Patents

Literature

46results about How to "Achieve metallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al3O3 ceramic substrate metallization process

InactiveCN103319208AAchieve metallizationMicrocosmic coarse particles fineChemical platingCopper plating

The invention relates to a technical field of ceramic material metallization production, and specifically relates to an Al3O3 ceramic substrate metallization process. According to the invention, the Al3O3 ceramic substrate is sequentially subjected to a coarsening treatment, a sensitization and activation treatment, a chemical plating treatment, and a metal or alloy electroplating treatment, such that a metal or alloy film is formed on the surface of the substrate. With the process method provided by the invention, the surface of the ceramic substrate is uniformly coarsened. Microscopic coarse particles are small and have high adsorption capacity. Therefore, reducing cores can be well absorbed during the subsequent sensitization and activation treatment, and chemical plating can be finally realized. The coarsened ceramic substrate can be subjected to the sensitization and activation treatment with a subsequent silver ammonia solution, and can be provided with a copper plating layer with the chemical copper plating process. Also, the substrate can be subjected to the sensitization and activation treatment with colloidal palladium, and can be subjected to a nickel plating process, such that a chemical nickel plating layer can be obtained. Copper, nickel, or other metal or alloy can be electroplated, and ceramic substrate metallization can be realized.

Owner:HEFEI UNIV OF TECH

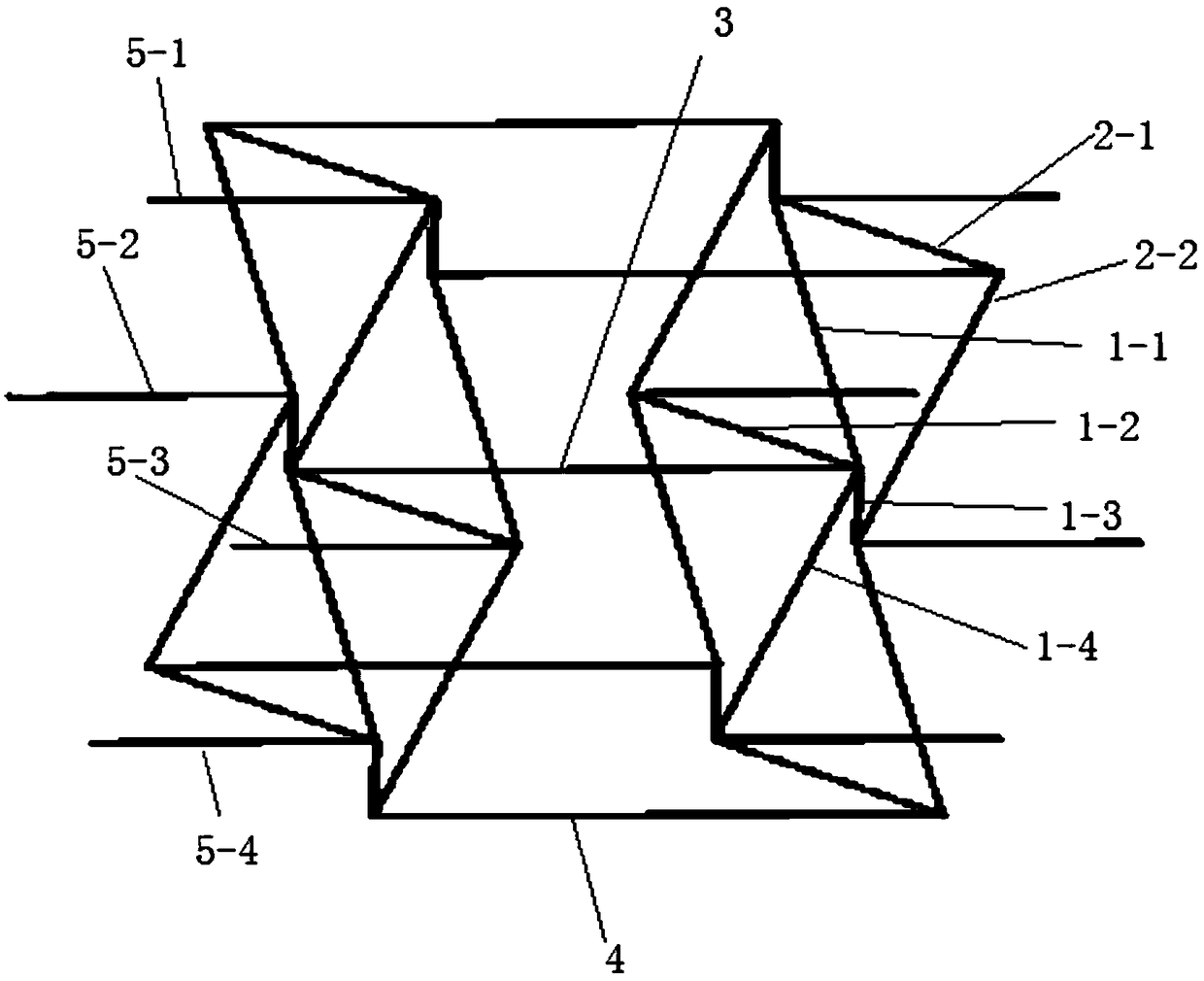

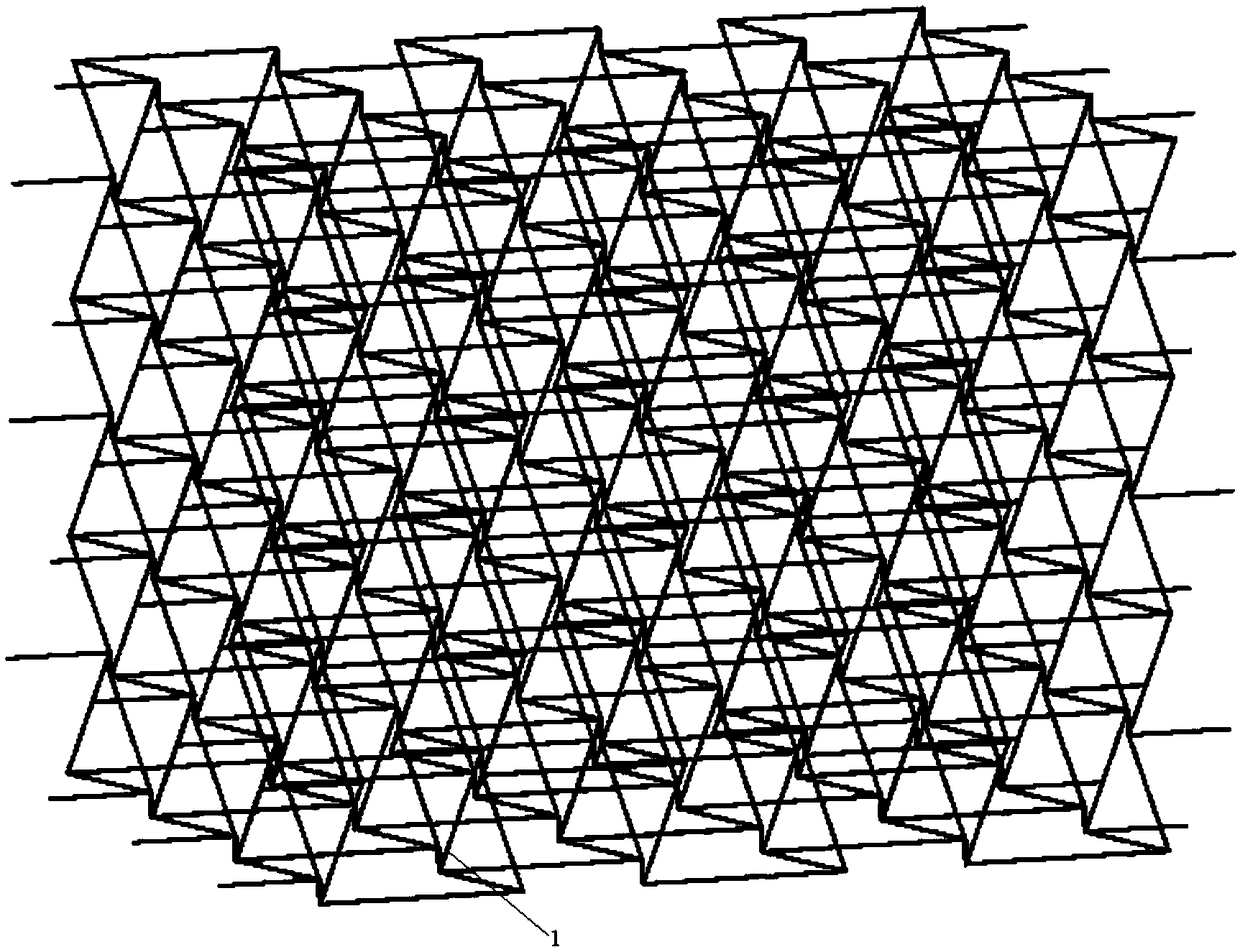

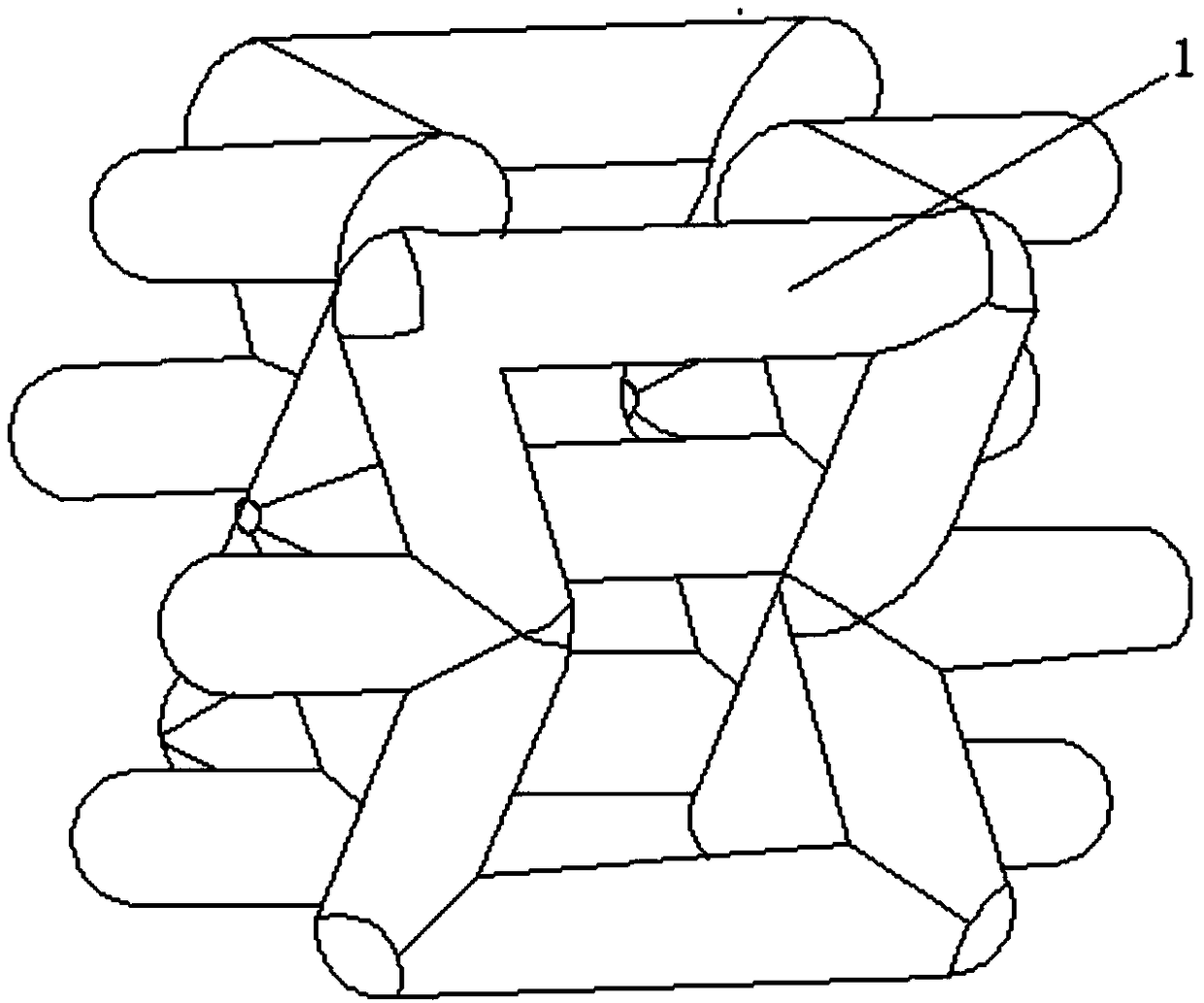

Negative Poisson's ratio aluminum-based lattice structure and preparation method thereof

InactiveCN109365787ARealize configuration diversificationRealize large-scaleAdditive manufacturing apparatusFoundry mouldsPositive pressureMultiple layer

The invention discloses a negative Poisson's ratio aluminum-based lattice structure and a preparation method thereof. The negative Poisson's ratio aluminum-based lattice structure is formed by periodically arranging one or more layers of unit cell structures, the unit cell structures are of pull bulging type three-dimensional negative Poisson's ratio structures, the material is a negative Poisson's ratio material, the negative Poisson's ratio material is industrial pure aluminum or an aluminum alloy, and the unit cell structures are formed by connecting a plurality of horizontally-arranged andslantly-arranged rod units; and the diameter of the unit cell rod units is 0.5-5.0 mm, the length of the unit cell rod units is 0.5-15.0 mm, and the included angle between the slantly-arranged rod units and the projective planes of the rod units is 30-70 degrees; and CATIA software is adopted for modeling and design, a polymer material and a 3D printing technology are adopted for manufacturing amodel, a porous skeleton is made by soluble gypsum, and the aluminum-based negative Poisson's ratio lattice material is prepared by a positive pressure gas pressure percolation technology. The 3D printing and pressure percolation technologies are adopted to prepare the aluminum-based lattice structure in a combined manner; and the negative Poisson's ratio aluminum-based lattice structure which hasthe characteristics of small unit cells, thin rod elements, multiple layer levels, complex configuration and the like is achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Unleaded Cu-based sliding bearing material and preparation method thereof

InactiveCN101576118AAchieve lead-freeImprove mechanical propertiesLiquid/solution decomposition chemical coatingSliding contact bearingsGraphiteHigh intensity

The invention relates to an unleaded Cu-based sliding bearing material and a preparation method thereof and the invention has the characteristics that: the material is composed of nickel, tin, zinc, iron, graphite, bismuth, copper and assistants, the substrate of the material is unleaded copper alloy, and the antifriction and antisticking constituent element is bismuth and graphite. The Cu-based bearing material features high intensity, and good antifriction and antisticking, thus realizing an unleaded Cu-based bearing material. The lead is cancelled in an original bearing material with lead and copper, and a synergistic effect of bismuth and graphite can replace the use of lead, thus completely overcoming the defect of lead pollution; moreover, the service performance of the bearing remains nearly the same, therefore the unleaded Cu-based sliding bearing material can completely replace the bearing material with lead and copper. The material of the invention can be applied in food machinery, drugs machinery, construction machinery, automobile and other products, and has advantages of good antifriction and antisticking, good heat dissipation effect, oxidation resistance and corrosive resistance.

Owner:HEFEI UNIV OF TECH

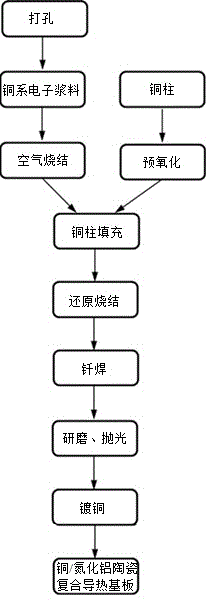

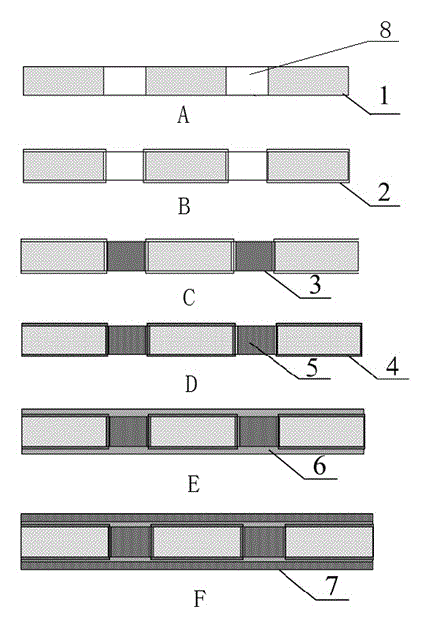

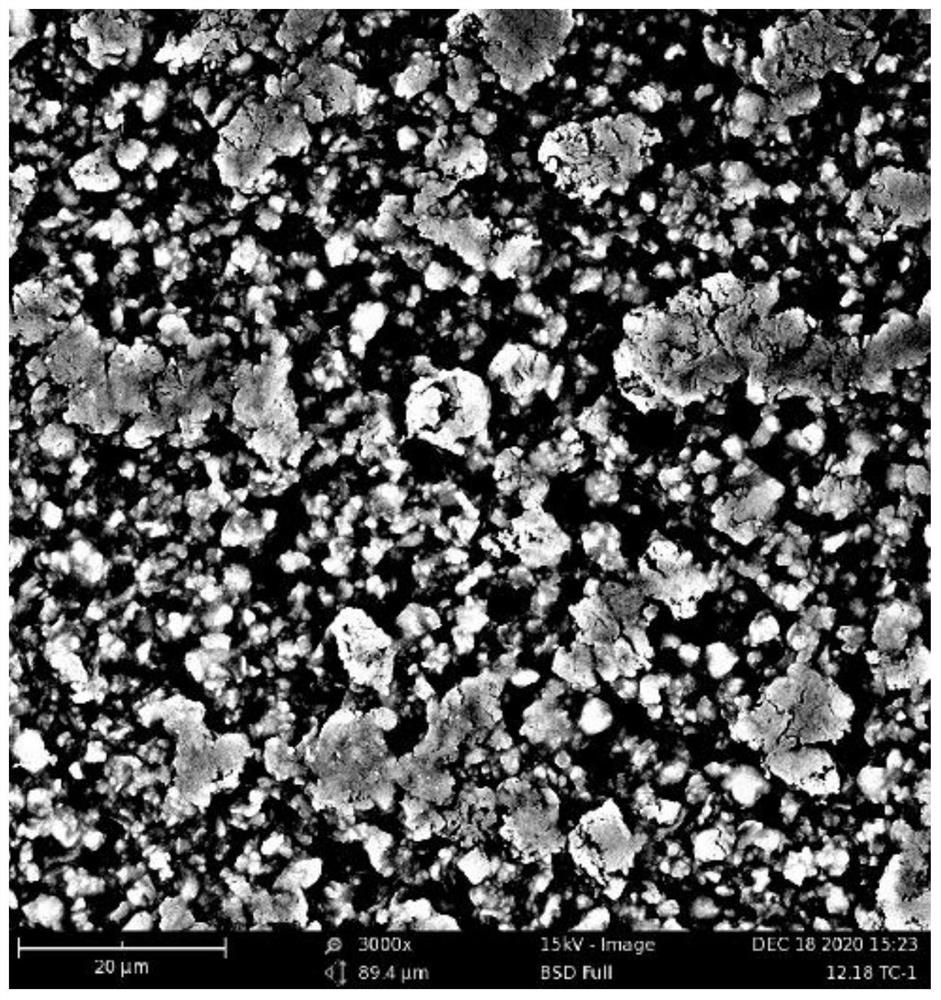

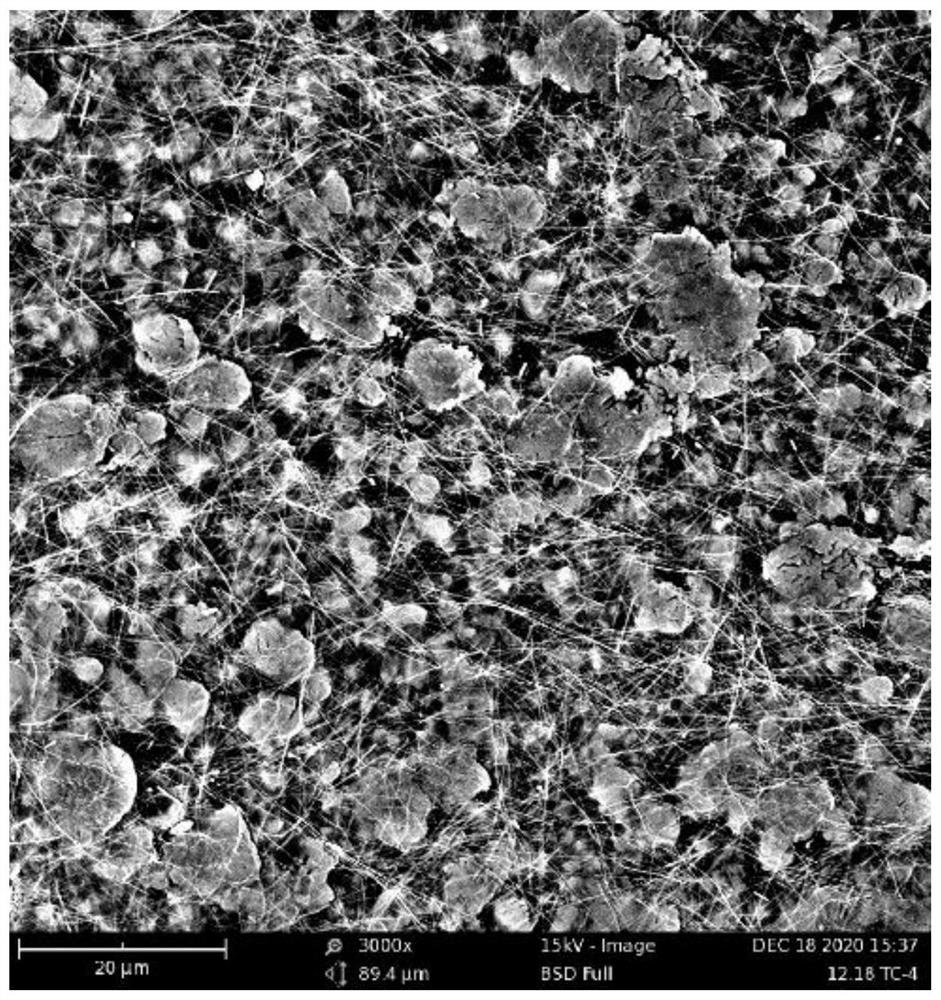

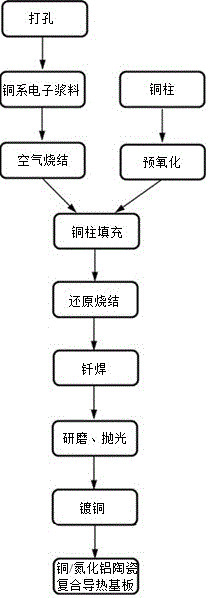

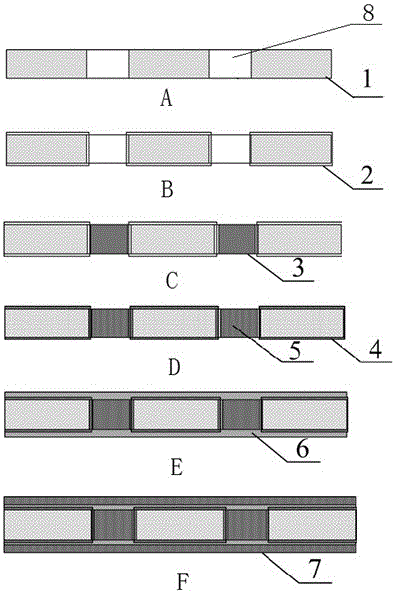

Preparation method for copper/aluminium nitride ceramic composite heat-conductive substrate

InactiveCN104064478AGuaranteed smoothGuaranteed flow capacitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingCeramic composite

The invention discloses a preparation method for a copper / aluminium nitride ceramic composite heat-conductive substrate. The method comprises the following steps: 1) providing through holes in the surface of an aluminium nitride substrate; 2) coating copper electronic paste layers on the double surfaces of the aluminium nitride substrate; 3) filling the through holes with pre-oxidation copper cylinders; 4) carrying out overall sintering for 30 min; 5) carrying out brazing after the double surfaces of the aluminium nitride substrate being coated with tin silver copper solder materials; 6) carrying out surface polishing; and 7) carrying out copper plating processing directly and forming uniform copper layers, and thus, the copper / aluminium nitride ceramic composite heat-conductive substrate is obtained. The through holes in the copper / aluminium nitride ceramic composite heat-conductive substrate produced with the preparation method are communicated up and down; the combination between the metalized layers in the holes and the ceramic substrate is strong; the middle copper cylinders can realize the communication of the copper layers on the upper and lower surfaces; and the copper / aluminium nitride ceramic composite heat-conductive substrate helps the transmission of electrical signals and has the advantages of ideal heat-conductive effect, low thermal expansion coefficients and good conductivity and the like.

Owner:NANJING MING KUANG ELECTRONICS TECH

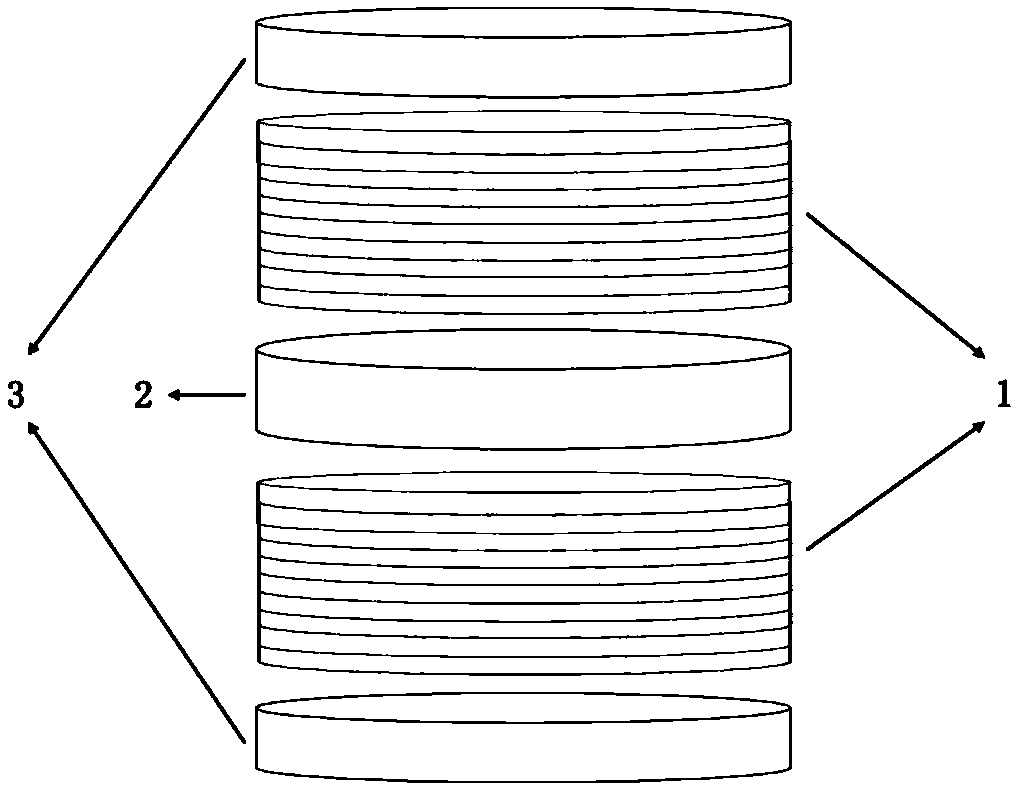

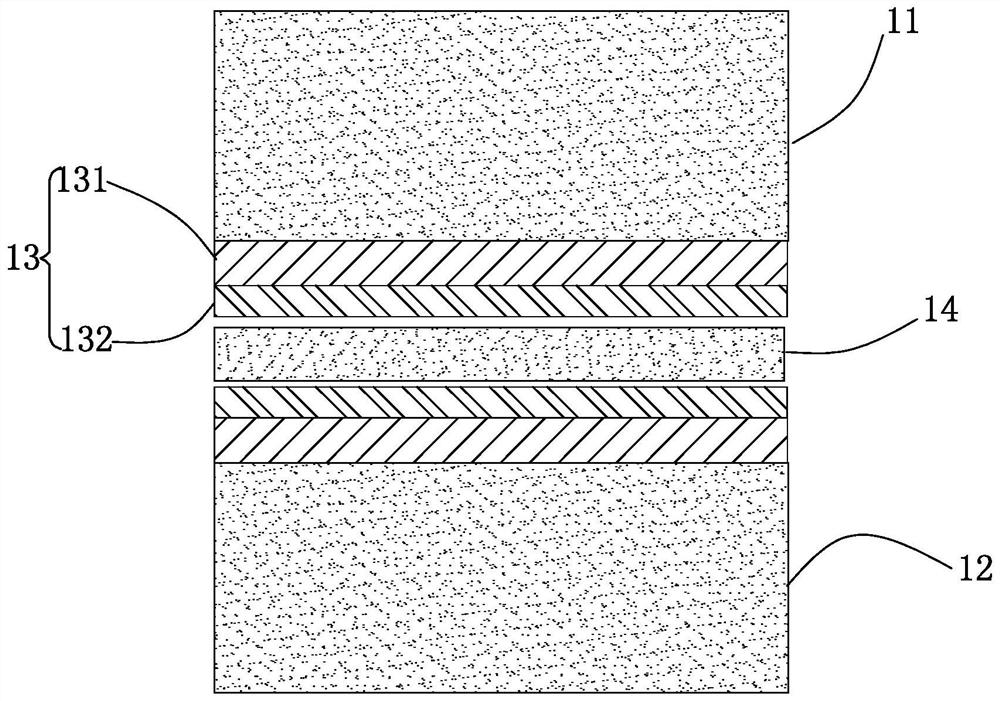

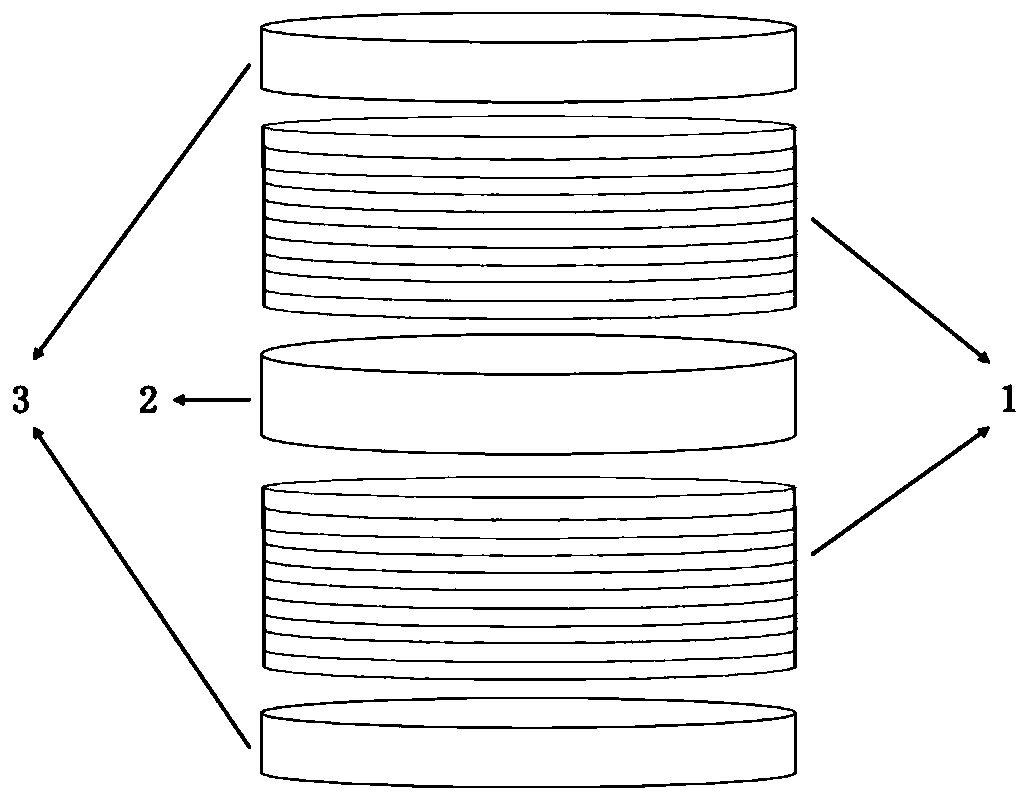

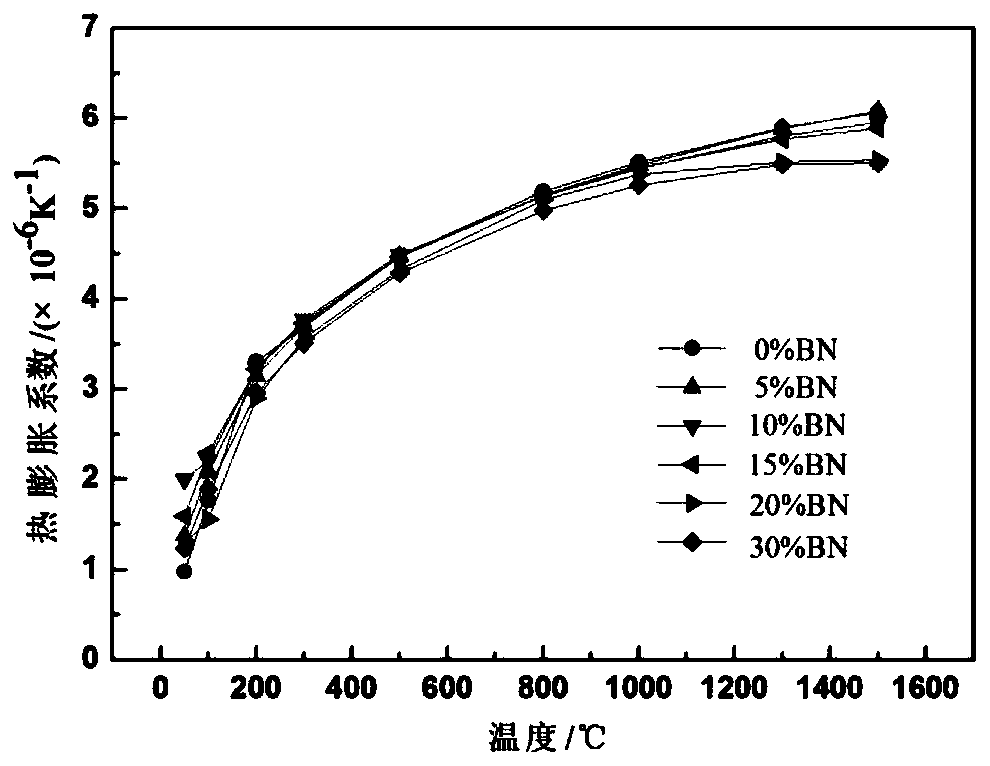

Ceramic/metal high-temperature packaging material of gradient structure and preparing method thereof

The invention relates to a ceramic / metal high-temperature packaging material of a gradient structure. A ceramic material comprises one or a plurality of nitrides (A1N, Si3N4, BN and the like), carbides (SiC, ZrC, TiC and the like) and oxides (Al2O3, SiO2, ZrO2 and the like). A metal material comprises one of high-melting-point metals, such as W, Mo, Ta, Cr and Nb. The preparing method of the material comprises the following steps: fully mixing required metal and ceramic powder according to designed gradient components, gradient layer number and the content of each component in each layer so asto obtain required raw materials for each gradient layer; stacking all layers and carrying out pressing forming; enabling the mass percent of ceramic powder to symmetrically and continuously vary ina gradient manner between 100 % and 0 % from the inner side to the outer side in the axial direction; utilizing a powder metallurgy and hot pressing co-firing technology, and finally obtaining the ceramic / metal high-temperature packaging material of the gradient structure. The helium leakage rate is smaller than 1x10<-11> Pa.m<3> / s, the bending strength is larger than 200Mpa, and the electric resistivity is larger than 6x10<9> omega.cm.

Owner:WUHAN UNIV OF TECH

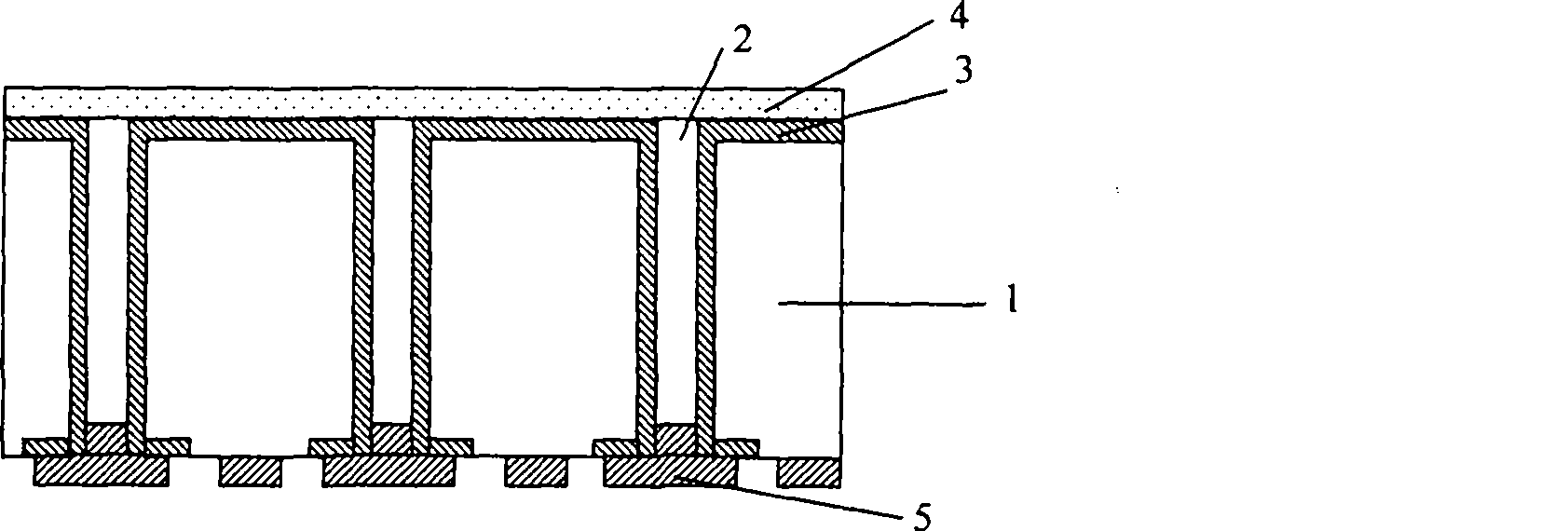

Emitter circulating type solar cell and preparation thereof

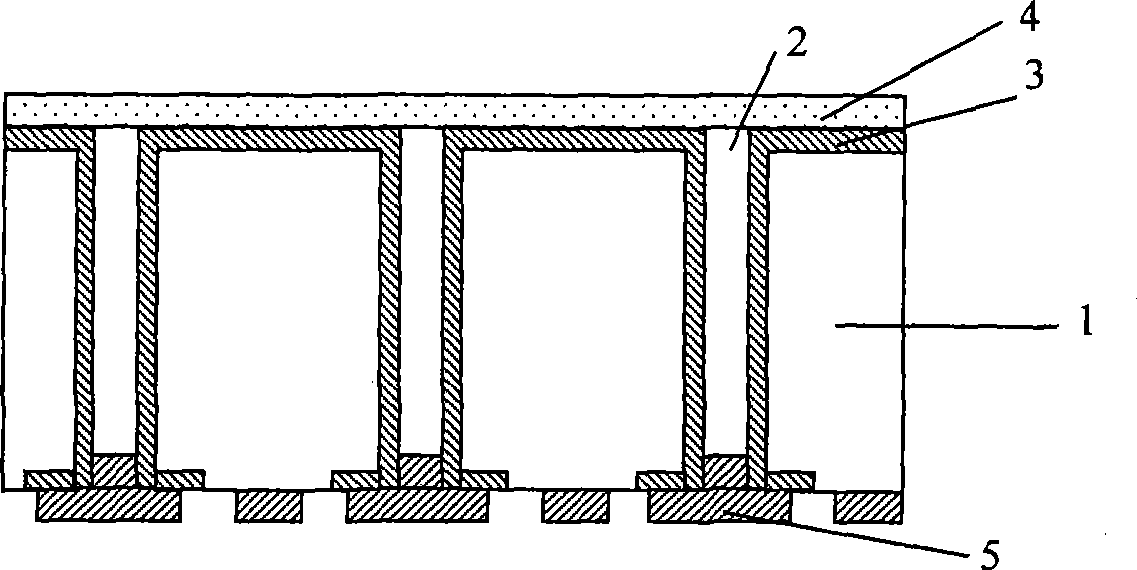

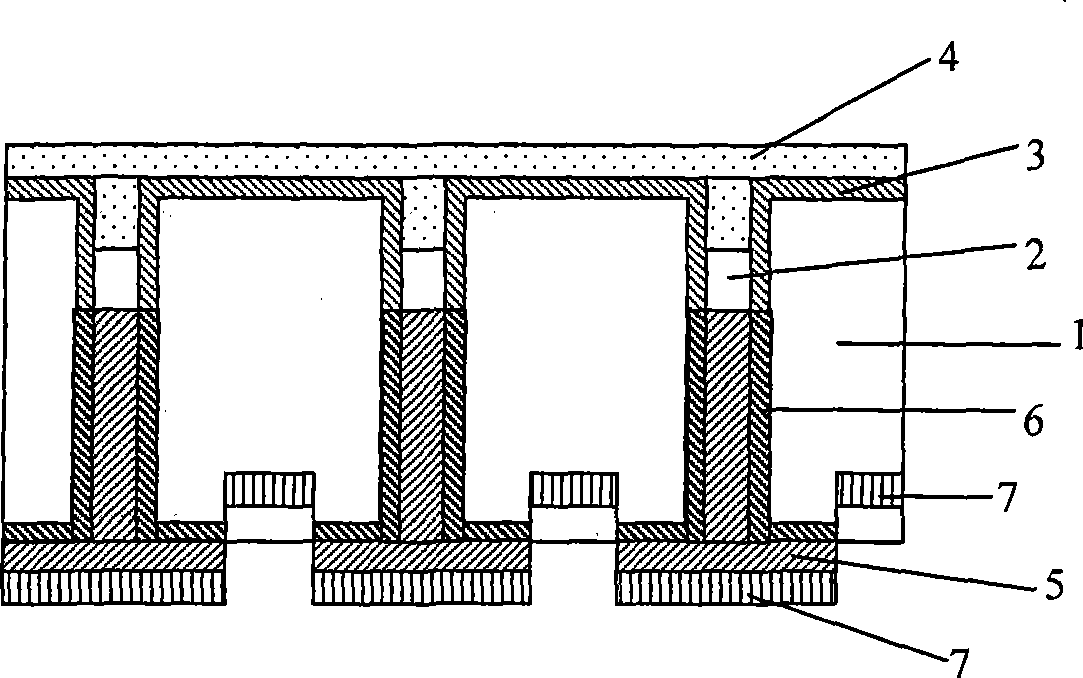

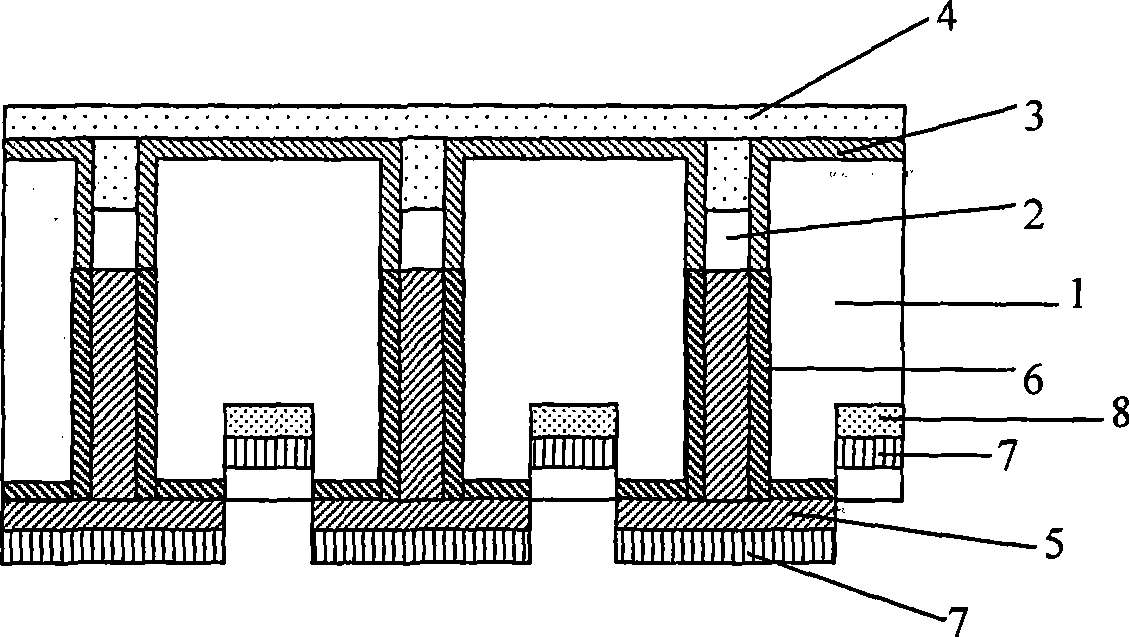

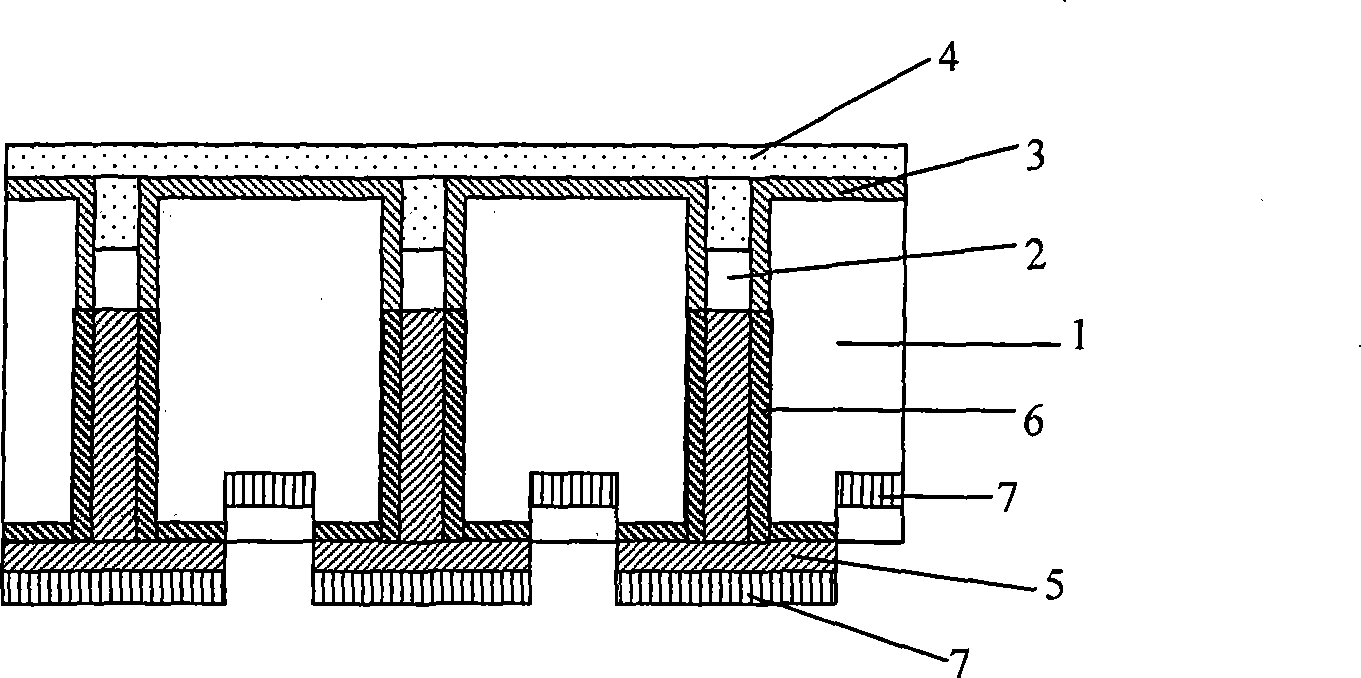

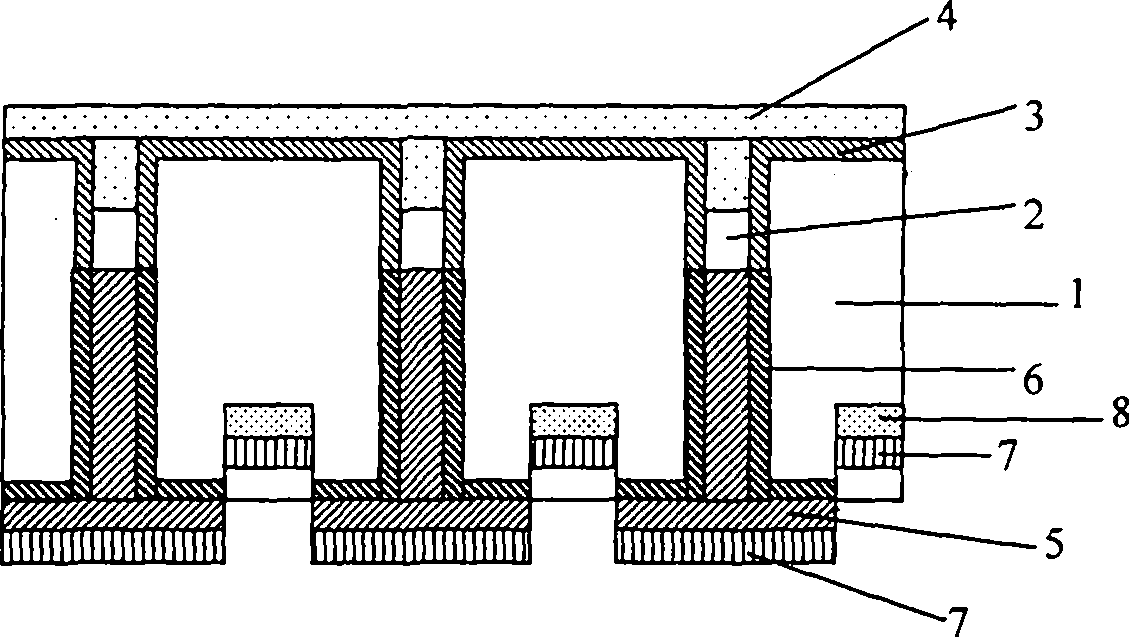

InactiveCN101383386AHigh mechanical strengthReduce metallizationPhotovoltaic energy generationSemiconductor devicesSolar cellMetal electrodes

The invention relates to a surrounding-emitting electrode solar cell and a preparation method thereof. The cell contains arrays which are arranged in a hexagonal lattice way and penetrate through holes 2 of an irradiation surface and a backlight surface of a silicon chip 1 in the silicon chip 1, therefore, the quantity of the through holes is minimized, and the breakage ratio of the silicon chip in the process of the hole drilling technology is reduced; a heavily doped emitting electrode 6 included on the back surface of the silicon chip 1 partially enters into the through holes, and a first conductive metal electrode 5 is arranged on the heavily doped emitting electrode 6, and plays the role of collecting minority carriers. A groove is arranged at the circumference of the first conductive metal electrode 5 by etching, a second conductive metal electrode 7 is arranged in the groove and plays the role of collecting majority carriers, and the first conductive metal electrode 5 and the second conductive metal electrode 7 deposited in the groove are insulated and isolated through the step of the groove.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Graphite surface titanium metallization method and product manufactured with the same

InactiveCN104694897ASolve the technical difficulties of low bonding strengthGood for diffusion reactionVacuum evaporation coatingSputtering coatingMetallic materialsGraphite substrate

The invention discloses a graphite surface titanium metallization method and a product manufactured with the same to solve the problem that when graphite is connected with Cu or Cu alloy, it is difficult to wet graphite with liquid metal, the difference between graphite and Cu or Cu alloy is large in terms of expansion factor and elasticity modulus, and connection is hard. According to the method, a titanium film is deposited on the surface of a graphite substrate with the magnetron sputtering method, and then hot isostatic pressing is conducted on the deposited titanium film, so that a titanium thin film is formed on the surface of the graphite substrate. The problem that coating-substrate combination strength of a surface titanium metallization layer is low during diffusion bonding of the non-metal material graphite can be effectively solved, and the metal titanium thin film high in coating-substrate combination strength can be prepared on the graphite substrate. According to the titanium thin film, the concentration of titanium becomes larger gradually from the graphite substrate to the outside in a gradient mode, and the strength of combination between a titanium coating and the substrate is high. The method can meet the requirement for research of fusion reactor plasma facing materials and has great significance for development of fusion reactor elements.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Liquid flow non-immersive measuring device and sensing probe

ActiveCN103344289AEnables non-immersive measurementsRealize measurementCladded optical fibreVolume/mass flow measurementMeasurement deviceGrating

The invention discloses a liquid flow non-immersive measuring device and a sensing probe. The liquid flow non-immersive measuring device comprises the sensing probe and is characterized in that the sensing probe is connected with a circulator through an optical path, light emitted by a pump light source of 980nm is received by the circulator through a separator, optical signals output by the circulator is sent to a coupler through the separator, two optical signals are output by the coupler, one signal is sent to a first Faraday rotary mirror through a phase modulator, and the other signal is directly sent to a second Faraday rotary mirror; the optical signals output by the coupler are sent to a photoelectric detector, electric signals output by the photoelectric detector enter a phase carrier wave demodulating device, weak dynamic variation of the wave length of a DFB optical fiber laser is demodulated, and flow is calculated according to the variation of the wave length; the sensing probe relates to a section of asymmetric phase shifting optical fiber grating fixed on the outer wall of an oil pipe in the circumferential direction.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Printed wiring board chemical copper plating solution

InactiveCN104152881AAchieve metallizationAchieve the effect of metallization in the hole of the printed circuit boardLiquid/solution decomposition chemical coatingPrinted circuit manufactureCopper platingChalcanthite

The invention discloses a printed wiring board chemical copper plating solution which is prepared from the following raw materials in parts by mass: 10-15 parts of chalcanthite, 30-35 parts of sodium hypophosphite, 10-15 parts of boric acid, 12-18 parts of complexing agent, 0.05-0.1 part of stabilizer, 0.5-1.5 parts of catalyst, 0.05-0.1 part of surfactant, 15-18 parts of sodium hydroxide and 300-320 parts of deionized water. By using the sodium hypophosphite as the main reducer, the chalcanthite, boric acid, complexing agent, stabilizer, catalyst, surfactant and sodium hydroxide are added to prepare the chemical copper plating solution; and the chemical copper plating solution is diluted to be used for chemical copper plating on the printed wiring board, thereby achieving the effects of the metallization of the non-conductor surface of the activated printed wiring board and the metallization in the printed wiring board holes. The printed wiring board chemical copper plating solution has the advantages of wide technological parameter range, long service life and no harmful formaldehyde vapor.

Owner:YANTAI HENGDIKE ENERGY TECH

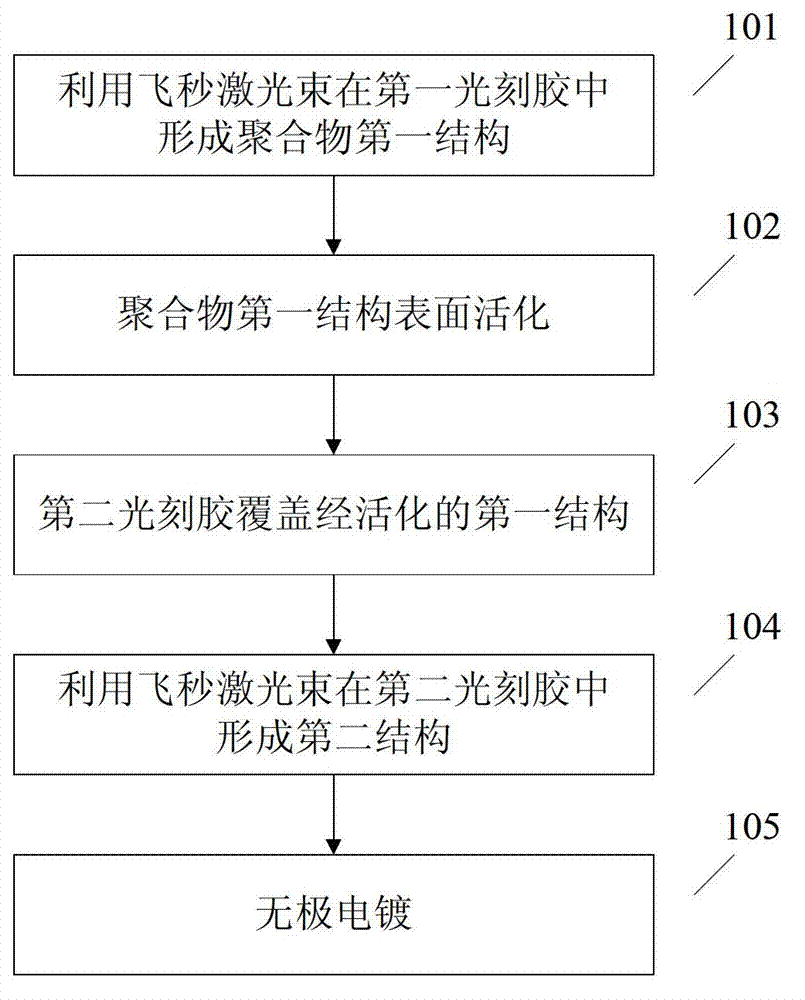

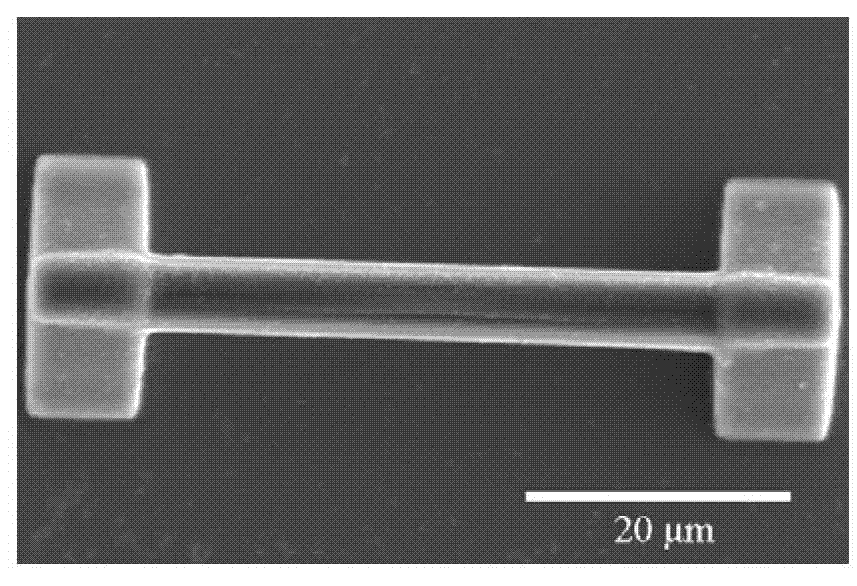

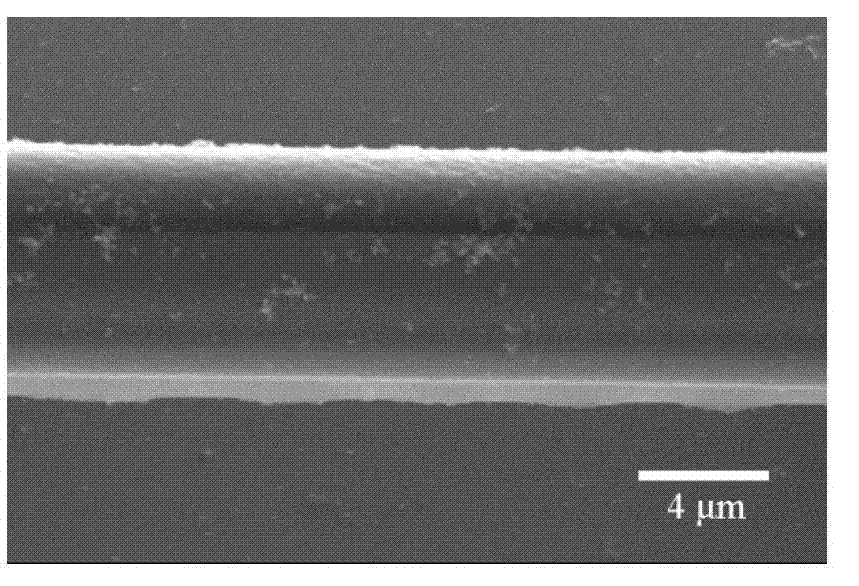

Preparation method for three-dimensional metal micro-nanometer device

ActiveCN102951604ALow costReduce process stepsDecorative surface effectsChemical vapor deposition coatingThin membraneNanometre

The invention relates to a preparation method for a three-dimensional metal micro-nanometer device. The method comprises the steps: forming a first structure of a polymer in a first photoresist by utilizing femtosecond laser beam; activating the surface of the first structure of the polymer; covering the activated first structure of the polymer by a second photoresist; forming a second structure partially contacted with the first structure in the second photoresist by utilizing femtosecond laser beam to obtain a complex of the partially exposed and activated surface of the first structure; and carrying out electrodeless plating to the complex in electroplate solution, and forming a metal thin membrane on the exposed surface of the first structure to obtain the three-dimensional metal micro-nanometer device. The first structure and the second structure are respectively machined so as to accurately align on three dimensions, selective electroplating of micro-nanometer structure can be realized by combining electrodeless electroplating technique, and the three-dimensional metal micro-nanometer device with any three-dimensional metal micro-nanometer structure can be obtained.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

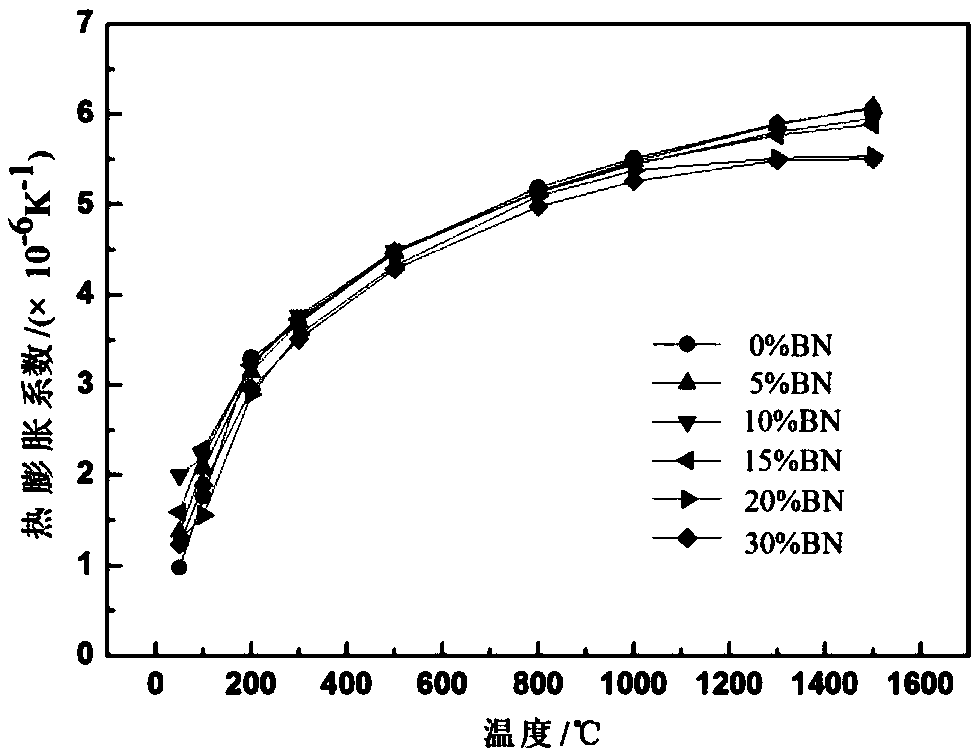

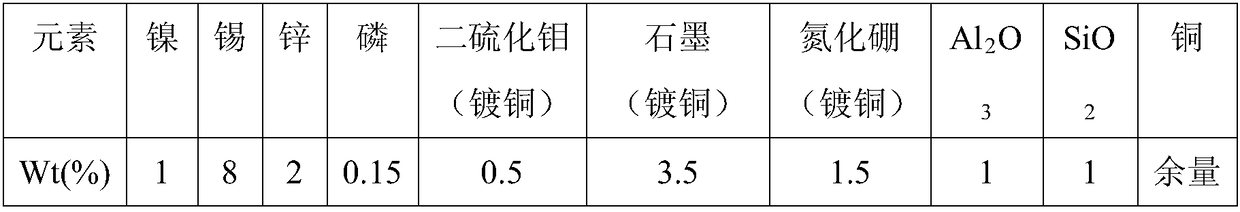

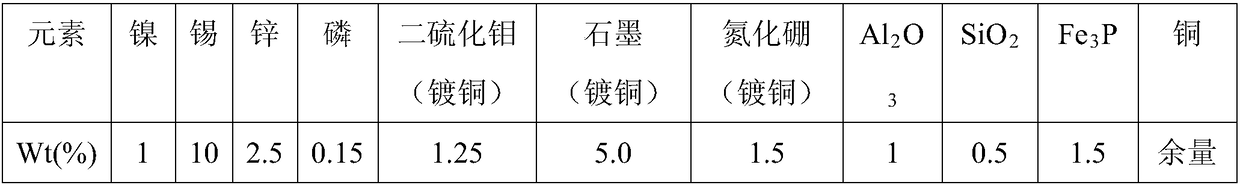

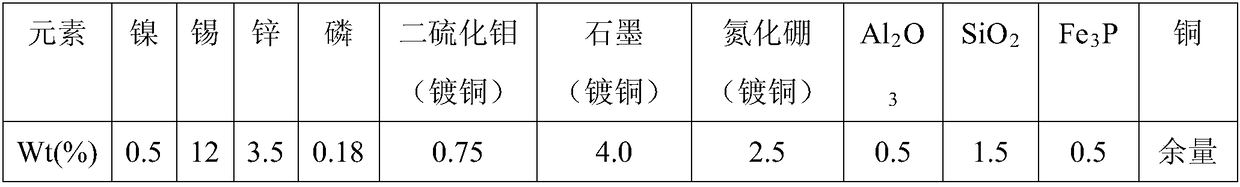

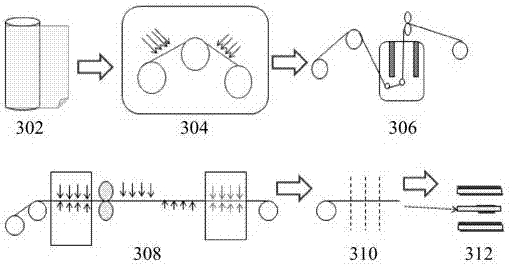

Lead-free copper-based bimetallic wear-resistant material and preparation method thereof

The invention discloses a lead-free copper-based bimetallic wear-resistant material and a preparation method thereof. According to the lead-free copper-based bimetallic wear-resistant material and thepreparation method thereof, copper-plated molybdenum disulfide, copper-plated graphite and copper-plated hexagonal boron nitride are added into lead-free bronze powder, alloy powder is laid on a steel plate, the copper-steel bimetallic lead-free wear-resistant composite material is prepared through a powder metallurgy re-sintering and re-rolling technology, and the effects of antifriction and wear resistance of the molybdenum disulfide, the graphite and the hexagonal boron nitride are exerted in a synergistic mode. The obtained composite material has the advantages of being good in antifriction and wear resistance performance, excellent in mechanical property, free of toxic element of lead, pollution-free to the environment and suitable for industries of medicine, food, machinery and thelike.

Owner:无锡神意模具新材料有限公司

Metalized materials for Si3N4 ceramic surface and preparation method as well as brazing technique

ActiveCN105057919AEvenly heatedReduce stress concentrationNon-macromolecular adhesive additivesEster polymer adhesivesInterfacial reactionAdhesive

The invention discloses metalized materials for Si3N4 ceramic surface and a preparation method as well as brazing technique. Silver-based materials are of powder particles, which are prepared from the following components in percentage by weight: 20 to 25 percent of Cu, 3 to 5 percent of Ti, 2 to 3 percent of Ni, 0.1 to 0.3 percent of Ce, 0.2 to 0.3 percent of Sc, 0.5 to 0.6 percent of Re, and the balance of Ag; a particle size of the Ag, the Cu, the Ti and the Ni is 40 mu. m to 55 mu. m, the particle size of the Ce, Sc and Re is 15 mu. m to 25 mu. m. The silver-based materials provided by the invention are of flexible fibrous metal cloth materials, which are prepared by the pressure roller under the effect of a special adhesive; the composition of Ag-base alloy materials are uniform and the Ag-base alloy materials have a certain adhesive property; the Ag-base alloy materials are conductive to the local binding of ceramic parts in various complex parts, can ensure that the metalized materials for the Si3N4 ceramic surface do not fall off and the distribution of the surface metal is uniform under the condition of brazing, are conductive to the atomic diffusion and the interfacial reaction in a brazed connection process, can improve the wettability of the metalized materials for a surface, and are conductive to a good connection between the ceramic and a metal.

Owner:JIANGSU UNIV OF SCI & TECH

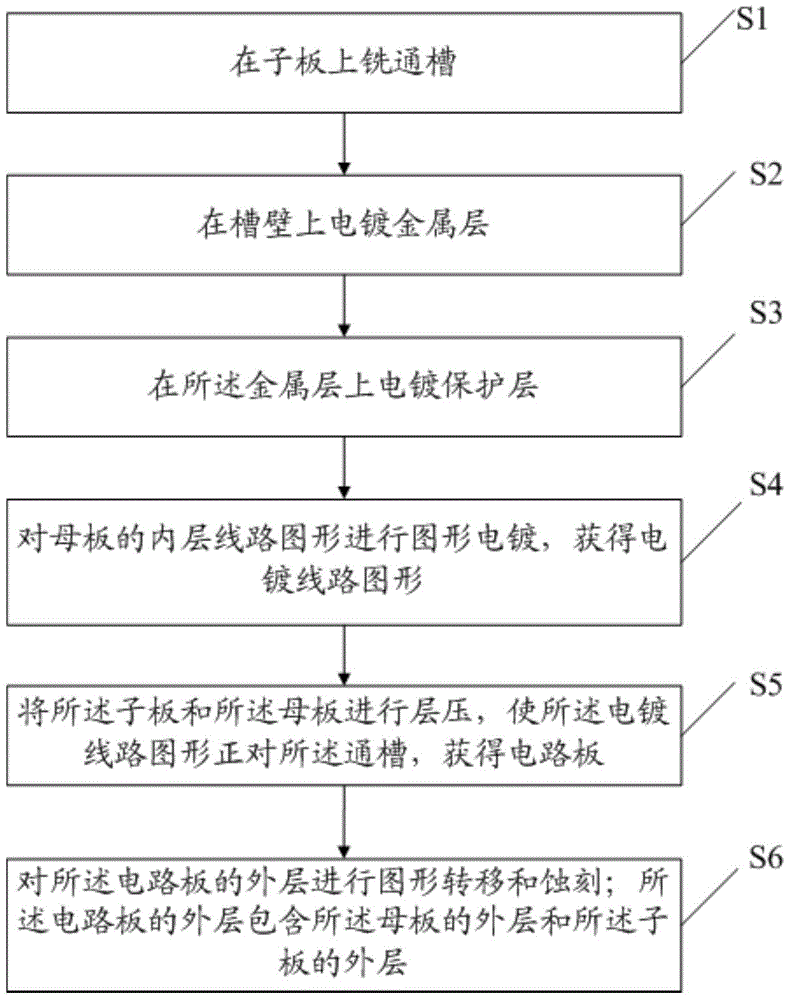

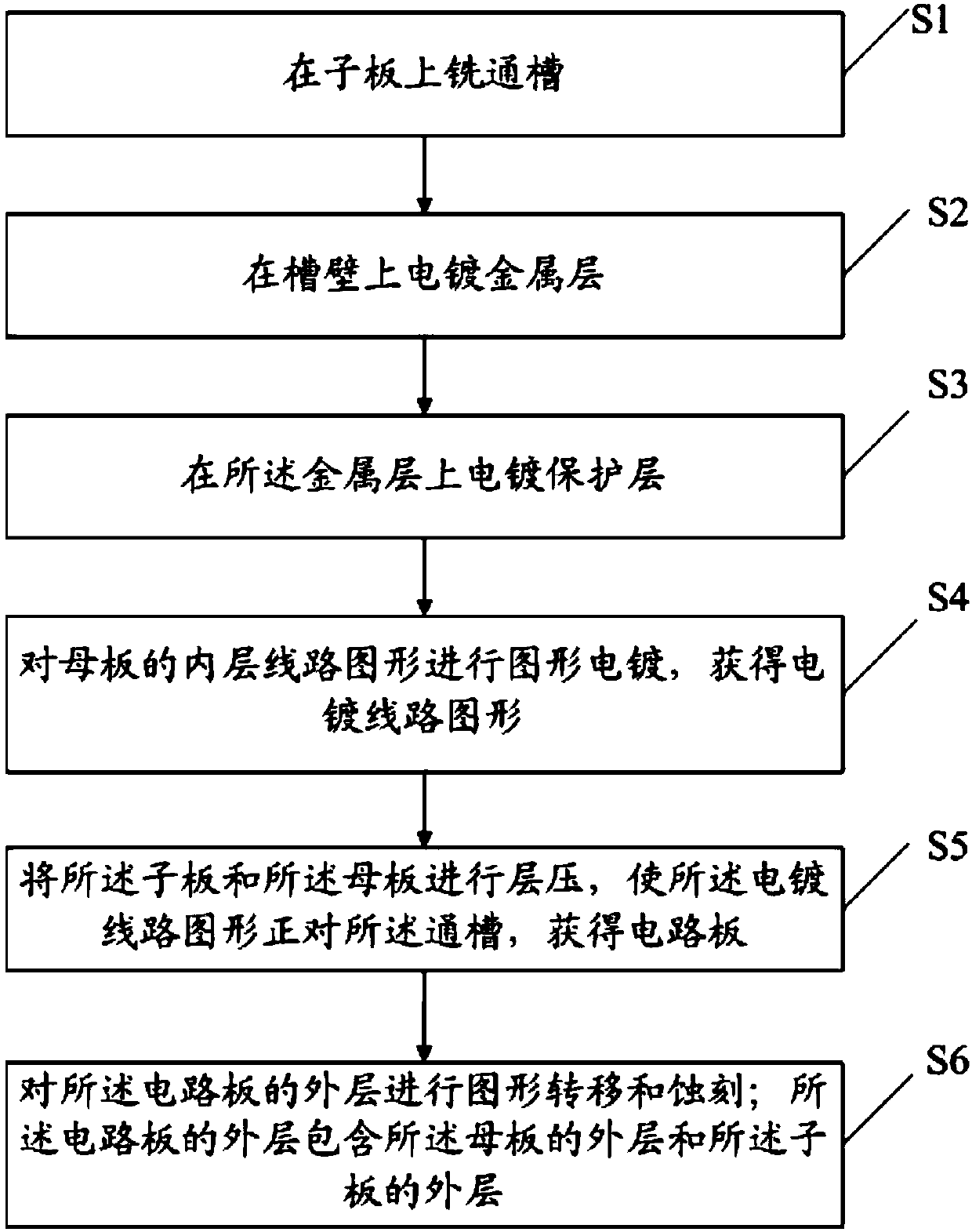

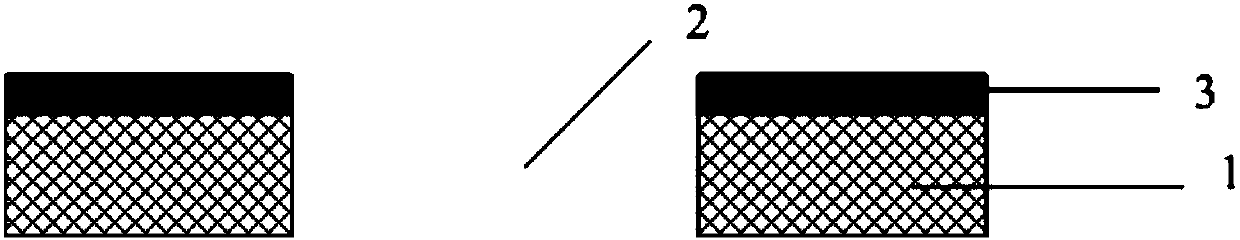

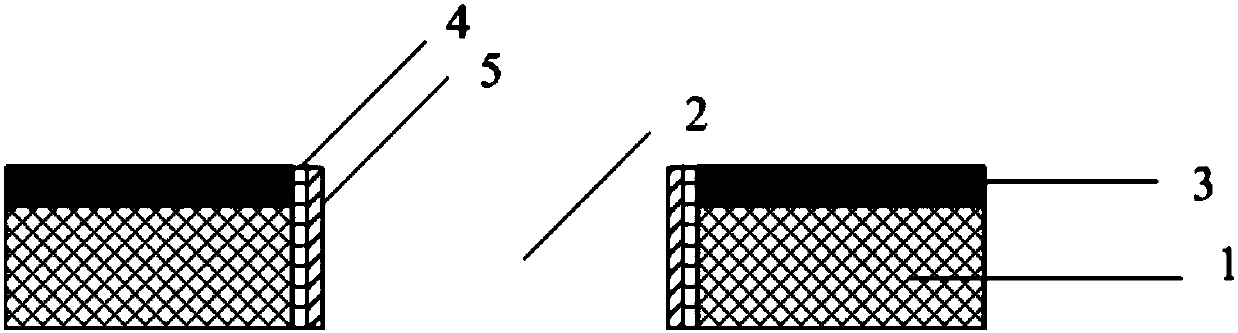

Manufacture method of circuit board

ActiveCN104837304AAchieve metallizationImprove pass ratePrinted element electric connection formationInternal layerElectroplating

The invention discloses a manufacture method of a circuit board. The method comprises the following steps: milling a through groove in a daughter board; electroplating a metal layer on the wall of the groove; electroplating a protective layer on the metal layer; performing pattern electroplating on the internal-layer line patterns of a motherboard to obtain electroplating line patterns; laminating the daughter board and the motherboard to enable the electroplating line patterns to be right opposite to the through groove, and obtaining the circuit board; and performing pattern transferring and etching on the external layer of the circuit board, wherein the external layer of the circuit board comprises the external layer of the motherboard and the external layer of the daughter board. By using the method provided by the embodiment of the invention, metallization of the groove wall of the circuit board can be realized, and the qualified rate of the circuit board is improved.

Owner:GCI SCI & TECH

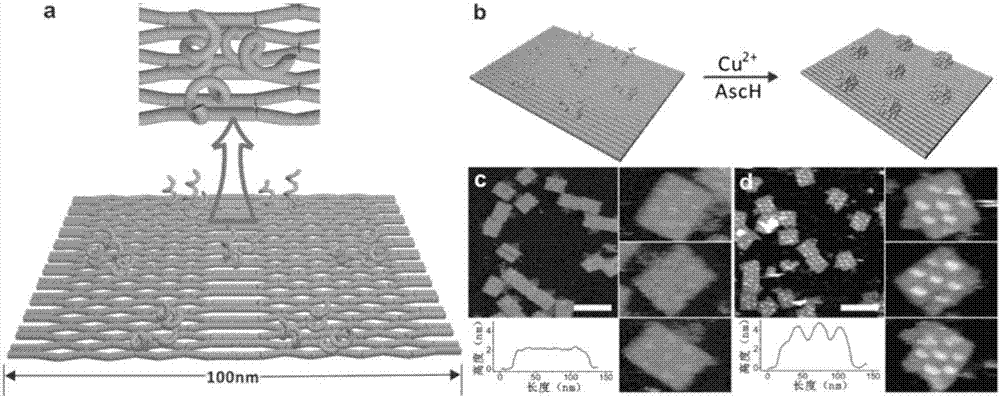

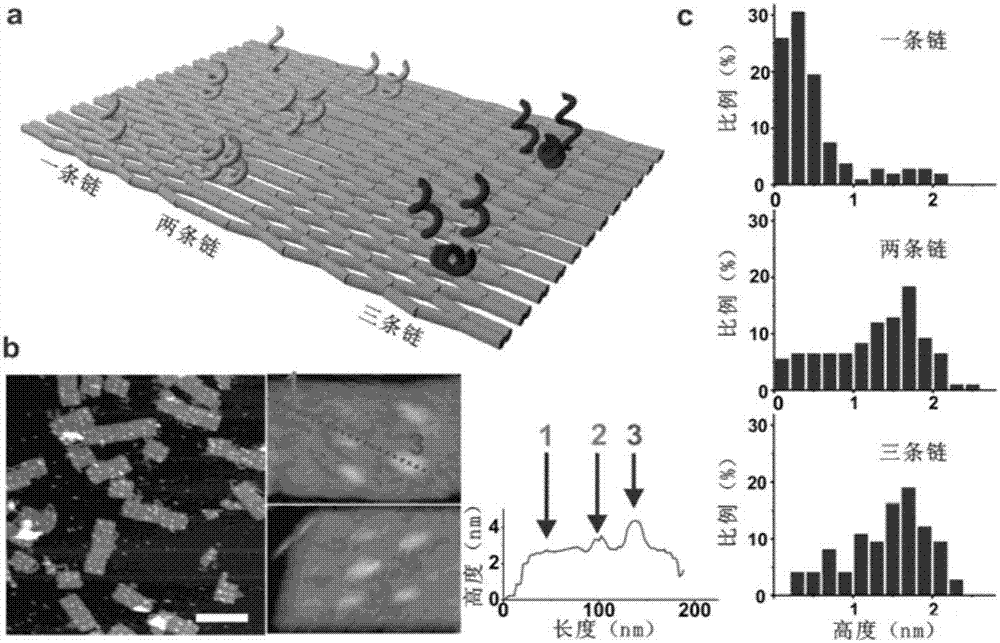

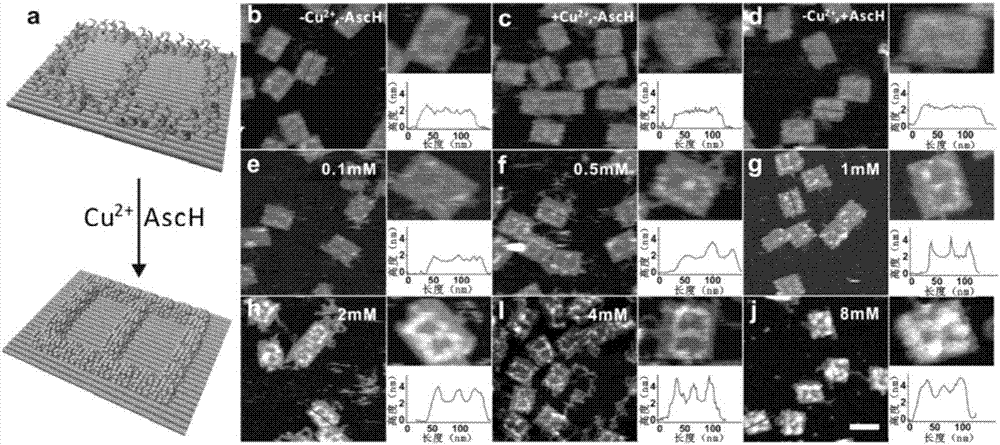

Manufacture method of metal nano circuit patterns based on DNA nano structures

ActiveCN107055465AWith nanoscale resolutionHigh position specificitySpecific nanostructure formationNano structuringDNA origami

The invention provides a manufacture method of metal nano circuit patterns based on DNA nano structures. The method includes taking DNA paper folding structures fixed to surfaces as templates, introducing artificial defects onto the templates, and performing selective metallization on the templates with the artificial defects so as to create the metal nano circuit patterns based on the DNA nano structures. The manufacture method is simple, rapid and effective, and a series of metal nano patterns with only few nanometers of zero-dimensional, one-dimensional and two-dimensional line width can be acquired through accurate positioning of DNA paper folding. DNA paper folding mainly applied to the manufacture method has high biocompatibility, and other needed chemical and biological materials do not have toxicity on human bodies; a novel thought and a novel technical support are provided for creating a nano circuit by 'bottom-to-up' self-assembly and breaking through the limit of conventional photolithography.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

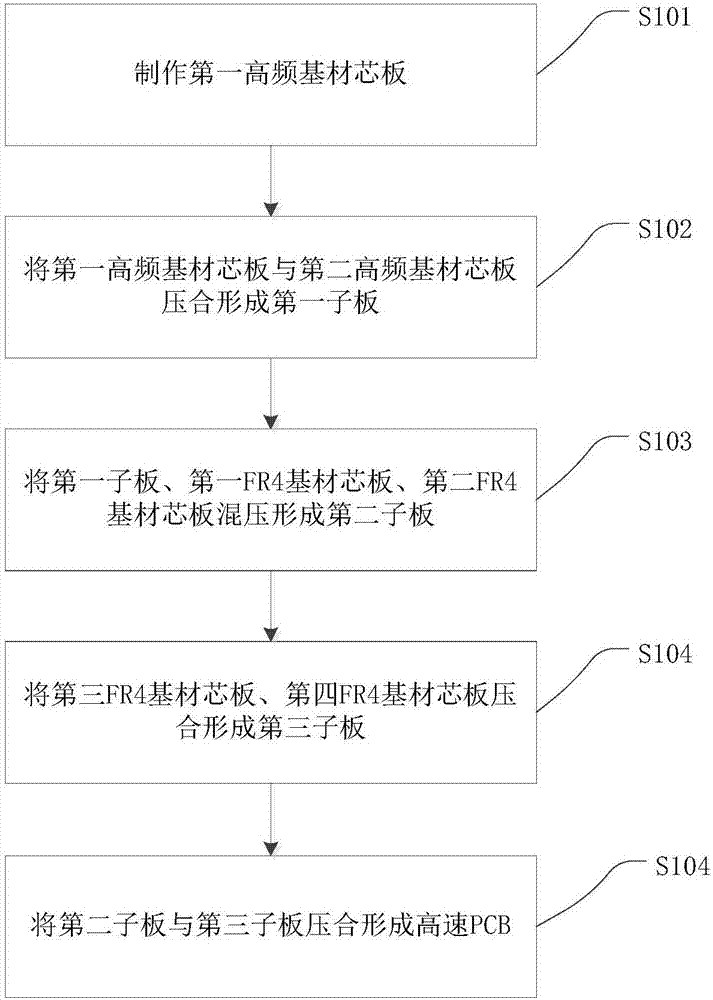

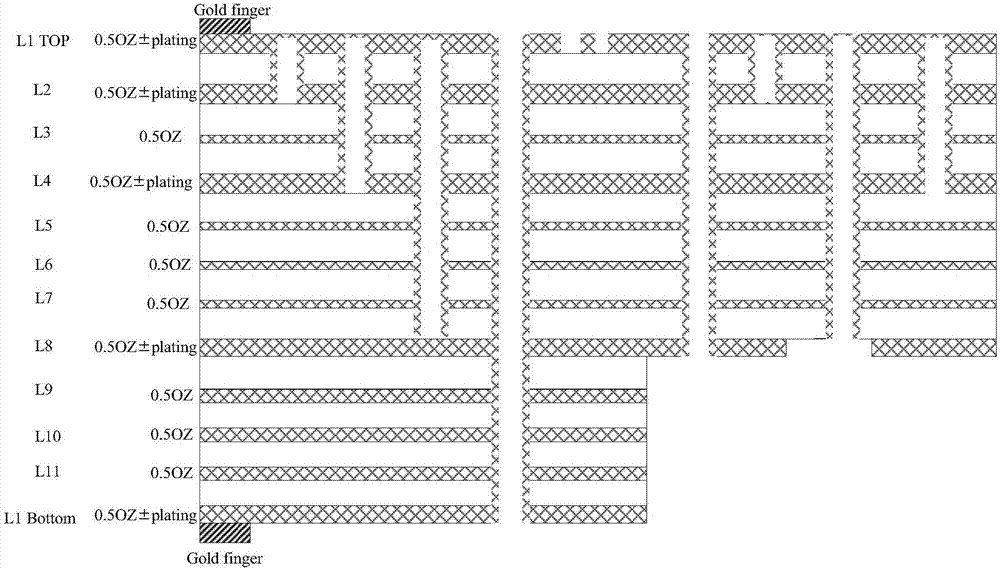

Manufacturing method for high-speed PCB, and high-speed PCB

InactiveCN107484361ALow loss factorLow Conductor Surface RoughnessPrinted circuit aspectsHigh frequency circuit adaptationsMicrowaveCopper

The invention discloses a manufacturing method for a high-speed PCB and the high-speed PCB, and the method comprises the steps: carrying out the stitching of at least two high-frequency base material core boards to form a first subboard; Carrying out the mixed pressing of the first subboard and at least one FR4 base material core board to form the high-speed PCB, wherein the outer core boards on two surfaces are respectively a high-frequency base material core board and an FR4 base material core board. The high-speed PCB is formed by the high-frequency base material core board and the FR4 base material core board in a mode of multiple mixed pressing, and the high-frequency base material core board serves as the outer core board. Because a high-frequency base material is low in dielectric constant and is low in loss factor, the transmission of high-frequency microwaves and other function signals can be achieved through manufacturing a radio frequency circuit on the first high-frequency base material core board, and the production cost is reduced at the same time. In addition, the second high-frequency base material core board is employed as the secondary outer core board, and a copper layer based on the second high-frequency base material core board is good in uniformity, thereby achieving the signal transmission through the combination of two sides, and greatly improving the signal transmission quality.

Owner:DONGGUAN SHENGYI ELECTRONICS

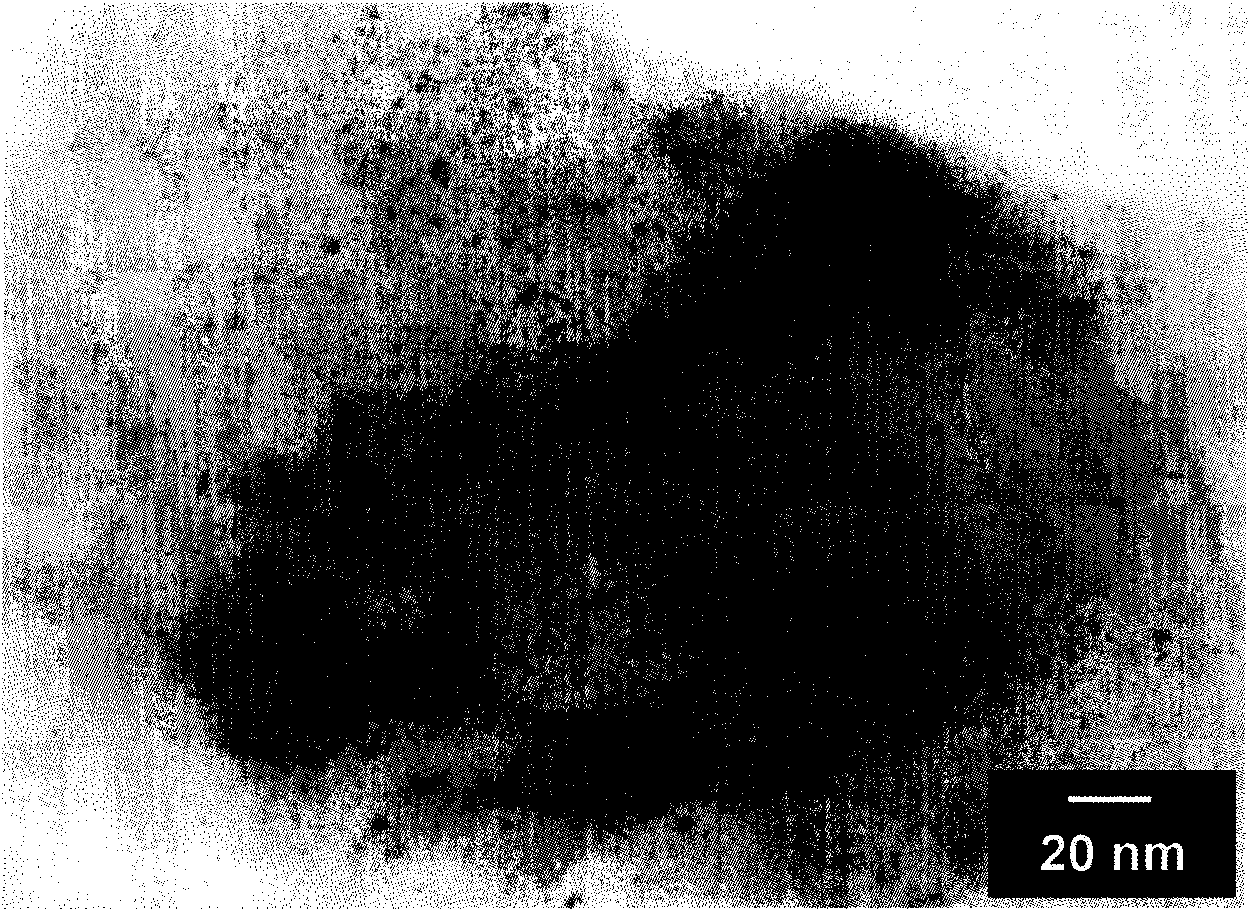

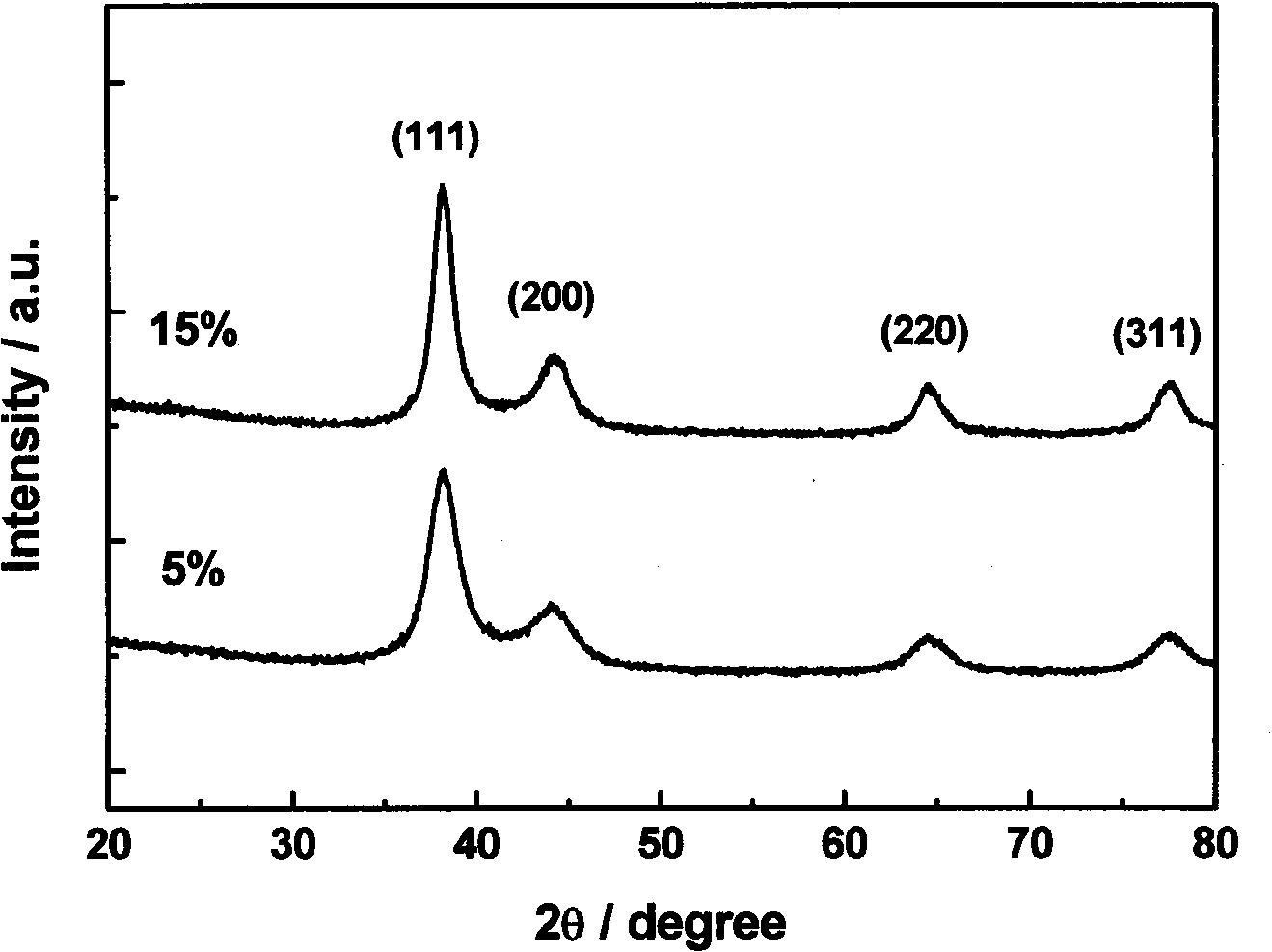

Carbon-supported metal catalyst and preparation method thereof

InactiveCN101618324AGood dispersionAchieve metallizationCell electrodesCatalyst activation/preparationFiltrationIon exchange

The invention discloses a carbon-supported metal catalyst and a preparation method thereof. The metal catalyst takes a transition metal element as an active metal, and the content of the metal component is accurate and adjustable within the range of 1-50wt%. The preparation method mainly comprises the following steps: (1) preparing salt precursor solution and placing in a reactor with continuously stirring; (2) adding negative resin which forms a certain proportion with metal content in the salt precursor or positive resin with the same proportion in the reactor for carrying out ion exchange reaction and controlling the temperature not to exceed 40 DEG C; (3) carrying out filtration on the solution of ion exchange reaction at room temperature, collecting filtered materials and drying at 80 DEG C; and (4) placing the dried filter materials in a tube furnace, increasing the temperature to 500 DEG C for baking under the protection of helium and nitrogen inert gas flow, keeping the temperature for a certain period of time and cooling to room temperature. The method removes impurities by synthesis process and self-reduction process of the catalyst and realizes metallization of the active component and high dispersion.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparation method of nickel-plated fiber grating sensor

InactiveCN104406625AAchieve metallizationHigh precisionForce measurement by measuring optical property variationLiquid/solution decomposition chemical coatingFiberGrating

The invention discloses a preparation method of a nickel-plated fiber grating sensor. The method comprises the following steps: first of all, performing surface roughening treatment on a fiber grating, then performing impregnation processing by use of a colloid palladium solution, and then immersing the fiber grating into a dispergation solution to obtain a fiber containing palladium atoms; and immersing the fiber containing the palladium atoms into a plating liquid, plating a layer of metal on the fiber containing the palladium atoms by use of an oxidation reduction reaction to obtain an initially plated fiber, immersing the initially plated fiber into an electroplate solution for electroplating to obtain a metallic nickel galvanized coating, and finally, welding the electroplated fiber grating on a sensor substrate by use of laser to obtain a nickel-plated fiber grating sensor. Compared to the prior art, the method provided by the invention has the following advantages: the metallization of the fiber grating is realized, the fiber grating can be welded on the sensor substrate through a welding mode, relative movement between a fiber core layer and a fiber coating can be prevented, measuring data can truly reflect the stress and strain of an object to be measured, and the sensor accuracy is improved.

Owner:ANHUI POPULAR SCI PROD ENG RES CENT

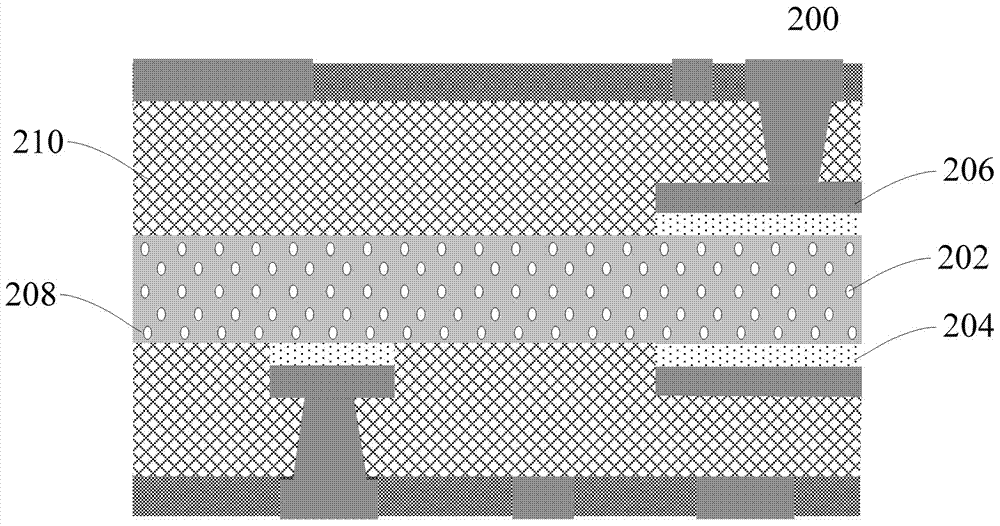

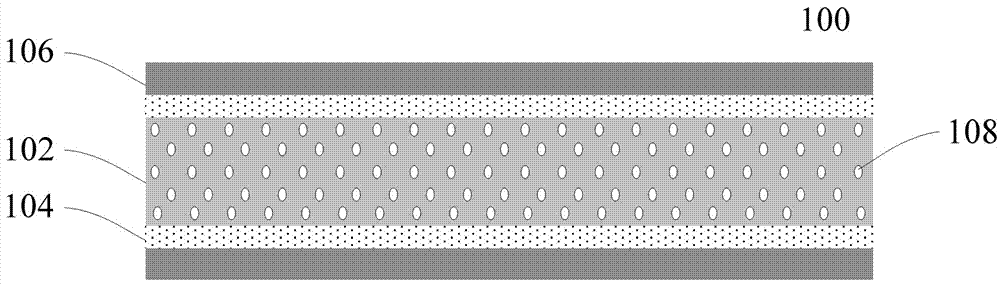

Capacitor, capacitor-burying circuit board and manufacturing method thereof

PendingCN107231747AHigh peel strengthLarge capacityPrinted capacitor incorporationMultilayer circuit manufactureCapacitanceEngineering

The invention relates to a capacitor, a capacitor-burying circuit board and a manufacturing method thereof. The capacitor comprises a high dielectric constant polymer composite material layer; an ion injection layer, wherein the ion injection layer is formed by injecting the conducting material ion into the high dielectric constant polymer composite material layer at high-speed through an ion injection way; and a metal layer formed and covered on the ion injection layer.

Owner:RICHVIEW ELECTRONICS CO LTD

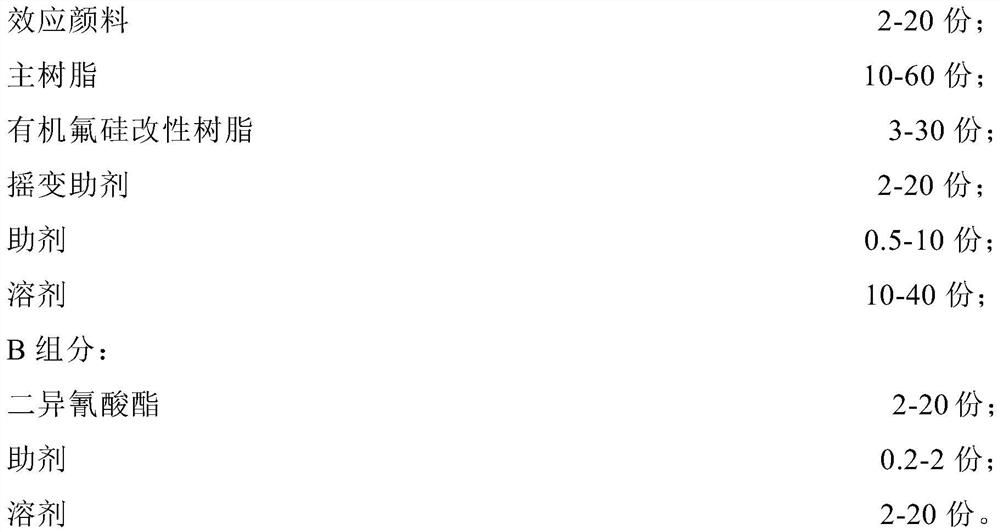

High-wear-resistance coating for automotive upholstery and preparation method of high-wear-resistance coating

The invention relates to a coating for automotive upholstery, in particular to a high-wear-resistance coating for automotive upholstery and a preparation method thereof.The high-wear-resistance coating for automotive upholstery comprises a component A and a component B. The component A comprises, by weight, 2-20 parts of effect pigment; 10 to 60 parts of main resin; 3 to 30 parts of organic fluorine-silicon modified resin; 2-20 parts of a shaking auxiliary agent; 0.5 to 10 parts of an auxiliary agent; 10 to 40 parts of a solvent; a component B: 2 to 20 parts of diisocyanate; 0.2 to 2 parts of an auxiliary agent; and 2-20 parts of a solvent. Compared with the prior art, the modified aldehyde ketone resin is selected as a matrix, the adhesion performance between a paint film and a material can be effectively improved, and the prepared paint is good in water resistance and chemical resistance. The modified aldehyde ketone matrix resin has high molecular weight, can effectively improve the Flip-Flop value of the silver powder, enables the arrangement effect of the silver powder to be excellent, can improve the shielding power of the metallic pigment, and can effectively improve the water resistance, alcohol resistance and high weather resistance of a coating.

Owner:DONGLAI COATING TECH SHANGHAI

Preparation method for molybdenum blank

The invention discloses a preparation method for a molybdenum blank. The method comprises the following steps that (1), under the condition of 160-300 MPa, pressing is carried out on the molybdenum powder with the average particle size of 3-4 microns, moreover, the pressure is maintained for 3-20 minutes, and a green body is prepared; (2), low-temperature sintering is carried out; (3), medium-temperature sintering is carried out; and (4), high-temperature sintering is carried out, finally, cooling is carried out until the temperature reaches the room temperature, and the molybdenum blank is obtained. The molybdenum blank prepared by the preparation method is high in purity and uniform in tissue structure, and a prepared molybdenum foil is stable in performance.

Owner:CHENGDU LIANHONG MOLYBDENUM IND CO LTD

A method of making a circuit board

ActiveCN104837304BImprove pass rateAchieve metallizationPrinted element electric connection formationEngineeringElectroplating

The invention discloses a manufacture method of a circuit board. The method comprises the following steps: milling a through groove in a daughter board; electroplating a metal layer on the wall of the groove; electroplating a protective layer on the metal layer; performing pattern electroplating on the internal-layer line patterns of a motherboard to obtain electroplating line patterns; laminating the daughter board and the motherboard to enable the electroplating line patterns to be right opposite to the through groove, and obtaining the circuit board; and performing pattern transferring and etching on the external layer of the circuit board, wherein the external layer of the circuit board comprises the external layer of the motherboard and the external layer of the daughter board. By using the method provided by the embodiment of the invention, metallization of the groove wall of the circuit board can be realized, and the qualified rate of the circuit board is improved.

Owner:GCI SCI & TECH

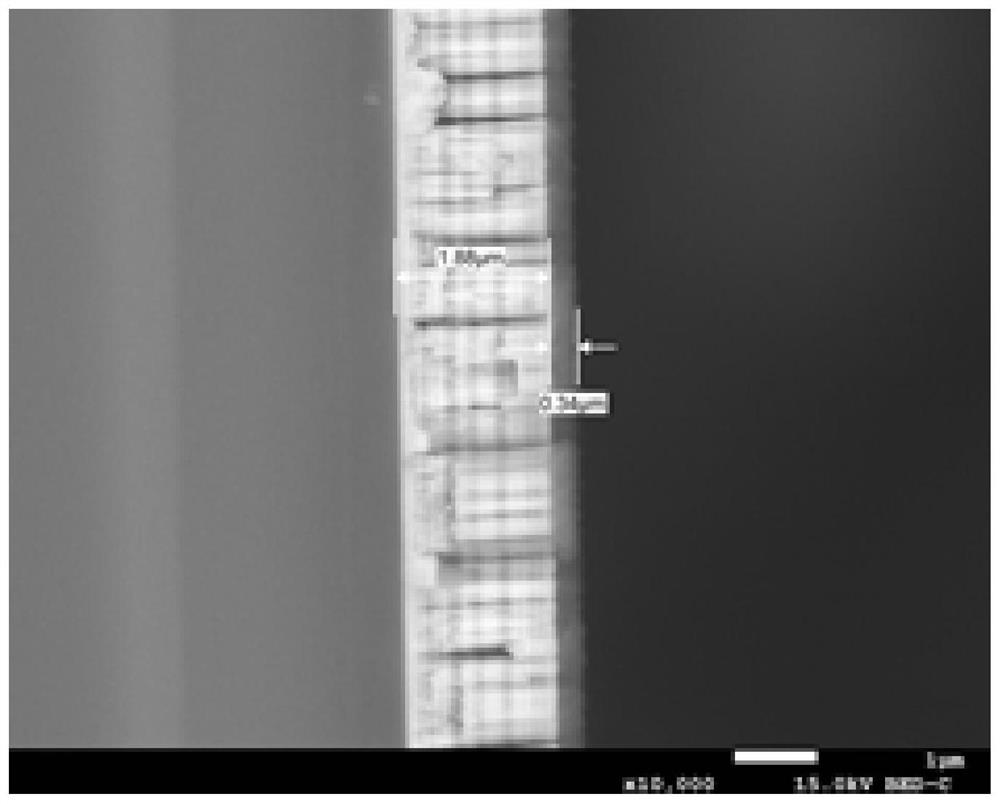

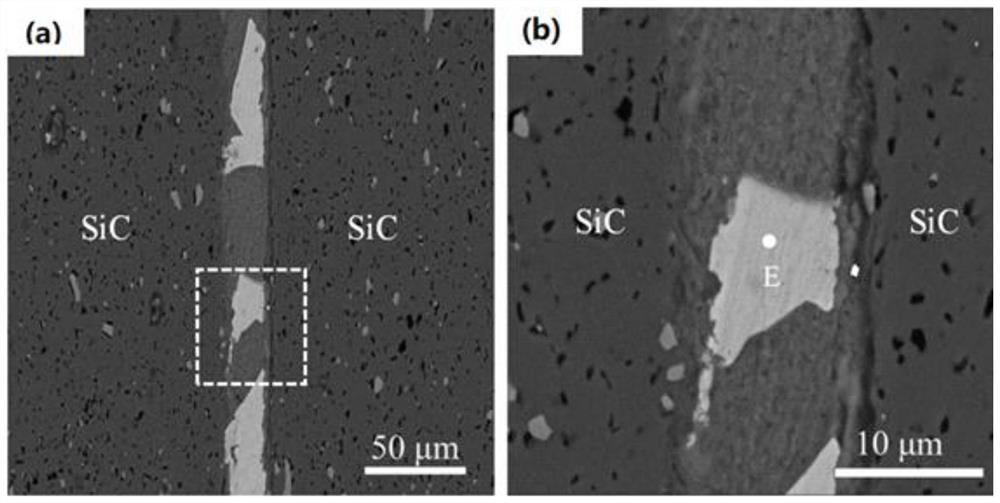

Brazing method for silicon carbide ceramics

ActiveCN112975032AImprove wettabilityImprove bindingSoldering apparatusCarbide siliconUltimate tensile strength

The invention discloses a brazing method for silicon carbide ceramics. The brazing method comprises the following steps: carrying out surface treatment on the silicon carbide ceramics; depositing a first metal layer on the surface of the silicon carbide ceramics by adopting a vapor deposition method, and then depositing a second metal layer on the surface of the first metal layer to obtain the silicon carbide ceramics deposited with double metal layers, wherein the material of the first metal layer is selected from one of Ni, Ti, Fe or Zr, and material of the second metal layer is selected from Al; placing the silicon carbide ceramics needing to be connected in a vacuum sintering furnace, then placing a pure Al foil between the silicon carbide ceramics needing to be connected, starting heating when vacuum in the furnace reaches 10 <-1 > Pa, increasing the temperature to 600-800 DEG C, and conducting heat preservation for 10-60 min; and after heat preservation is finished, performing cooling to room temperature along with the furnace to obtain the silicon carbide ceramics subjected to brazing connection. According to the brazing method for the silicon carbide ceramics, the wettability of aluminum-based brazing filler metal to the silicon carbide material can be improved, the brazing temperature can be reduced, and the bonding strength of a brazed joint can be improved.

Owner:浙江浙能兰溪发电有限责任公司 +1

Emitter circulating type solar cell and preparation thereof

InactiveCN101383386BReduce the number of viasHigh mechanical strengthPhotovoltaic energy generationSemiconductor devicesSolar cellIrradiation

The invention relates to a surrounding-emitting electrode solar cell and a preparation method thereof. The cell contains arrays which are arranged in a hexagonal lattice way and penetrate through holes 2 of an irradiation surface and a backlight surface of a silicon chip 1 in the silicon chip 1, therefore, the quantity of the through holes is minimized, and the breakage ratio of the silicon chip in the process of the hole drilling technology is reduced; a heavily doped emitting electrode 6 included on the back surface of the silicon chip 1 partially enters into the through holes, and a first conductive metal electrode 5 is arranged on the heavily doped emitting electrode 6, and plays the role of collecting minority carriers. A groove is arranged at the circumference of the first conductive metal electrode 5 by etching, a second conductive metal electrode 7 is arranged in the groove and plays the role of collecting majority carriers, and the first conductive metal electrode 5 and the second conductive metal electrode 7 deposited in the groove are insulated and isolated through the step of the groove.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

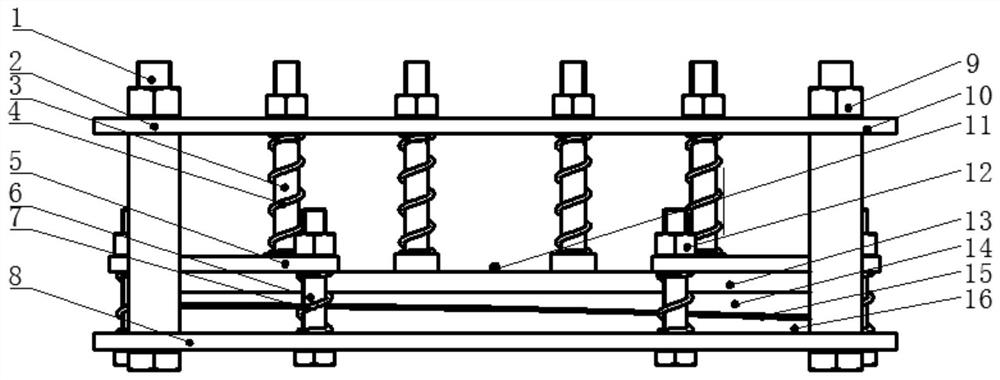

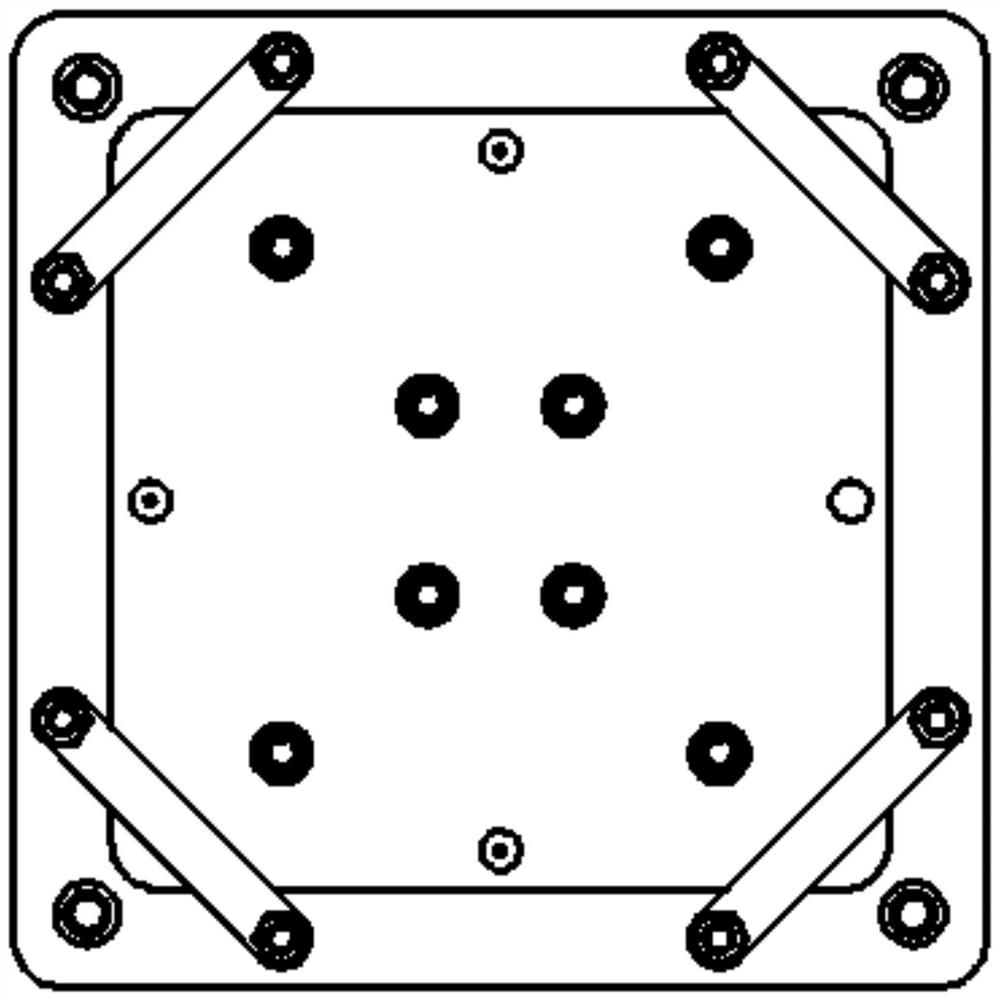

Welding method of curved-surface microstrip antenna

InactiveCN111958079AMeet welding requirementsStrong welding adaptabilityAntenna adaptation in movable bodiesWelding apparatusStructural engineeringClose contact

The invention provides a welding method of a curved-surface microstrip antenna, and aims to provide the welding method of the curved-surface microstrip antenna, which is high in welding success rate and high in welding quality so as to meet the reliability requirement of the curved-surface microstrip antenna in long-term use. The method comprises the following steps that a clamping tool for supporting an upper pressing plate and a lower pressing plate through a fixed stand column is prepared, a pressure stand column is sleeved with a main pressure spring, and penetrates through the upper pressing plate to be connected with a main pressure nut; a layer of welding flux is printed at the bottom of the micro-strip in a steel mesh printing mode, and the micro-strip is fixed to a base, a flexible voltage-sharing plate and a rigid voltage-sharing plate through pins; auxiliary pressing plates are arranged at the four corners of the rigid voltage-sharing plate, and the auxiliary pressing plates, auxiliary stand columns and auxiliary pressure springs are fixed to the lower pressing plate through auxiliary pressure nuts to compress main pressure springs and the auxiliary pressure springs, sothat the micro-strip makes close contact with the base; and after assembly is completed, the whole clamping tool is put into a vacuum gas phase furnace to be heated, and after cooling, the tool is disassembled to complete welding of the micro-strip and the base.

Owner:10TH RES INST OF CETC

Method for electroplating metal on surface of insulating base material

PendingCN112746298AAvoid harmAvoid pollutionPolyurea/polyurethane coatingsResin coatingElectroplating

The invention belongs to the technical field of electroplating, and discloses a method for electroplating metal on the surface of an insulating base material. The method for electroplating the metal on the surface of the insulating base material comprises the following steps of S1, mixing resin, a solvent, a solid filler and a curing agent to prepare a coating; S2, coating the surface of the insulating base material with a resin coating, and forming a coating with fine gaps after the insulating base material is cured; S3, coating the resin coating in the S2 with a conductive substance, wherein the conductive substance can permeate into a gap structure of the resin coating, and a conductive film is formed after drying; and S4, placing the insulating base material containing the conductive film in the S3 in electroplating liquid for direct electroplating. According to the method for electroplating the metal on the surface of the insulating base material provided by the invention, the resin is used as an intermediate layer of an conductive layer formed by the insulating base material and the conductive substance, and the electroplated metal layer with excellent adhesive force on the base material can be obtained by growing and filling the metal in the fine gaps of the resin coating, so that the types of the used insulating base materials can be expanded, and wide application is realized.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

A kind of manufacturing method of copper/aluminum nitride ceramic composite heat conduction substrate

InactiveCN104064478BAchieve depositionAchieve metallizationSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingThermal dilatationCeramic composite

The invention discloses a preparation method for a copper / aluminium nitride ceramic composite heat-conductive substrate. The method comprises the following steps: 1) providing through holes in the surface of an aluminium nitride substrate; 2) coating copper electronic paste layers on the double surfaces of the aluminium nitride substrate; 3) filling the through holes with pre-oxidation copper cylinders; 4) carrying out overall sintering for 30 min; 5) carrying out brazing after the double surfaces of the aluminium nitride substrate being coated with tin silver copper solder materials; 6) carrying out surface polishing; and 7) carrying out copper plating processing directly and forming uniform copper layers, and thus, the copper / aluminium nitride ceramic composite heat-conductive substrate is obtained. The through holes in the copper / aluminium nitride ceramic composite heat-conductive substrate produced with the preparation method are communicated up and down; the combination between the metalized layers in the holes and the ceramic substrate is strong; the middle copper cylinders can realize the communication of the copper layers on the upper and lower surfaces; and the copper / aluminium nitride ceramic composite heat-conductive substrate helps the transmission of electrical signals and has the advantages of ideal heat-conductive effect, low thermal expansion coefficients and good conductivity and the like.

Owner:NANJING MING KUANG ELECTRONICS TECH

A kind of anti-friction copper base bimetallic bearing material and its manufacturing method

ActiveCN106756214BAchieve lead-freeIncrease moistureTransportation and packagingShaftsRutheniumAlloy

The invention discloses a friction-reducing copper-based bimetallic bearing material and a manufacturing method thereof. The steel plate is used as a base body, and a copper-based alloy friction-reducing layer is formed on the surface of the steel plate. The copper-plated graphite, copper-plated molybdenum disulfide and Bismuth is used as the lubricating component, copper is used as the base material, and nickel, tin and phosphorus are added, and the copper-steel bimetal bearing material is prepared by sintering in the steel plate. The invention synergistically exerts the excellent anti-friction properties of molybdenum disulfide and graphite and the anti-adhesion effect of bismuth element, and the friction coefficient of the material can reach 0.10-0.15; the obtained bearing material has good anti-friction and wear resistance, does not contain toxic element lead, and is environmentally friendly. any contamination.

Owner:荣成远海滑动轴承有限公司

Liquid flow non-immersive measuring device and sensing probe

ActiveCN103344289BEnables non-immersive measurementsRealize measurementCladded optical fibreVolume/mass flow measurementMeasurement deviceGrating

The invention discloses a liquid flow non-immersive measuring device and a sensing probe. The liquid flow non-immersive measuring device comprises the sensing probe and is characterized in that the sensing probe is connected with a circulator through an optical path, light emitted by a pump light source of 980nm is received by the circulator through a separator, optical signals output by the circulator is sent to a coupler through the separator, two optical signals are output by the coupler, one signal is sent to a first Faraday rotary mirror through a phase modulator, and the other signal is directly sent to a second Faraday rotary mirror; the optical signals output by the coupler are sent to a photoelectric detector, electric signals output by the photoelectric detector enter a phase carrier wave demodulating device, weak dynamic variation of the wave length of a DFB optical fiber laser is demodulated, and flow is calculated according to the variation of the wave length; the sensing probe relates to a section of asymmetric phase shifting optical fiber grating fixed on the outer wall of an oil pipe in the circumferential direction.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

A ceramic/metal gradient structure high-temperature packaging material and its preparation method

Owner:WUHAN UNIV OF TECH

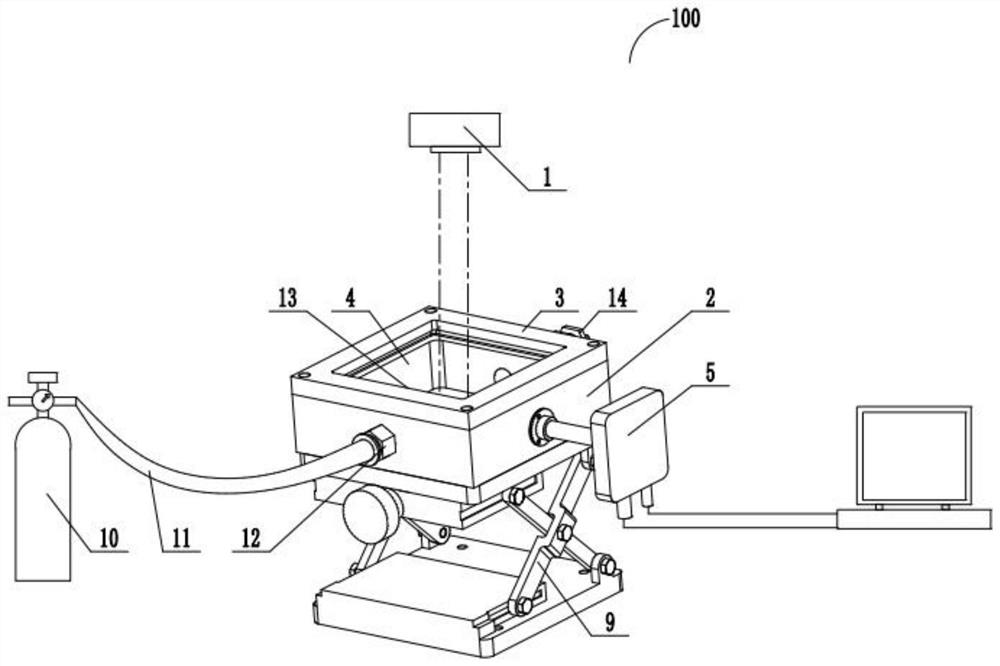

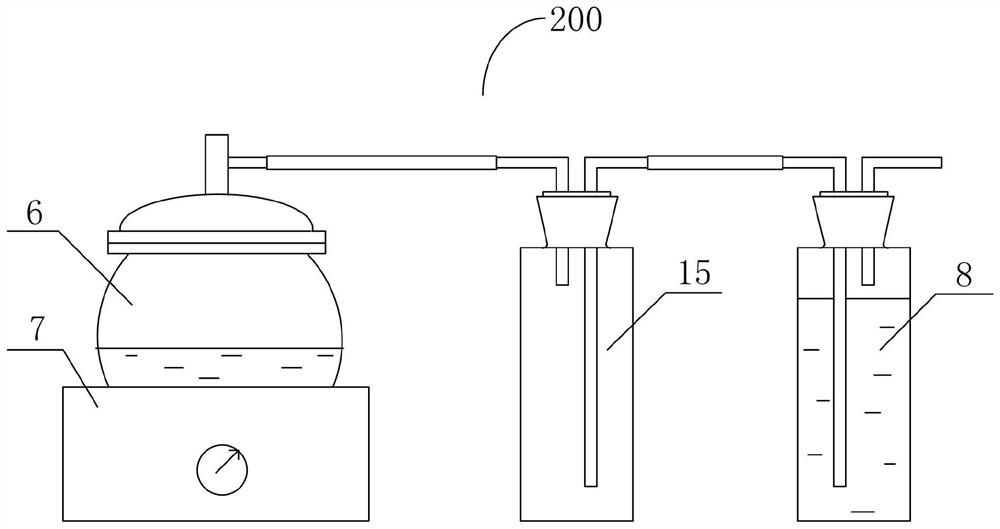

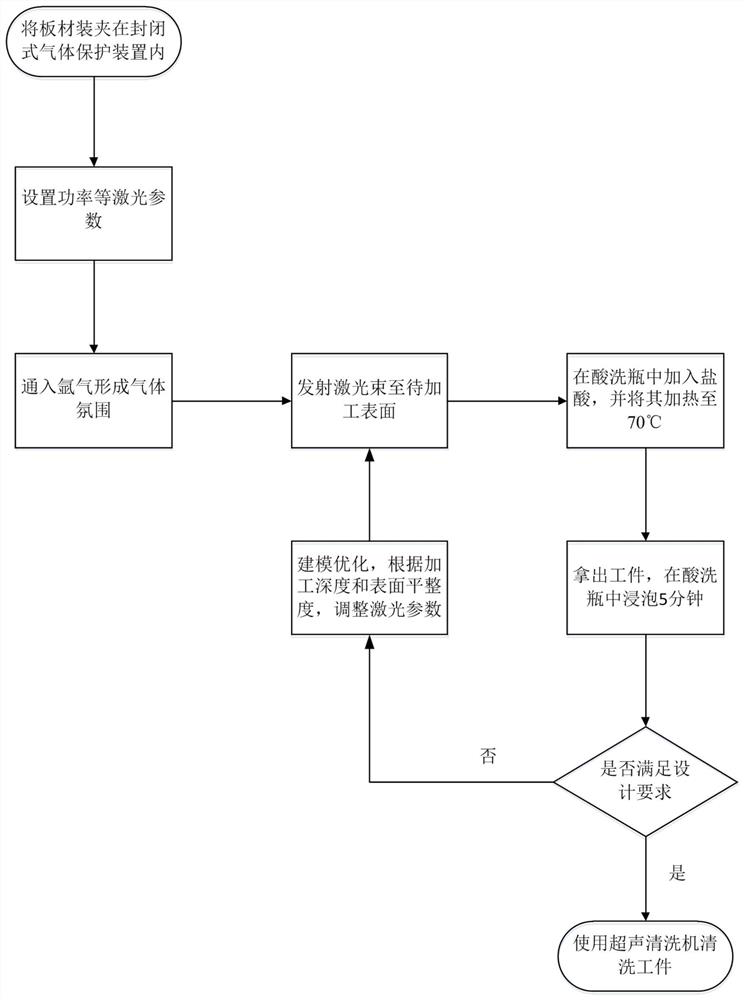

Laser processing device and method suitable for AlN plates

ActiveCN112958906AMonitor pressureMonitor gas concentrationLaser beam welding apparatusLight spotGas detector

The invention discloses a laser processing device suitable for AlN plates. The laser processing device comprises a processing unit and a pickling unit, and the processing unit comprises a laser, a base body, a cover plate, quartz glass and a gas detector; and the pickling unit comprises a pickling bottle, a heater and a gas washing bottle. The invention further provides a laser processing method suitable for the AlN plates. The laser processing method comprises the steps that the plates to be processed is arranged in the base body, and the cover plate is assembled; parameters of the laser are set; then argon is introduced into an inner cavity of the base body; the laser is turned on, the laser emits a laser beam to the surfaces of the plates to be processed, and nanosecond laser irradiates the to-be-processed area to achieve metallization; hydrochloric acid is added into the pickling bottle, and heating is carried out; the to-be-processed plates are put into the pickling bottle to be soaked, so that a surface metal layer is removed; and through a modeling optimization method, according to the processing depth and the surface flatness of the AlN plates, the laser power is gradually reduced, the laser scanning speed and the light spot diameter are adjusted till the processing meets the design requirement, and the processed plates are cleaned.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com