Austempering/marquenching powder metal parts

a technology of metal parts and marquenching powder, which is applied in the field of austempering/marquenching powder metal parts, can solve the problems of reducing bending fatigue strength, limited use, and lowering wear resistance, and achieves the effect of high performance powder and medium to high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

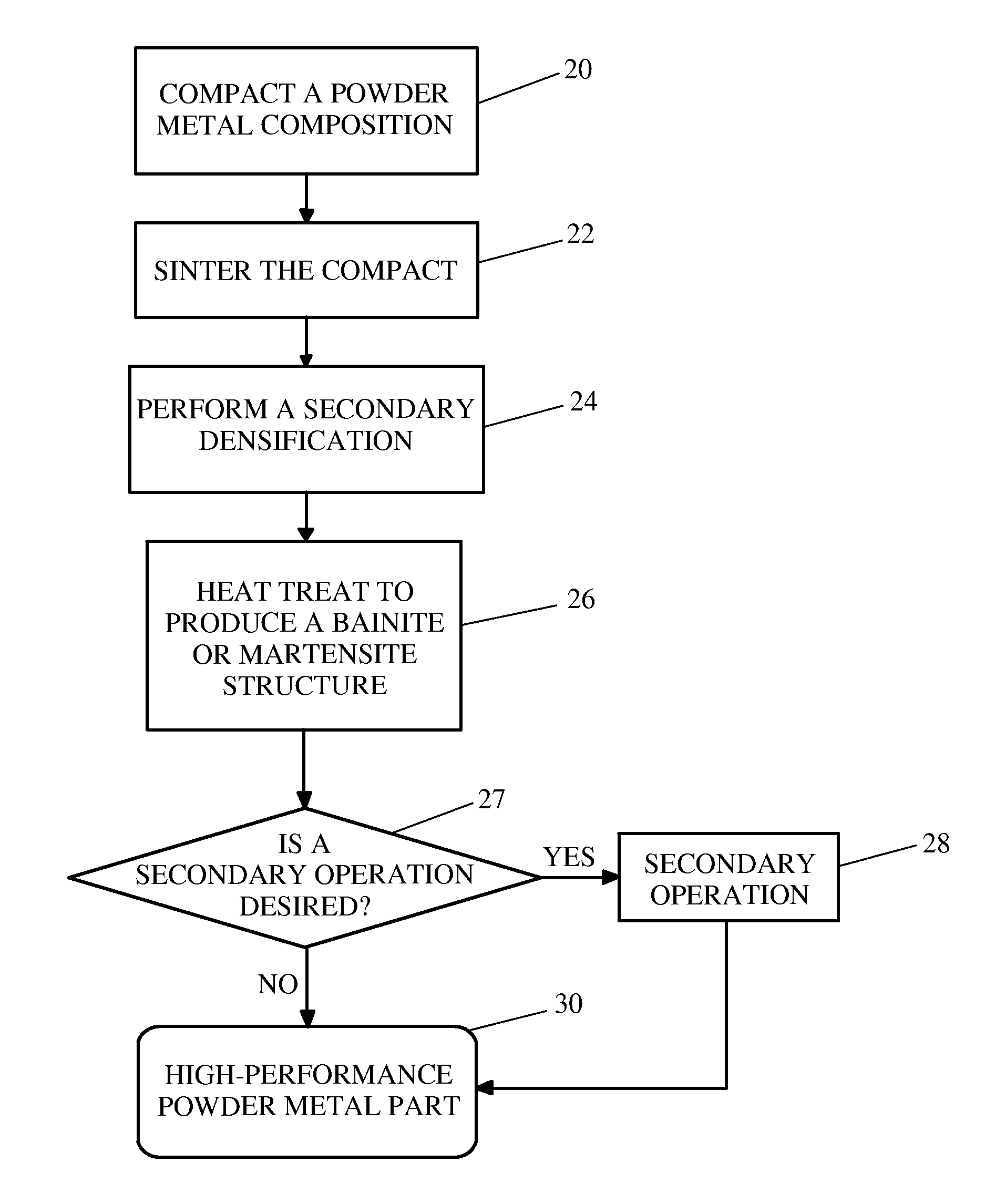

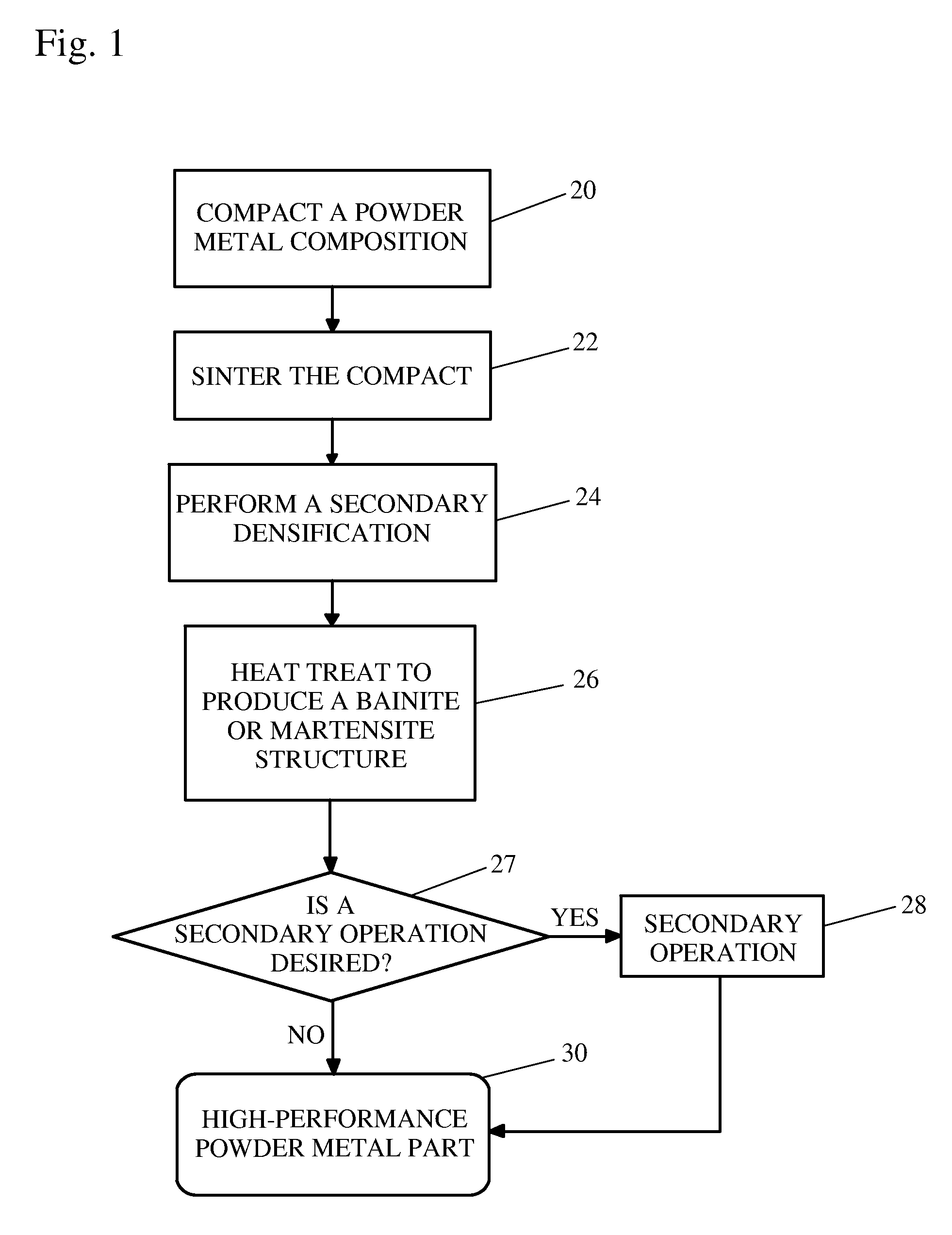

[0037]FIG. 1 shows a method of manufacturing a high-performance powder metal part. A powder metal composition is compacted (20) at a desired pressure to a desired green density. A preferred pressure range is 25 to 65 TSI, and a preferred green density range is 6.4 to 7.4 g / cc. The compaction occurs in the desired shape, or substantially in the desired shape for the final part to be produced. Many powder metal compositions may be used in conjunction with the embodied methods, and their equivalents, disclosed herein. One such preferred powder metal composition has a chemical composition as listed in Table 1. It should be readily understood that other powder metal compositions may be used with the embodied methodologies disclosed herein.

TABLE 1ElementPercentage by Weight (wt %)Cu0-2.0wt %C0.15-0.9wt %Mo0.5-2.0wt %Ni0.5-4.5wt %Cr0-4.0wt %Mn0-1.5wt %Si0-1.5wt %Febalance

[0038] After the powder metal composition is compacted (20), the green compact is sintered (22) at a desired temperature...

second embodiment

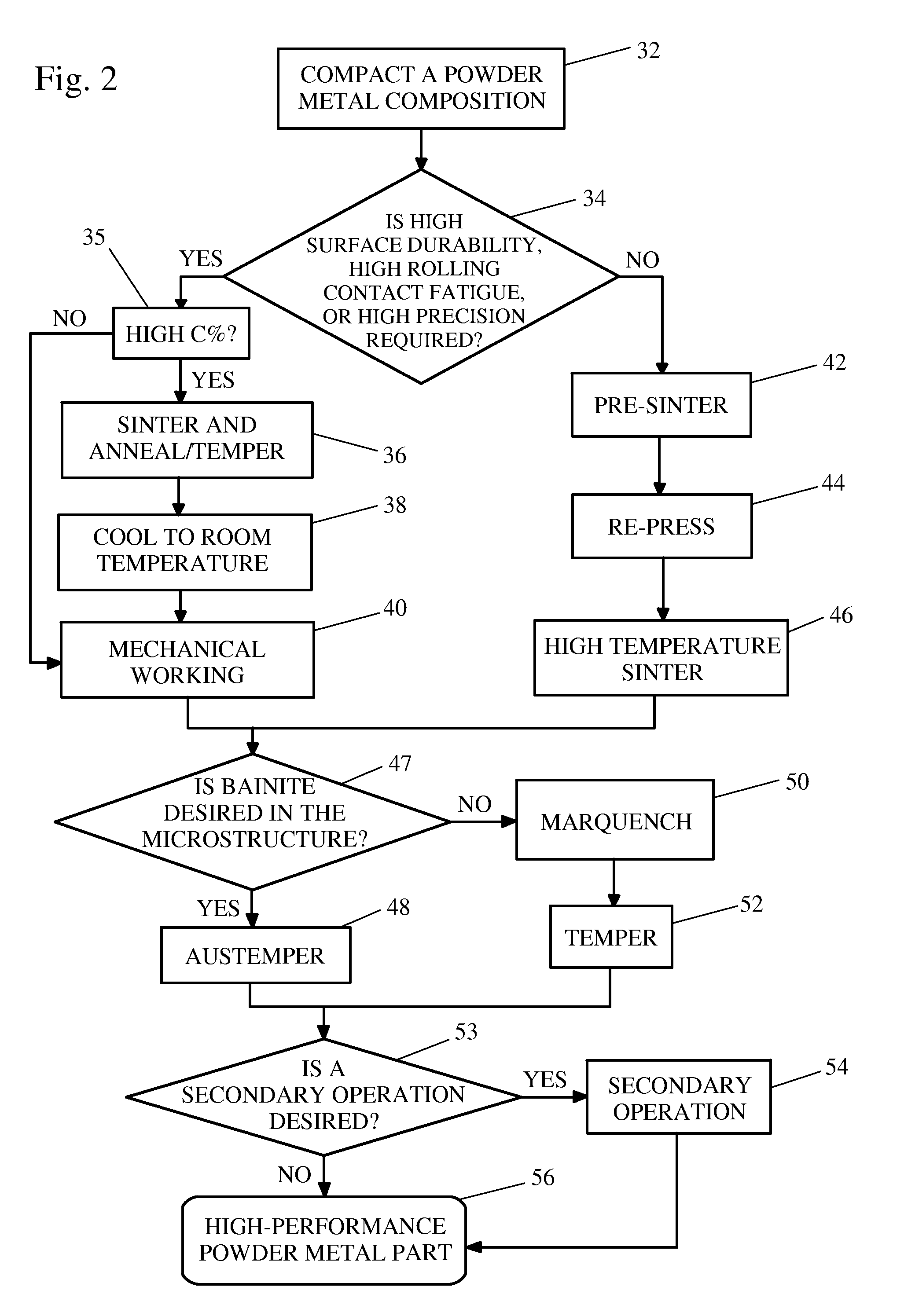

[0039]FIG. 2 shows a method of manufacturing a high-performance powder metal part. First, the powder metal composition is compacted (32) at a desired pressure to a desired green density. The next steps depend on whether or not a high surface durability, high rolling contact fatigue, or high precision is required (34) in the final product. If at least one of these features is required and the metal composition has a high carbon percentage (35), the composition is sintered and annealed / tempered (36), cooled to room temperature (38), and mechanically worked (40). If the powder composition is a low-carbon composition, the substeps of sintering and annealing / tempering (36) and cooling (38) are not necessary and the compact may be directly mechanically worked (40). The part may also be directly worked after sintering to increase the surface density. If none of the final product features is required, the composition is pre-sintered (42), re-pressed (44), and high-temperature sintered (46) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| green density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com