High-strength steel sheet excellent in workability and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

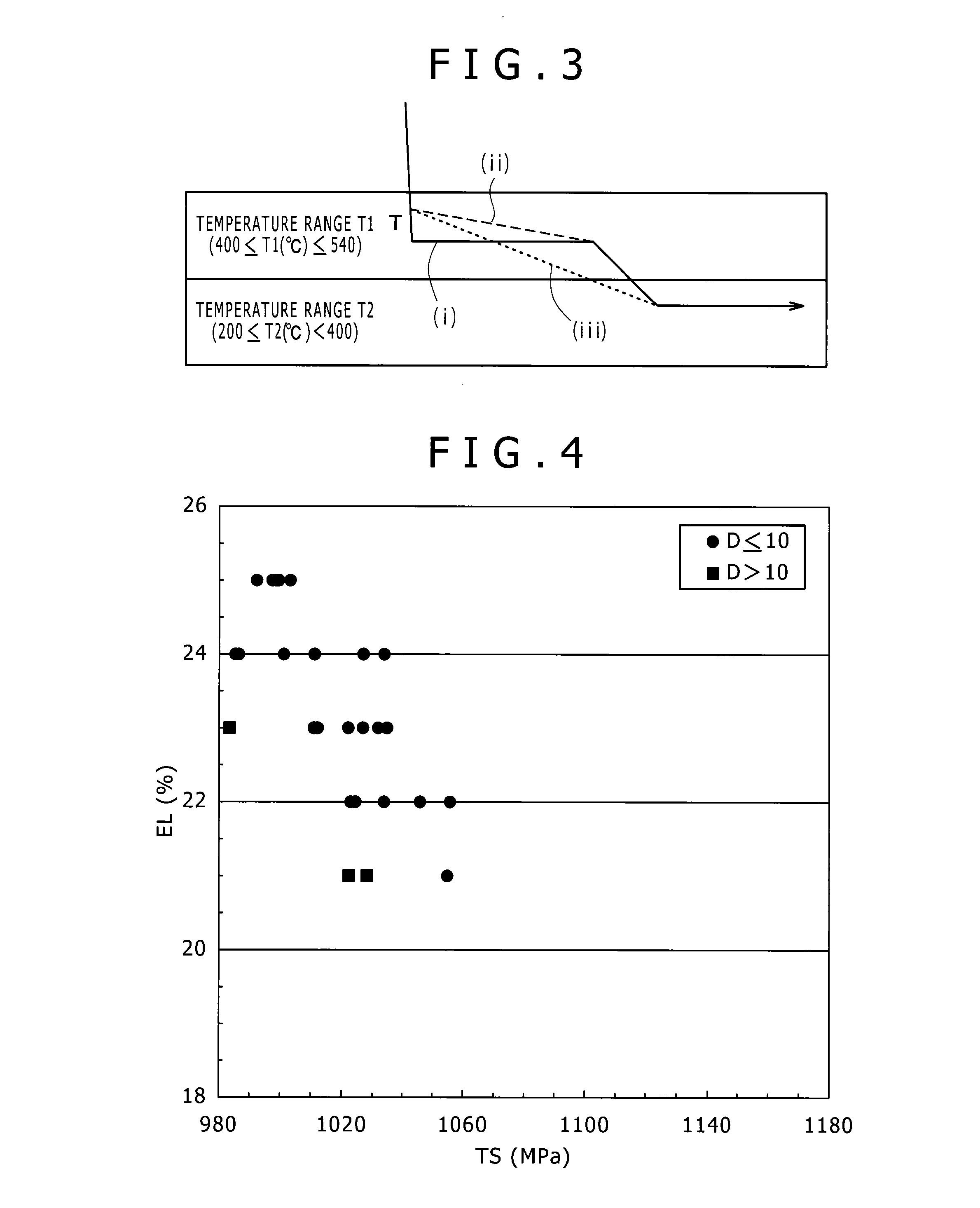

experimental example 1

[0238]Experimental slabs were prepared by subjecting steels having chemical compositions given in Tables 1 and 2 below (with the remainder consisting of iron and inevitable impurities other than P, S, N, and O) to vacuum ingot making. The rare-earth elements (REM) in Tables 1 and 2 employed a misch metal containing about 50% of La and about 30% of Ce.

[0239]The Ac1 points and the Ac3 points of the steels (slabs) were calculated based on the chemical compositions given in Tables 1 and 2 and on Expression (a) and Expression (b), respectively. The results are indicated in Tables 3 to 5 below.

[0240]The prepared experimental slabs were sequentially subjected to hot rolling, cold rolling, and continuous annealing and yielded specimens. Specific conditions are as follows.

[0241]The experimental slabs were heated to 1250° C. and held at this temperature for 30 minutes, hot-rolled to a rolling reduction of about 90% at a finishing mill delivery temperature of 920° C., and cooled from this temp...

experimental example 2

[0308]Experimental slabs were prepared by subjecting steels having chemical compositions given in Table 9 below (with the remainder consisting of iron and inevitable impurities other than P, S, N, and O) to vacuum ingot making. The rare-earth elements (REM) in Table 9 employed a misch metal containing about 50% of La and about 30% of Ce.

[0309]The Ac1 points and the Ac3 points of the steels (slabs) were calculated based on the chemical compositions given in Table 9 and on Expression (a) and Expression (b), respectively. The results are indicated in Tables 10 and 11 below.

[0310]The prepared experimental slabs were sequentially subjected to hot rolling, cold rolling, and continuous annealing and yielded specimens. Specific conditions are as follows.

[0311]The experimental slabs were heated to 1250° C. and held at this temperature for 30 minutes, hot-rolled to a rolling reduction of about 90% at a finishing mill delivery temperature of 920° C., and cooled from this temperature down to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com