Manufacture method of metal nano circuit patterns based on DNA nano structures

A technology of metal nano and circuit patterns, applied in the direction of nanostructure manufacturing, specific nanostructure formation, nanotechnology, etc., can solve the problems of high cost and complicated application of photolithography technology, and achieve easy standardization, good biocompatibility, location highly specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

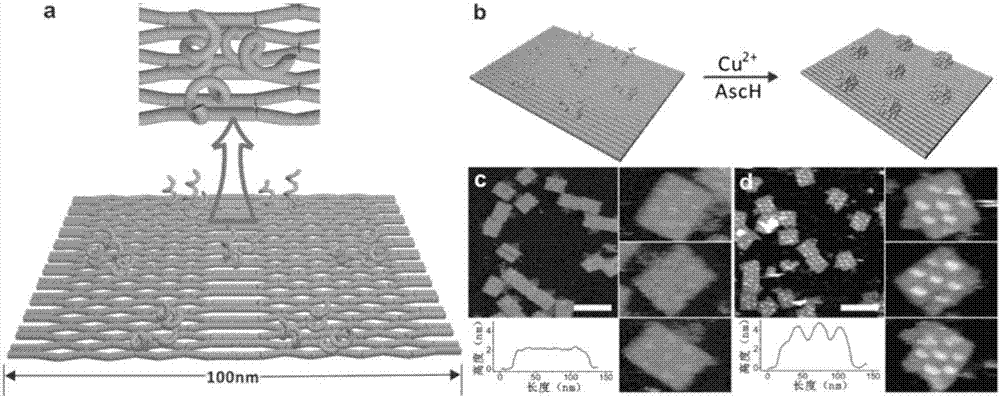

[0036] Example 1: Seed-free, selective copper metallization with nanometer-scale resolution by introducing "seven-dot" defect patterns on DNA origami by extending staple chains

[0037] Preparation of defect-introduced DNA origami: All required staple strands (including 5'-end extension single-stranded DNA as defective staple strand and normal staple strand without extension) were mixed with M13 long strand at a ratio of 10:1 Mixed at a ratio of 1 x TAE-Mg 2+ Buffer (tris, 40mM; acetic acid, 20mM; EDTA, 2mM; and magnesium acetate, 12.5mM; pH8.0) was annealed to synthesize DNA origami. The annealing process is the process reported in references (Rothemund, P.W.R. Nature 2006, 440, 297-302): the sample is slowly cooled from 95°C to 20°C at a rate of 1°C per minute.

[0038] Experimental procedure for selective Cu metallization with nanoscale resolution without seeding on defect-introduced DNA origami: at 1 × TAE-Mg 2+ DNA origami synthesized in buffer without ultrafiltration t...

Embodiment 2

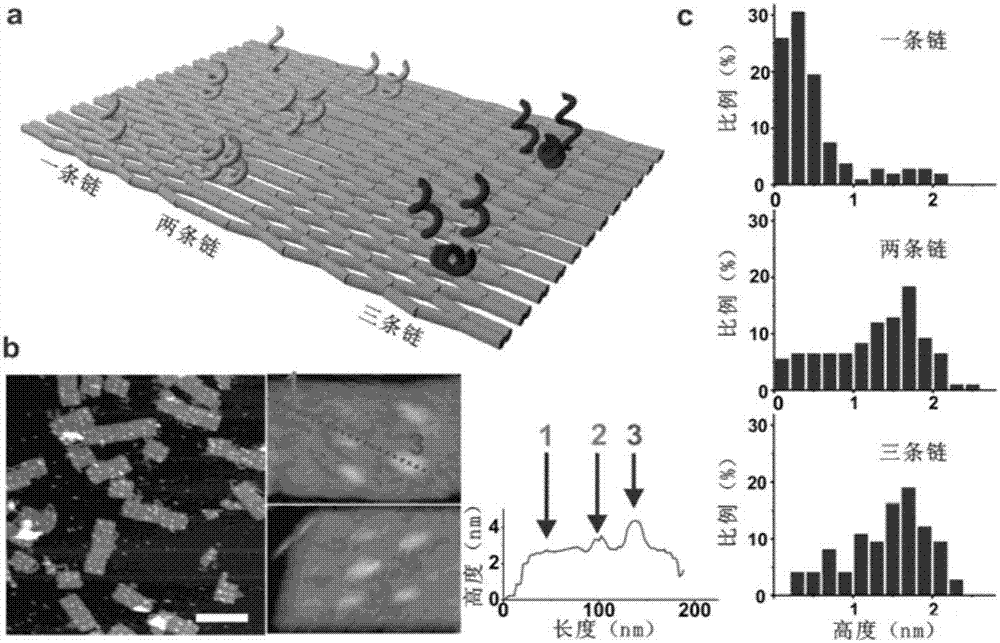

[0041] Example 2: Effect of defect size of "eight-dot" defect pattern on DNA origami (that is, each "dot" defect contains different number of DNA single strands) on its effect of copper metallization.

[0042] We designed such an array on the square DNA origami, respectively stretching out one, two and three 15bp DNA single strands ( figure 2 ), in view of the resolution of the square DNA origami in the long axis direction, when there are two or three DNA strands at each point, the horizontal spacing between two adjacent single strands protruding out is about 5.4nm, and the vertical spacing is about 3nm, so The straight-line distance between two adjacent single strands will be shortened to about 6nm. We were expecting to see significantly different metallization results for one single-strand defect versus multiple single-strands. The results were as we expected. After the metallization of the sample, it was obvious that the sites with only one 15bp DNA single strand per poin...

Embodiment 3

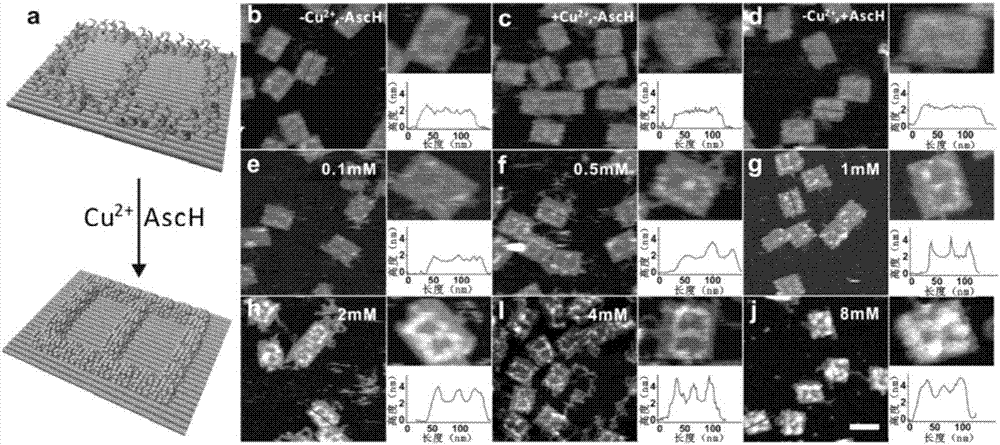

[0043] Example 3: Effects of different concentrations of copper ions on the metallization effect in the metallization reaction solution

[0044] We further investigated CuCl 2 Concentration effect on defect copper metallization on DNA origami, we keep the rest of the reaction conditions unchanged and only gradually change the CuCl 2 concentration. Here, instead of using the DNA origami with the defect pattern of "seven points", the defect pattern of "number 8" is introduced into the square DNA origami. The concentration of copper ions in the added metallization reaction solution varies from 0.1 mM to 8 mM. When the concentration of copper ions is relatively low (0.1mM), from the attached image 3 In the AFM image in e, it can be seen that only sporadic brighter points appear. As the concentration of copper chloride increases, the lines of the pattern become more and more continuous. When it reaches 2mM, the complete number 8 is more obvious. Manifested on DNA origami. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com