Cu2O-Au composite microparticle surface enhanced Raman scattering active substrate and production method thereof

A technology of microparticles and nanoparticles, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of weak surface-enhanced Raman scattering activity and limited applications, and achieve the effect of mild reaction conditions and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] First weigh 0.68g CuSO 4·5H 2 O, 0.87g C 6 h 5 o 7 Na 3 2H 2 O, 0.51g Na 2 CO 3 , 6.00g PVP K30, 1.11g C 6 h 12 o 6 ·H 2 O and 3.00 mL of 1% HAuCl 4 4H 2 O solution.

[0045] CuSO 4 ·5H 2 O was dissolved in 76 mL of deionized water. C 6 h 5 o 7 Na 3 2H 2 O and Na 2 CO 3 Dissolve in 4mL deionized water to make sodium mixed solution.

[0046] Then, the sodium mixed solution was added dropwise to the vigorously stirred CuSO 4 ·5H 2 O solution, the solution turns dark blue. After the dropwise addition, the above mixed solution continued to stir for 10 minutes, and PVP was added to the vigorously stirred solution. After the solution was vigorously stirred for 20 min, PVP was completely dissolved, and C dissolved in 4 mL of deionized water was added dropwise to the solution. 6 h 12 o 6 ·H 2 O.

[0047] After the dropwise addition, the mixed solution was placed in a water bath at 80° C. for 15 minutes, the solution turned brick red, and then the...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that HAuCl 4 4H 2 The concentration of O was 1%, and the addition amount was 1.00 mL.

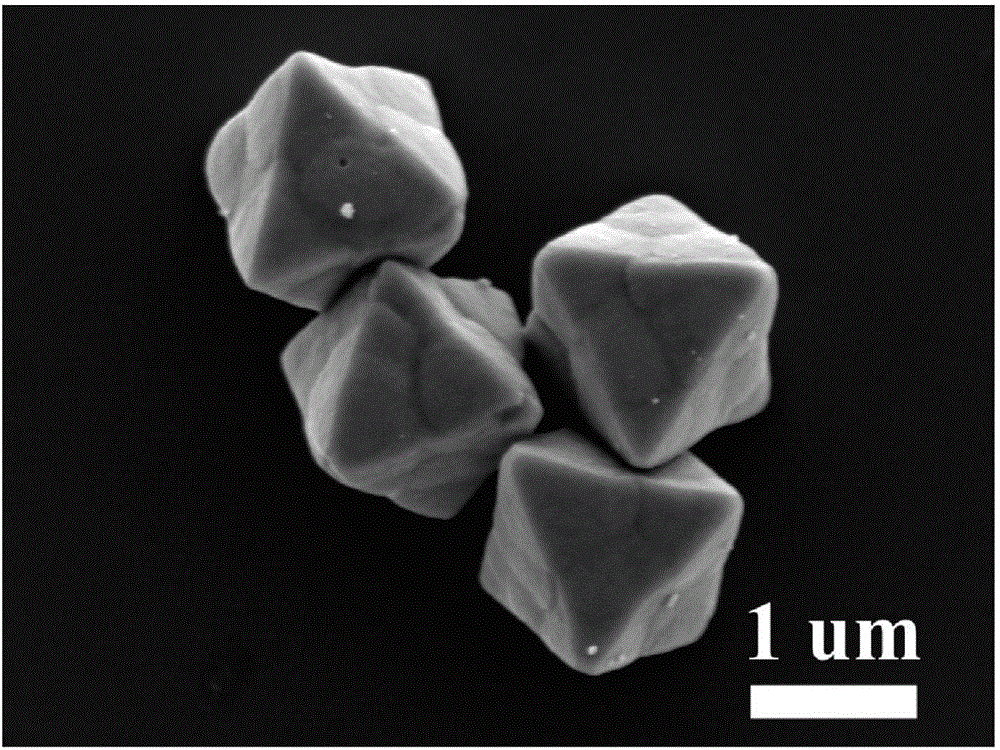

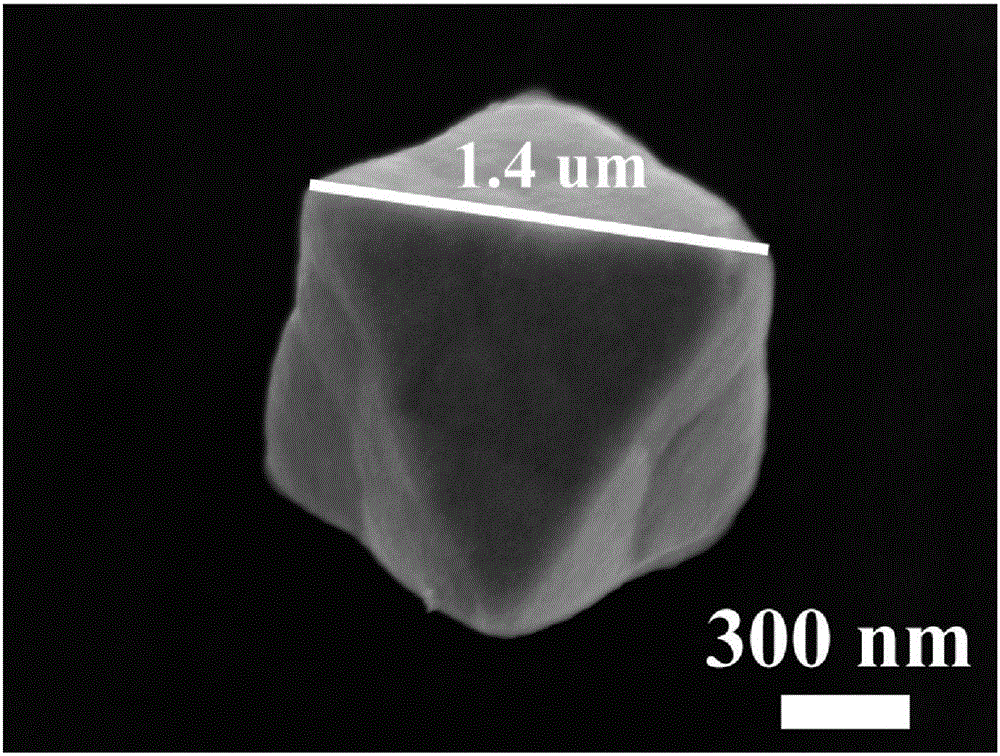

[0053] Such as Figure 7 ~ Figure 9 As shown, in Cu 2 In the O-Au composite microstructure, Cu 2 The edge length of the O-Au composite microstructure is about 1.3 μm, and the diameter of Au nanoparticles is about 17 nm, which is uniformly deposited on Cu 2 O micron crystals on the surface.

Embodiment 3

[0055] The difference between this example and examples 1 and 2 is that HAuCl 4 4H 2 The concentration of O is 1%, and the addition amount is 5.00 mL.

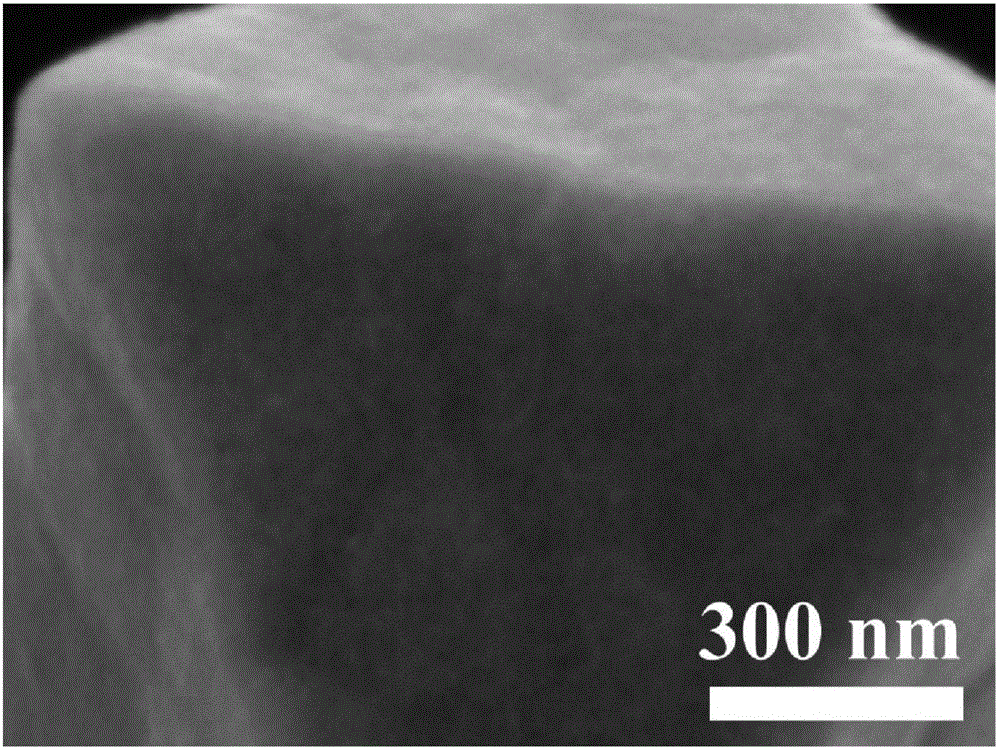

[0056] Structure Characterization

[0057] Such as Figure 10 ~ Figure 12 As shown, the formed structure is Cu 2 O-Au core-shell microstructure, Cu 2 The surface of O is all covered by Au nanoparticles, with almost no exposed Cu 2 O surface. Cu 2 The edge length of the O-Au core-shell microstructure is about 1.6 μm, and the diameter of the Au nanoparticles is about 28 nm.

[0058] In the above steps, copper ions (Cu 2+ ) and C 6 h 5 o 7 Na 3 2H 2 O and Na 2 CO 3 reaction, where C 6 h 5 o 7 Na 3 2H 2 O as a chelating agent, and a small amount of Na 2 CO 3 to inhibit C 6 h 5 o 7 Na 3 2H 2 The hydrolysis of O produces copper citrate after the reaction. Copper citrate is reduced by glucose in a water bath at 80°C to produce Cu 2 O crystals. The PVP added during the reaction acts as a stabilizer and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com