Thin steel sheet, plated steel sheet, manufacturing method thereof, and manufacturing method of hot-rolled steel sheet, cold-rolled full-hard steel sheet, and heat-treated sheet

A manufacturing method and technology for hot-rolled steel sheets, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as increased deviation, poor shape, and reduced mass production efficiency, and achieve improved fuel efficiency, in-plane directions The effect of excellent heterosexuality and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

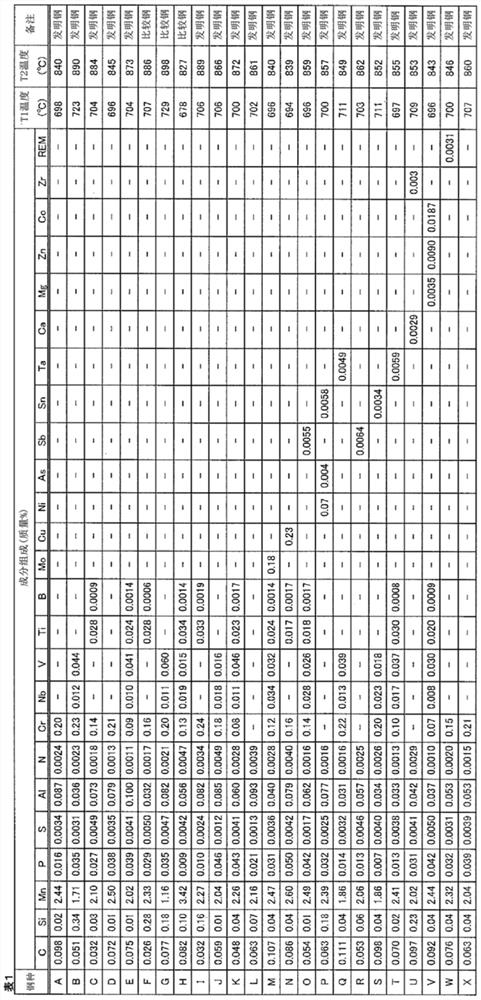

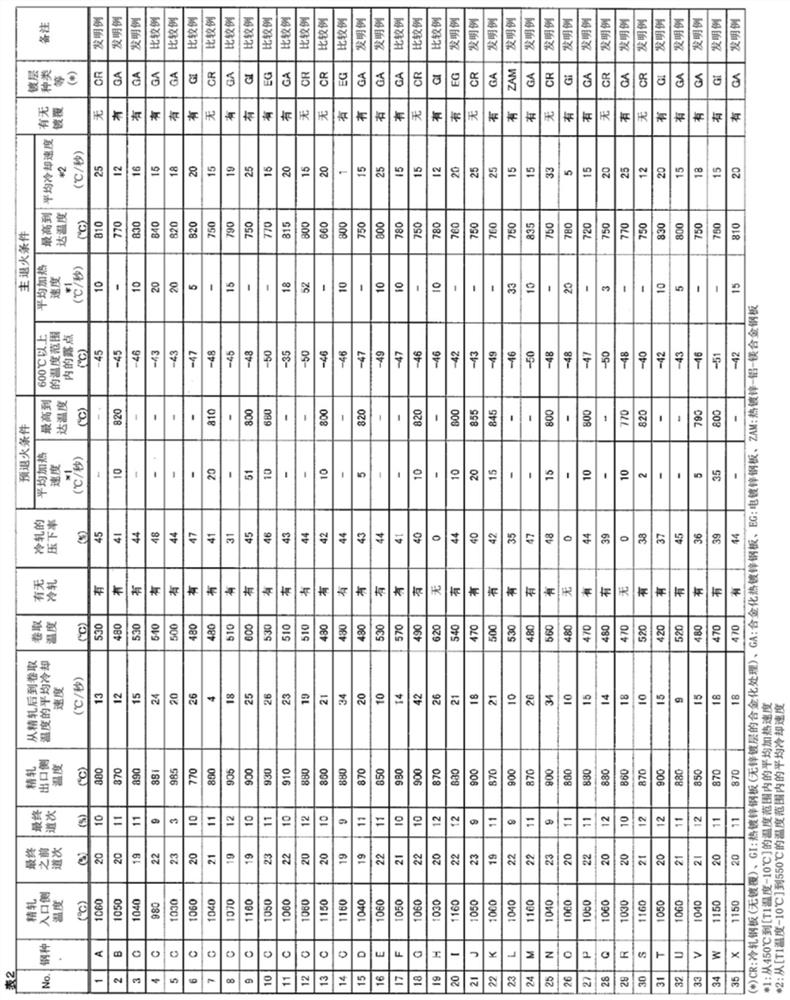

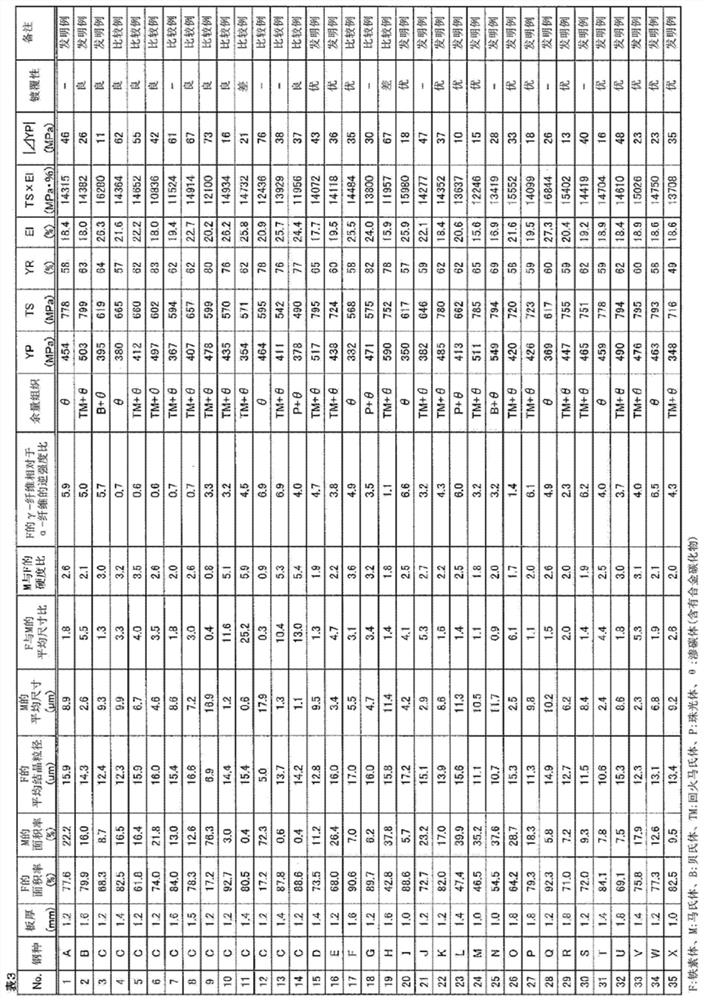

[0162] The composition having the composition shown in Table 1 consists, the remaining amount of steel is smelted by the steel which is made of Fe and the inevitable impurities, and is made into a slab by a continuous casting method. After heat rolling, after hot rolling under the conditions shown in Table 2, the acid washing treatment was carried out, and the No. 1 to 18, 20 to 25, 27, 28, 30 to 35 shown in Table 2 was cooled. Rolled.

[0163] Next, annealing treatment was performed under the conditions shown in Table 2 to obtain a thin steel sheet (a secondary method according to the pre-relief bar).

[0164] Further, a part of the thin steel sheet is plated to obtain a hot-dip galvanized steel plate (GI), alloy hot galvanized steel plate (Ga), electroplated steel plate (EG), hot galvanized-aluminum-magnesium alloy steel plate (ZAM), etc. . Regarding the hot-dip galvanized bath, for GI, the zinc bath containing Al: 0.14 ~ 0.19% by weight is used, and the bath containing Al: 0.14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com