Nickel-doped lanthanum ferrite/clay nano-structure composite and preparation method and application thereof

A composite material and nanostructure technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of ecological environment and human health hazards, low utilization of visible light, high working temperature, and achieve Increased lattice defects, beneficial to catalytic activity and uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First weigh 0.2666g of lanthanum nitrate, 0.0716g of nickel nitrate, 0.2320g of ferric nitrate dissolved in 100ml of deionized water, then add 0.4162g of complexing agent citric acid and finally add 1g of attapulgite and stir for 2h to obtain a mixed solution. Then place it in a 70°C water bath in a water bath, wait for the water to evaporate to obtain a wet gel, dry it in a drying oven at 80°C, and place it in a muffle furnace at 550°C (heating rate 1 °C / min) calcined for 2h, and finally ground to obtain a nickel-doped lanthanum ferrite / attapulgite nanostructure composite LaFe with a loading of 20wt%. 0.7 Ni 0.3 o 3 / Attapulgite (the mass ratio of nickel-doped lanthanum ferrite to attapulgite clay is 1:5);

[0023] On the basis of the above process in Example 1, the (undoped) lanthanum ferrite / attapulgite nanostructure composite (LaFeO 3 The mass ratio to attapulgite clay is 1:5).

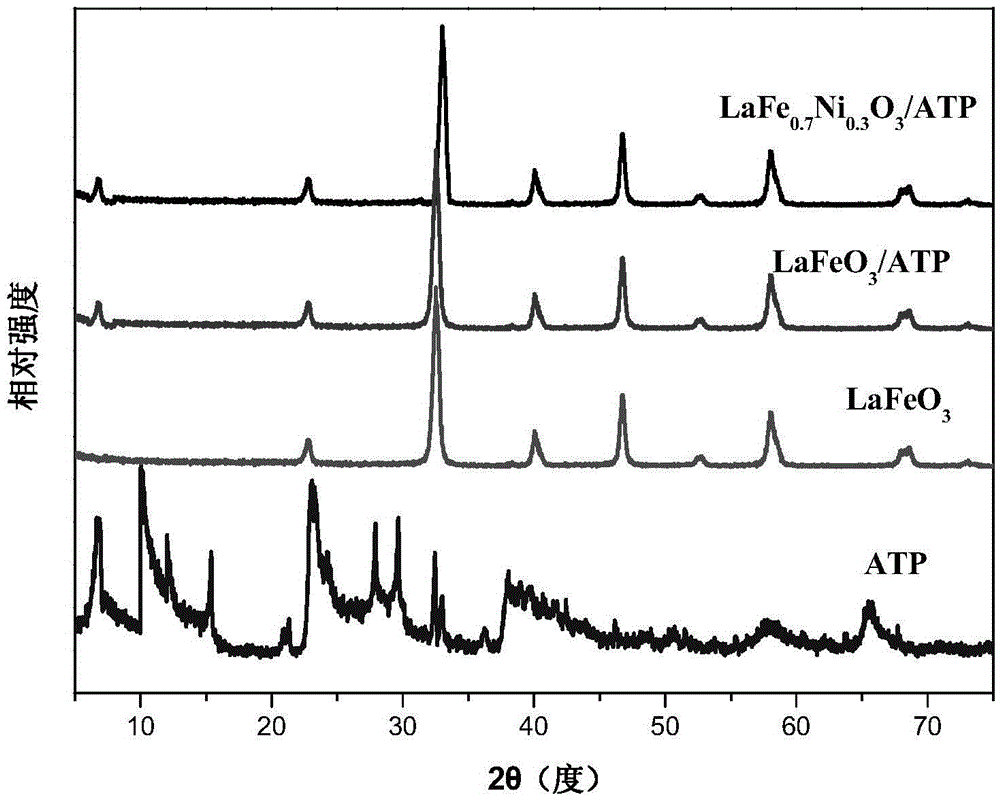

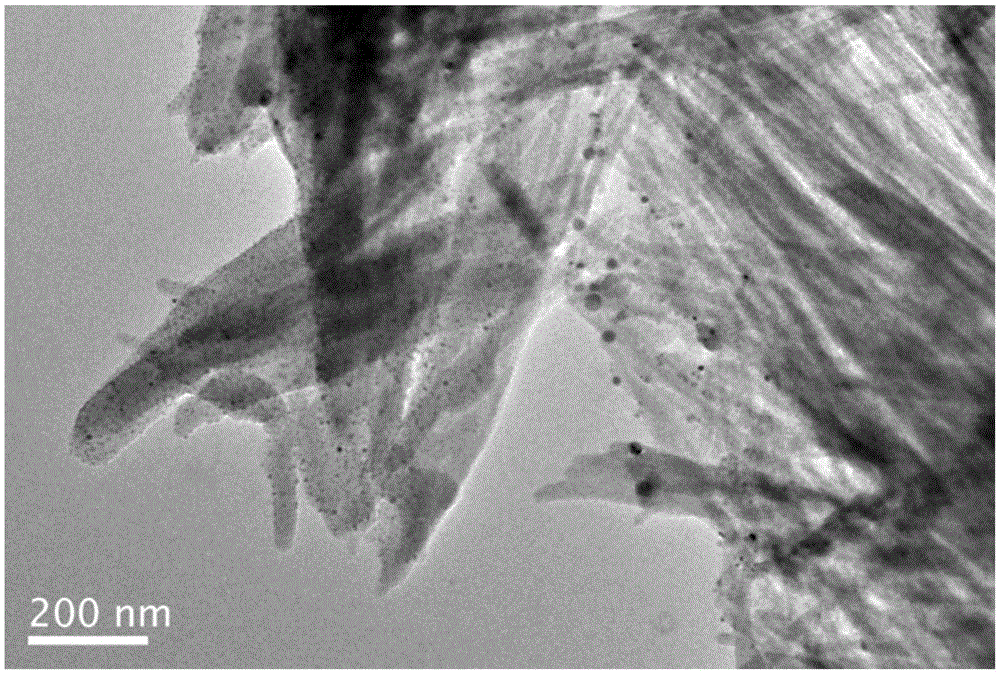

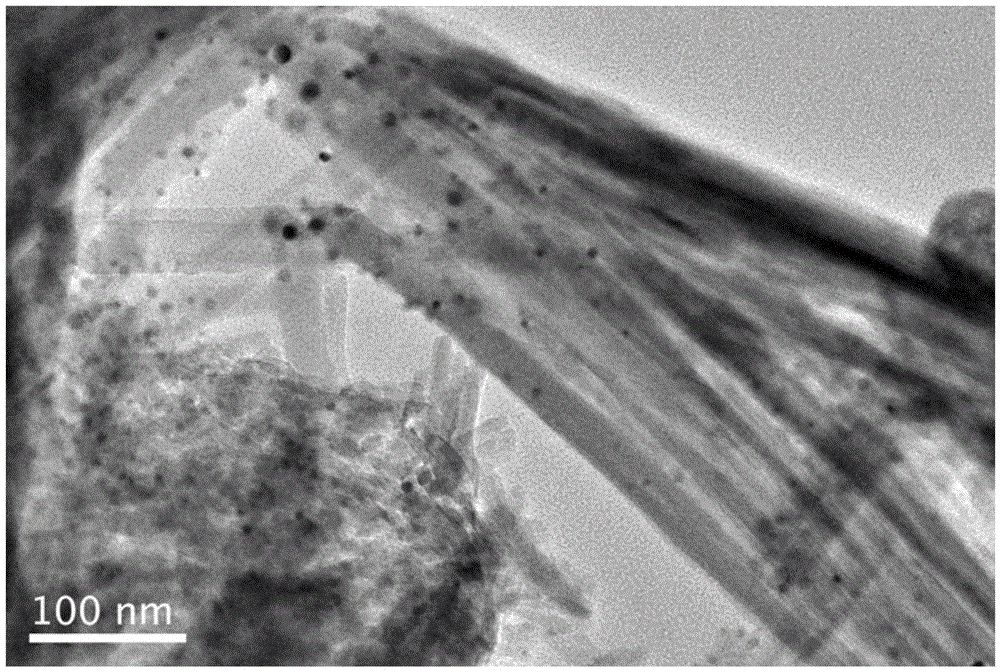

[0024] The obtained sample is subjected to X-ray powder diffraction experiment, and...

Embodiment 2

[0029] First weigh 0.211g of lanthanum nitrate and 0.234g, 0.11g of nickel nitrate and iron nitrate dissolved in 100ml of deionized water, then add 0.168g of complexing agent citric acid, and finally add 1g of attapulgite and stir for 2 hours to obtain a mixed solution Then place it in a 70°C water bath in a water bath, wait for the water to evaporate to obtain a wet gel, dry it in a drying oven at 80°C, and place it in a muffle furnace at 550°C (heating rate 1 °C / min) and calcined for 2 h, and finally ground to obtain a nickel-doped lanthanum ferrite / attapulgite nanostructure composite material with a loading of 20 wt%, and the subsequent detection was as in Example 1.

Embodiment 3

[0031] First weigh 0.176g of lanthanum nitrate and 0.214g, 0.25g of nickel nitrate, and dissolve ferric nitrate in 100ml of deionized water, then add 0.168g of complexing agent citric acid, and finally add 1g of attapulgite and stir for 2 hours to obtain a mixed solution Then place it in a 70°C water bath in a water bath, wait for the water to evaporate to obtain a wet gel, dry it in a drying oven at 80°C, and place it in a muffle furnace at 550°C (heating rate 1 °C / min) and calcined for 2 h, and finally ground to obtain a nickel-doped lanthanum ferrite / attapulgite nanostructure composite material with a loading of 20 wt%, and the subsequent detection was as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com