nitric acid to adjust the pH of the slurry to 3, and peptize for 150 minutes to obtain stable aluminum sol. Sol, wherein the mass ratio of pseudo-boehmite powder: deionized water: urea is 4:28:2.

[0050] (3) Dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com