Low-specific-gravity clad steel sheet having excellent strength and plateability, and manufacturing method therefor

A composite steel plate and coating technology, which is applied in the field of low specific gravity composite steel plate and its manufacturing, can solve the problems of poor coating properties and achieve excellent coating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, the present invention will be described more specifically by way of examples. However, it should be noted that the following examples are only used to illustrate the present invention for more detailed description, and are not intended to limit the scope of rights of the present invention. This is because the scope of rights of the present invention is determined by the content described in the claims and the content reasonably derived therefrom.

[0094] (Example)

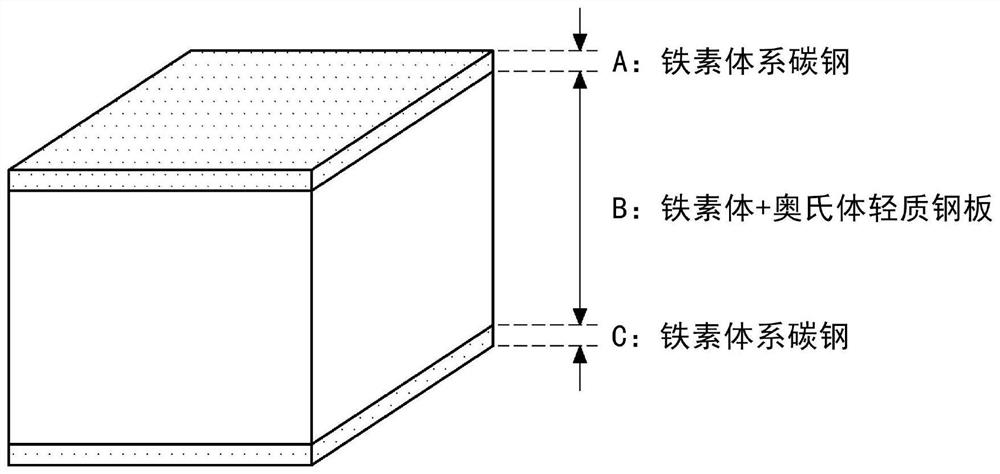

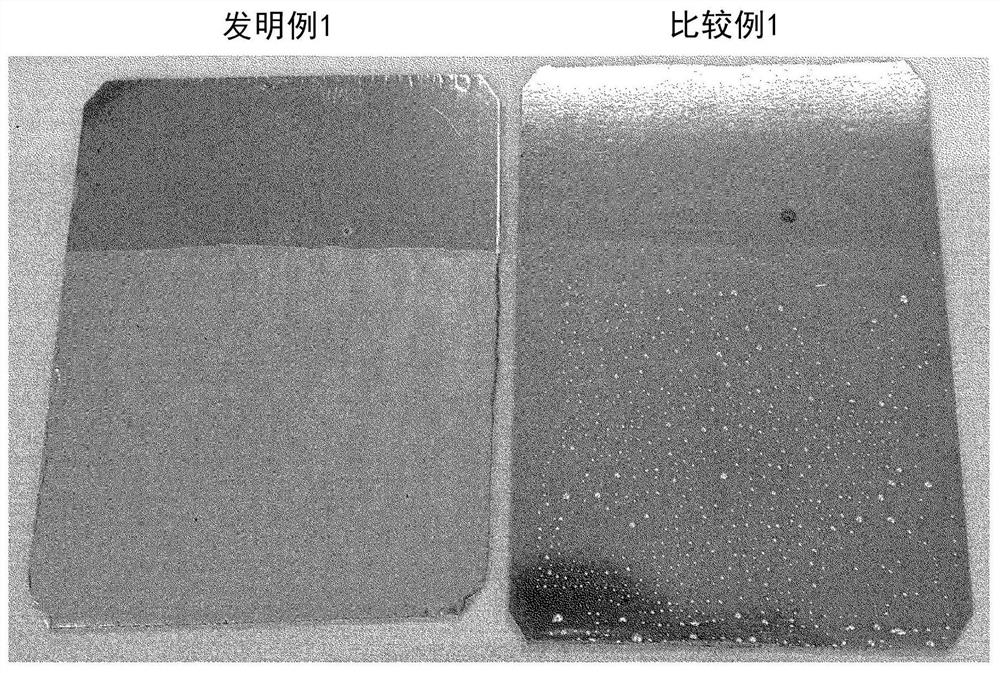

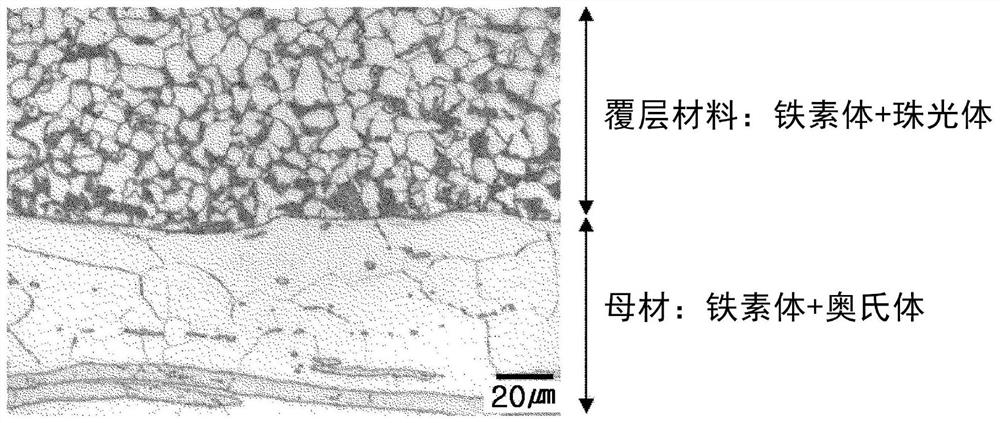

[0095] Steel ingots of carbon steel and light steel plate having the composition shown in the following Table 1 were prepared, and the surface of the steel ingot was washed, and then the light steel plate was arranged between two carbon steels to manufacture a three-layer laminate so that The three-layer laminates have the lamination ratios of Table 2 below. Afterwards, arc welding is carried out along the boundary surfaces of the laminates using welding rods. The laminate with the boundary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com