Fabrication of high surface to volume ratio structures and their integration in microheat exchangers for liquid cooling systems

A heat exchanger, miniature technology, used in heat exchange equipment, lighting and heating equipment, metal processing equipment, etc., to solve problems such as undescribed manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

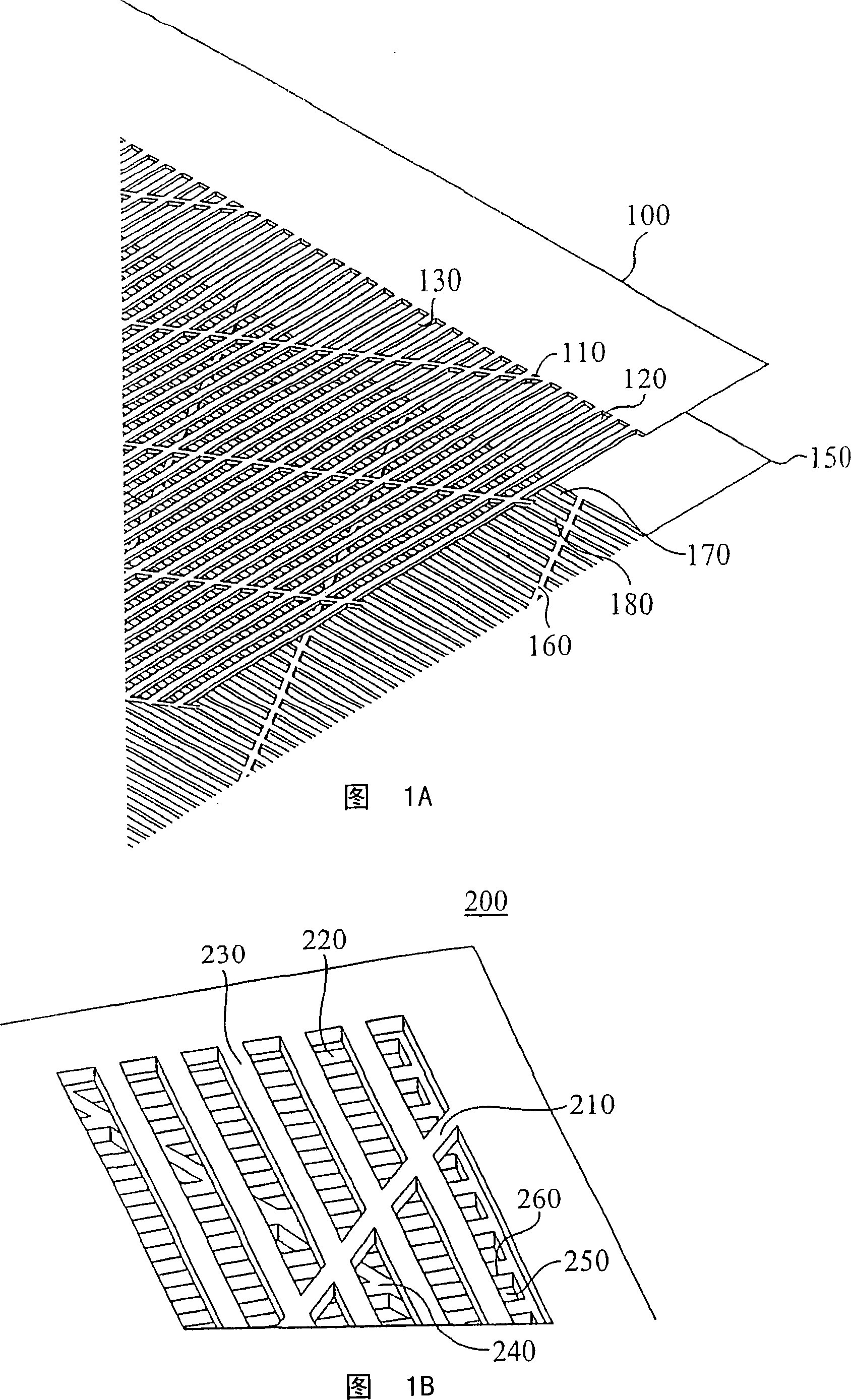

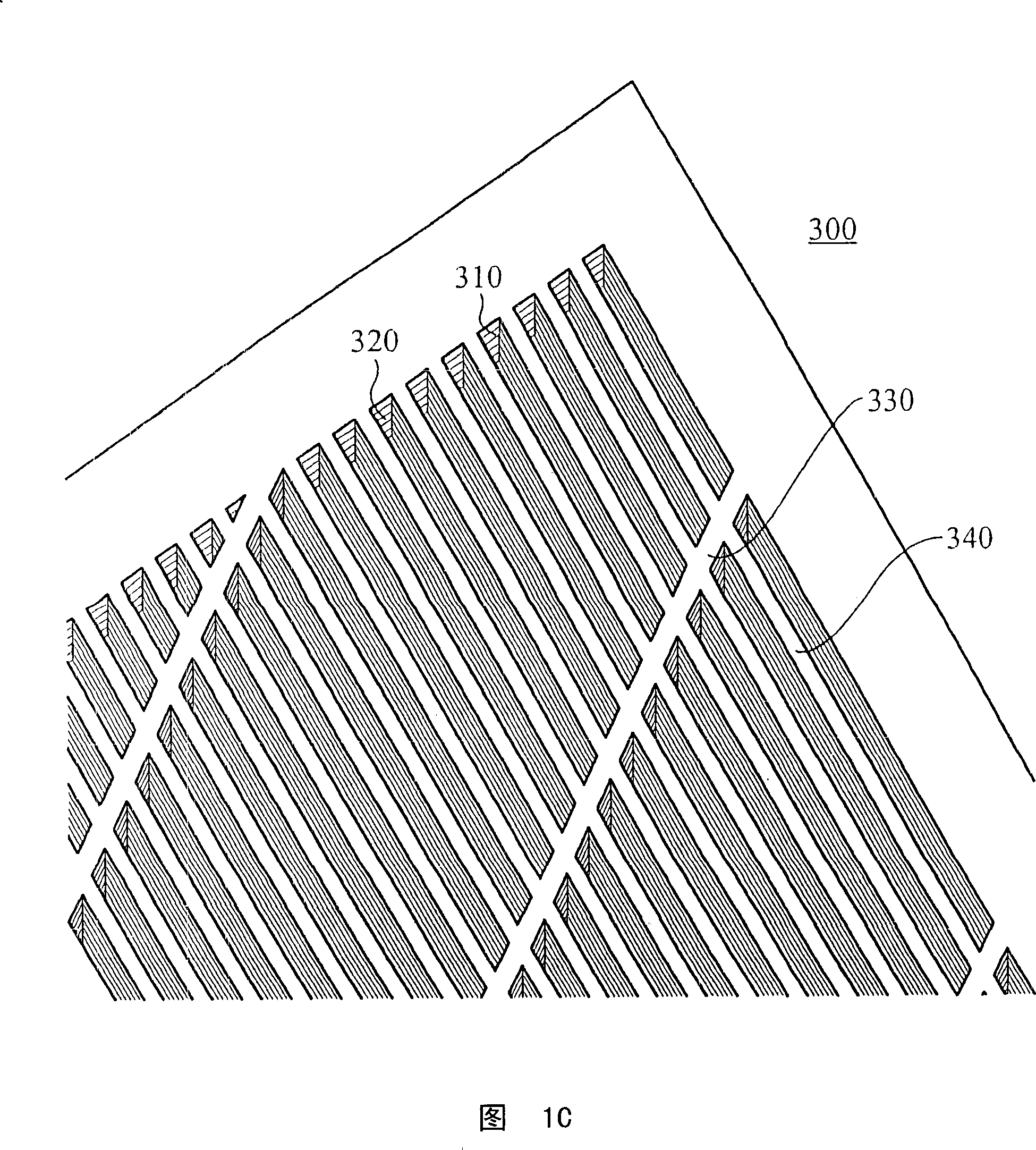

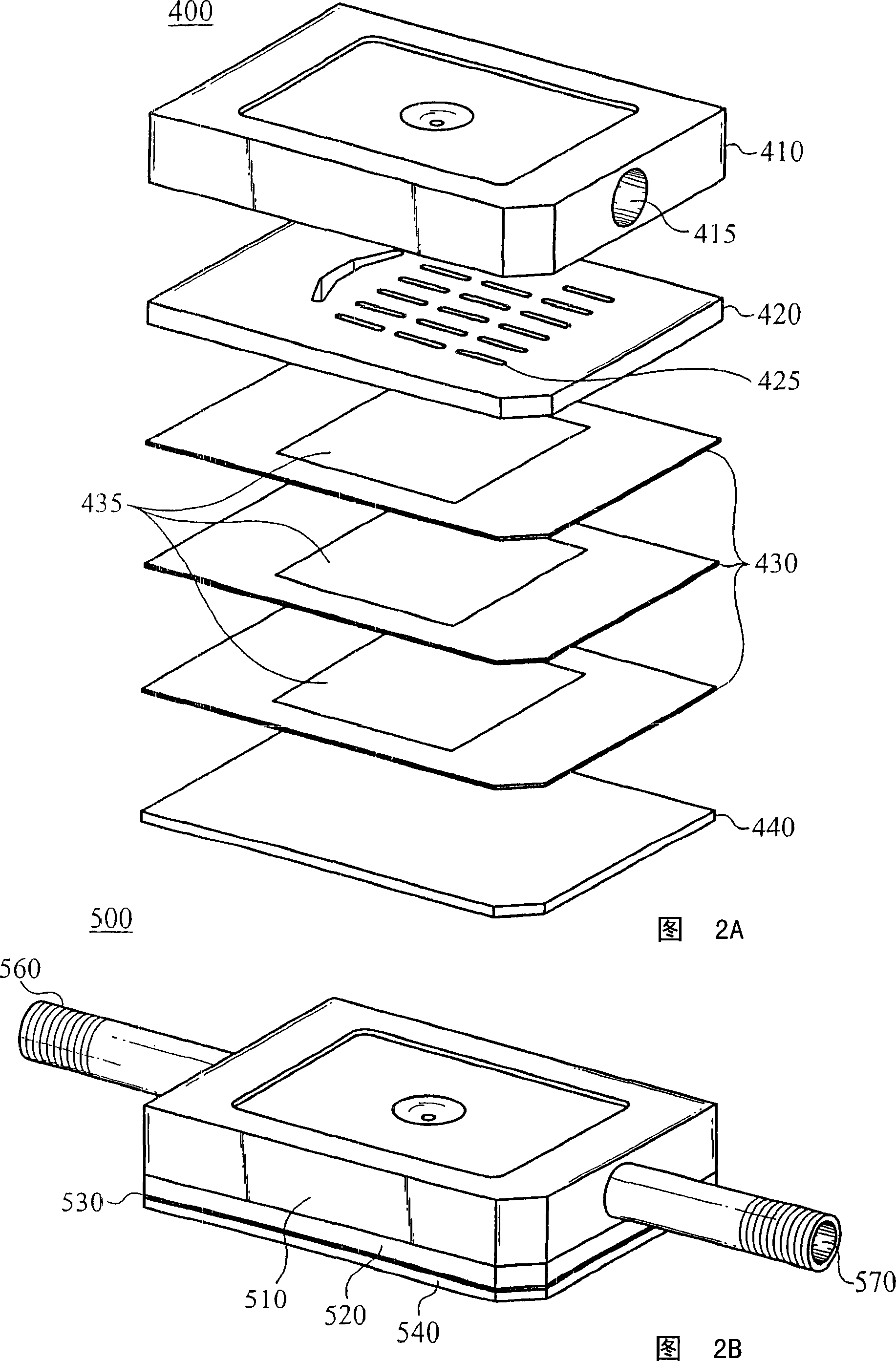

[0057] The present invention describes a method of forming a conductive layer and joining multiple layers together to form a three-dimensional microstructured region. According to the present invention, microstructured regions comprise microgrids, microchannels, or some other microstructures. FIG. 1A shows a first embodiment of a micro-grid region, and FIG. 2A shows a second embodiment of a micro-grid region. Figure 1C shows multiple layers formed and joined together to form microchannels in accordance with an embodiment of the present invention.

[0058] Figure 1A shows two window layers 100, 150 formed from two thermally conductive layers in accordance with the present invention. Preferably, the two thermally conductive layers are formed using a wet etch process in which a photographic tool is used to determine the location and pattern of the microscopic openings 120, 170 of the window layers 100, 150. The two window layers include a plurality of thick solid rods 110, 160 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com