Emitter circulating type solar cell and preparation thereof

A technology of emitter surround and solar cells, which is applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of many through holes and complicated preparation process, and achieve the effect of simplifying the preparation process, reducing the number of through holes and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

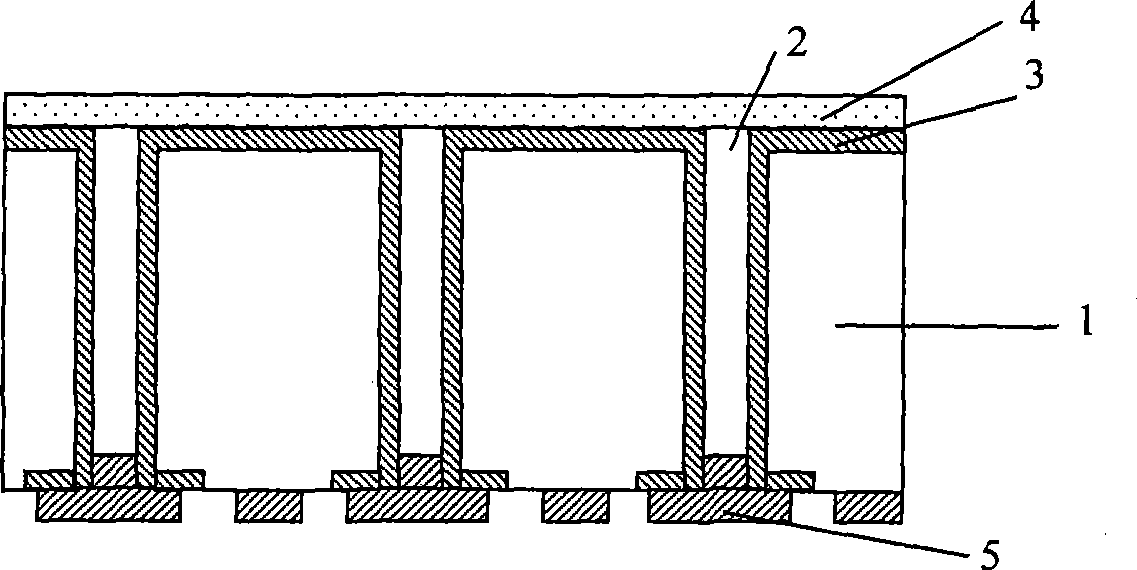

[0058] combined with figure 2 , 4 , 5, a kind of EWT solar cell provided by the present embodiment is as follows: the silicon chip 1 is a p-type silicon chip, and the interior contains an array of through holes 2 that run through the silicon chip 1 arranged in a hexagonal lattice, and the diameter of the through holes 2 is 50 μm, and the interval between adjacent through holes 2 is 0.5 mm. An n-type lightly doped emitter 3 is contained on the light-facing surface of the silicon wafer 1 and in the through hole 2 , and the sheet resistance of the lightly doped emitter 3 is 150Ω / □. A passivation medium layer 4 is deposited on the lightly doped emitter 3, and the passivation medium layer 4 is a silicon nitride film with a thickness of 80nm. There is an n-type heavily doped emitter 6 on the backlight surface of the silicon wafer 1, and the through hole 2 on the backlight surface of the silicon wafer 1 is in the pattern of the heavily doped emitter 6, and the heavily doped emitte...

Embodiment 2

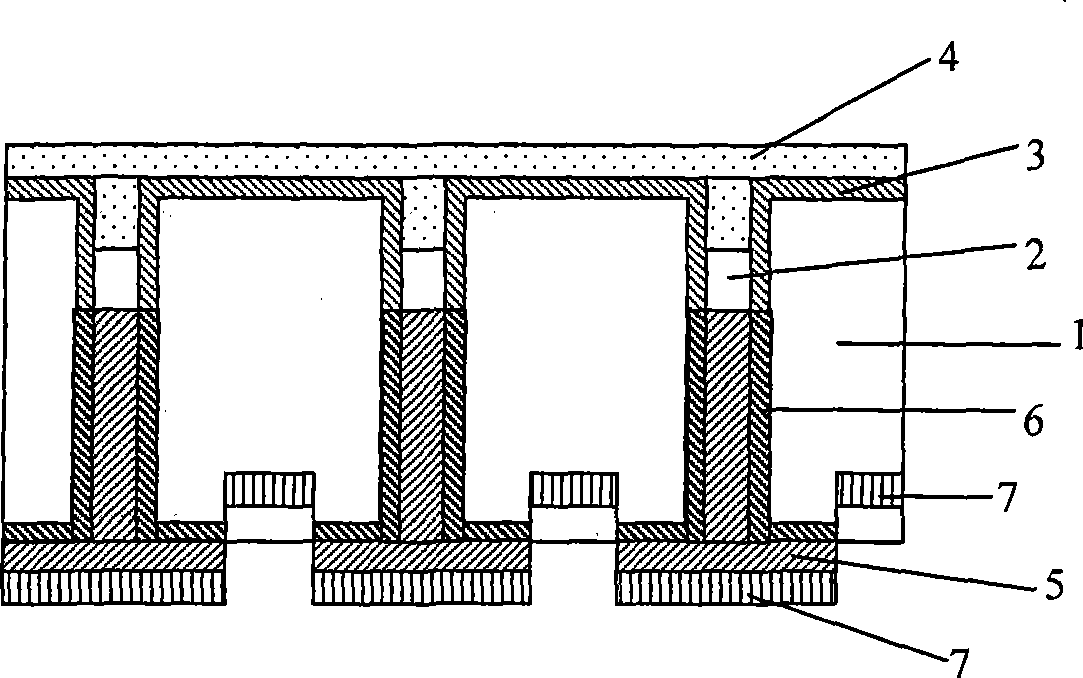

[0060] combined with image 3 , 4 , 5. The EWT solar cell provided in this embodiment is as follows: the silicon wafer 1 is an n-type silicon wafer, which contains an array of through holes 2 that run through the silicon wafer 1 arranged in a hexagonal lattice, and the diameter of the through holes 2 is 50 μm. The interval between adjacent through holes 2 is 1.5mm. There is a p-type lightly doped emitter 3 on the light-facing surface of the silicon wafer 1 and in the through hole 2 , and the sheet resistance of the lightly doped emitter 3 is 100Ω / □. A passivation medium layer 4 is deposited on the lightly doped emitter 3, and the passivation medium layer 4 is a silicon nitride film with a thickness of 80nm. There is a p-type heavily doped emitter 6 on the backlight surface of the silicon wafer 1, and the through hole 2 on the backlight surface of the silicon wafer 1 is in the pattern of the heavily doped emitter 6, and the heavily doped emitter 6 partially enters the throug...

Embodiment 3

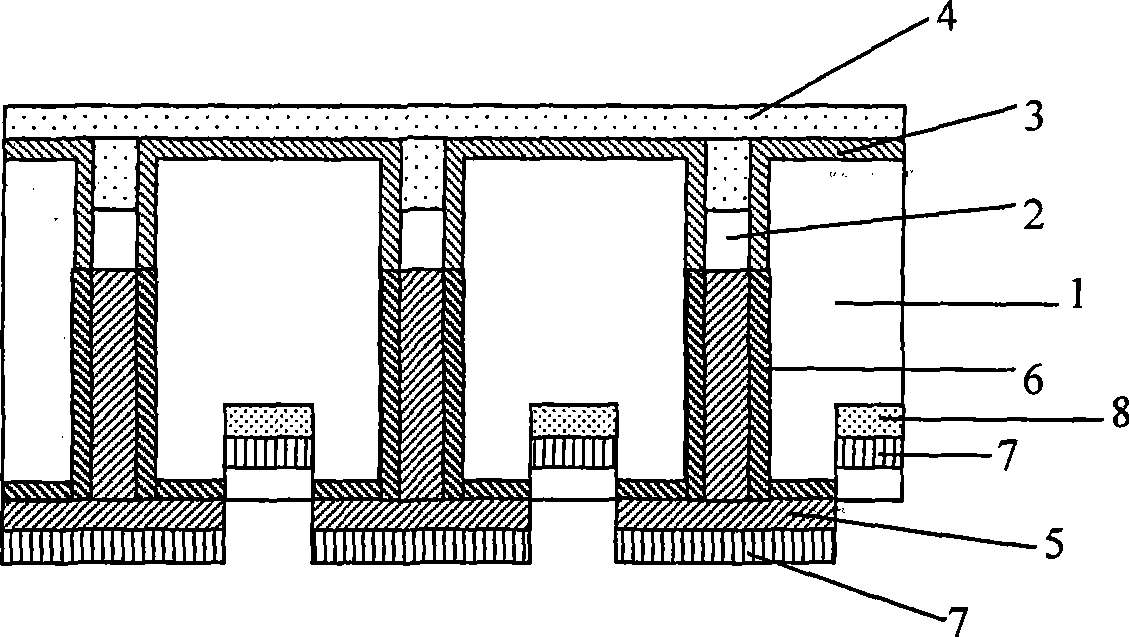

[0062] Such as Figure 6 As shown, the present embodiment is a method for preparing the EWT solar cell, and the main steps include in order:

[0063] Step 1: Provide a p-type silicon wafer 1, the silicon wafer 1 has a light facing surface and a backlight surface, and an array of through holes 2 penetrating the silicon wafer is prepared on the silicon wafer 1 by a laser etching process, and the through holes 2 are 50 μm in diameter;

[0064] Step 2: pickling and rinsing with deionized water to clean the silicon wafer 1 prepared with through holes 2;

[0065] Step 3: POCl using a diffusion furnace 3 Diffusion, forming an n-type lightly doped emitter 3 on the light-receiving surface, the backlight surface and the inside of the through hole 2 of the silicon wafer 1, and the sheet resistance of the lightly doped emitter 3 is 130Ω / □;

[0066] Step 4: Deposit a silicon nitride film with a thickness of 80 nm on the light-facing surface of the silicon wafer 1 as a passivation dielec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com