Polyether-ether-ketone based wear-resistant composite material and preparation method thereof

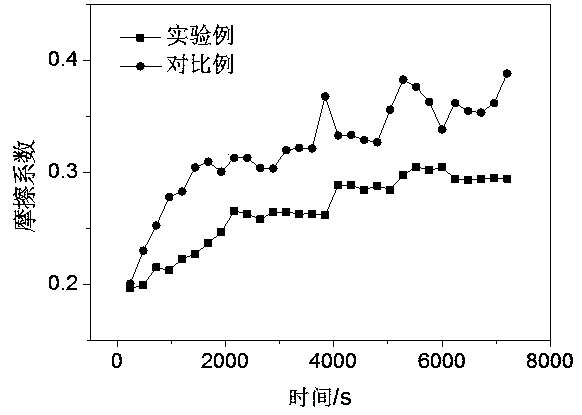

A composite material, polyether ether ketone technology, applied in the field of functional composite material production, to achieve excellent low wear, excellent low friction coefficient, improve the effect of boundary lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

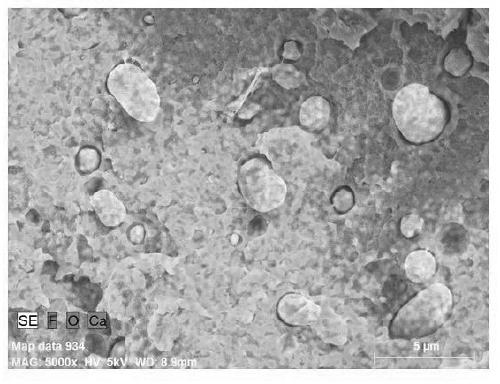

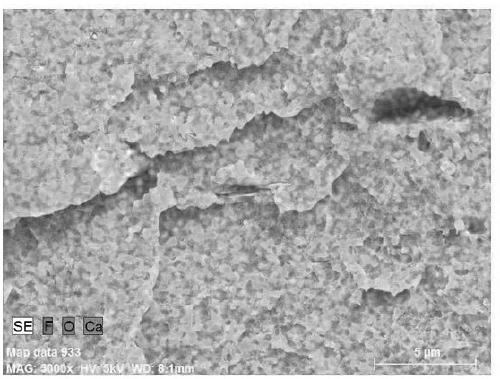

Examples

Embodiment Construction

[0021] 1. The preparation process of modified graphene nano-chips:

[0022] Add 100 g of graphene microflakes and 14.8 g of calcium hydroxide into 1000.0 g of water, stir to form a uniform suspension, and then pass in carbon dioxide to carry out gas-solid reaction under the reaction condition of 60°C.

[0023] When the pH value of the suspension drops to 7, the aeration is stopped, and 120 g of calcium carbonate-loaded graphene filter cake is obtained by suction filtration and washing, and dried in a vacuum oven at 80°C for 12 hours to obtain the modified graphene nanometer cake. Microchips, spare.

[0024] Second, the preparation process of composite materials:

[0025] 1. Embodiment:

[0026] The following parts by weight were weighed: 90 parts of polyether ether ketone, 9.9 parts of extrusion grade polytetrafluoroethylene, and 0.5 parts of modified graphene nanosheets.

[0027] All the above raw materials are added to a high-speed mixer for mechanical mixing, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com