High-wear-resistance coating for automotive upholstery and preparation method of high-wear-resistance coating

A technology for automotive interior parts and high wear resistance, applied in the coating and other directions, can solve the problems of poor mechanical properties of the paint film such as poor wear resistance and limited spray construction, and achieve water resistance and chemical resistance. Good effect, excellent arrangement effect, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

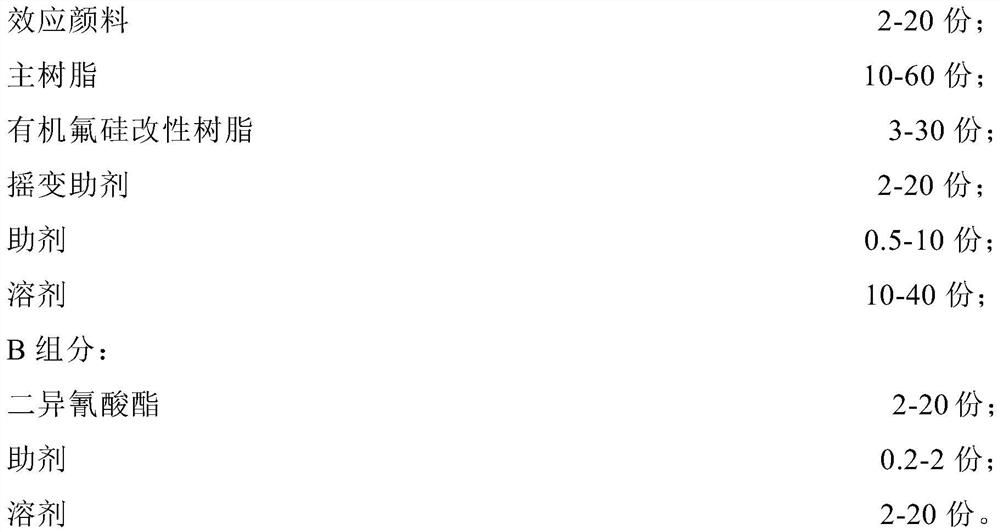

[0050] The high wear-resistant coating of this embodiment is formed by combining A component resin paint and B component curing agent in a weight ratio of 100:25, wherein the A component resin paint includes the following components and contents by weight:

[0051]

[0052] B component curing agent includes the following components and content by weight:

[0053] N3390 10 servings ADDITIVE TI 0.5 servings N-butyl acetate 14.5 servings total 25 servings

[0054] The high wear-resistant coating of the present embodiment is prepared by the following steps:

[0055] (1) Add the effect pigment, main resin, auxiliary agent and organofluorosilicon modified resin into the dispersion tank by weight, stir evenly, then add the solvent, stir at a low speed of 600rpm for 30min, and then stir at a high speed of 1000rpm for 30min, then Introduce it into a sand mill disperser, grind and disperse it to a fineness of less than 30 μm, add a thixotropic agen...

Embodiment 2

[0059] The high wear-resistant coating of this embodiment is formed by combining A component resin paint and B component curing agent in a weight ratio of 100:25, wherein the A component resin paint includes the following components and contents by weight:

[0060]

[0061] B component curing agent includes the following components and content by weight:

[0062] N3390 8.3 servings ADDITIVE TI 0.5 servings N-butyl acetate 16.2 servings total 25 servings

[0063] The high wear-resistant coating of the present embodiment is prepared by the following steps:

[0064] (1) Add the effect pigment, main resin, auxiliary agent and organofluorosilicon modified resin into the dispersion tank by weight, stir evenly, then add the solvent, stir at a low speed of 800rpm for 25min, and then stir at a high speed of 1000rpm for 30min, then Introduce it into a sand mill disperser, grind and disperse it to a fineness of less than 30 μm, add a thixotropic ag...

Embodiment 3

[0068] The high wear-resistant coating of this embodiment is formed by combining A component resin paint and B component curing agent in a weight ratio of 100:25, wherein the A component resin paint includes the following components and contents by weight:

[0069]

[0070]

[0071] B component curing agent includes the following components and content by weight:

[0072] N3390 8.3 servings ADDITIVE TI 0.5 servings N-butyl acetate 16.2 servings total 25 servings

[0073] The high wear-resistant coating of the present embodiment is prepared by the following steps:

[0074] (1) Add the effect pigment, main resin, auxiliary agent and organofluorosilicon modified resin into the dispersion tank by weight, stir evenly, then add the solvent, stir at a low speed of 750rpm for 20min, and then stir at a high speed of 800rpm for 35min, then Introduce it into a sand mill disperser, grind and disperse it to a fineness of less than 30 μm, add a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com