A ceramic/metal gradient structure high-temperature packaging material and its preparation method

A technology of packaging materials and gradient structures, which is applied in the field of sealing materials to achieve the effects of long-term high-temperature insulation and sealing, strong high-temperature stability, and high mechanical strength of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh an appropriate amount of AlN powder with an average particle size of 2 μm, use a ball mill for 4 hours, and then put it in a drying oven at 80 ° C for 12 hours; :8, 3:7, 4:6, 5:5, 6:4, 7:3, 8:2, 9:1 ratios were weighed raw materials, ball milled by ball mill for 2 hours and then placed in a drying oven at 80°C Dry in medium for 12h.

[0035] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO2 The ratio of balls = 1:1:4 is used for ball milling. The model of the ball mill used is Retsch PM100, and the speed of the ball mill is set at 300 rpm to obtain a mixed powder with a particle size of 0.5-2 μm.

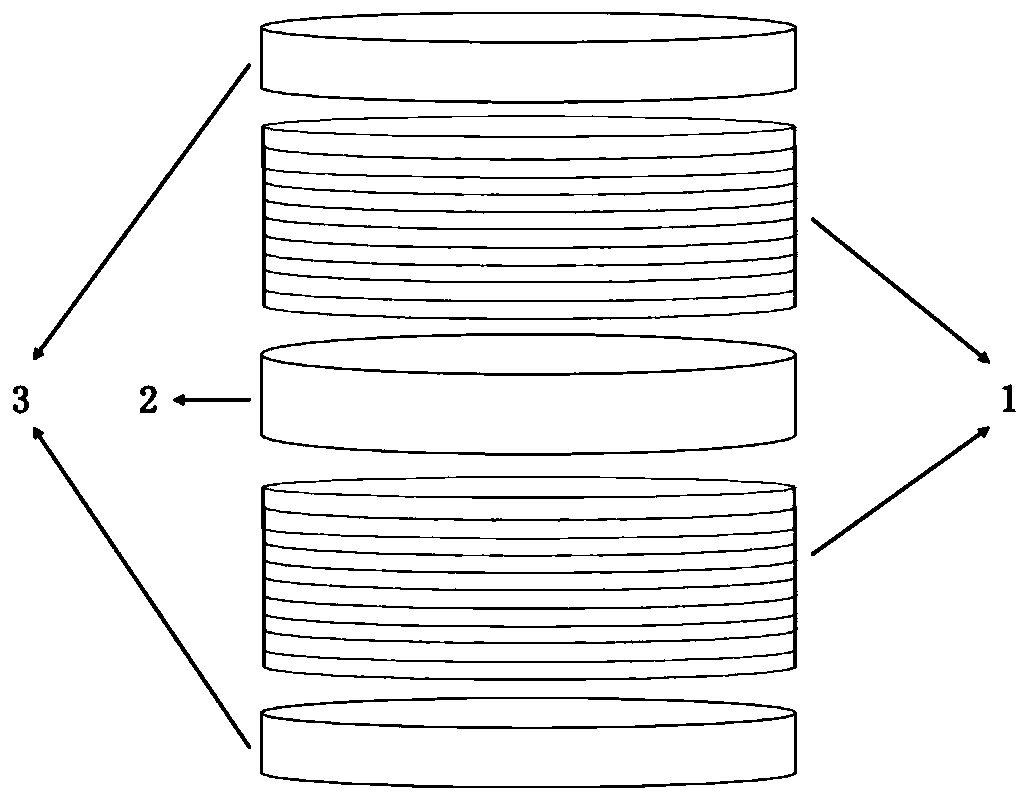

[0036] Mix the powder according to the figure 1 The schematic diagram of the structure of the ceramic / metal gradient composite high-temperature packaging material shown is laid layer by layer into a graphite mold with an inner diameter of 25mm. The amount of the middle ceramic la...

Embodiment 2

[0039] According to AlN powder, BN powder, sintering aid Y 2 o 3 The ratio of mass percentage is 77.6:19.4:3 Weigh an appropriate amount of raw materials, the average particle size of the AlN and BN powder used is 2 μm, use a ball mill for 2 hours and put it in a drying oven at 80 ° C for 12 hours; The mass percentage of powder is 1:9, 2:8, 3:7, etc. up to 9:1. Weigh an appropriate amount of raw materials, use a ball mill for 1 hour, and then put them in a drying oven at 80°C for 12 hours.

[0040] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The ratio of balls = 1:1:4 is used for ball milling. The model of the ball mill used is Retsch PM100, and the speed of the ball mill is set at 300 rpm to obtain a mixed powder with a particle size of 0.5-2 μm.

[0041] Mix the powder according to the figure 1 The schematic diagram of the structure of the ceramic / metal gradient composite hig...

Embodiment 3

[0044] According to SiC powder, sintering aid Y 2 o 3 The ratio of mass percentage is 97:3. Weigh an appropriate amount of raw materials. The average particle size of the SiC powder used is 2 μm. It is ball-milled by a ball mill for 2 hours and then dried in a drying oven at 80°C for 12 hours. The mass percentage of W powder and SiC powder is 1:9, 2:8, 3:7, etc. until 9:1, weigh appropriate amount of raw materials respectively, use a ball mill to grind for 1 hour, and then put it in a drying oven at 80°C for 12 hours;

[0045] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The ratio of balls = 1:1:4 is used for ball milling. The model of the ball mill used is Retsch PM100, and the speed of the ball mill is set at 300 rpm to obtain a mixed powder with a particle size of 0.5-2 μm.

[0046] Mix the powder according to the figure 1 The schematic diagram of the structure of the ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com