Thin steel sheet, plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing thin steel sheet, and method for producing plated steel sheet

A manufacturing method and technology of hot-rolled steel sheets, applied in the direction of manufacturing tools, heat treatment furnaces, hot-dip coating processes, etc., can solve problems such as reduced workability, achieve improved collision safety, excellent bendability and coating properties, and fuel efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] Hereinafter, the present invention will be specifically described based on examples. The technical scope of the present invention is not limited to the following examples.

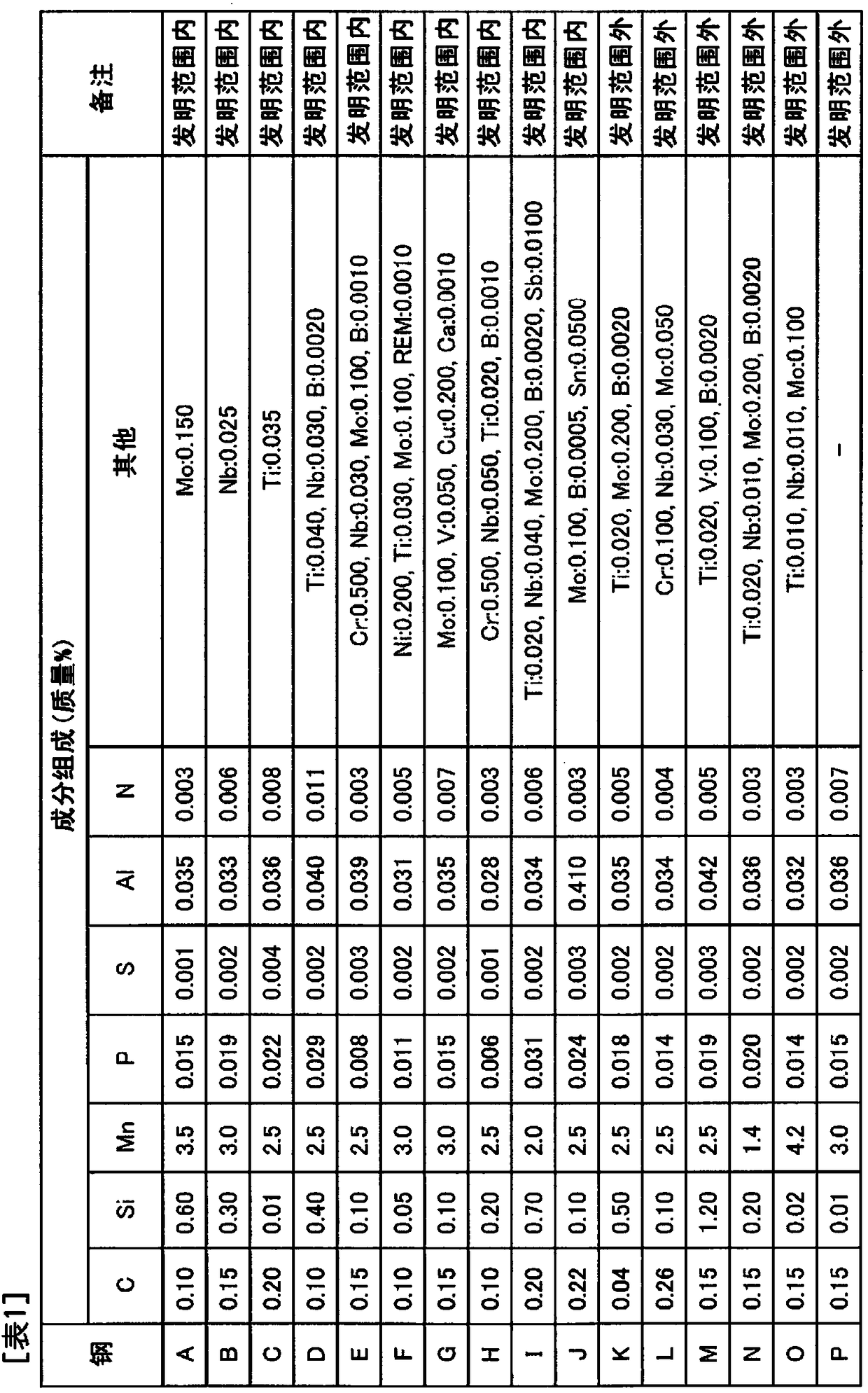

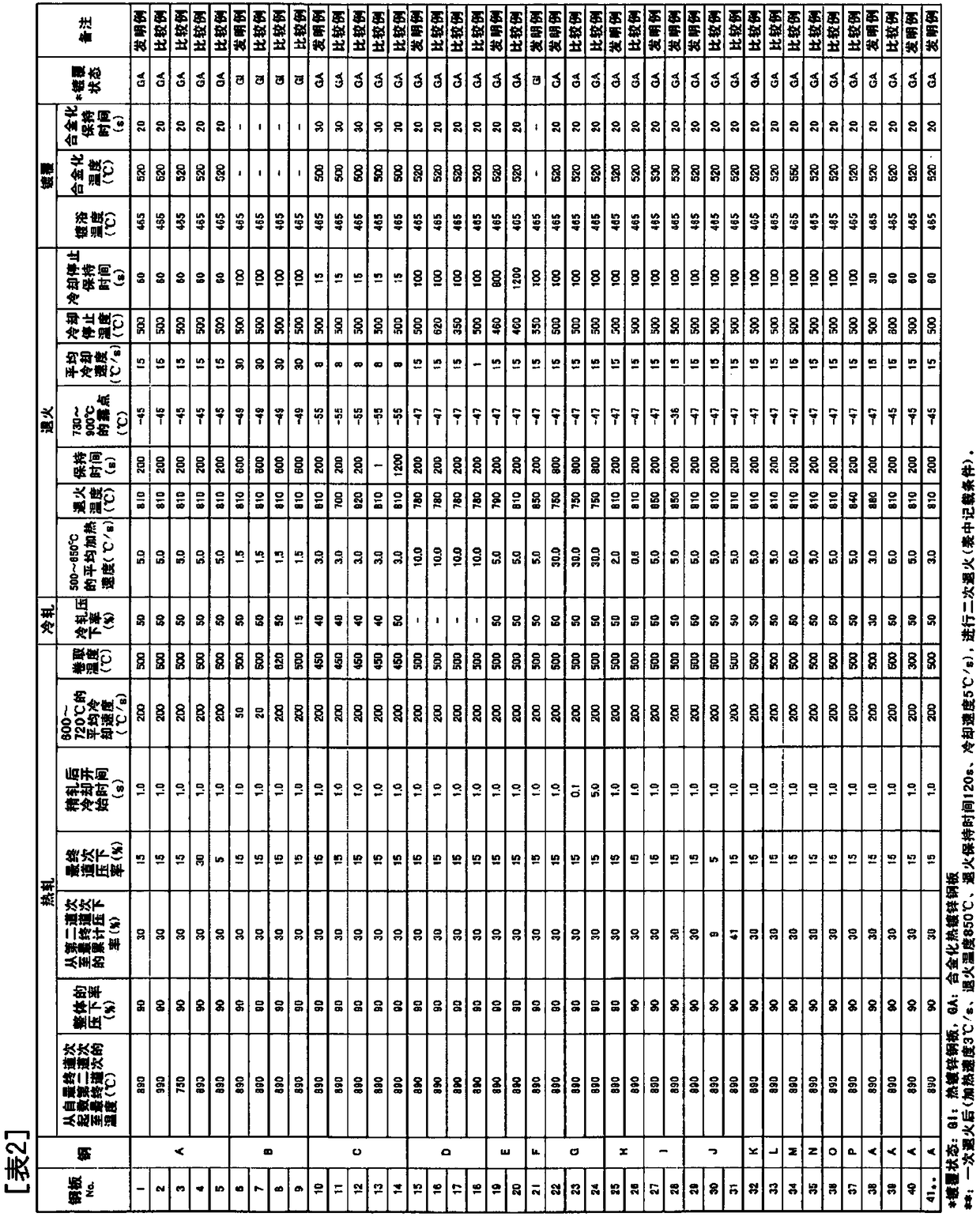

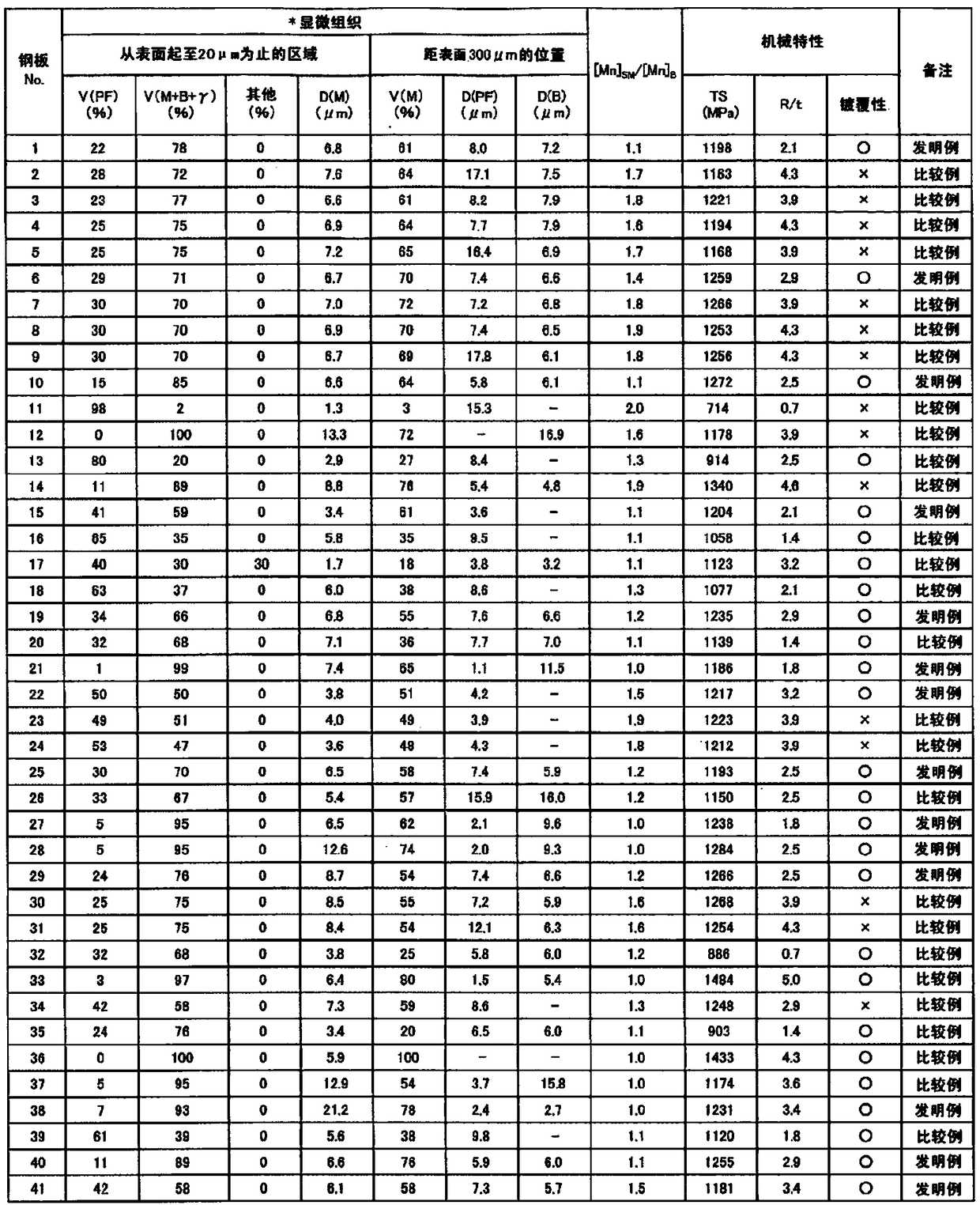

[0159] Steel with the composition shown in Table 1 (the balance being Fe and unavoidable impurities) was melted in a vacuum melting furnace in a laboratory, and rolled to form a billet. These billets were heated to 1200° C., rough-rolled, and then hot-rolled under the conditions shown in Table 2 to obtain hot-rolled steel sheets (HR). Next, a part was cold-rolled to 1.4 mm to make a cold-rolled full-hard steel sheet (CR). The obtained hot-rolled steel sheets and cold-rolled full-hard steel sheets were subjected to annealing. Next, a galvanizing treatment and, if necessary, a galvanizing treatment are performed to produce a galvanized steel sheet (GI) and a galvannealed steel sheet (GA). Annealing was carried out in the laboratory under the conditions shown in Table 2 using a heat treatment and pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com