Patents

Literature

46results about How to "Excellent plating property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength hot-dip galvanized steel sheet having excellent uniform elongation and plating properties, and method for manufacturing same

ActiveCN103210105AExcellent plating propertyEasy to processHot-dipping/immersion processesFurnace typesUltimate tensile strengthQuality characteristics

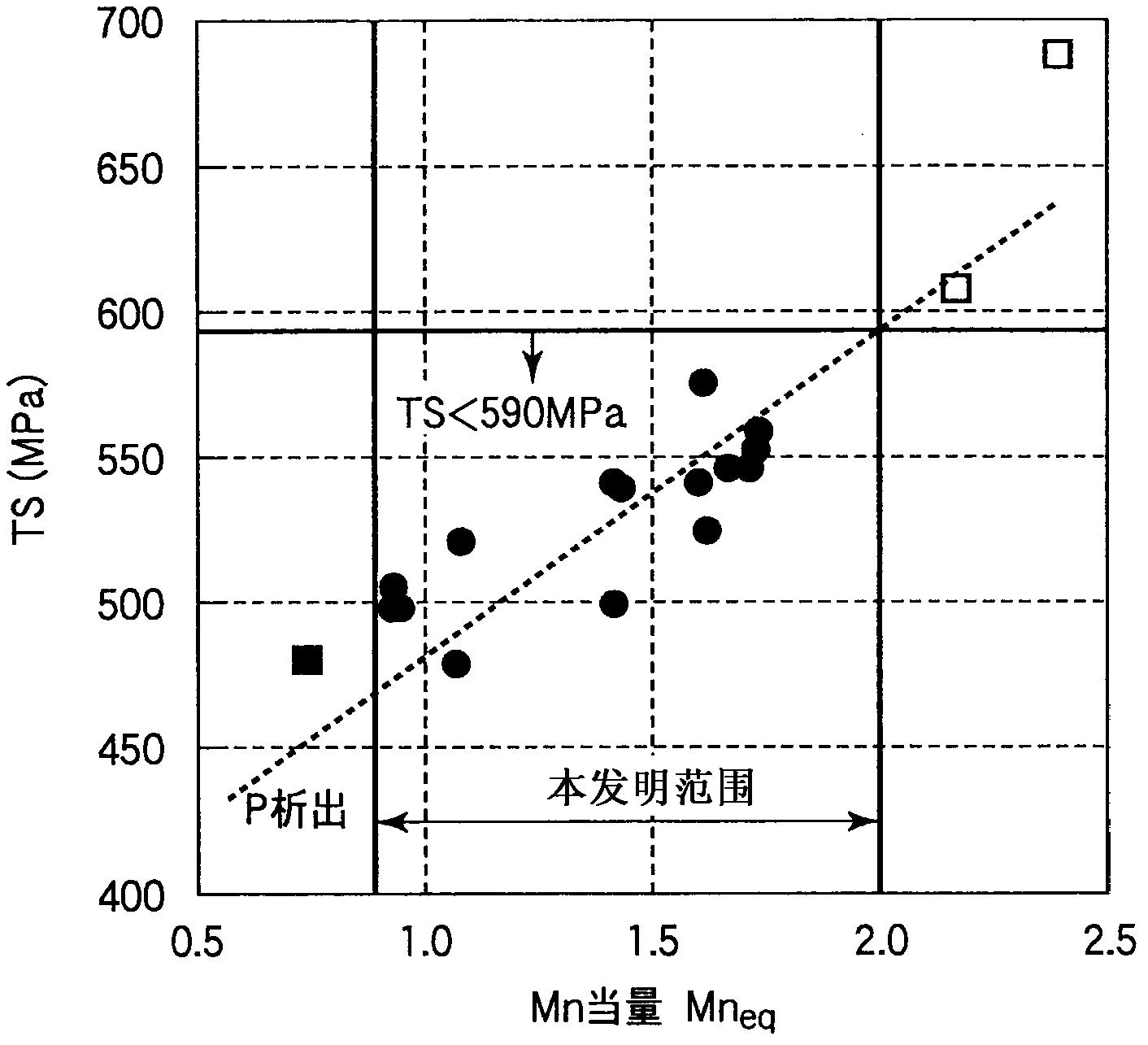

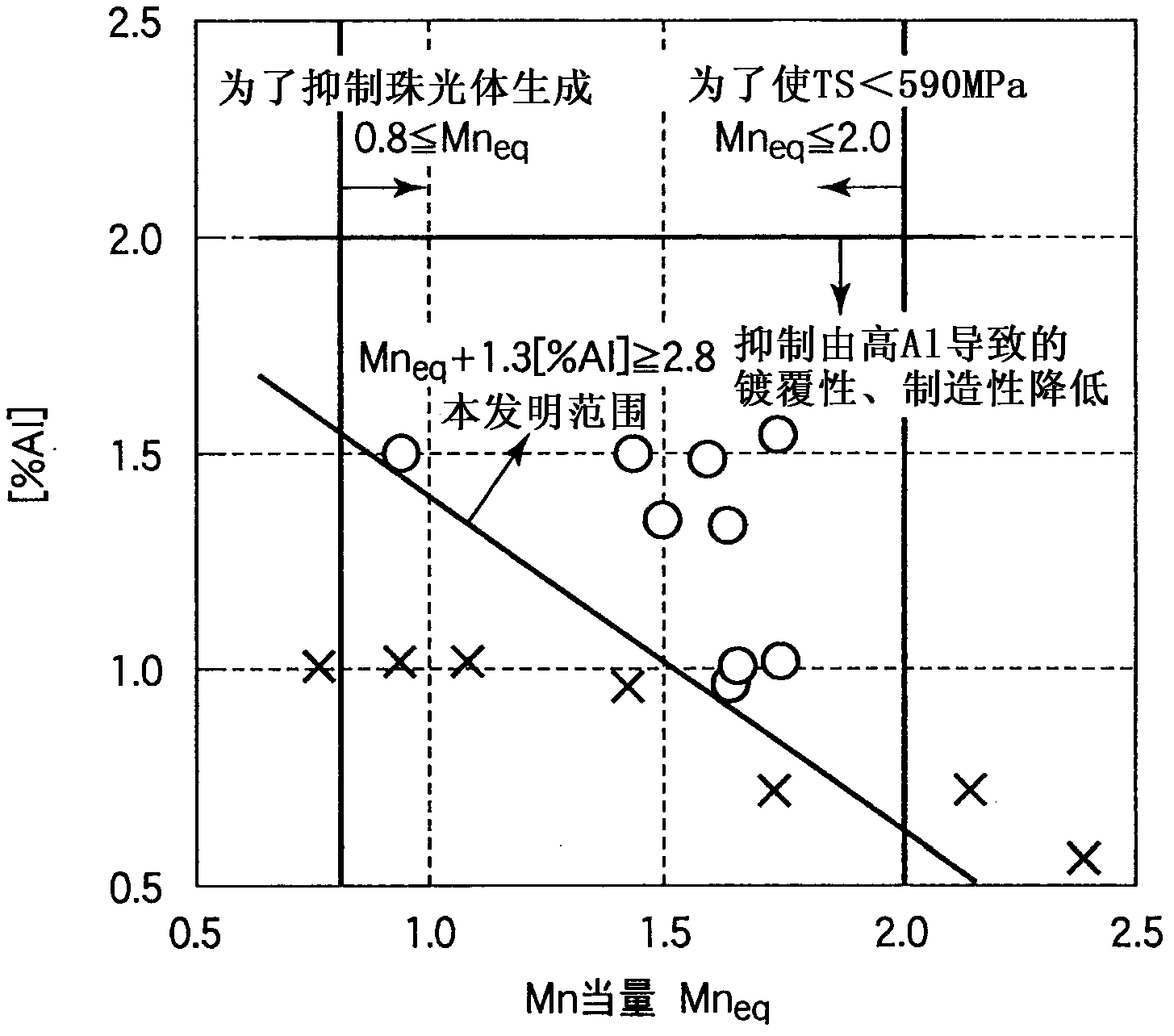

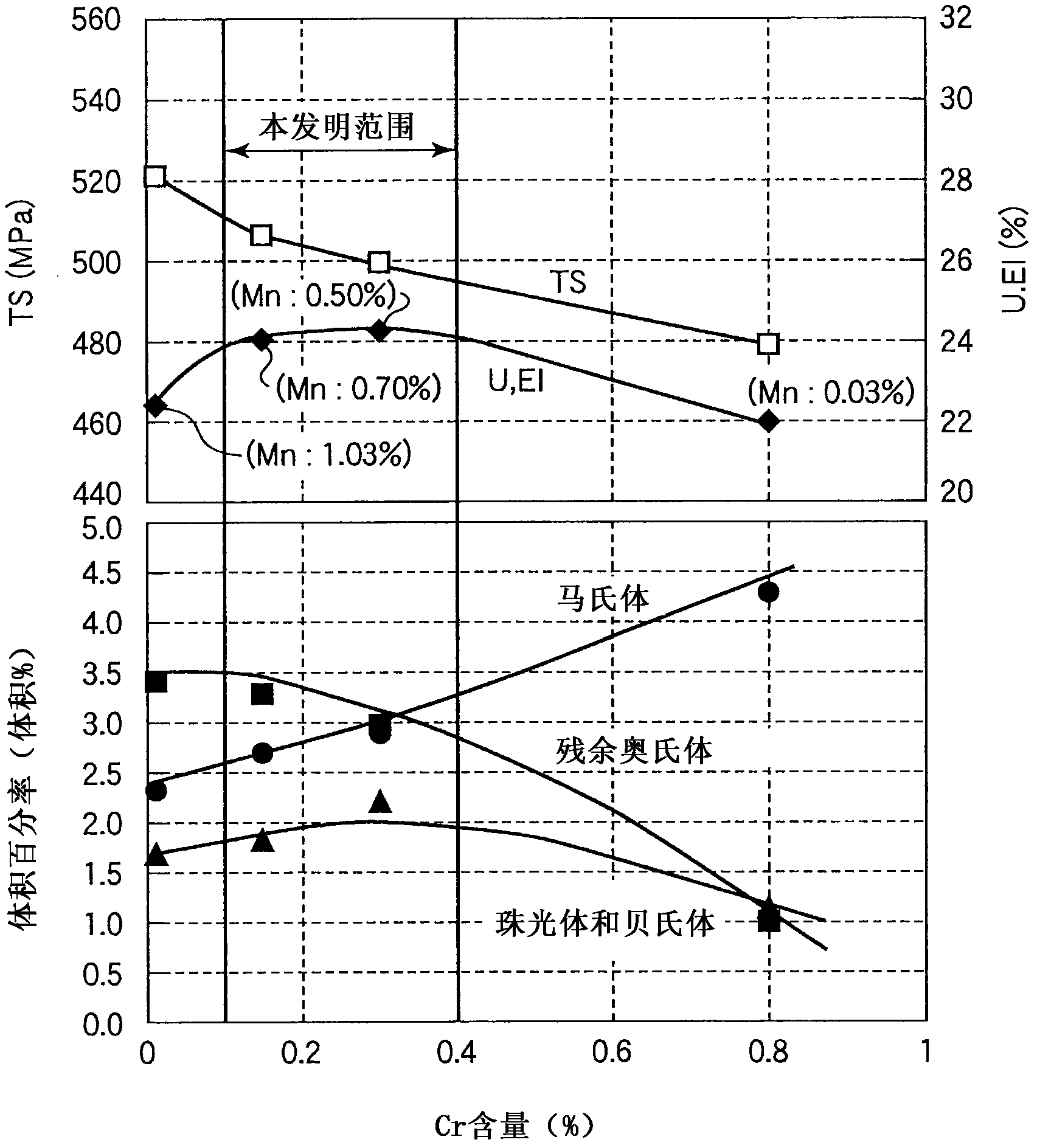

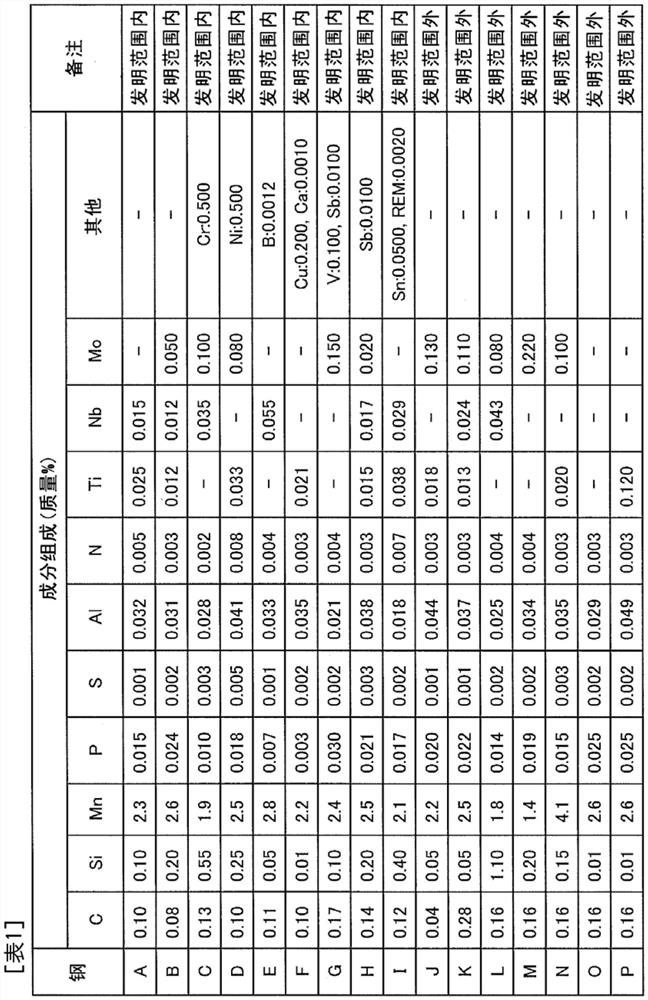

This invention provides a high-strength hot-dip galvanized steel sheet having a tensile strength of from 440 MPa to less than 590 MPa, excellent uniform elongation as a formability characteristic, reduced yield elongation as a quality characteristic of an outer panel, and good plating properties. This invention also provides a method for manufacturing the steel sheet. This steel sheet contains 0.06-0.20% C, less than 0.50% Si, from 0.5% to less than 2.0% Mn, no more than 0.05% P, no more than 0.02% S, 0.60-2.00% Al, less than 0.004% N, 0.10-0.40% Cr, and no more than 0.003% (including 0%) B. The expressions 0.8 =< Mneq <= 2.0 and Mneq + 1.3 [%Al] >= 2.8 are satisfied. Ferrite is the matrix, and the second phase has a volume fraction of 15% or less. The second phase has martensite at a volume fraction of 3% or more and residual austenite at a volume fraction of 3% or more. The total volume fraction of pearlite and bainite is equal to or less than the volume fraction of martensite and residual austenite.

Owner:JFE STEEL CORP

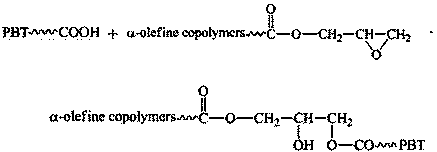

Resin composition for plating substrate and resin moldings using the same, and metal plated parts

InactiveCN1513028ANo plating swellingHigh Plating Adhesion StrengthCoatingsThin material handlingPhosphatePolyresin

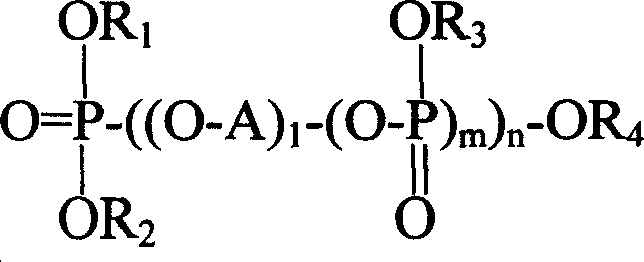

The resin composition for a platable substrate of the present invention comprises 100 parts by weight of a resin composition (C) comprising 10 to 60% by weight of a graft copolymer (A) prepared by graft polymerization of a rubbery polymer (A1) and a monomer component (A2) containing an aromatic alkenyl compound monomer unit (a) and a vinyl cyanide compound monomer unit (b) and 40 to 90% by weight of the other polymer (B) (provided that the total amount of the components (A) and (B) is 100% by weight), and 5 to 40 parts by weight of a phosphate ester flame retardant (D) having a molecular weight of more than 326 or 2 to 40 parts by weight of a red phosphorus flame retardant (D'). The resin composition for a platable substrate of the present invention is excellent in production stability such as moldability, dimensional stability, mechanical strength and plating properties, and is also environmentally friendly. Excellent plated parts having good thermal conductivity can be provided by forming a metal plating layer on a resin molded article obtained by molding the resin composition for a platable substrate using a plating treatment. The resulting plated parts are suitable for use as housings for laptop PC and portable devices.

Owner:大科能宇菱通株式会社

Method for manufacturing nickel-chromium plating steel band for battery steel shell

The invention discloses a method for manufacturing a nickel-chromium plating steel band for a battery steel shell. According to the method, ingredients of low-carbon steel are adjusted, proper amount of alloy elements of Ti, Ni, Nb and the like is added, and the content of N and O is controlled to improve surface states; parameters of a cold milling process and an annealing process are adjusted aiming at the adjusted ingredients of the steel; a chromium coating is used as a diffusion impervious layer, so that the diffusion of iron can be blocked effectively; and an anticorrosive coating which contains 20 to 30 percent of chromium and has a quasi-stainless steel structure is formed in the diffusion layer, so that the anticorrosive performance is enhanced doubly. Aiming at double-layer plating design concept of nickel-chromium plating, the ingredients of a nickel plating solution and a chromium plating solution and a plating process are adjusted, so that the coating has the characteristics of bright surfaces, low porosity and high mechanical performance.

Owner:WUXI FANGZHENG METAL LIGATURE

Polyester molding composition, preparation method and applications thereof

The invention discloses a polyester molding composition, a preparation method and applications thereof, wherein the polyester molding composition comprises 30-99.7 parts of a polyester resin, 2-20 parts of an anti-impact modifier, 2-15 parts of a laser sensitive additive, and 0.1-50 parts of a reinforcing material and / or a filler. According to the present invention, the research results show thatthe prepared polyester molding composition and the surface treated metal can form the metal-plastic complex with excellent adhesion through injection molding, wherein the mechanical properties are excellent, the heat resistance is good, the bonding force between the metal and the plastic is greater than 120 kgf, and the requirements of the NMT process on the bonding force between the metal and theplastic can be met; and the prepared polyester molding composition can be used for preparing members for metal deposition, wherein the plating index MI value is more than 0.85, the LDS metal platingperformance is excellent, and the metal can be selectively deposited in the laser etched area so as to form the beautiful chemical plating layer.

Owner:ZHUHAI WANTONG SPECIAL ENG PLASTICS CO LTD

Wrought magnesium alloy having excellent formability and method of producing same

Disclosed is a wrought magnesium alloy having excellent strength and extrusion or rolling formability, and a method of producing the same. The wrought magnesium alloy comprises 0.1 - 1.5 at% group IIIa, 1.0 - 4.0 at% group IIIb, 0.35 at% or less of one selected from the group consisting of groups IIa, IVa, VIIa, IVb, and a mixture thereof, 1.0 at% or less of group IIb, and a balance of Mg and unavoidable impurities and thus has a second phase composite microstructure. The wrought magnesium alloy of the present invention has high strength, toughness, and formability in addition to the electromagnetic wave shield ability of magnesium. Accordingly, the wrought magnesium alloy is a material useful to portable electronic goods, such as notebook personal computers, mobile phones, digital cameras, camcorders, CD players, PDA, or MP3 players, automotive parts, such as engine room hoods, oil pans, or inner panel of door, or structural parts for airplane.

Owner:PRIMOMETAL CO LTD

High-silicon aluminum alloy adapter plate and preparation method thereof

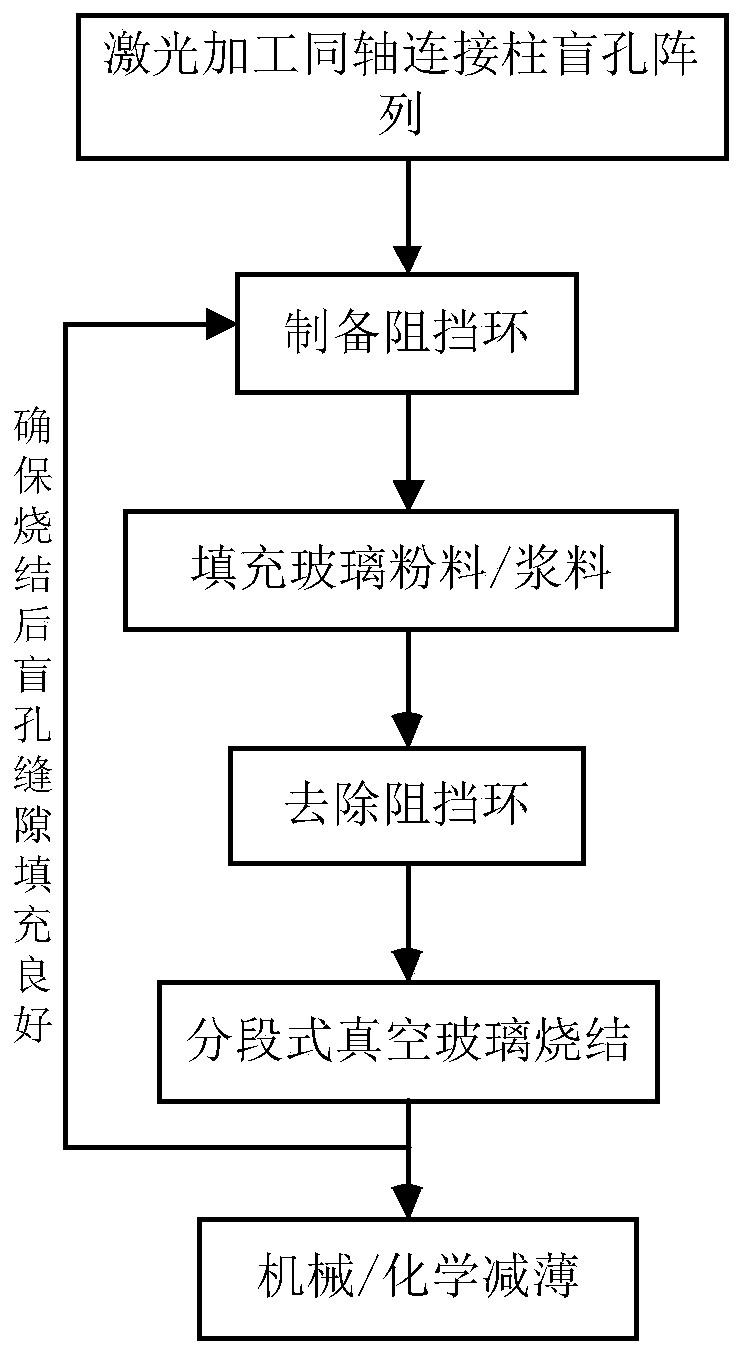

ActiveCN111081674AThe preparation process is simpleShorten production timeSemiconductor/solid-state device detailsSolid-state devicesAir tightnessDielectric layer

The invention discloses a high-silicon aluminum alloy adapter plate and a preparation method thereof. The adapter plate comprises a substrate, a connecting column array and an insulating dielectric layer filled in a gap between the connecting column array and the substrate, the connecting column array is formed by processing the substrate through a laser vertical through hole technology; the substrate and the connecting column array are made of high-silicon aluminum alloy, the insulating dielectric layer is made of a glass dielectric, connecting columns of the connecting column array are coaxial with the insulating dielectric layer, and the connecting columns, the glass dielectric and the substrate have the same height. The adapter plate prepared by adopting the method provided by the invention is firm and reliable in bonding interface and high in air tightness, and the blind hole center connecting column has electrical conductivity and can be directly used for electrical interconnection, so that a through hole metallization process can be omitted, the adapter plate preparation process flow is simplified, and the adapter plate preparation time and cost are reduced.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

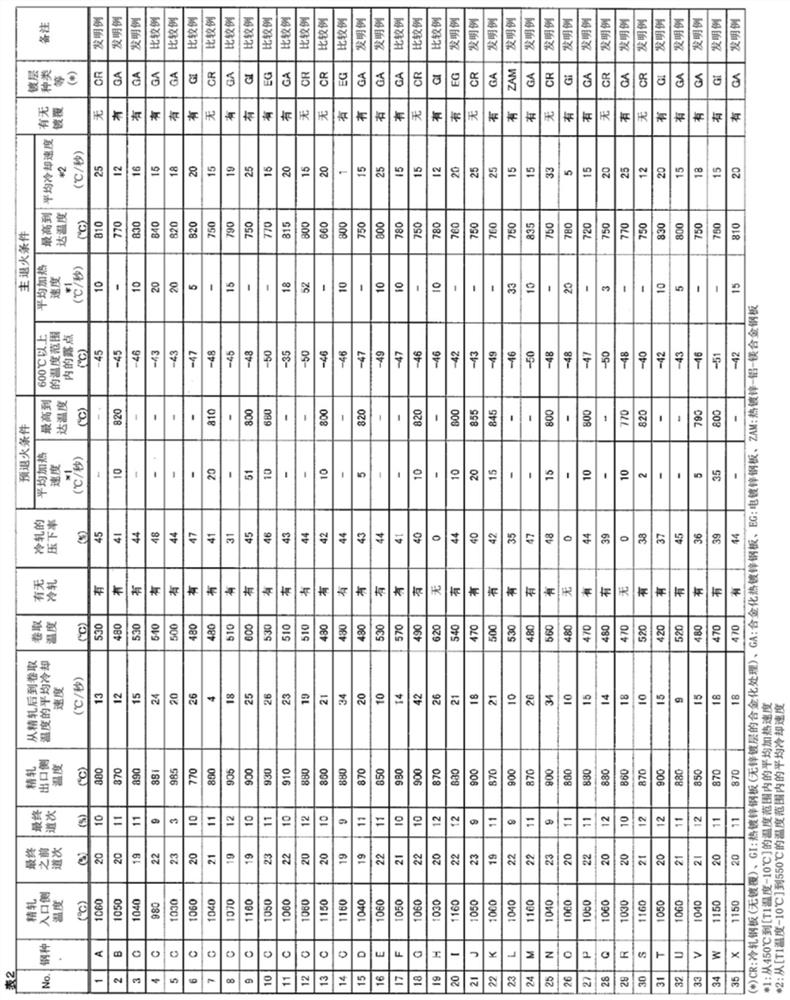

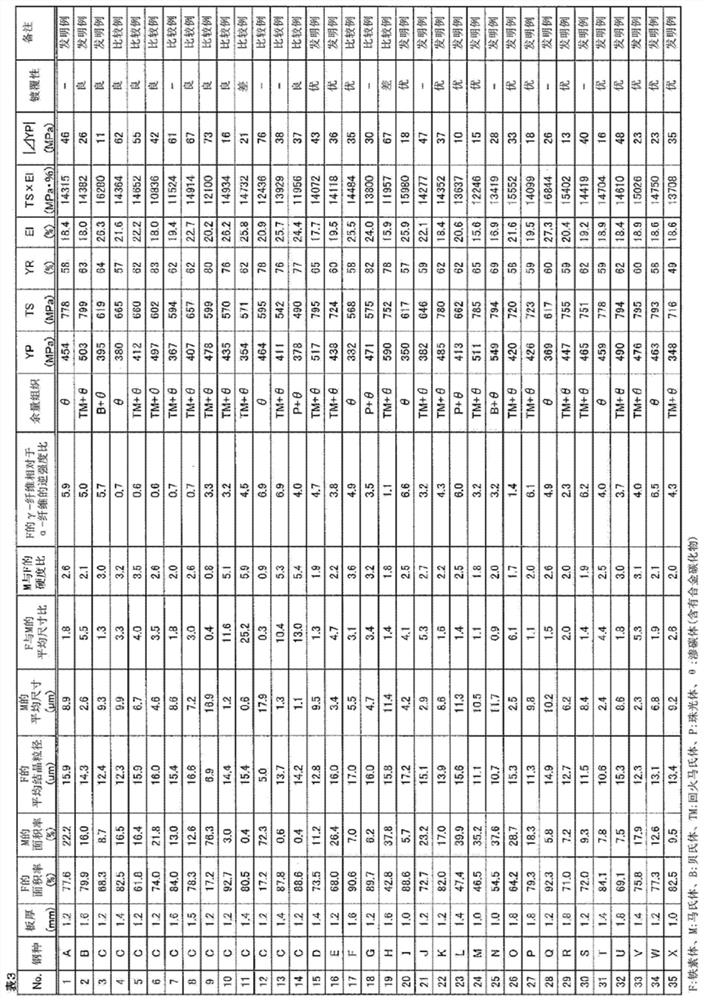

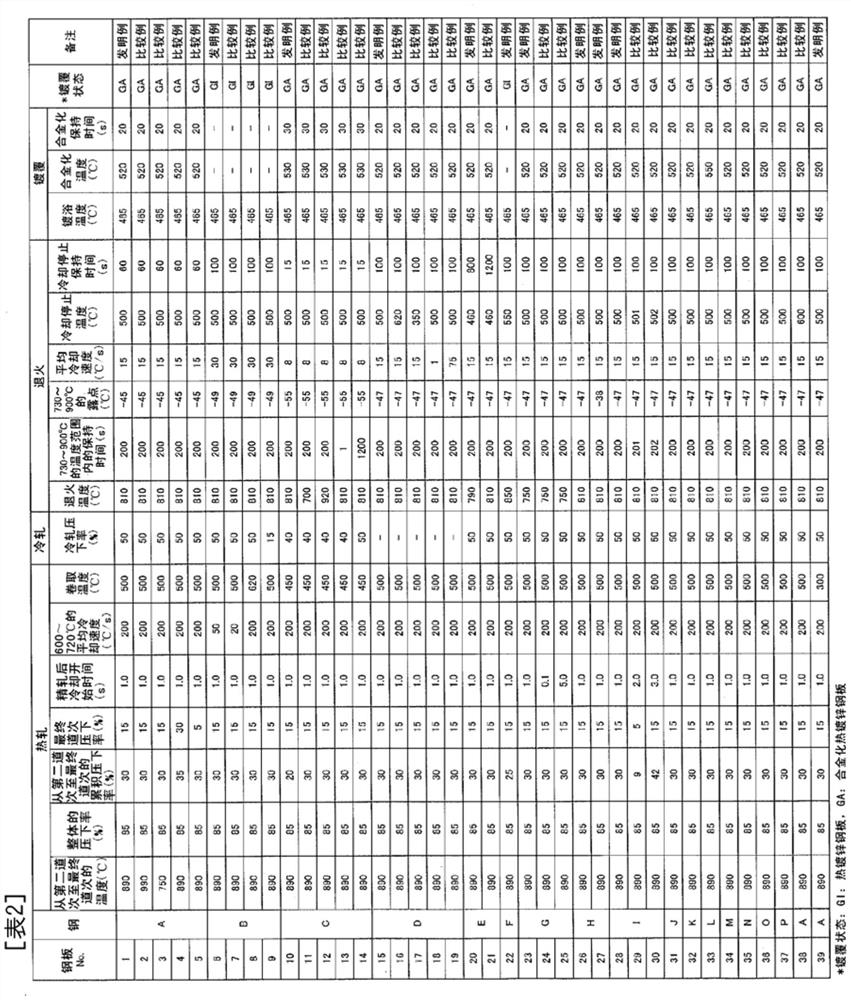

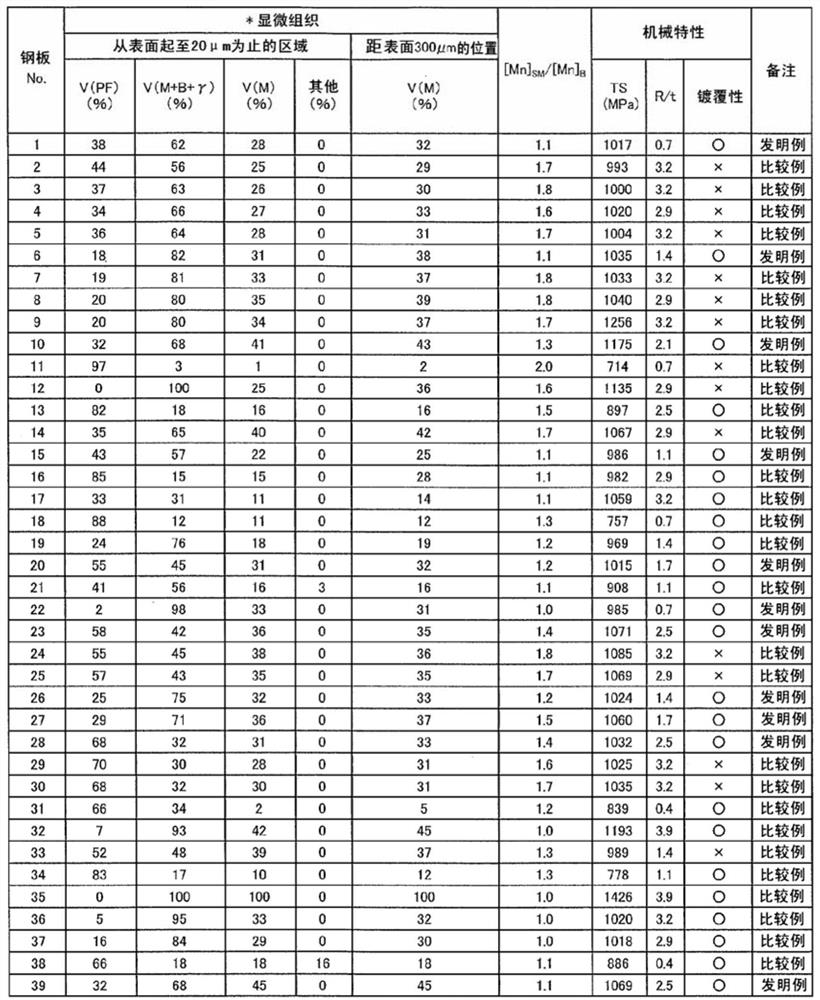

Thin steel sheet, plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing thin steel sheet, and method for producing plated steel sheet

ActiveCN108884537AImprove bending performanceExcellent plating propertyHot-dipping/immersion processesFurnace typesSheet steelCrystallization

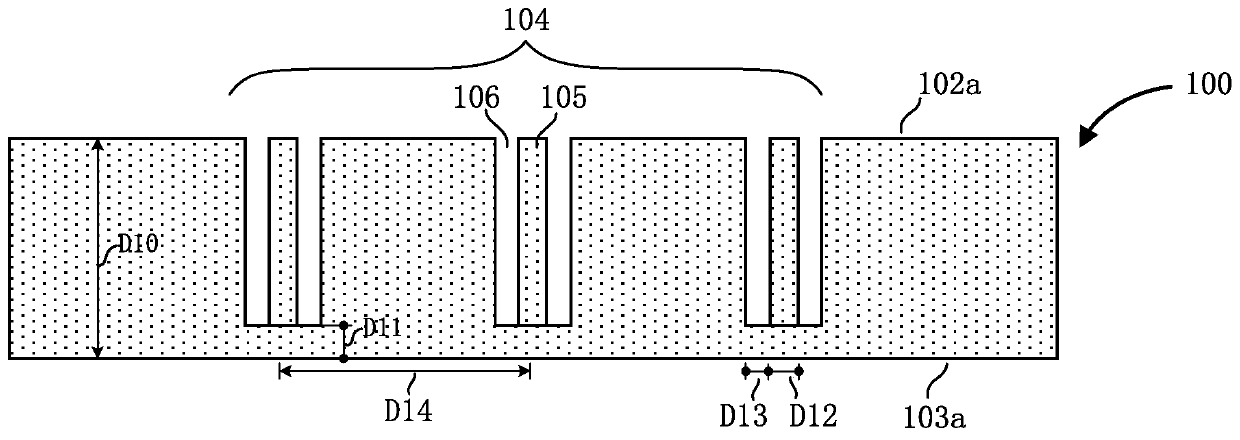

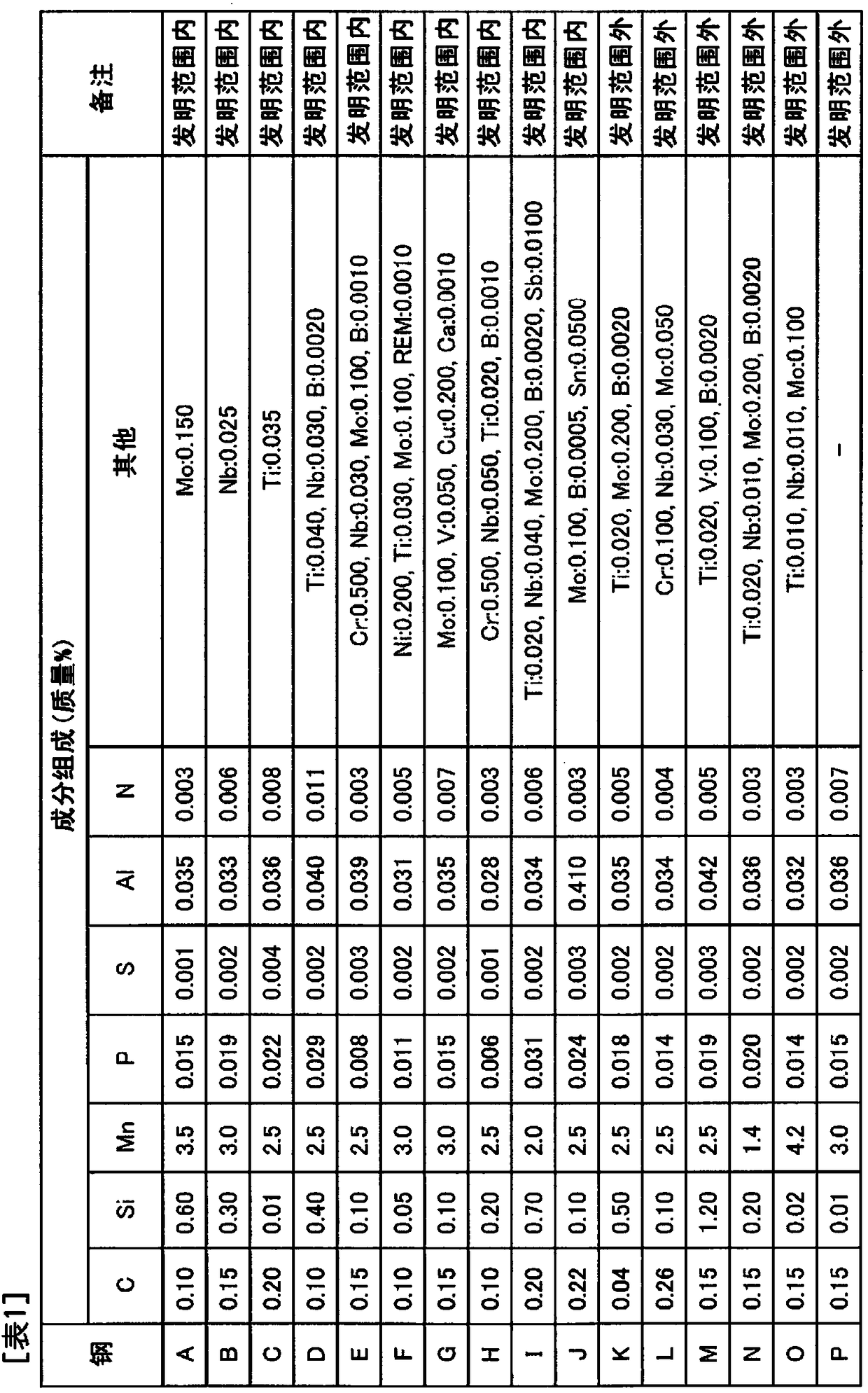

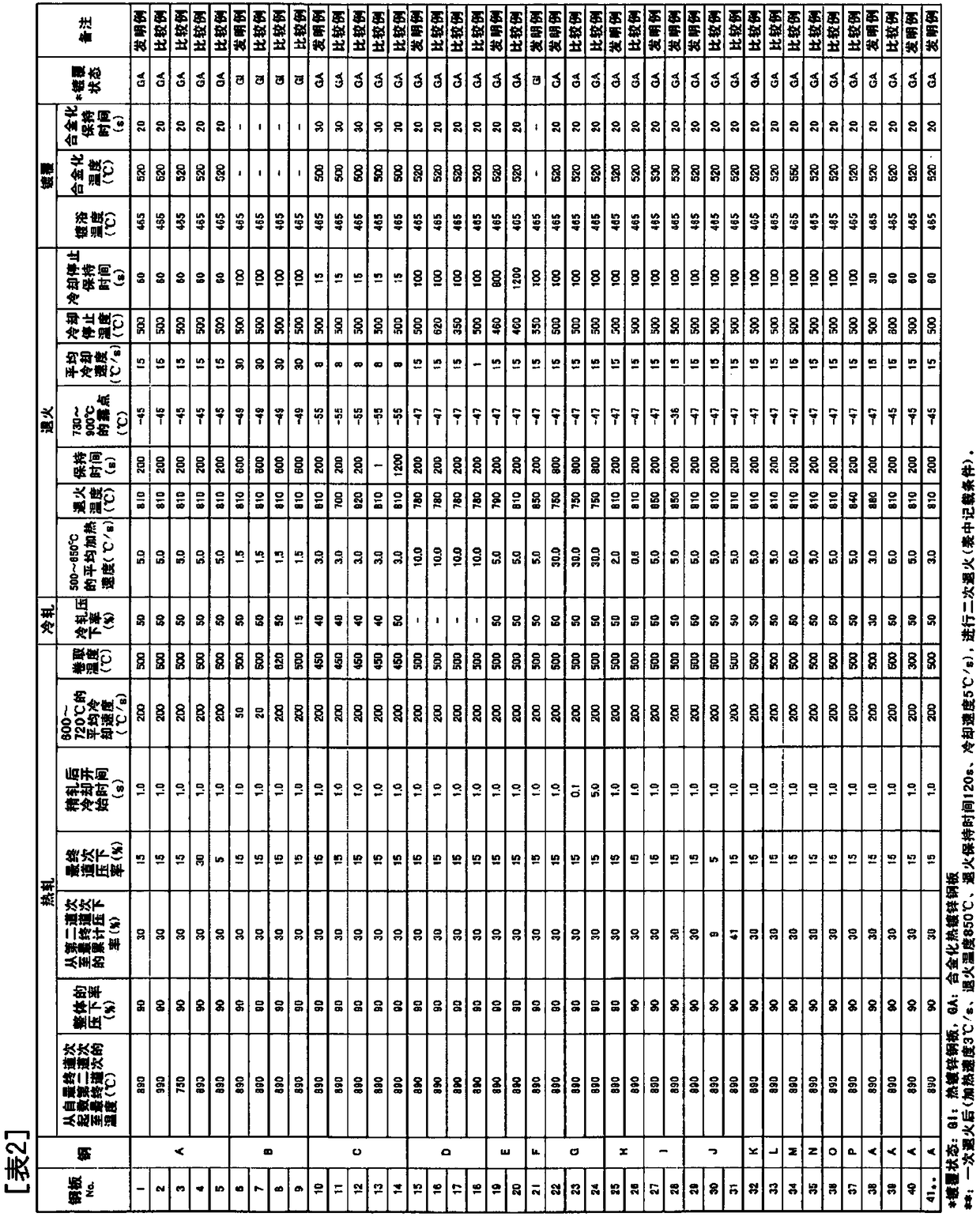

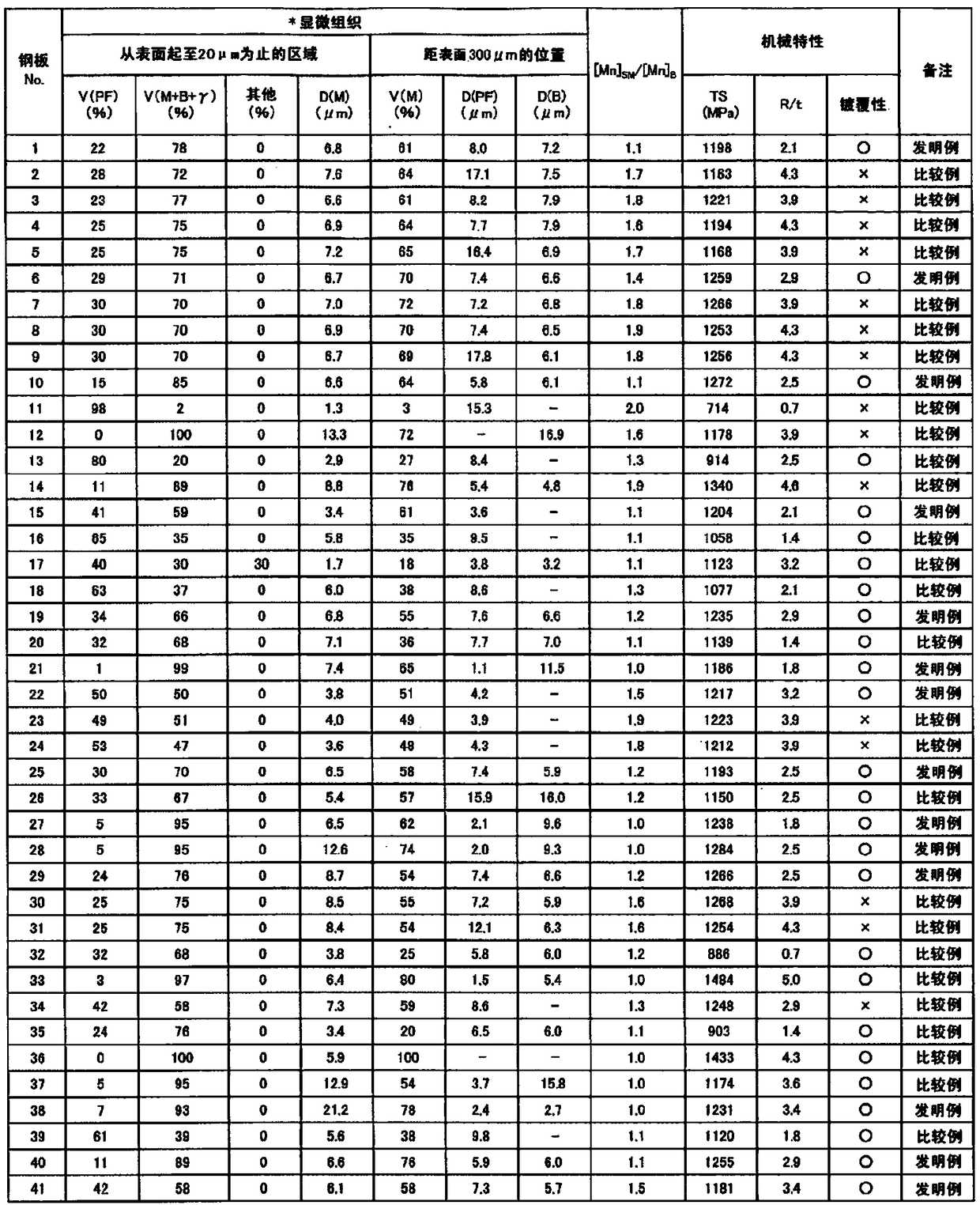

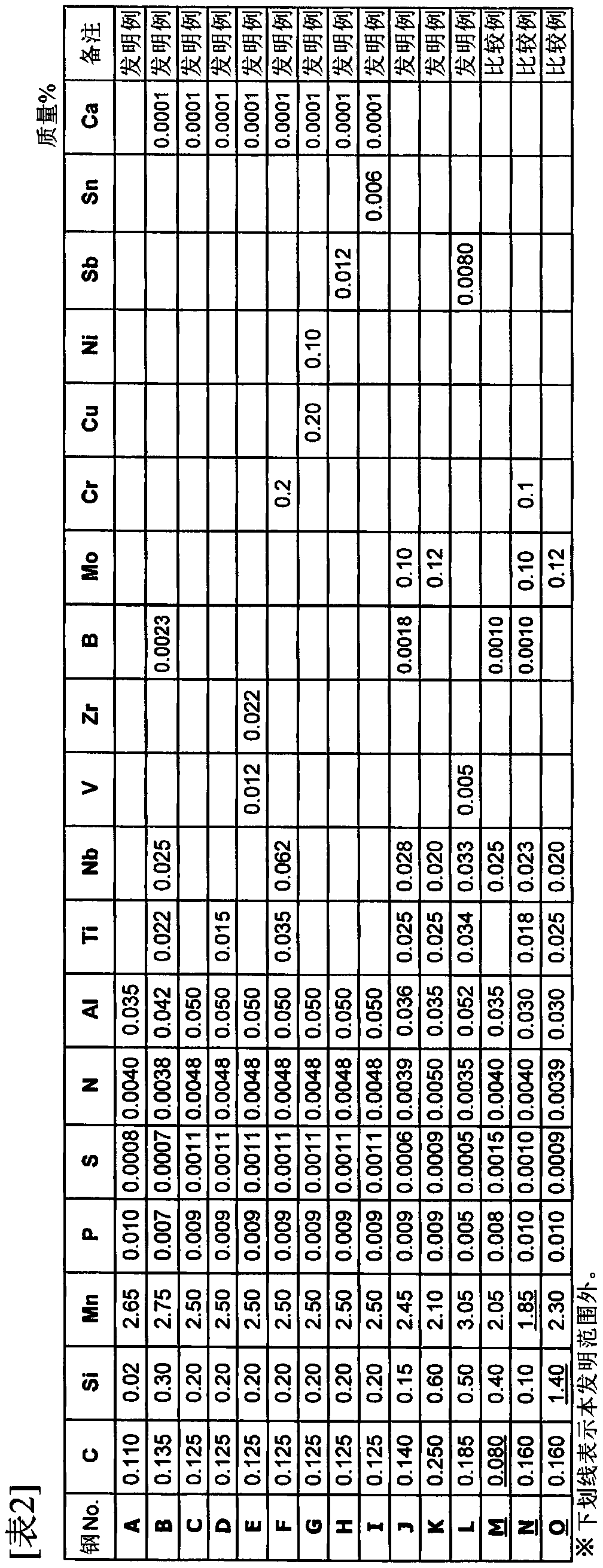

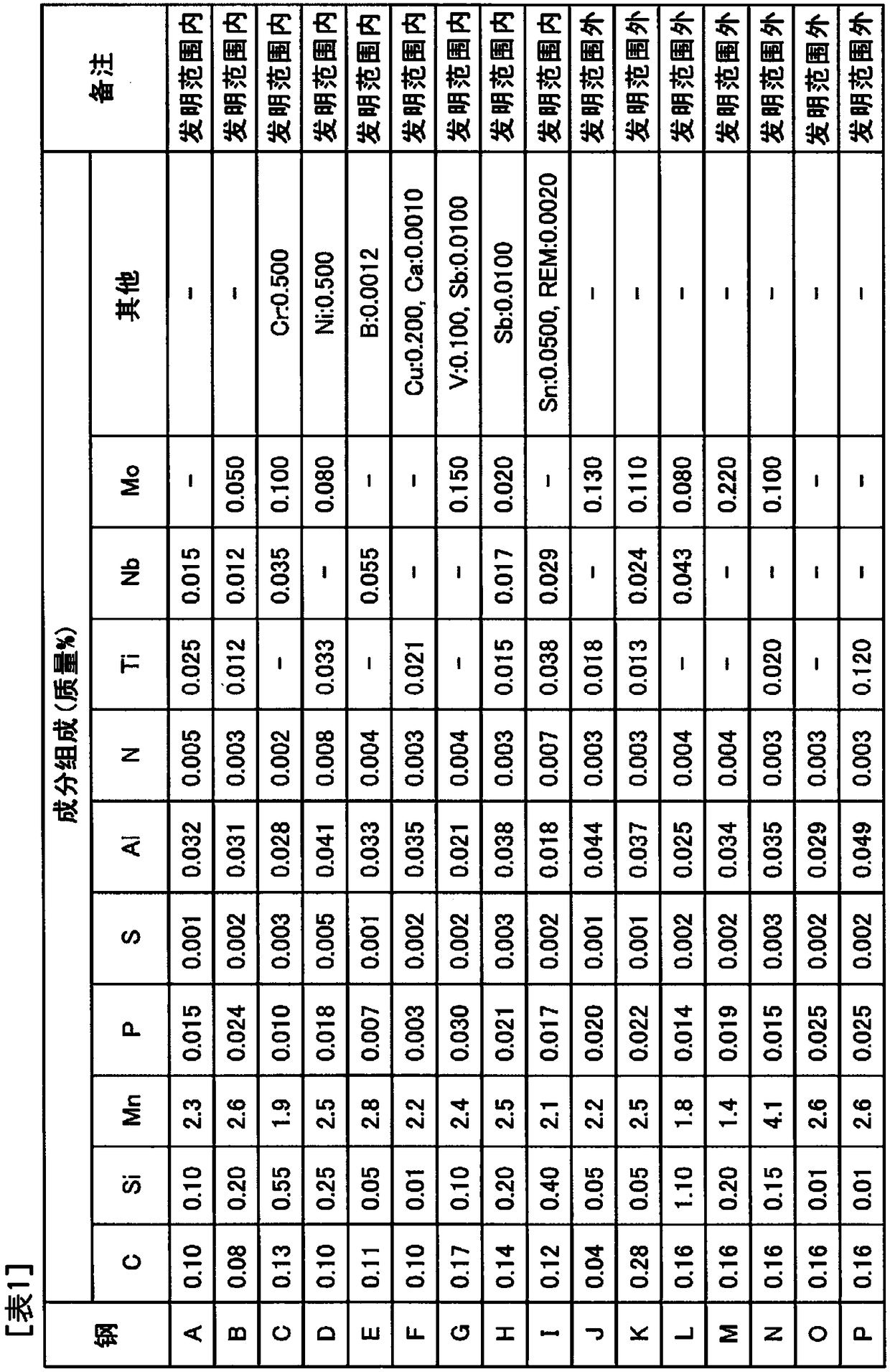

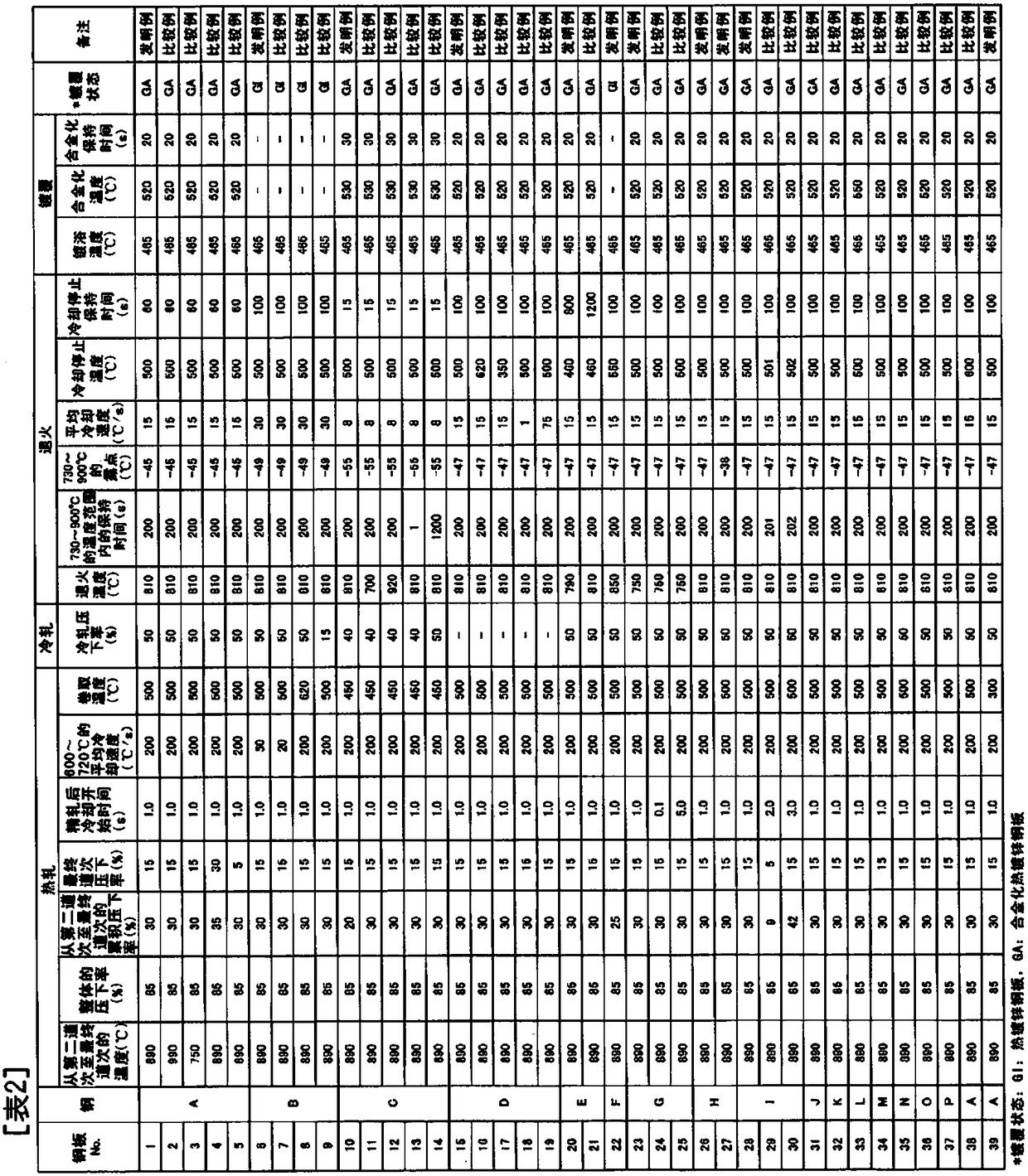

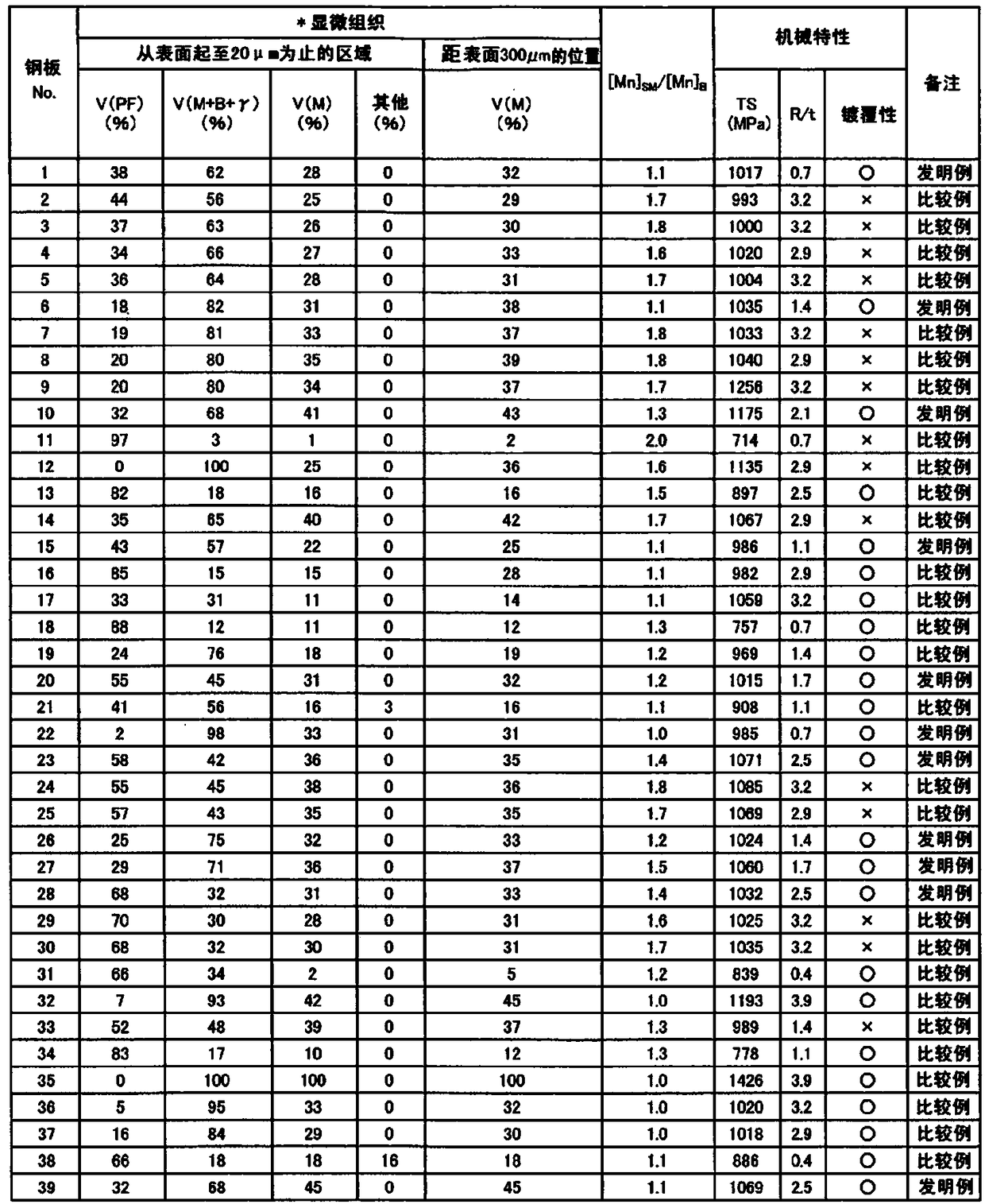

Provided are: a thin steel sheet and a plated steel sheet having a TS of 1180 MPa or higher and excellent bendability and plating properties; and methods for producing a hot-rolled steel sheet, a cold-rolled full-hard steel sheet, and a thin steel sheet. This thin steel sheet has a predetermined component composition and comprises at least one element selected from 0.003-0.100% of Ti, 0.003-0.100%of Nb, and 0.005-0.500% of Mo. In a range up to 20 [mu]m from the surface in the sheet thickness direction, polygonal ferrite accounts for 0-60%, and the total of martensite, bainite, and retained austenite is 40-100%. The amount of Mn in martensite present in a range up to 20 [mu]m from the steel sheet surface in the sheet thickness direction ([Mn]SM) and the amount of Mn in the bulk ([Mn]B) satisfies an equation that is [Mn]SM / [Mn]B <= 1.5. At a position 300 [mu]m from the surface in the sheet thickness direction, the area percentage of martensite is 40-80%, and the average crystal grain size of polygonal ferrite and that of bainite are less than 15 [mu]m.

Owner:JFE STEEL CORP

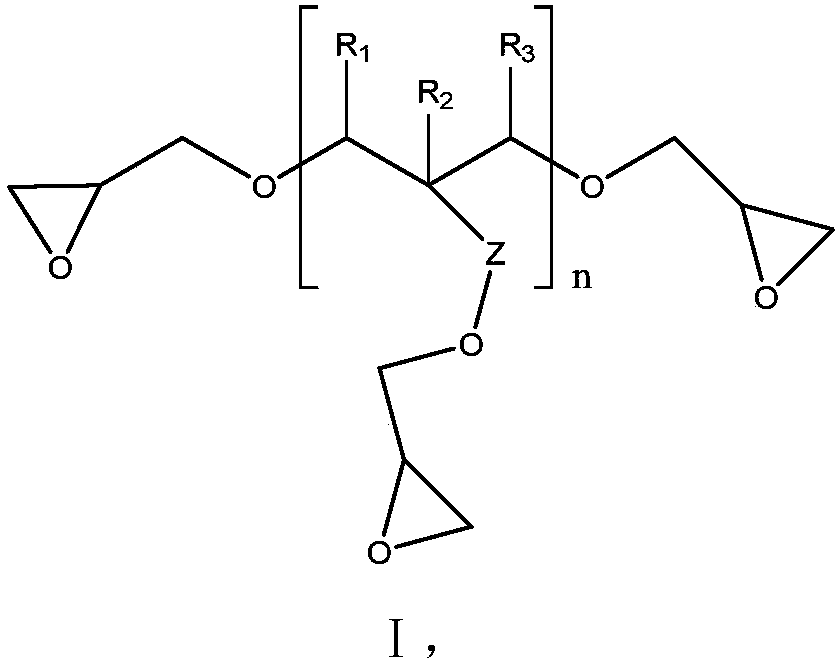

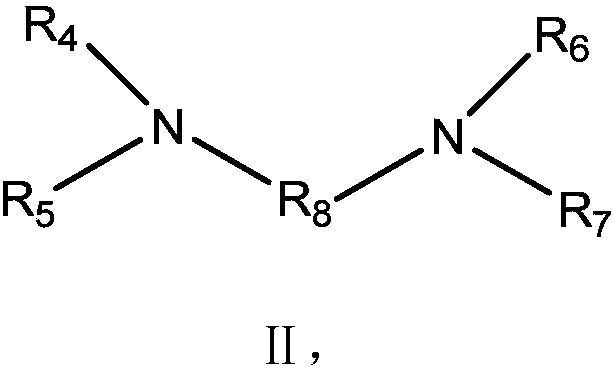

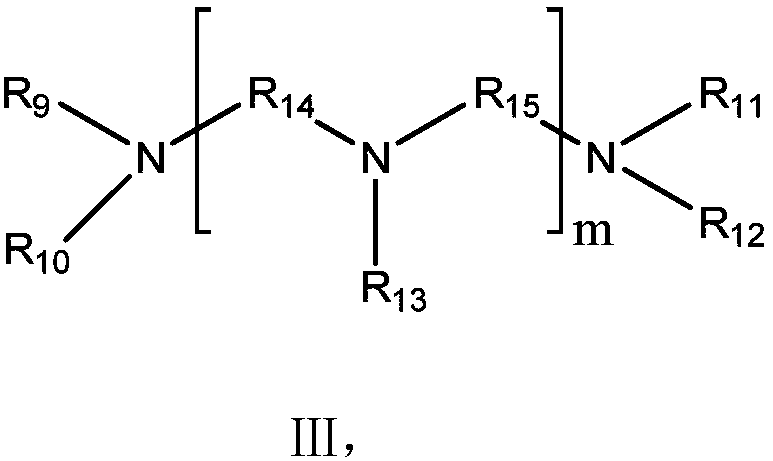

Leveling agent

InactiveCN109989076AUniform thicknessGood throwing abilityHigh densityNitrogenous heterocyclic compound

The invention discloses a leveling agent. The leveling agent is a polymer with the number-average molecular weight distribution being 500-20000, and the polymer is formed by reacting one or more kindsof nitrogenous heterocyclic compounds, two or more kinds of polyepoxy compounds and one or more kinds of poly-amino compounds. When the leveling agent is used for electrocoppering, copper layers withthe thicknesses being uniform and surfaces being smooth and flat can be obtained at the opening positions and the insides of high-aspect-ratio through holes as well as the surface of a base materialor the surface of the base material and the insides of high-density interconnected blind holes, copper electroplating liquid has good plating homogenization power and throwing power, good plating capacity is achieved especially for the through holes with the aspect ratio reaching 15 or above and the high-density interconnected blind holes, and the problem that the plating homogenization power andthrowing power of an existing leveling agent cannot meet the practical needs is solved.

Owner:GUANGDONG TONESET SCI & TECH

Pre-galvanizing process for electroplating copper on surface of magnesium alloy shell

The invention discloses a pre-galvanizing process for electroplating copper on the surface of a magnesium alloy shell. The process comprises the following steps: (1) washing: washing with alkali, water and acid; (2) activating: activating for 5-15 minutes in an activate fluid; (3) zinc-immersing alloying: immersing a magnesium alloy cast in zinc alloy immersion liquid for 10-15 minutes at 75-85 DEG C; (4) pregalvanizing, wherein the pregalvanizing fluid comprises 32-36g / L of ZnSO4.7H2O, 164-168g / L of K4P2O7.3H2O, 18-20g / L of KF, 32-36g / L of C6H17O7N3, 0.4-0.6g / L of phytic acid, 4-6g / L of H2CSNH2 and the balance of water, the pregalvanizing temperature is 35-45 DEG C, the electroplating time is 30-40 minutes, and the current density is 2-3A / dm<2>.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Nickel-chromium-plated steel band for battery steel shell

InactiveCN102873935AExcellent plating propertyImprove surface conditionCell component detailsMetal layered productsChlorideBoric acid

The invention discloses a nickel-chromium-plated steel band for a battery steel shell. The steel band comprises the following chemical components in percentage by weight: 0.15 to 0.20 percent of C, 0.2 to 0.4 percent of Si, 0.5 to 0.7 percent of Mn, 0.01 to 0.02 percent of Als, 0.05 to 0.08 percent of Ti, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.5 percent of Ni, 0.7 to 0.9 percent of Nb, less than or equal to 0.015 percent of N, less than or equal to 0.006 percent of O and the rest of Fe and unavoidable impurities, wherein the thickness of a chromium layer is 1.5 to 2.5 mu m; a solution for preparing the chromium layer comprises 600 to 620 g / L anhydrous chromic anhydride, 20 to 25 ml / L hydrochloric acid and the rest of water; the thickness of a nickel layer is 6 to 8 mu m; and a solution for preparing the nickel layer comprises 560 to 600 g / L nickel aminosulfonate, 12 to 14 g / L nickel chloride, 35 to 45 g / L boric acid and the rest of water.

Owner:WUXI FANGZHENG METAL LIGATURE

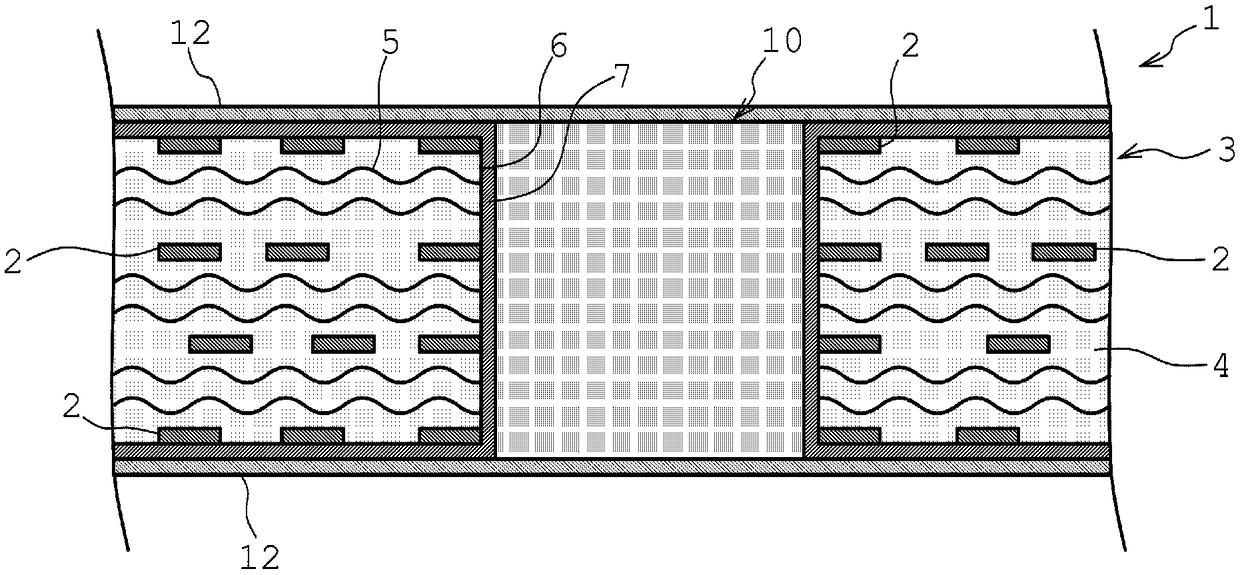

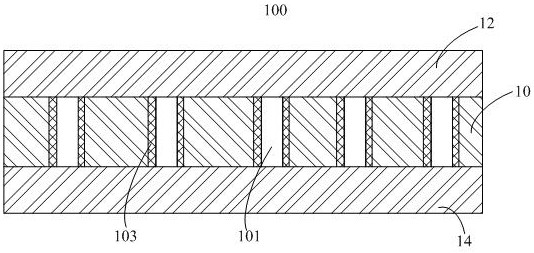

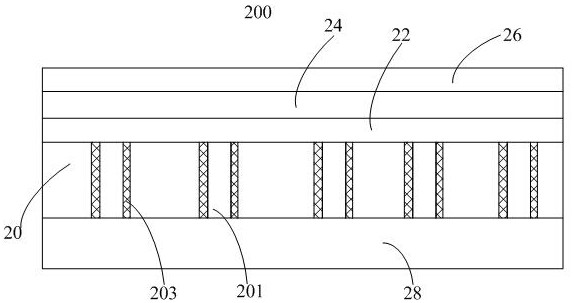

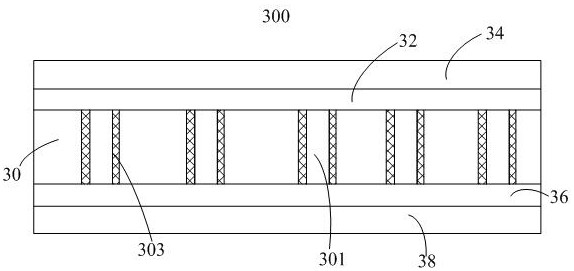

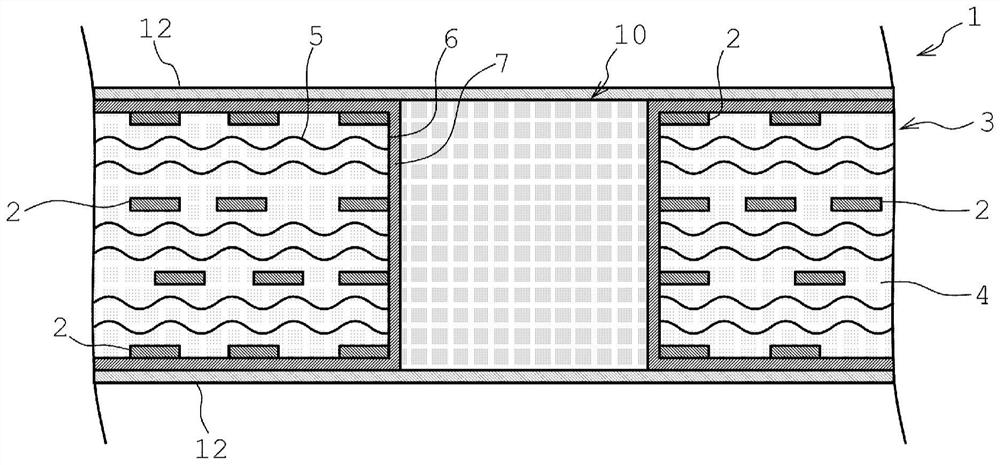

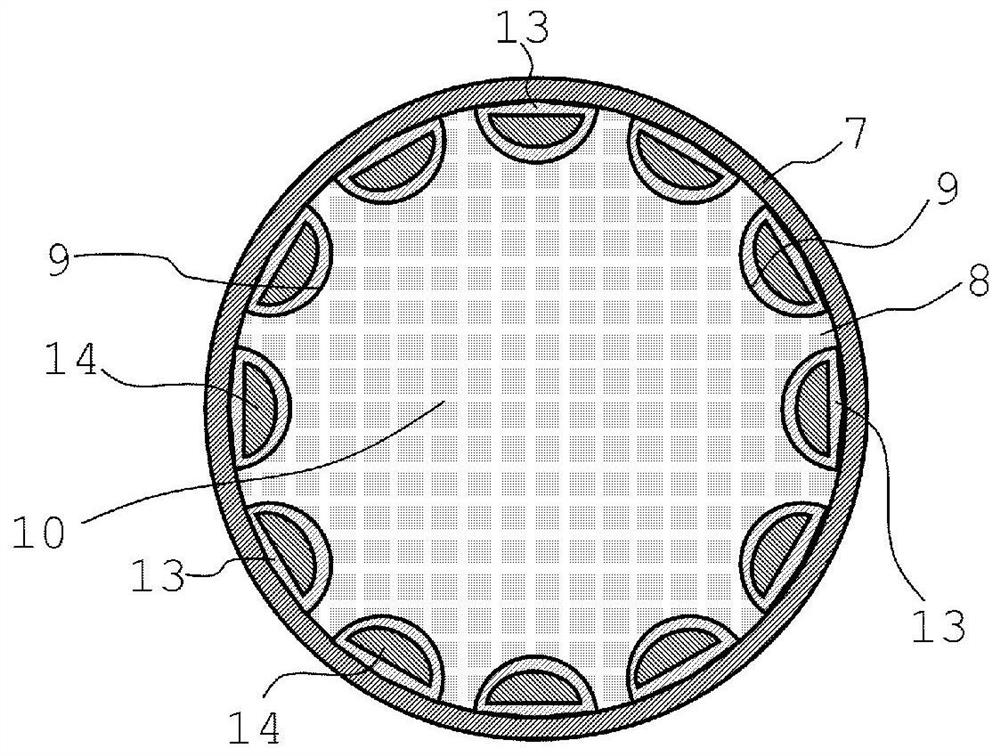

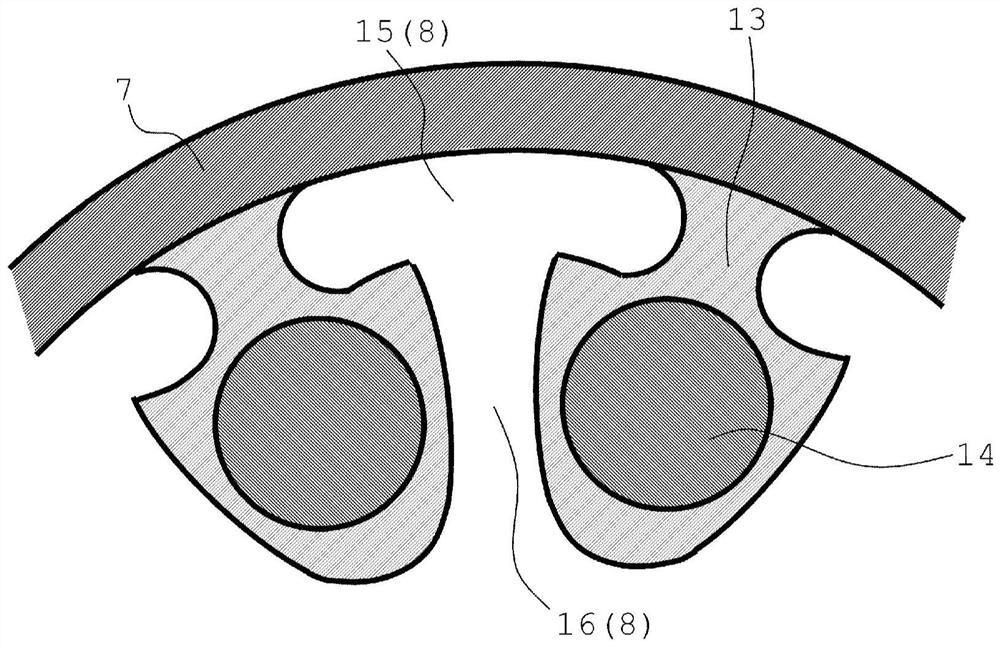

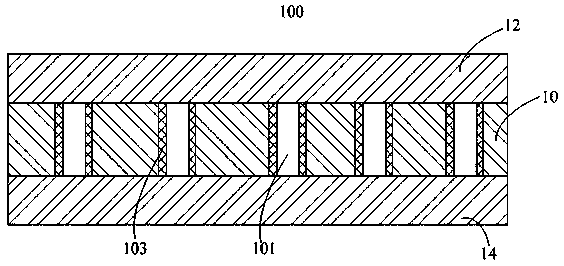

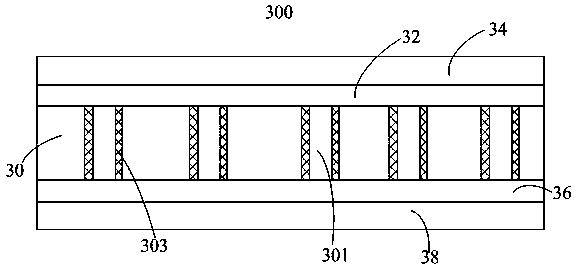

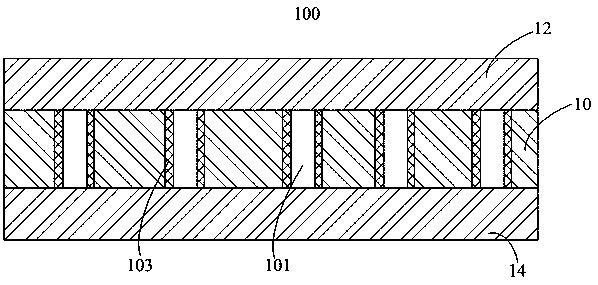

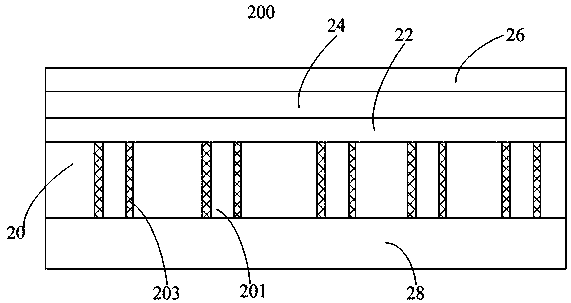

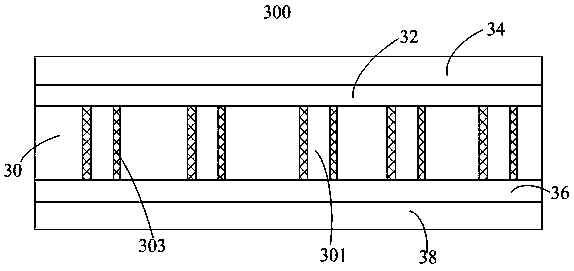

Substrate and method for manufacturing substrate

InactiveCN108353508AInhibit sheddingHas cooling propertiesMultilayer circuit manufactureFilling materialsEngineering

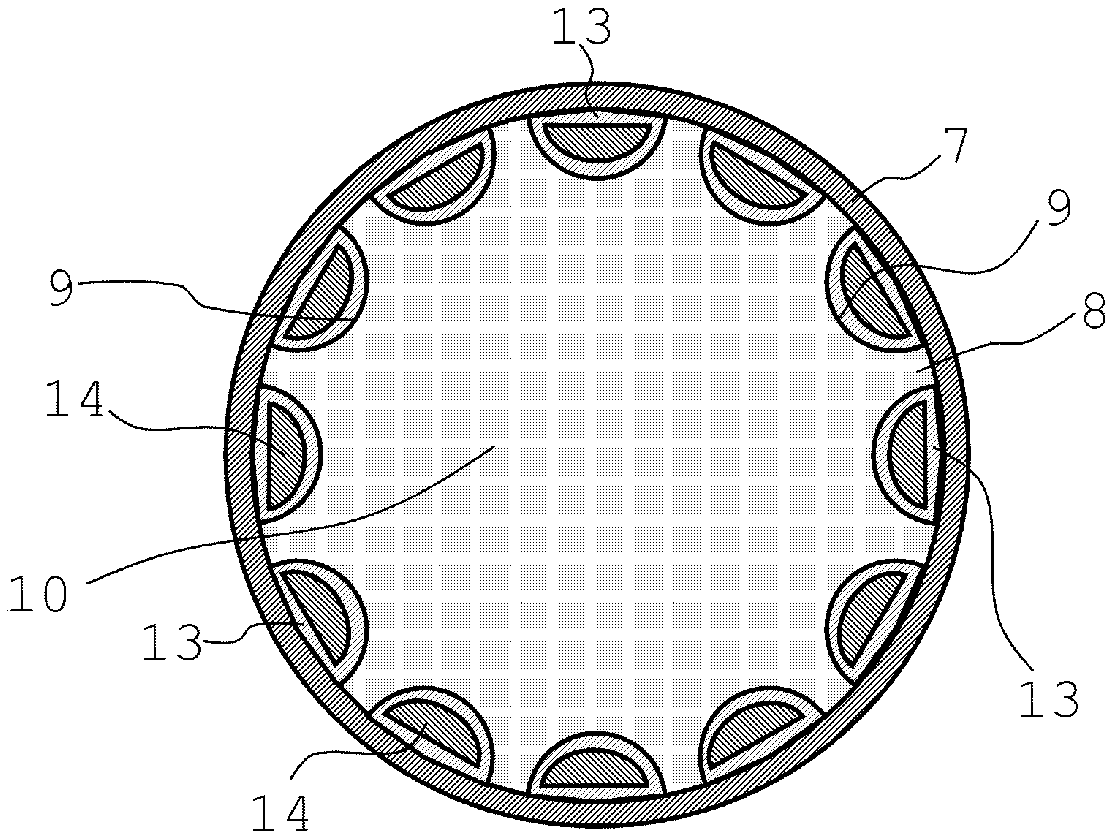

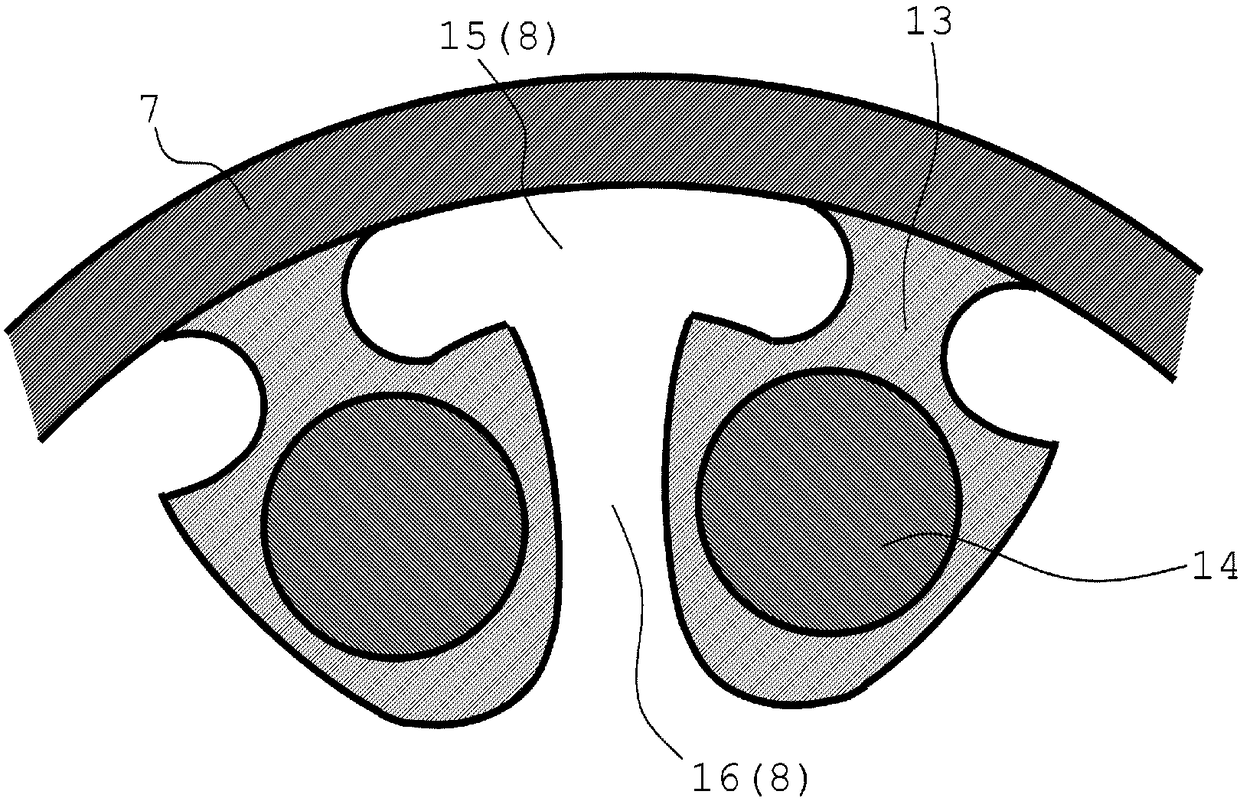

A substrate of the present invention is provided with: a laminated wiring board wherein a conductive layer is formed; a through hole penetrating the laminated wiring board; a through hole plating (7)electrically connected to the conductive layer; and a metal piece (10) disposed on the inner side of the through hole plating (7). In the side surface of the metal piece (10), a protruding section (8)directly in contact with the through hole plating (7), and a separated section (9) at a position separated from the through hole plating (7) are formed, and a space surrounded by the separated section (9) and the through hole plating (7) is covered with a metal plating film (13), and the inside of the plating film (13) is filled with a filling material (14).

Owner:MEIKO ELECTRONICS CO LTD

Preparation method for plating silver on surface of hollow glass bead

The invention discloses a preparation method for plating silver on the surface of a hollow glass bead. The preparation method comprises the following steps of mixing an ethanol solution and an alkaline solution to treat the surface of the hollow glass bead, then putting into a SnCl2 solution for surface sensitization treatment, and then putting into a prefabricated silver-ammonia solution activation solution for full reaction, the reducing solution being a mixed solution of glucose and tartaric acid, directly adding the reducing solution into the activation solution to enable Ag<+> in the activation solution to completely react, and then dropwise adding a silver ammonia solution oxidation solution for chemical silver plating. According to the preparation method, expensive and toxic PbCl2 is not selected as an activating agent, and the silver-ammonia solution is adopted as the activating agent, so that the cost is saved, the utilization rate of Ag is increased, and the purpose of protecting the environment is achieved; and the prepared silver-plated glass bead has a uniform and compact silver coating layer, is not easy to fall off, has excellent conductivity, and can be used in theindustry of electromagnetic shielding materials.

Owner:XI'AN POLYTECHNIC UNIVERSITY

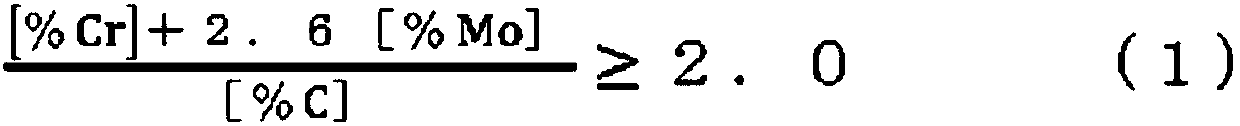

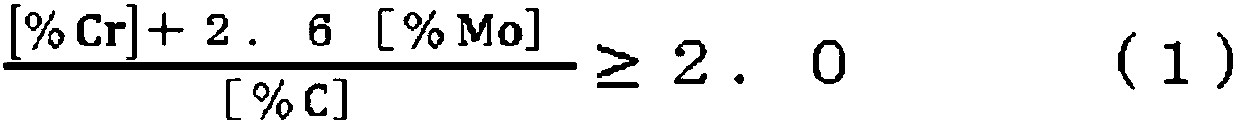

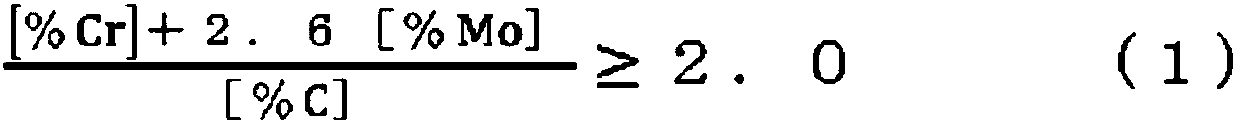

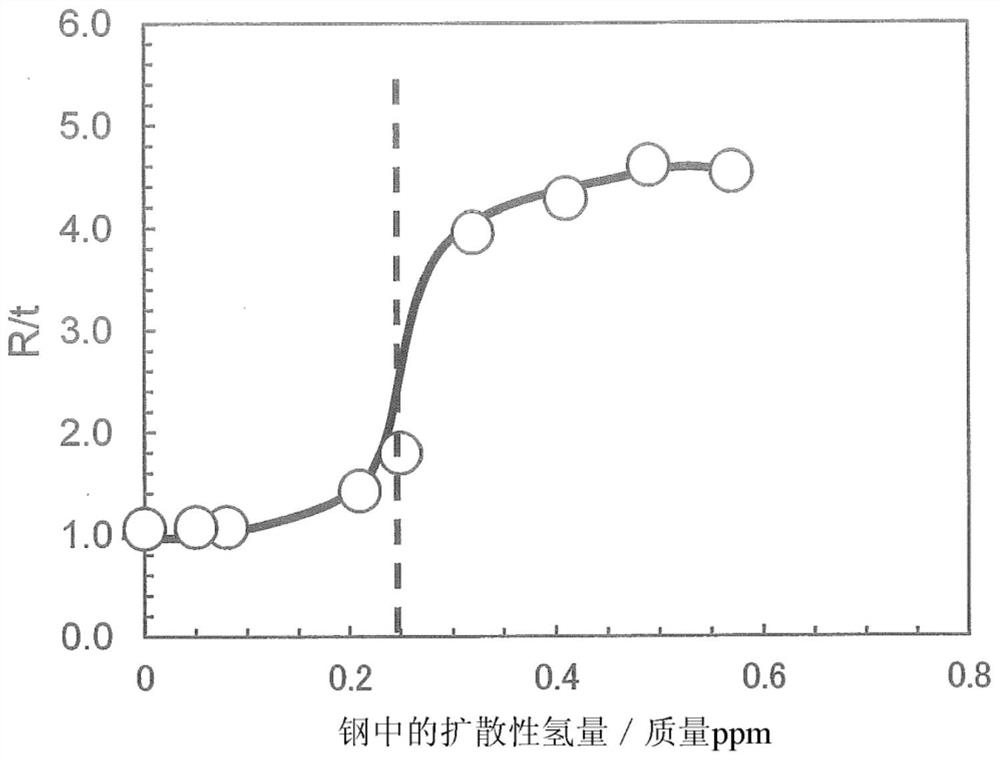

High-strength galvanized steel sheet, and method for manufacturing same

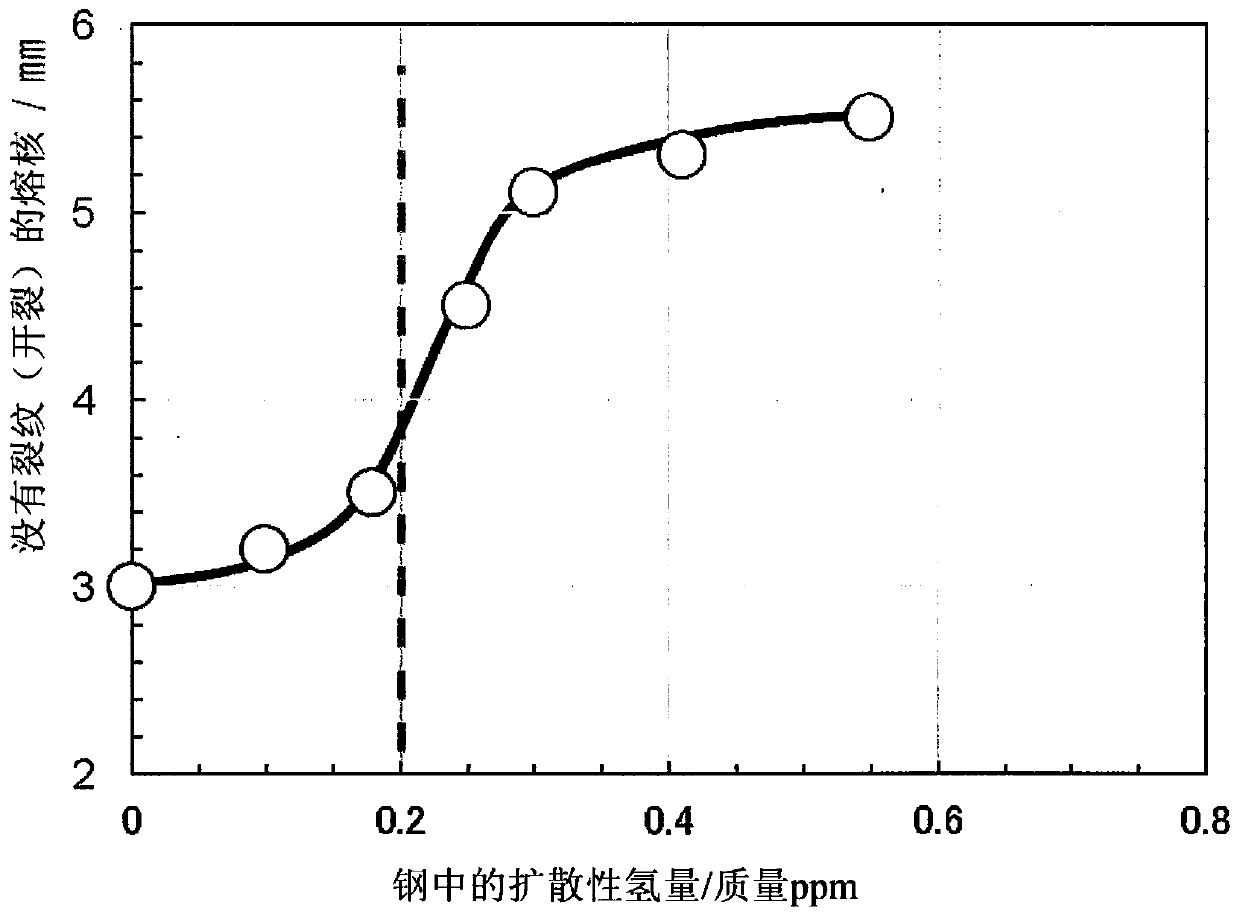

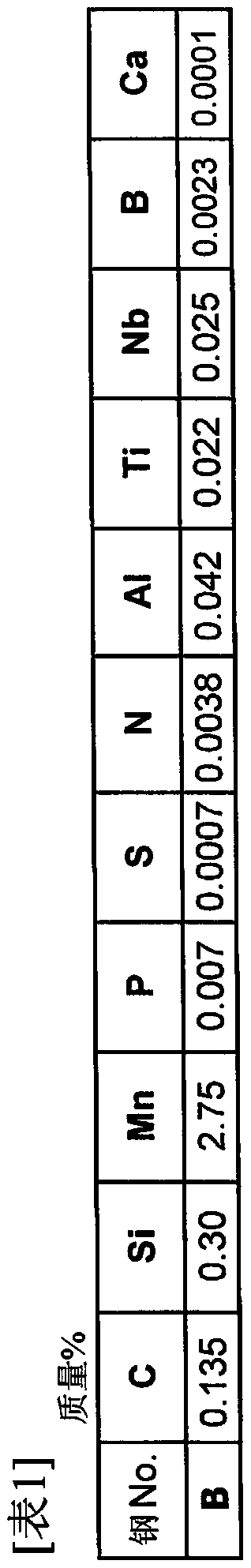

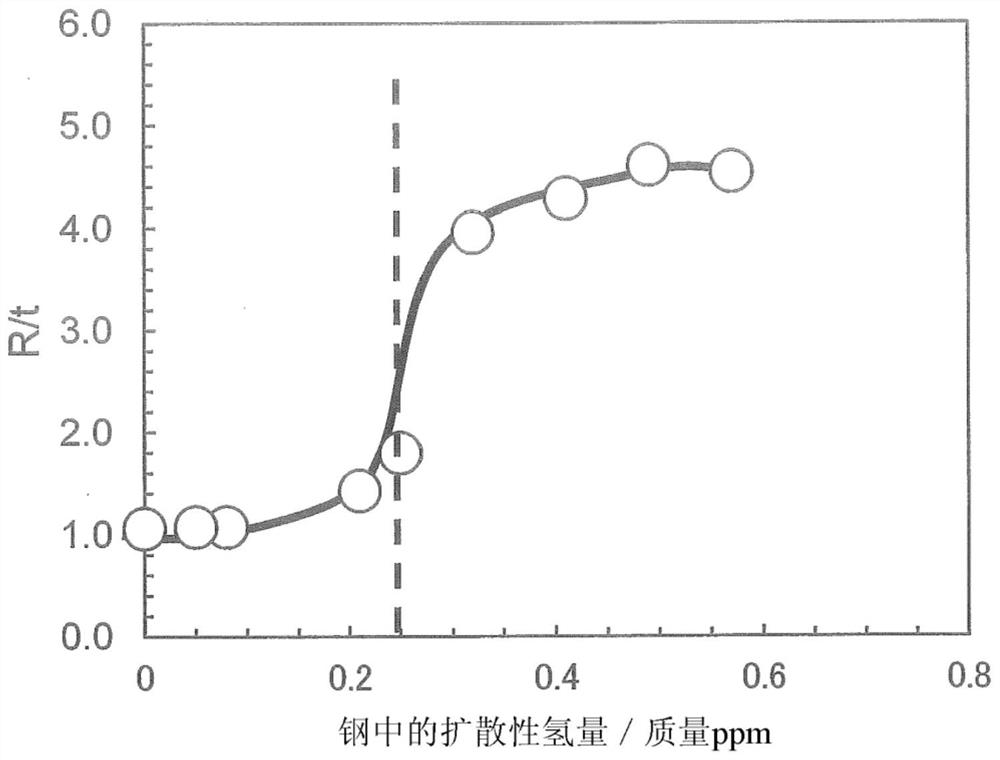

ActiveCN111433380AHigh strengthExcellent resistance to hydrogen embrittlementHot-dipping/immersion processesFurnace typesHydrogen contentUltimate tensile strength

Provided are: a high-strength hot-dip galvanized steel sheet that has a material quality meeting the high yield strength highly demanded for ultra-high-strength plated steel sheets for which hydrogenembrittlement is a concern, has an excellent plating appearance and excellent hydrogen embrittlement resistance, and has high yield strength suitable for building materials and automotive impact-resistant parts; and a method for manufacturing the same. This high-strength galvanized steel sheet comprises: a steel sheet having a specific component composition and a steel structure that contains at least 70% (including 100%) martensite and bainite, less than 20% (including 0%) ferrite, and less than 5% (including 0%) residual austenite, and having an in-steel diffusible hydrogen content of no more than 0.20 mass ppm; and a galvanized layer formed on the surface of the steel sheet and having an Fe content of 8 to 15%, in mass%, and a plating adhesion amount per surface of 20 to 120 g / m2, wherein the amount of Mn oxide contained in the galvanized layer is no more than 0.050 g / m2, the tensile strength is at least 1,100 MPa, and the yield ratio is at least 0.85.

Owner:JFE STEEL CORP

Thin steel sheet, plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing thin steel sheet, and method for producing plated steel sheet

ActiveCN109072375AHigh tensile strengthImprove bending performanceHot-dipping/immersion processesFurnace typesSheet steelArea ratio

Provided herein are a steel sheet and a plated steel sheet having a TS of 980 MPa or more and excellent bendability and plating capabilities, a method for producing a hot-rolled steel sheet, a methodfor producing a cold-rolled full hard steel sheet, and a method for producing a steel sheet. The steel sheet includes predetermined compositions, and includes at least one selected from 0.003-0.100% of Ti, 0.003-0.100% of Nb, and 0.005-0.500% of Mo. Polygonal ferrite is 0-80%, and a total of martensite, bainite, and residual austenite is 20-100% in terms of an area ratio in a range of 20 [mu]m ina sheet thickness direction from a steel sheet surface. The content of Mn in martensite present in the range of 20 [mu]m in the sheet thickness direction from the steel sheet surface ([Mn]SM) and thecontent of Mn in a bulk ([Mn]B) satisfies [Mn]SM / [Mn]B <= 1.5, and the martensite has an area ratio of 20-50% at a position 300 [mu]m in the sheet thickness direction from the steel sheet surface.

Owner:JFE STEEL CORP

High-strength steel sheet, and production method therefor

ActiveCN109642280AHigh strengthGood formabilityHot-dipping/immersion processesFurnace typesCrystallographyMartensite

Provided is a high-strength steel sheet which has a tensile strength of 980 MPa or higher, and excellent mouldability. This high-strength steel sheet has a specific component composition, and a structure in which the average grain size of a ferrite phase is 1.5 microns or lower, the area ratio of the ferrite phase is at least 2% but not more than 15%, the area ratio of a tempered martensite phaseis at least 75% but not more than 96%, and the total value of the lengths of interfaces between an untempered martensite phase and the ferrite phase, and the lengths of interfaces between the untempered martensite phase and the tempered martensite phase, per unit area, is at least 6.3*108 microns / m2 but not more than 5.0*1011 microns / m2.

Owner:JFE STEEL CORP

High-strength galvanized steel sheet, high-strength member, and manufacturing methods therefor

ActiveCN111936649AExcellent plating propertyImprove bending performanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMetal

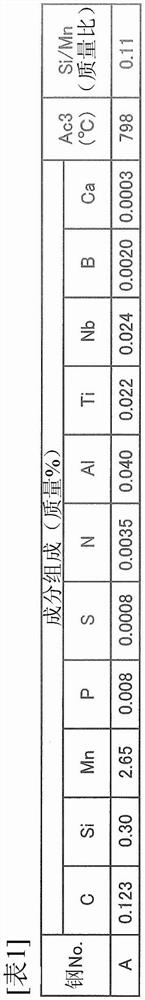

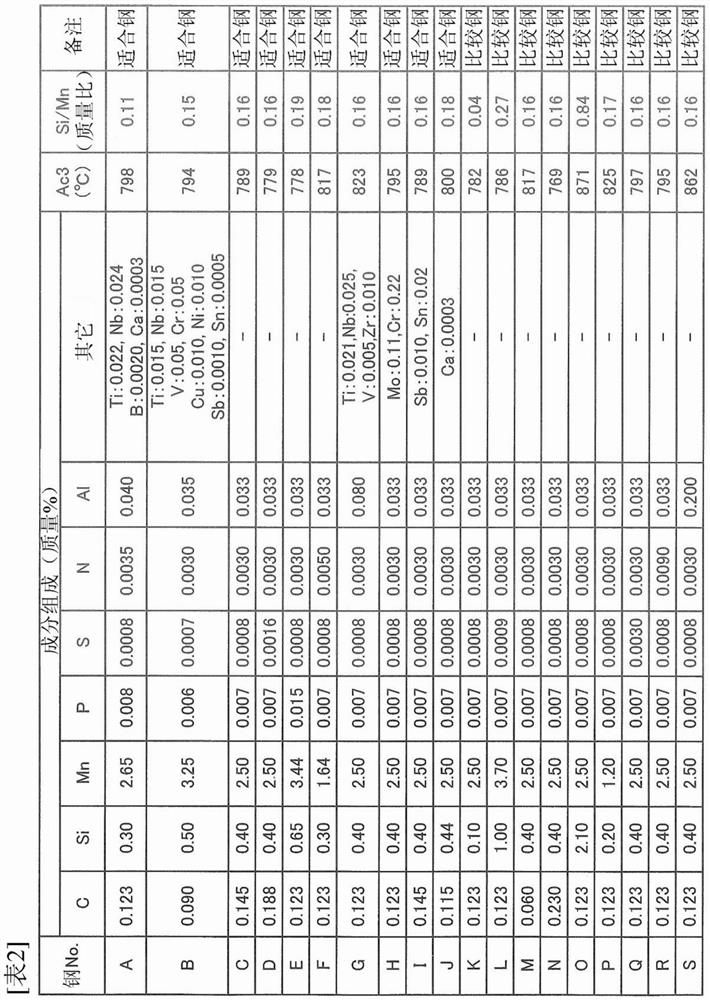

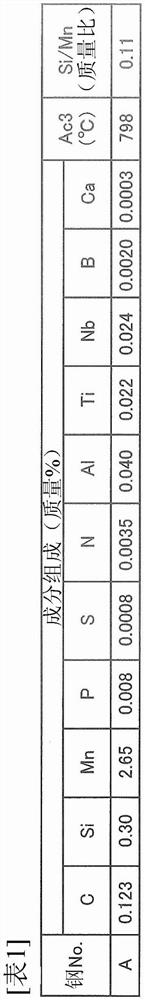

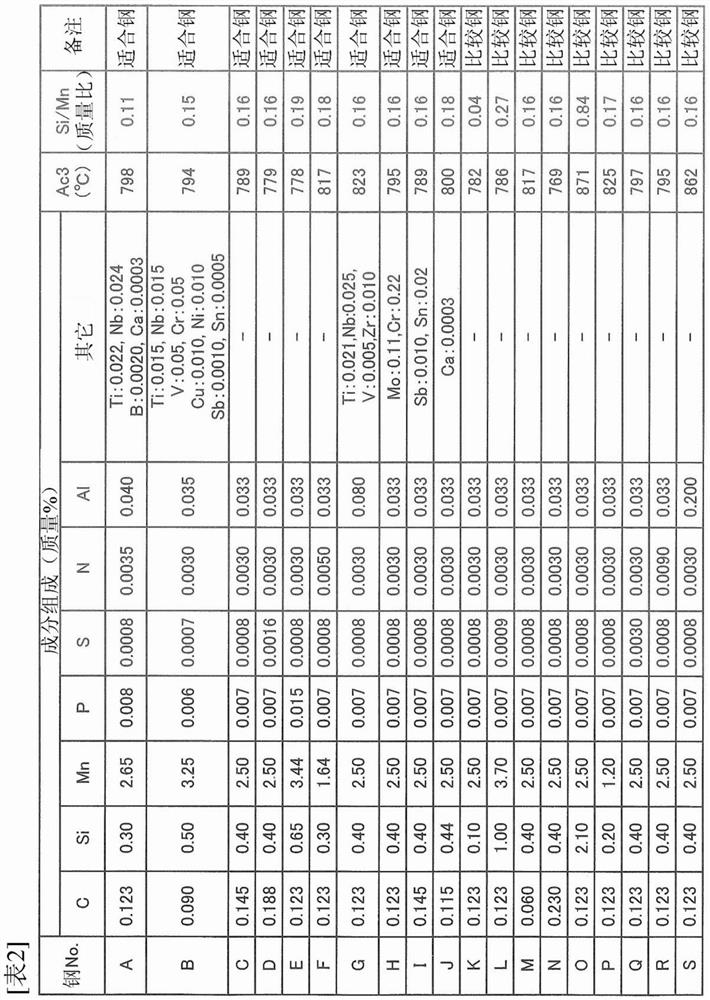

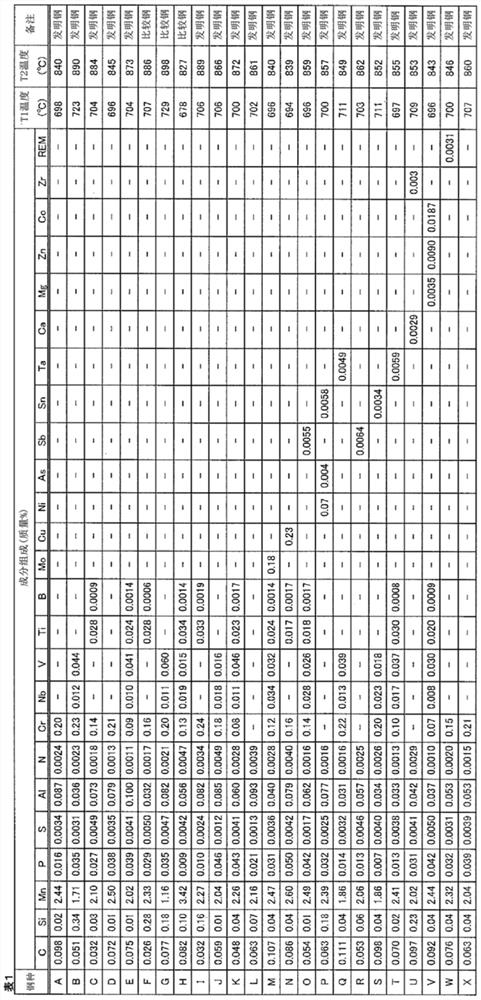

The present invention addresses the problem of providing a high-strength galvanized steel sheet having excellent plating properties and bendability, and providing a high-strength member, and manufacturing methods therefor. This high-strength galvanized steel sheet comprises: a steel sheet having a component composition which contains prescribed component elements, and for which the mass ratio (Si / Mn) of Si content with respect to Mn content in the steel is at least 0.1 but less than 0.2, the remainder comprising Fe and unavoidable impurities, and a metal structure for which the average particle size of inclusions present in a range from the surface to a position at 1 / 3 the sheet thickness and containing at least one element among Al, Si, Mg, and Ca is 50 mum or less, and the average nearest distance of the inclusions is 20 mum or greater; and, on the surface of the steel sheet, a zinc plating layer for which the plating adhesion amount per surface is 20-120 g / m<2>. The amount of diffusible hydrogen in the steel is less than 0.25 mass ppm, and the tensile strength is 1100 MPa or higher.

Owner:JFE STEEL CORP

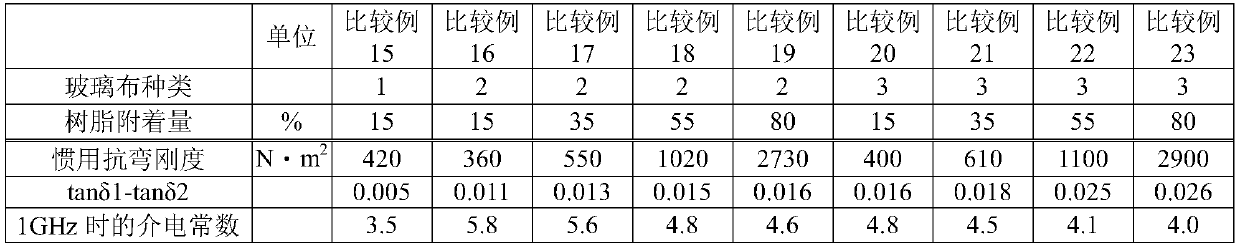

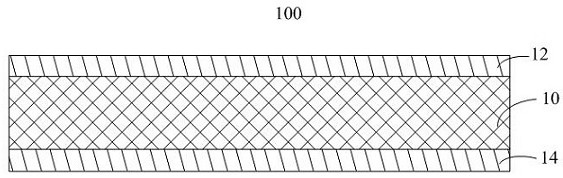

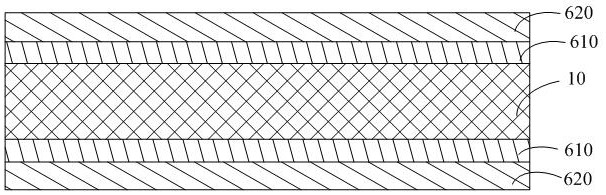

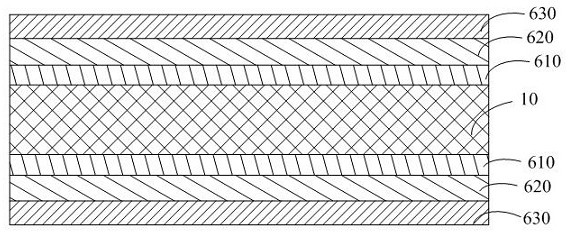

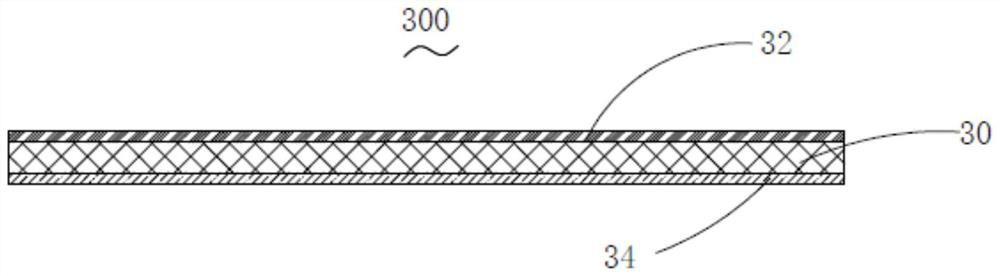

Quartz glass fiber-containing prepreg quartz glass fiber-containing film and quartz glass fiber-containing substrate

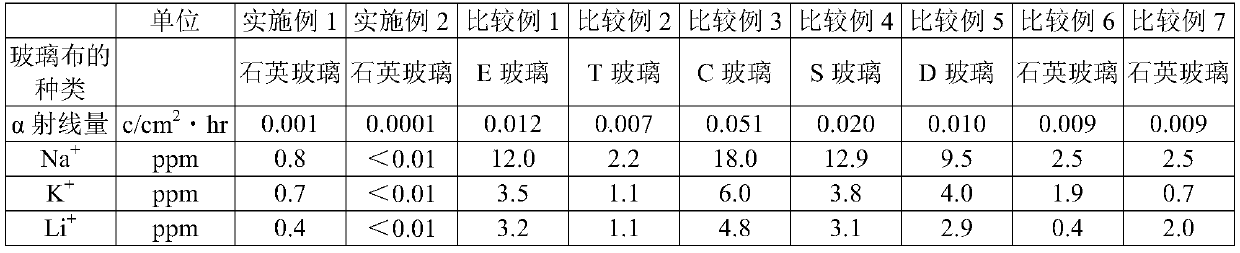

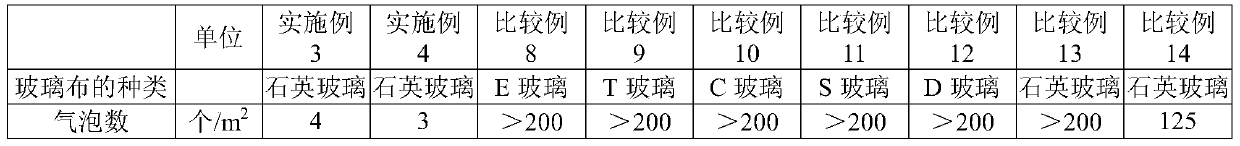

InactiveCN110054870AImprove surface uniformityReduce radiation doseGlass/slag layered productsIon contentGlass fiber

The present invention is a quartz glass fiber-containing prepreg, which is characterized by including: (A) a quartz glass fiber; and (B) a curable resin composition, wherein at least one condition ofconditions: (1) a dose of alpha-ray contained in the quartz glass fiber is 0.005 c / cm<2>*hr or smaller, and, each of metal ion contents of Na<+>, Li<+> and K<+> is 1 ppm or lower; (2) the quartz glassfiber contains the number of foams of 10 foams / m<2> or smaller a unit area; and (3) the quartz glass fiber-containing prepreg has the common bending stiffness in the range of a thickness of 100 to 200 [mu]m measured by a method described in JIS R 3420:2013 of 500 N*m<2> or larger is satisfied. This provides a quartz glass fiber-containing prepreg that has particularly excellent dielectric characteristics, has excellent dielectric characteristics and the heat resistance, and / or has high handling property because of high bending stiffness characteristics.

Owner:SHIN ETSU CHEM IND CO LTD

Aluminum and silicon-based brazing filler metal

InactiveCN103785966ALower melting temperatureGood wettabilityWelding/cutting media/materialsSoldering mediaCorrosionMachinability

The invention relates to brazing filler metal, in particular to aluminum and silicon-based brazing filler metal. The aluminum and silicon-based brazing filler metal comprises Al, Si, Cu, Zn and Mn. The aluminum and silicon-based brazing filler metal has the advantages of low melting temperature, excellent wettability, flowability, plating property, machinability and performance, low manufacturing cost, high welded joint strength, corrosion resistance and cost performance and good toughness.

Owner:SHINAN BRANCH OF QINGDAO BLUEPRINT CULTURE COMM

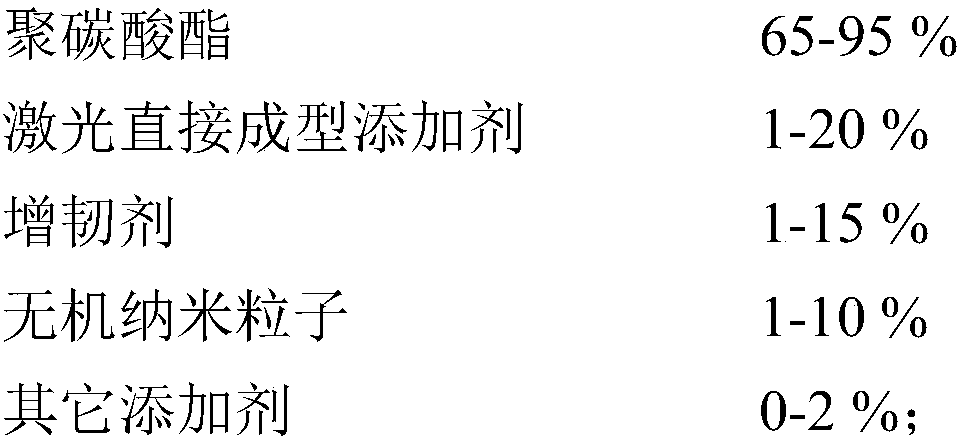

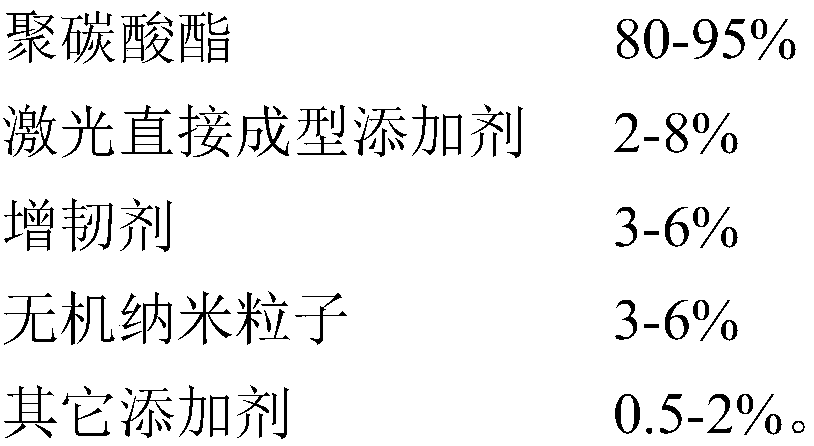

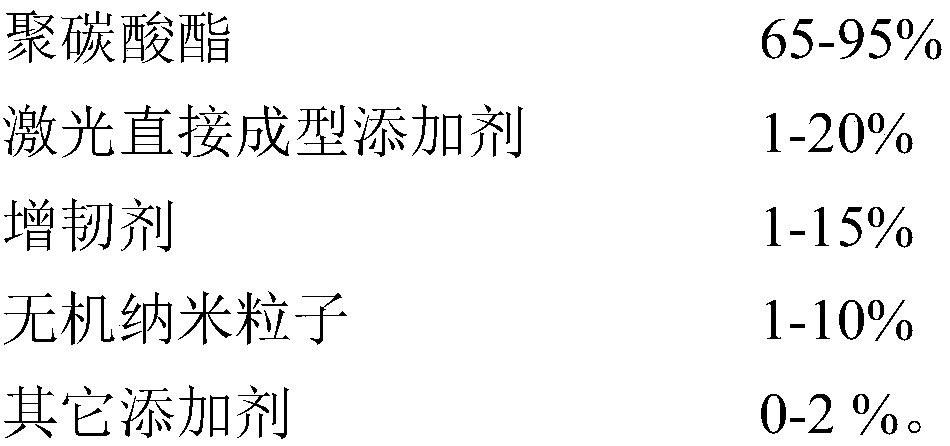

A laser direct structuring material with good comprehensive properties and its preparation method

Owner:无锡赢同新材料科技有限公司

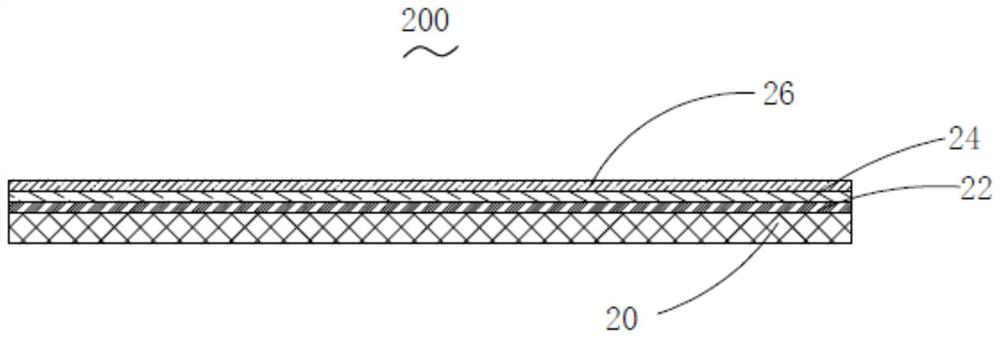

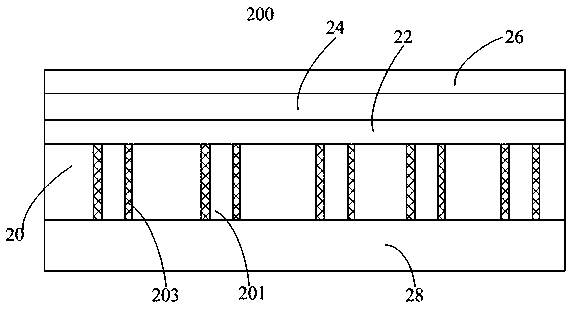

Manufacturing method of flexible ultrathin conductive material

PendingCN112259281AIncrease dyne valueHigh energyConductive layers on insulating-supportsMagnetic/electric field screeningThin membraneConductive materials

The invention discloses a manufacturing method of a flexible ultra-thin conductive material, the flexible ultra-thin conductive material prepared by adopting the manufacturing method and an electronicproduct applying the flexible ultra-thin conductive material. The manufacturing method of the flexible ultra-thin conductive material comprises the following steps of: providing a double-sided non-conducting thin film layer, wherein the thickness of the thin film layer is greater than or equal to 1.0 micron and less than or equal to 6 microns; roughening the thin film layer to enable a dyne valueof the thin film layer to be larger than or equal to 44 and smaller than or equal to 70; and carrying out vapor deposition on the two roughened surfaces, and forming at least one metal shielding layer on each surface, wherein the metal shielding layers on the two surfaces are insulated and isolated by the thin film layer. According to the manufacturing method of the flexible ultra-thin conductivematerial, the flexible ultra-thin conductive material with the two non-conducting sides is very thin.

Owner:深圳市乐工新技术有限公司

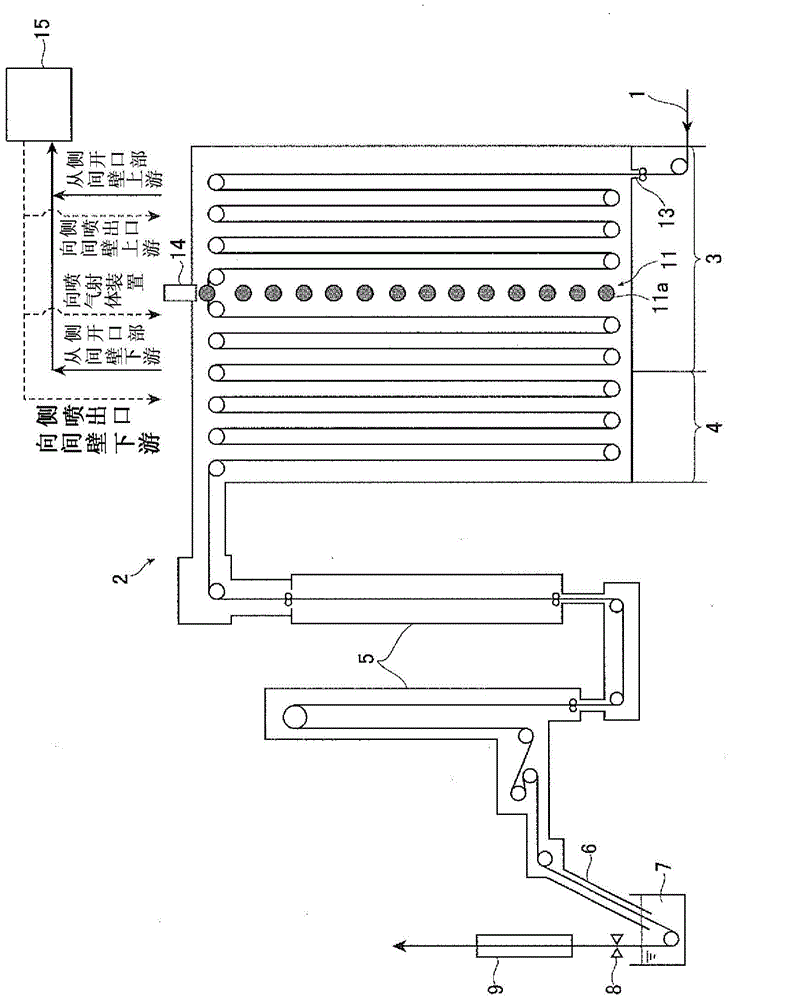

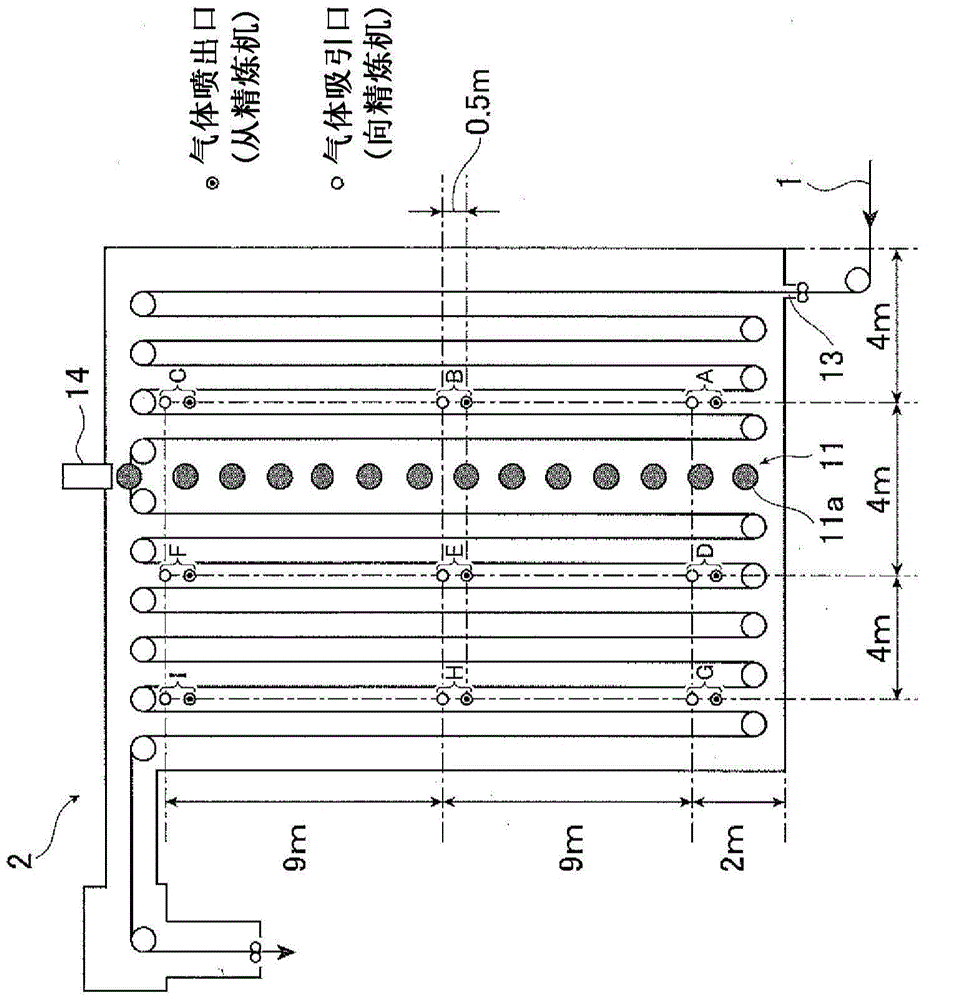

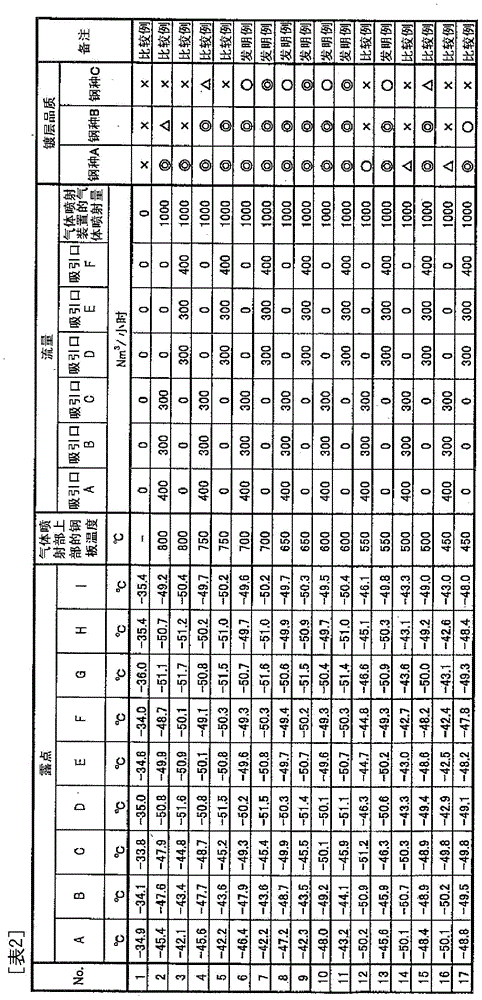

Method of continuous annealing of steel strip, and method of manufacturing hot-dip galvanized steel strip

ActiveCN104379777AExcellent plating propertyHot-dipping/immersion processesFurnace typesMetallurgyDeoxygenation

Provided is a method of continuous annealing of steel strips capable of realizing at low cost a low-dew-point annealing atmosphere suitable to annealing steel strips containing an easily oxidizable element such as Si. A vertical annealing furnace is configured such that: a heating zone and a soaking zone are provided in which the steel strip is conveyed vertically; an atmosphere gas is supplied from outside of the furnace into the furnace, and gas in the furnace is discharged from a steel strip introduction section at the bottom of the heating zone; part of the gas in the furnace is sucked in and discharged to a refiner having a deoxygenation device and a dehumidifier device disposed outside the furnace, oxygen and water in the gas are removed to lower the dew point, and the gas with the lowered dew point is returned back into the furnace. When annealing a steel strip in this vertical annealing furnace, a gas injection device having multiple gas outlets in the steel strip sheet-passing direction is provided in the heating zone-soaking zone, suppressing mixing of the furnace atmosphere upstream of the gas injection device and the furnace atmosphere downstream thereof, and the temperature of the steel strip when passing the gas injection device is controlled to 600-700°C.

Owner:JFE STEEL CORP

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN111621051AHigh energyEasy to acceptMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material prepared by the manufacturing method and an electronic product applyingthe electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps: a polymer film layer is provided, and the thickness of the polymer film layer is larger than or equal to 1.5 micrometers and smaller than or equal to 6 micrometers; the polymer film layer is punched, so that a plurality of through holes are formed in the polymerfilm layer, the hole diameter of the through holes ranges from 0.1 micrometer to 100 micrometers, and the hole distance ranges from 0.1 micrometer to 100 micrometers; roughening the polymer film layer to enable the dyne value of the polymer film layer to be greater than or equal to 44 and less than or equal to 70; vapor deposition is carried out on the two roughened surfaces respectively, and atleast one metal shielding layer is formed on each surface and the hole walls of the through holes respectively; according to the technical scheme, the electromagnetic shielding material with the two-sided conduction function is very thin and good in flexibility.

Owner:深圳市乐工新技术有限公司

Substrate and manufacturing method of substrate

InactiveCN108353508BInhibit sheddingHas cooling propertiesMultilayer circuit manufactureElectrical connectionMetal sheet

The substrate includes: a laminated wiring board formed with a conductive layer; a through hole penetrating through the laminated wiring board; a through hole plating layer (7) electrically connected to the conductive layer; and a metal sheet (10) arranged on the through hole plating layer Inside of (7), a protrusion (8) directly in contact with the through-hole plating (7) and a separation portion (9) at a position spaced from the through-hole plating (7) are formed on the side of the metal sheet (10) , the space surrounded by the separation part (9) and the through-hole plating layer (7) is covered with a metal plating film (13), and the inner side of the plating film (13) is filled with a filling material (14).

Owner:MEIKO ELECTRONICS CO LTD

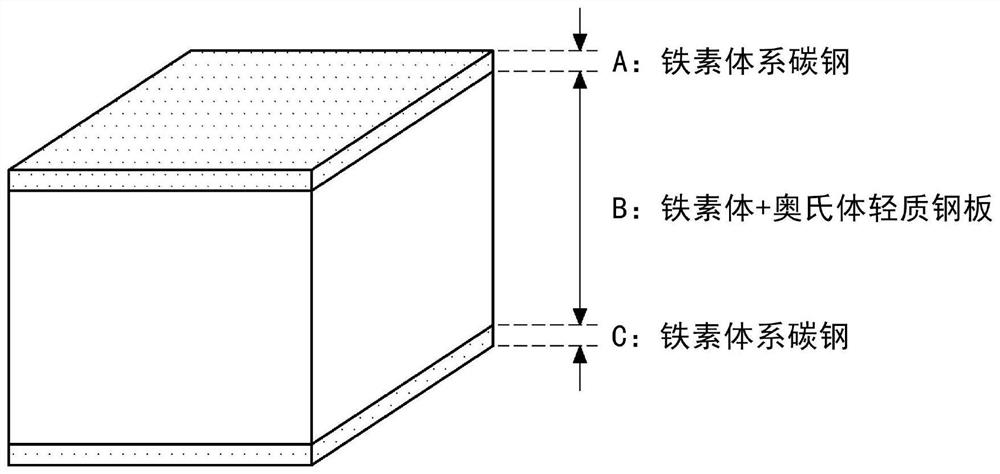

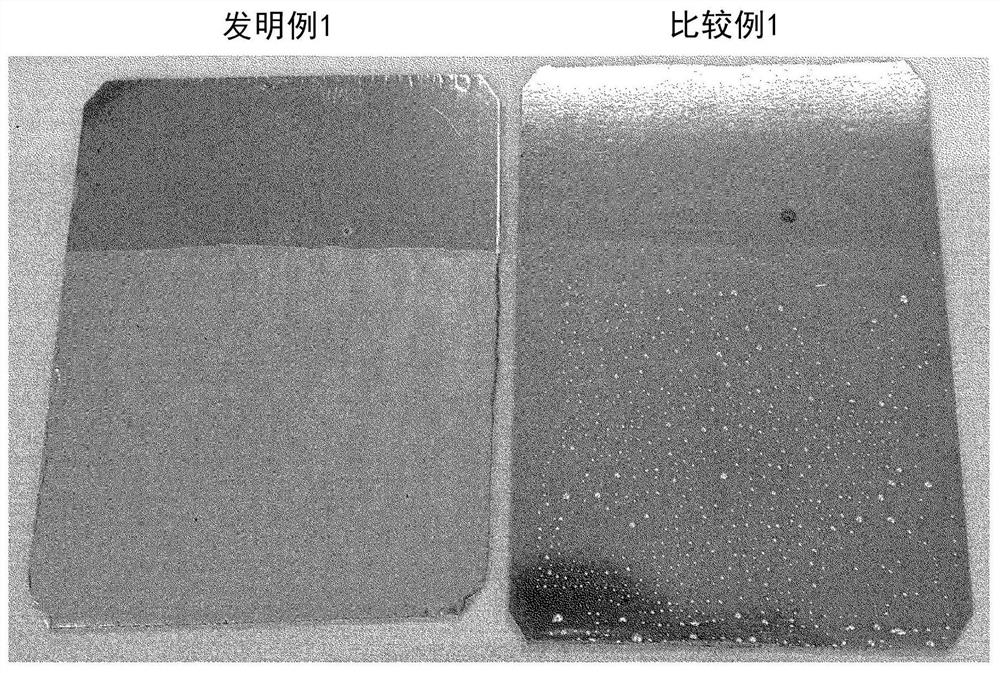

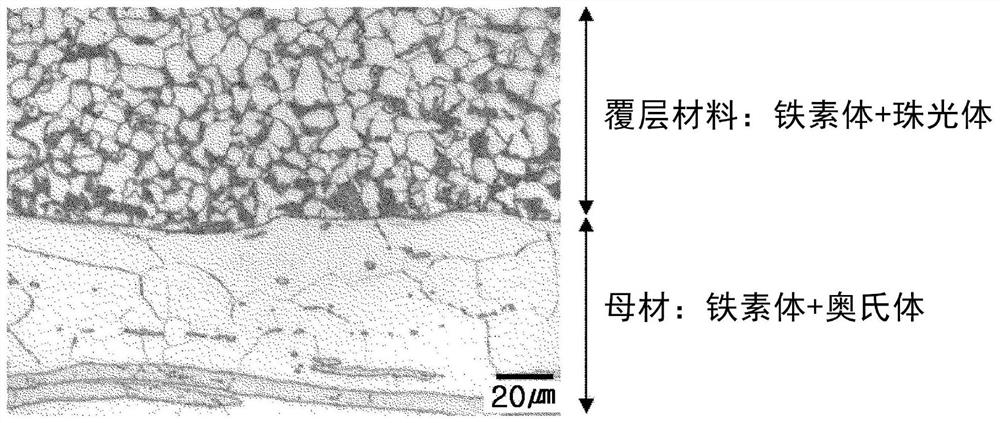

Low-specific-gravity clad steel sheet having excellent strength and plateability, and manufacturing method therefor

PendingCN112368145AExcellent plating propertyHot-dipping/immersion processesLamination ancillary operationsMetallurgyUltimate tensile strength

One aspect of the present invention relates to a low-specific-gravity clad steel sheet having excellent strength and plateability, the clad steel sheet comprising a base metal, and a clad material provided at both sides of the base metal, wherein the base metal is a ferritic-austenitic duplex lightweight steel sheet comprising, by wt%, 0.3-0.7% of C, 2.0-9.0% of Mn, 4.5-8.0% of Al and the balanceof Fe and inevitable impurities, and the clad material is a ferritic carbon steel comprising, by wt%, 0.0005-0.2% of C, 0.05-2.5% of Mn and the balance of Fe and inevitable impurities.

Owner:浦项股份有限公司

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN113186488AEasy to acceptOvercoming Poor PlatingMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material manufactured by the manufacturing method and an electronic product applying the electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps that a polymer film layer is provided, and the thickness of the polymer film layer is larger than or equal to 1.5 microns and smaller than or equal to 6 microns; at least one surface of a polymer film is subjected to roughening treatment, so that the dyne value of the at least one surface is larger than or equal to 44 and smaller than or equal to 70; and at least one metal shielding layer is deposited on the roughened surfaces. According to the manufacturing method of the electromagnetic shielding material, the thickness of the polymer film layer can be reduced by 75% to the maximum extent, the flexibility of the electromagnetic shielding material is better, the using effect is better, and the product cost is lower.

Owner:深圳市乐工新技术有限公司

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN111484640AIncrease dyne valueHigh energyMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material prepared by the manufacturing method and an electronic product applyingthe electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps: providing a polymer film layer of which two sides are conducted, wherein the thickness of the polymer film layer is greater than or equal to 0.8 micron and less than or equal to 12 microns; roughening the polymer film layer to enable the dyne value of the polymer film layer to be greater than or equal to 44 and less than or equal to 70; performing vapor deposition on the two roughened surfaces, forming at least one metal shielding layer on each surface, andperforming the metal shielding layers on the two surfaces through the polymer film layer; according to the technical scheme, the electromagnetic shielding material which is very thin and is conductedon two sides is provided.

Owner:深圳市乐工新技术有限公司

Manufacturing method of nano-alloy material, nano-alloy material and electronic product

PendingCN111534795ALow costLittle flexibilityMaterial nanotechnologyLighting support devicesMetallurgyThin membrane

The invention discloses a manufacturing method of a nano-alloy material, the nano-alloy material prepared by the manufacturing method and an electronic product applying the nano-alloy material. The manufacturing method of the nano-alloy material comprises the following steps of providing an aluminum foil film layer with the thickness of more than or equal to 10 microns, and is less than or equal to 100 microns; vapor deposition is carried out on the surface of the aluminum foil film layer, at least one weldable metal layer is formed on the surface, and the thickness of the weldable metal layeris larger than or equal to 0.05 micrometer and smaller than or equal to 15 micrometers. According to the manufacturing method of the nano-alloy material, the weldable metal layer is arranged on the aluminum foil film layer, so that the cost of the weldable nano alloy material is greatly reduced.

Owner:深圳市乐工新技术有限公司

High-strength galvanized steel sheet, high-strength parts and their manufacturing method

ActiveCN111936649BExcellent plating propertyImprove bending performanceHot-dipping/immersion processesFurnace typesHigh intensityUltimate tensile strength

An object of the present invention is to provide a high-strength galvanized steel sheet excellent in platability and bendability, a high-strength member, and a method for producing them. The high-strength galvanized steel sheet of the present invention comprises a steel sheet and a galvanized layer on the surface of the above-mentioned steel sheet, the above-mentioned steel sheet has the following composition and steel structure, the composition contains predetermined composition elements, the mass of the Si content and the Mn content in the steel The ratio (Si / Mn) is 0.1 or more and less than 0.2, and the rest is composed of Fe and unavoidable impurities. In this steel structure, Al, Si, and Mg exist in the range from the surface to the 1 / 3 of the plate thickness. The average particle size of inclusions of at least one type of Ca and Ca is 50 μm or less, the average closest distance of the above-mentioned inclusions is 20 μm or more, and the coating weight per one side of the above-mentioned zinc-coated layer is 20 g / m 2 ~120g / m 2 , the amount of diffusible hydrogen contained in the steel is less than 0.25 mass ppm, and the tensile strength is more than 1100 MPa.

Owner:JFE STEEL CORP

Thin steel sheet, plated steel sheet, manufacturing method thereof, and manufacturing method of hot-rolled steel sheet, cold-rolled full-hard steel sheet, and heat-treated sheet

ActiveCN108884533BImprove ductilityLow yield ratioHot-dipping/immersion processesFurnace typesFiberSheet steel

Owner:JFE STEEL CORP

Steel sheet, coated steel sheet, and method for manufacturing hot-rolled steel sheet, method for manufacturing cold-rolled full-hard steel sheet, method for manufacturing thin steel sheet, and method for manufacturing coated steel sheet

ActiveCN109072375BHigh tensile strengthImprove bending performanceHot-dipping/immersion processesFurnace typesSheet steelBainite

The present invention provides a method for manufacturing thin steel sheets, plated steel sheets, hot-rolled steel sheets, cold-rolled full-hard steel sheets, and thin steel sheets having a TS of 980 MPa or more and excellent bendability and platability. It has a predetermined composition and contains at least one selected from Ti: 0.003 to 0.100%, Nb: 0.003 to 0.100%, and Mo: 0.005 to 0.500%. In the range of 20 μm from the surface in the thickness direction, the polygonal ferrite is 0 to 80%, and the sum of martensite, bainite and retained austenite is 20 to 100%. The amount of Mn in the martensite existing in the range of 20 μm in the direction: [Mn] SM With the amount of Mn in the body: [Mn] B meet [Mn] SM / [Mn] B ≤1.5, at the position 300 μm away from the surface in the thickness direction, the martensite is 20-50%.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com