Patents

Literature

62results about How to "Reduce the number of vias" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

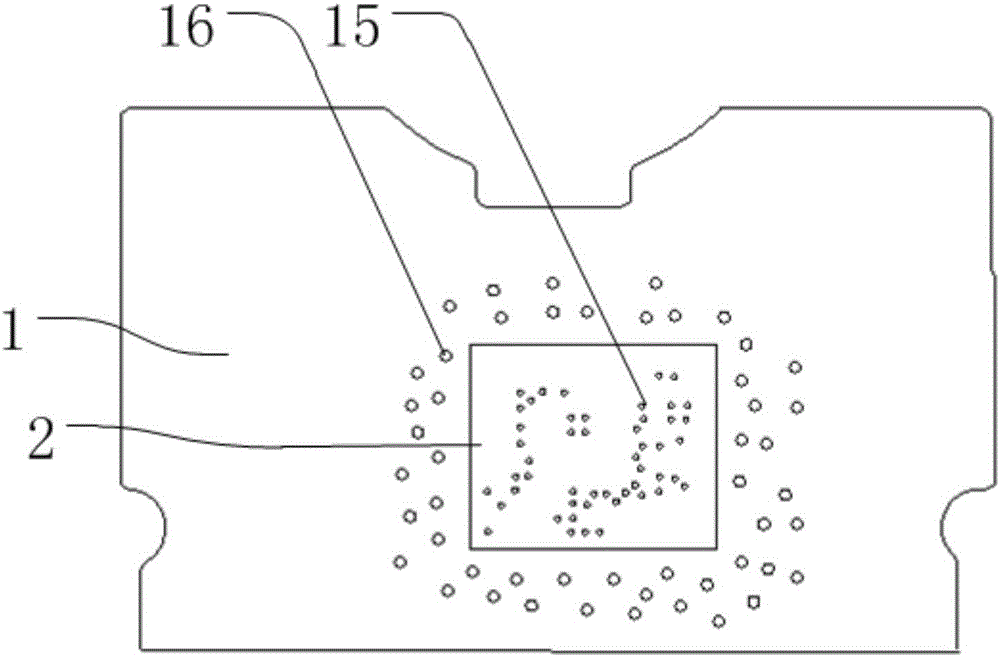

Emitter circulating type solar cell and preparation thereof

InactiveCN101383386AHigh mechanical strengthReduce metallizationPhotovoltaic energy generationSemiconductor devicesSolar cellMetal electrodes

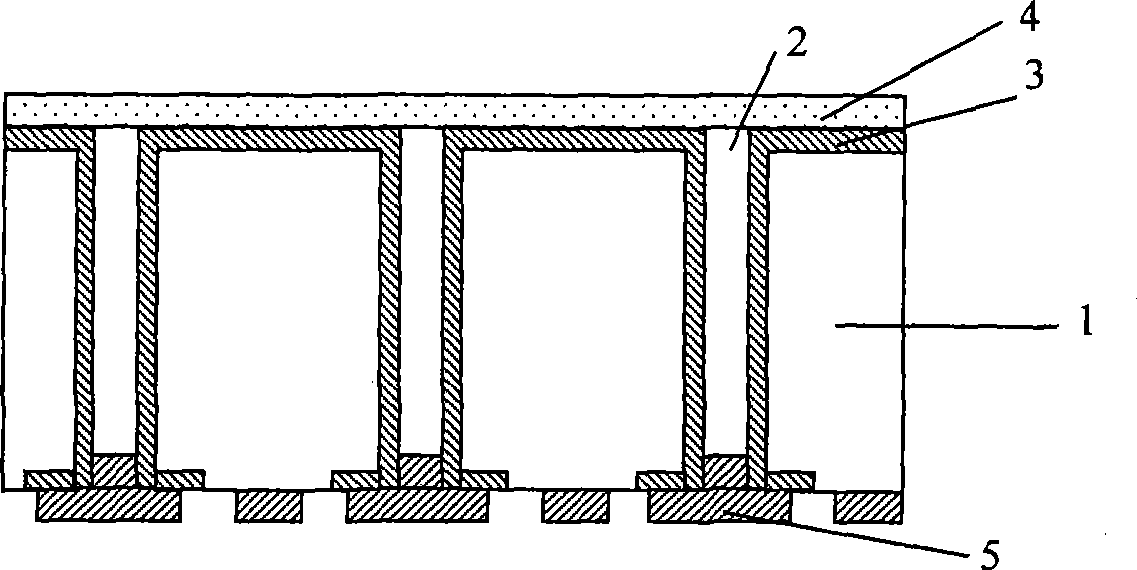

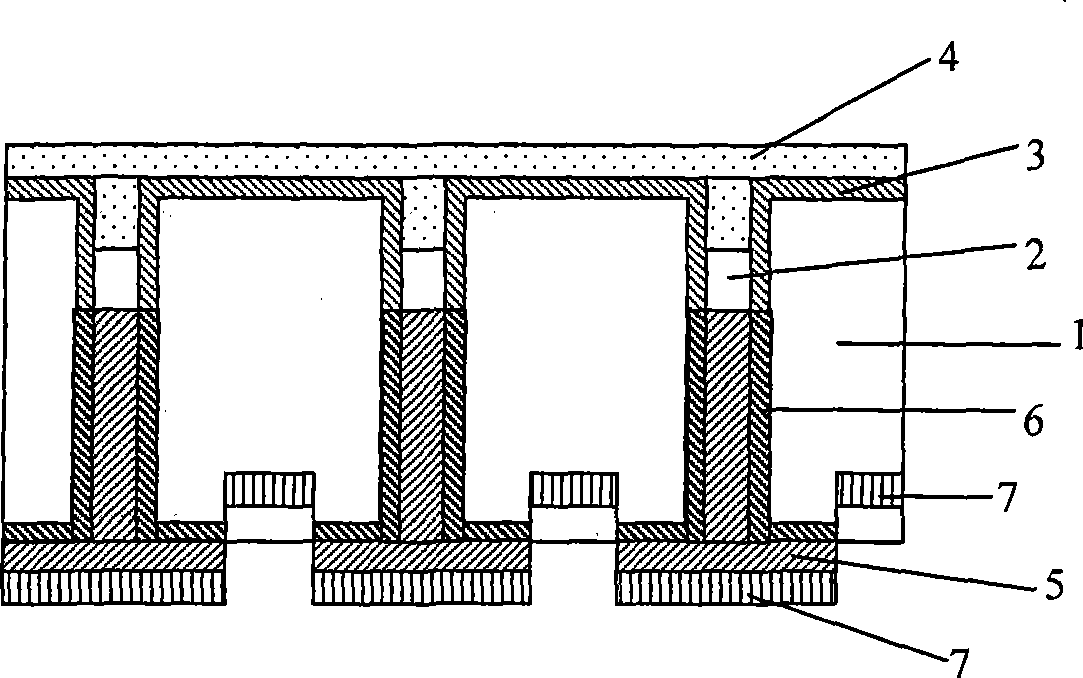

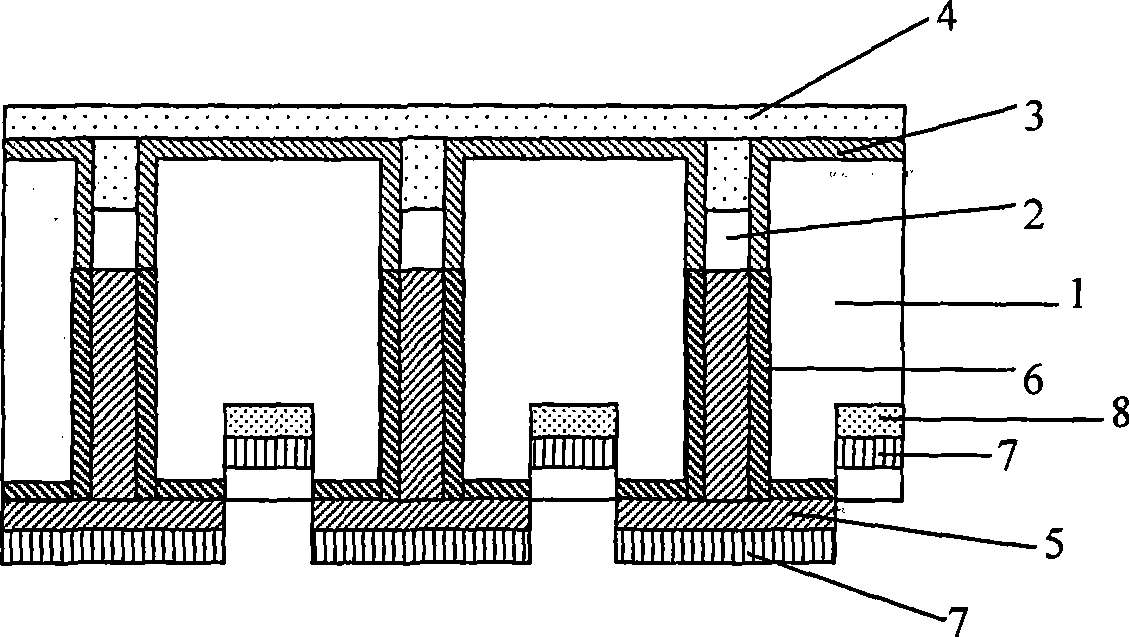

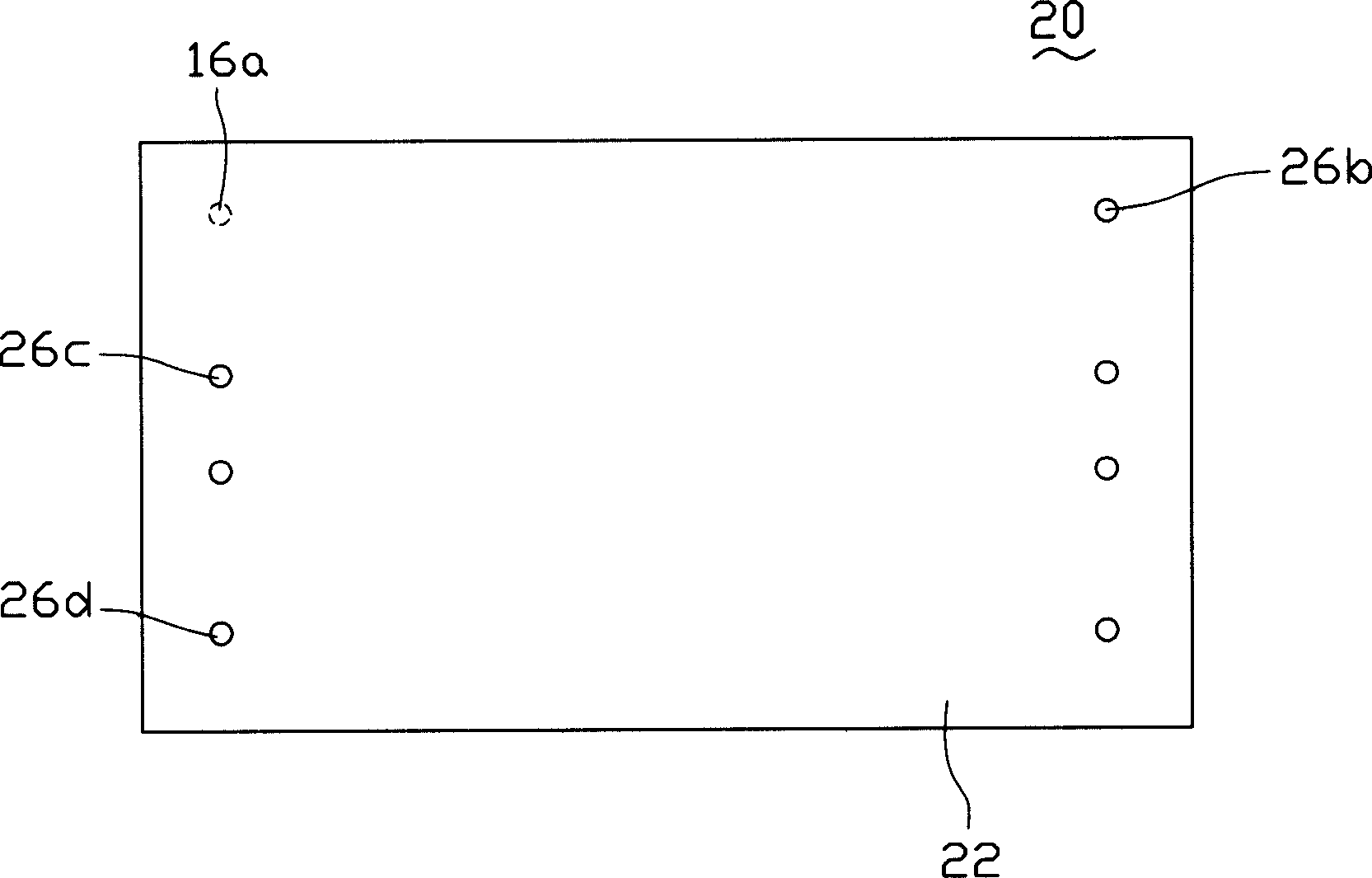

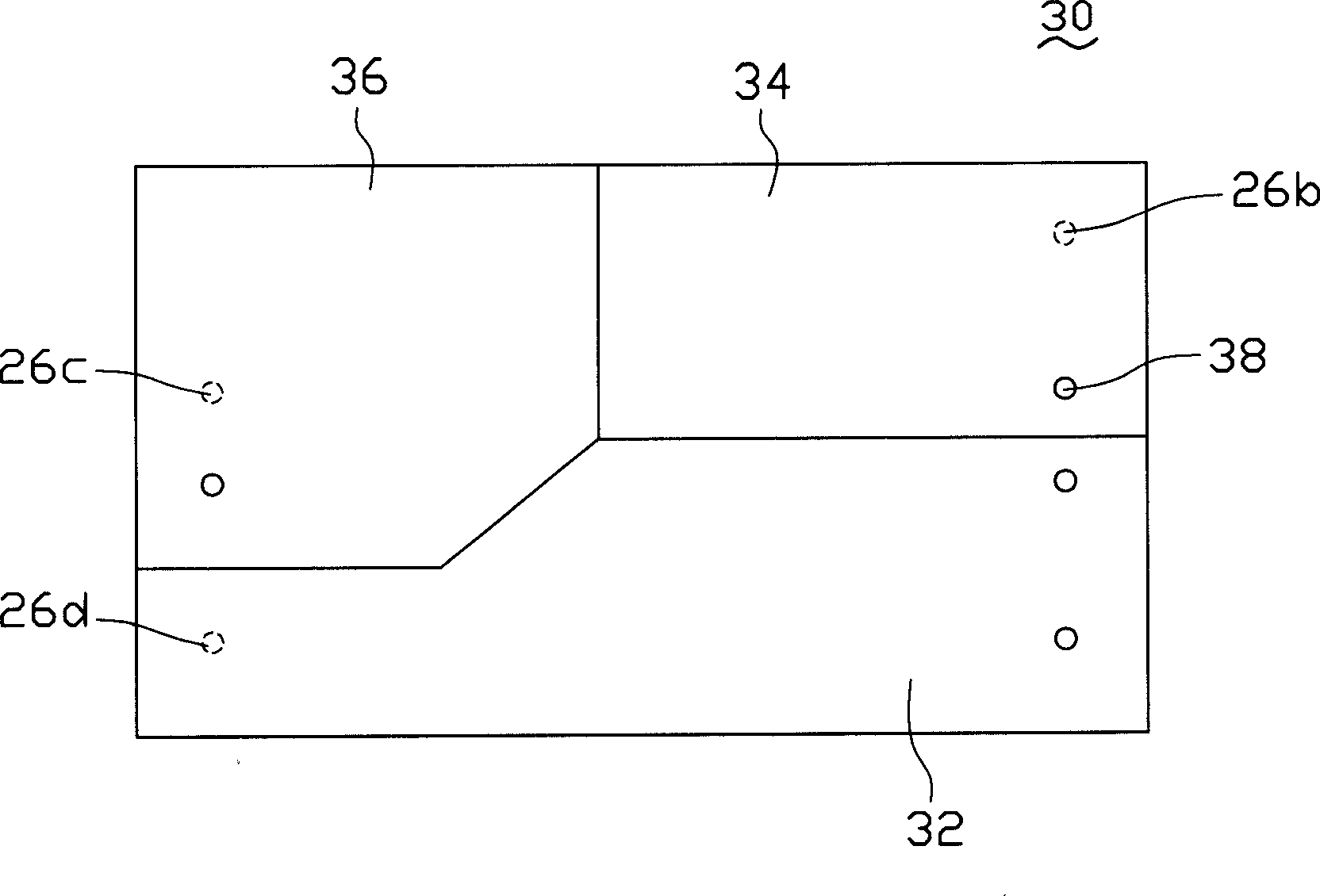

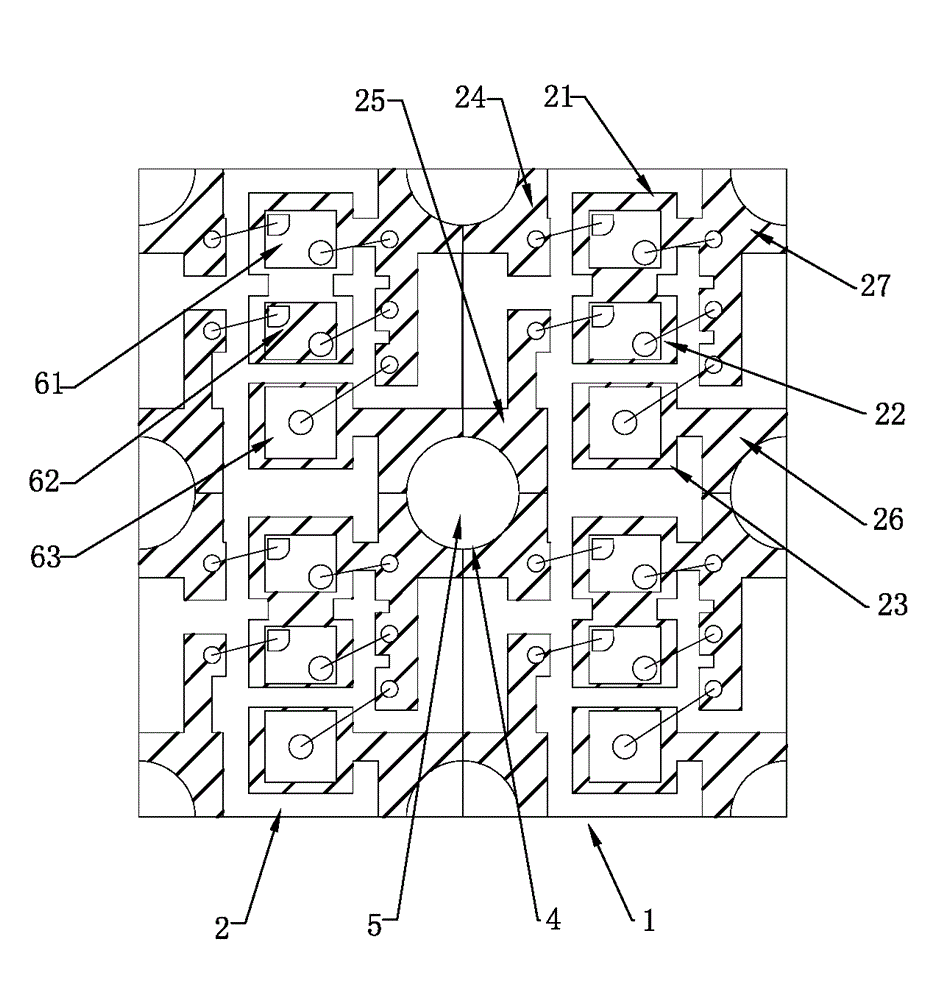

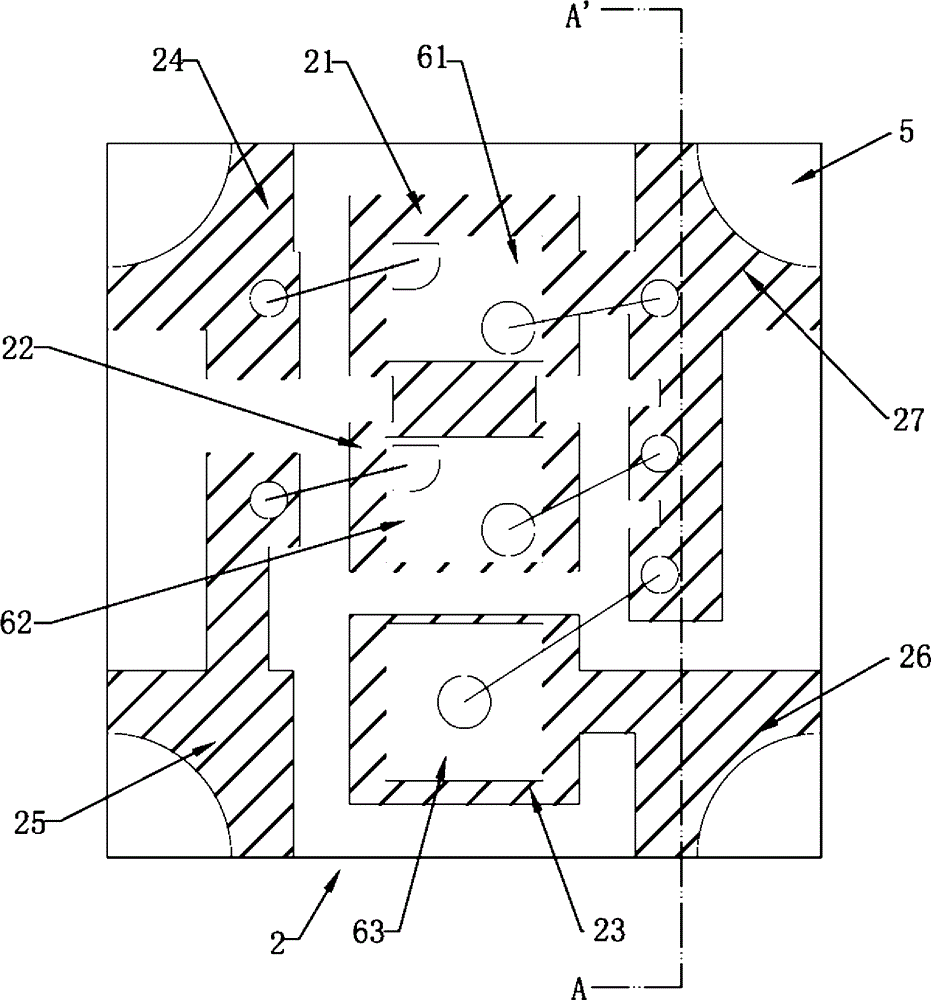

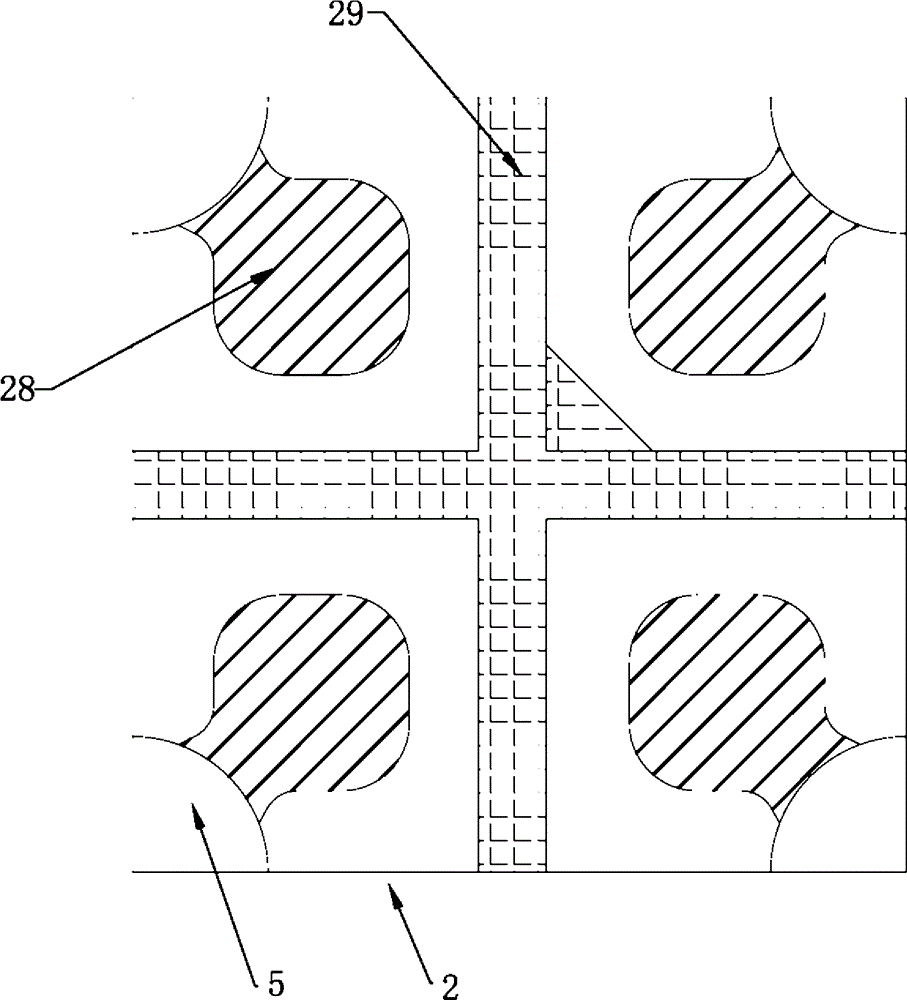

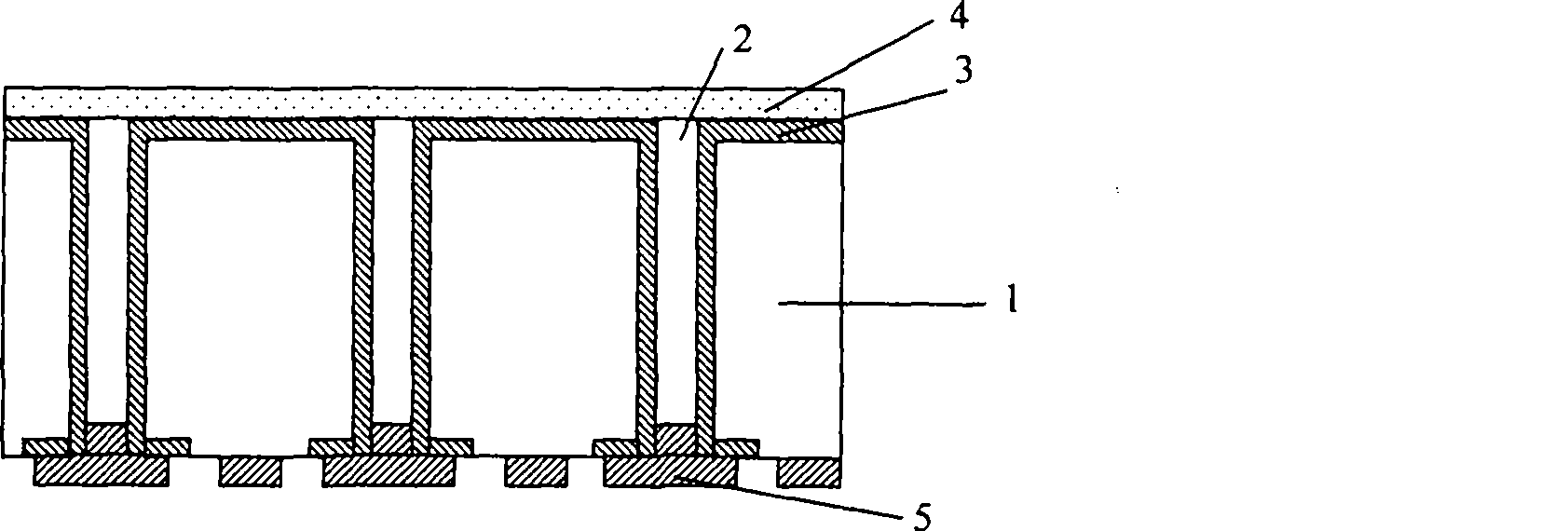

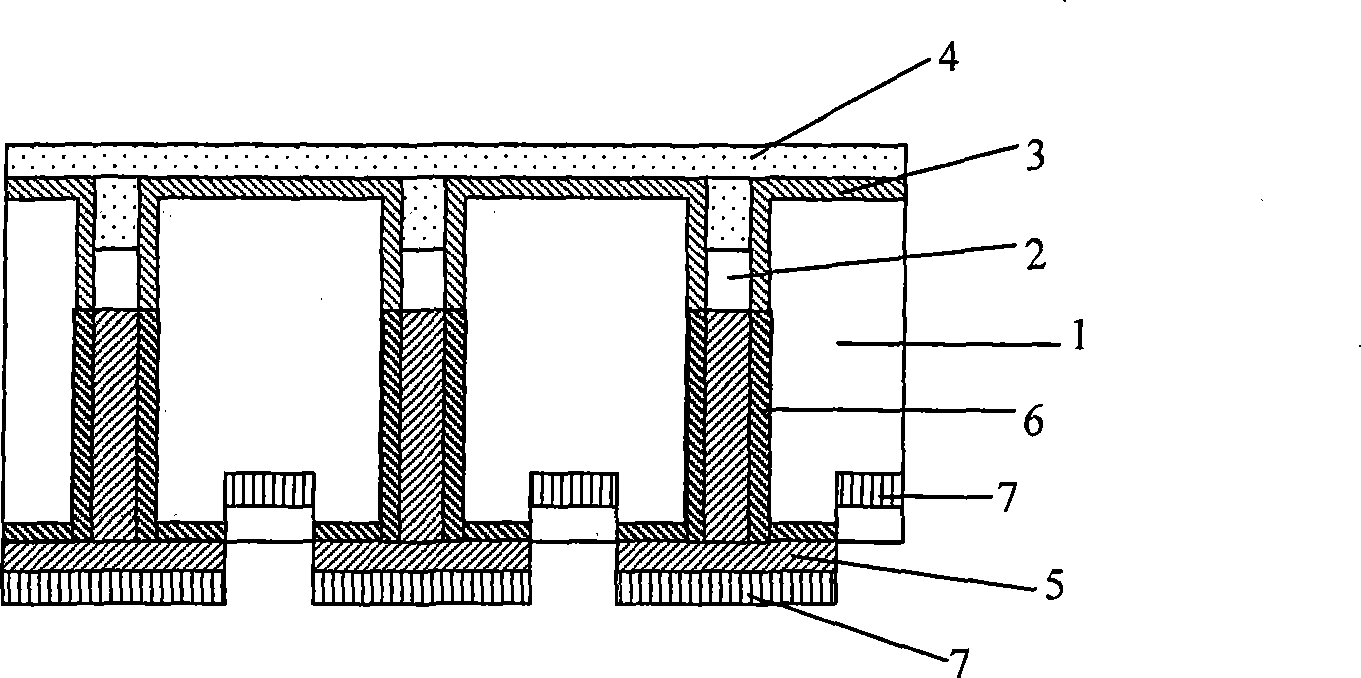

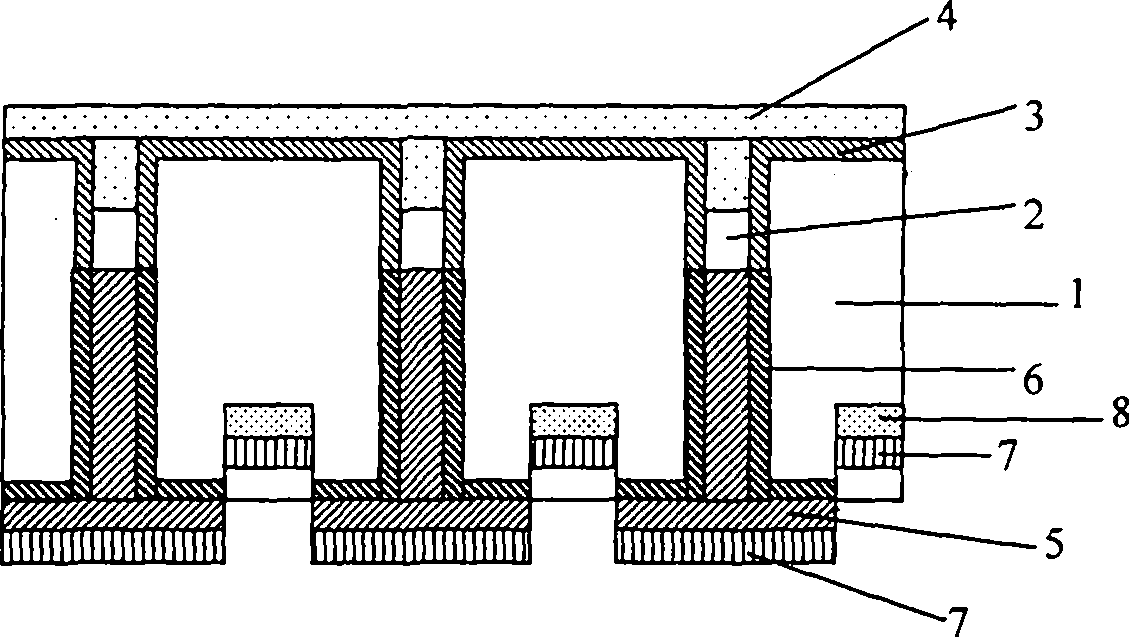

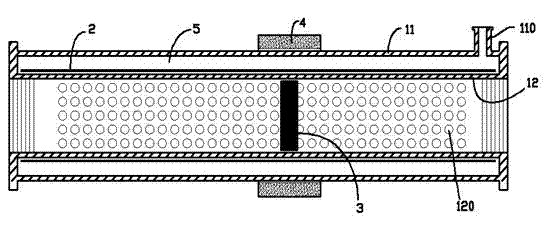

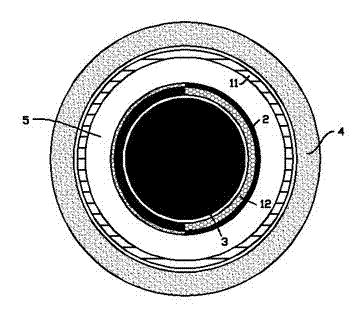

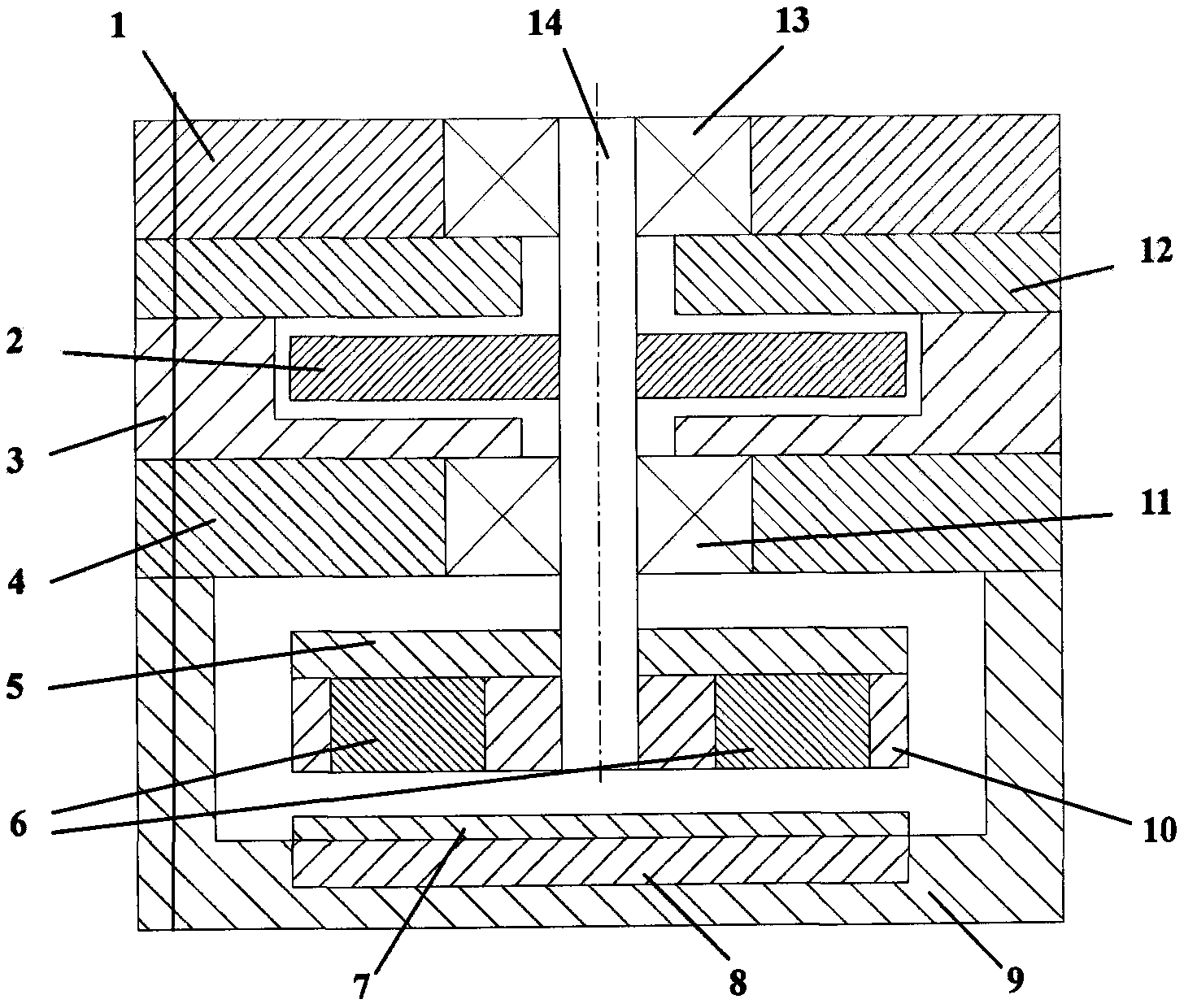

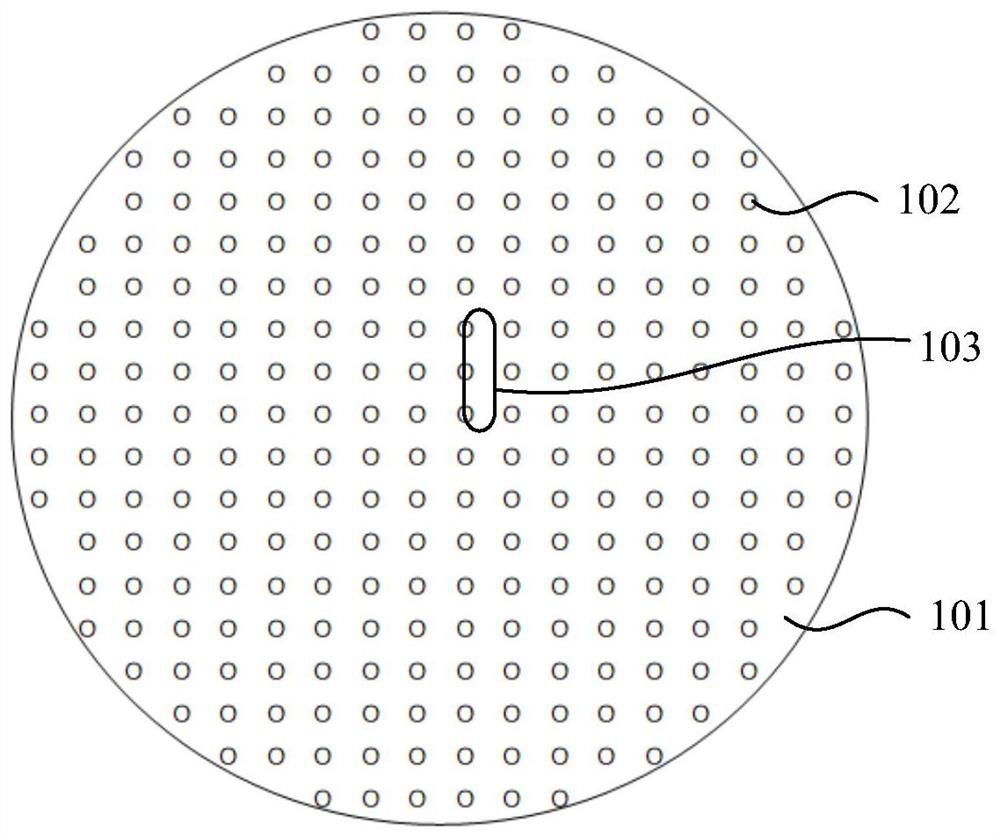

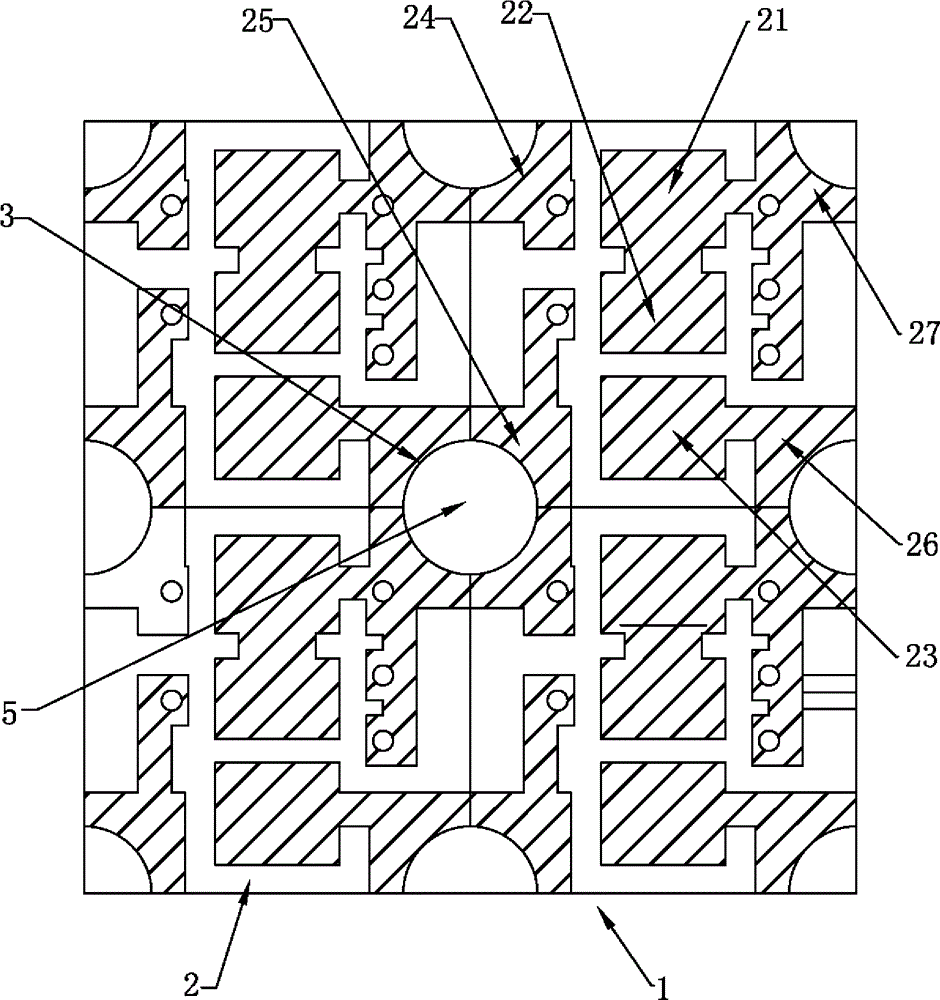

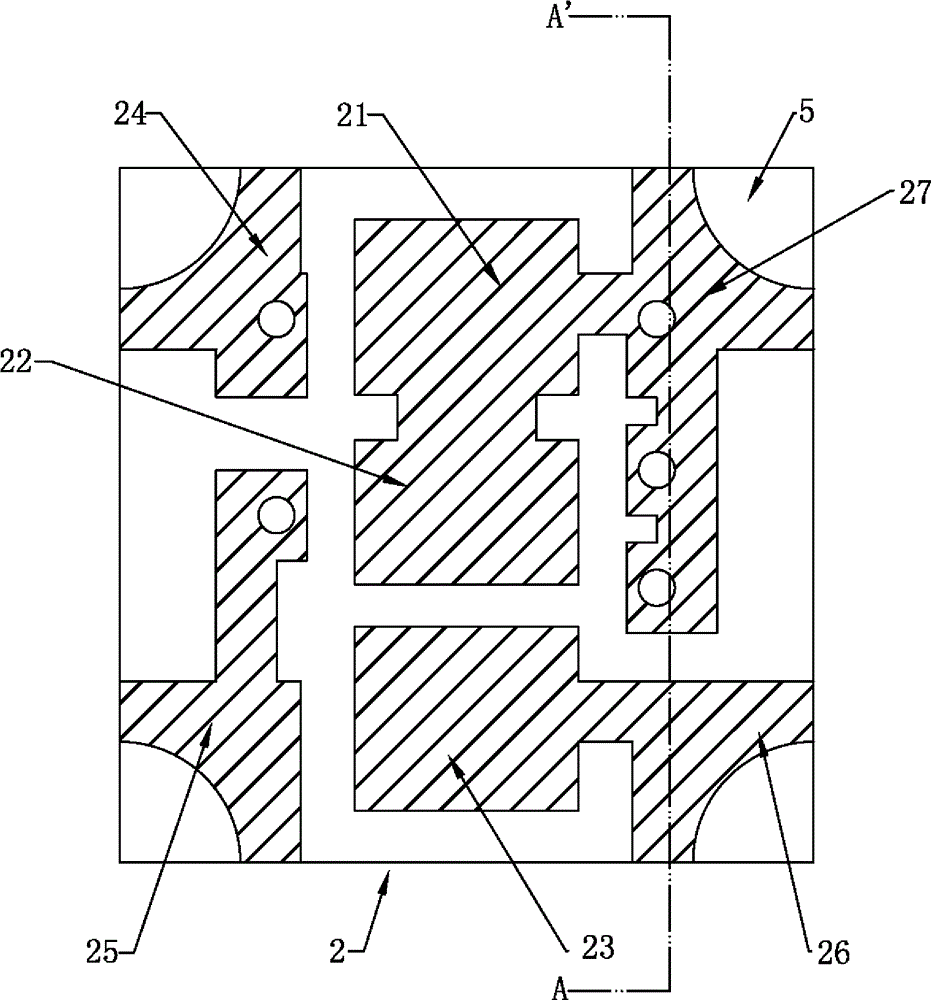

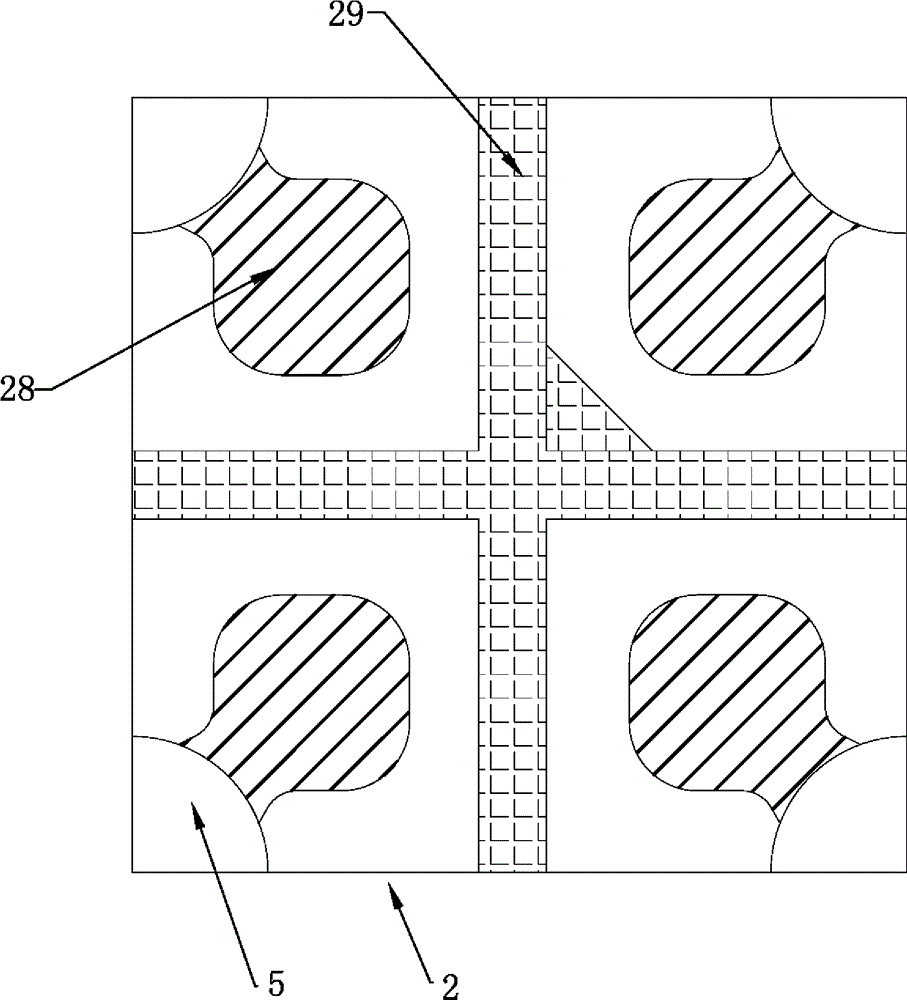

The invention relates to a surrounding-emitting electrode solar cell and a preparation method thereof. The cell contains arrays which are arranged in a hexagonal lattice way and penetrate through holes 2 of an irradiation surface and a backlight surface of a silicon chip 1 in the silicon chip 1, therefore, the quantity of the through holes is minimized, and the breakage ratio of the silicon chip in the process of the hole drilling technology is reduced; a heavily doped emitting electrode 6 included on the back surface of the silicon chip 1 partially enters into the through holes, and a first conductive metal electrode 5 is arranged on the heavily doped emitting electrode 6, and plays the role of collecting minority carriers. A groove is arranged at the circumference of the first conductive metal electrode 5 by etching, a second conductive metal electrode 7 is arranged in the groove and plays the role of collecting majority carriers, and the first conductive metal electrode 5 and the second conductive metal electrode 7 deposited in the groove are insulated and isolated through the step of the groove.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

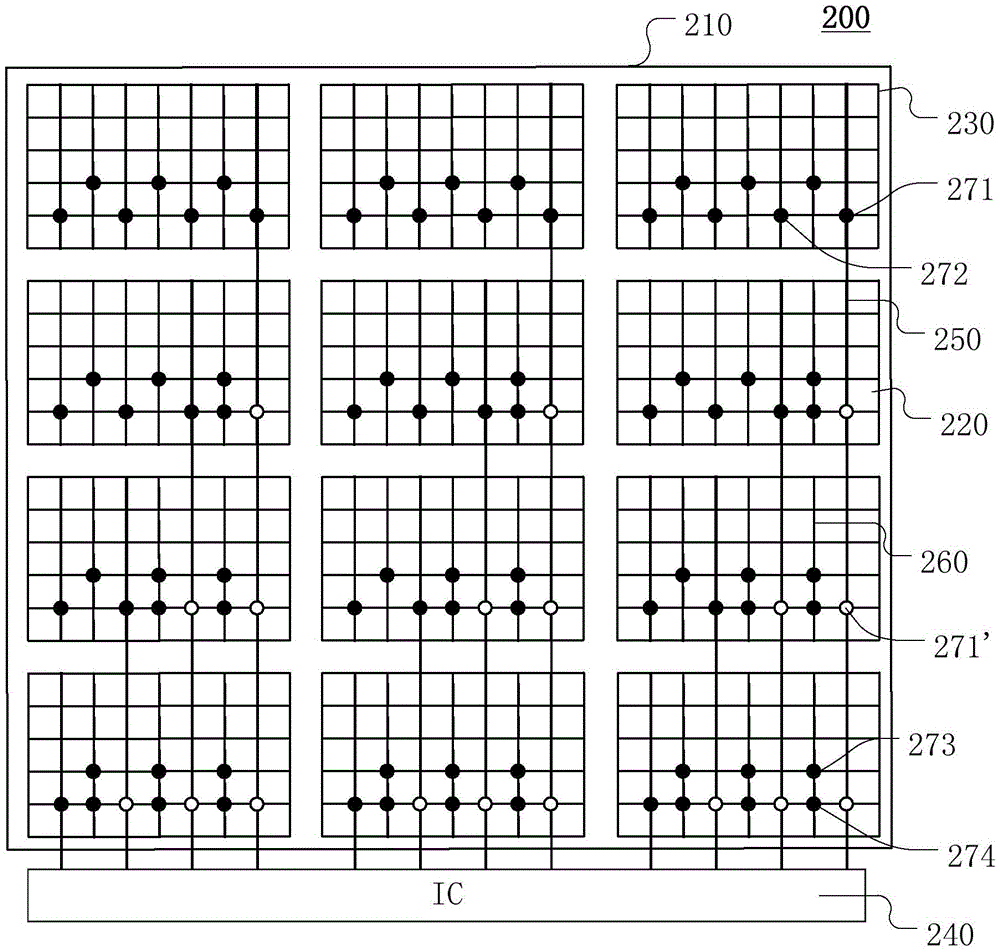

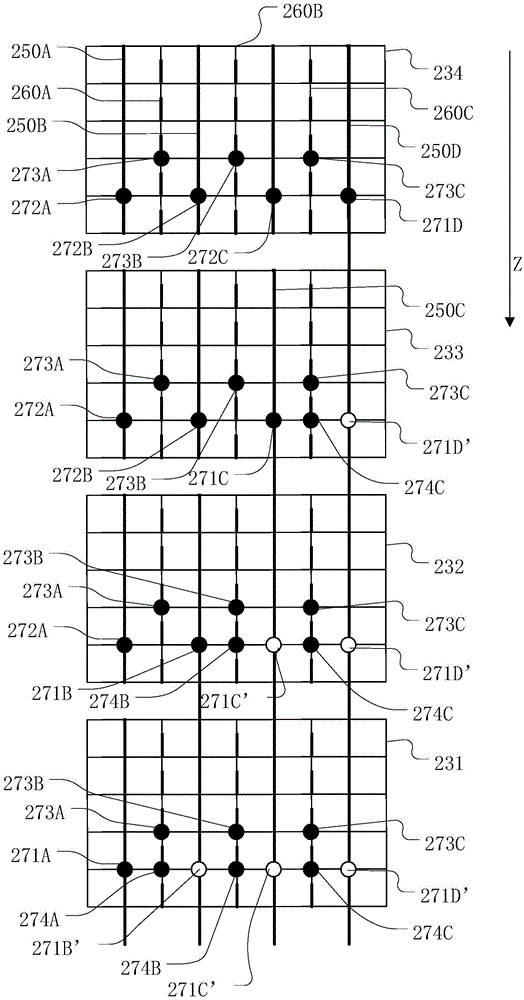

Touch control display device, touch control display panel and array substrate

ActiveCN105677076AImprove the display effectImprove problems such as streaks visible to the human eyeInput/output processes for data processingDisplay deviceHuman–computer interaction

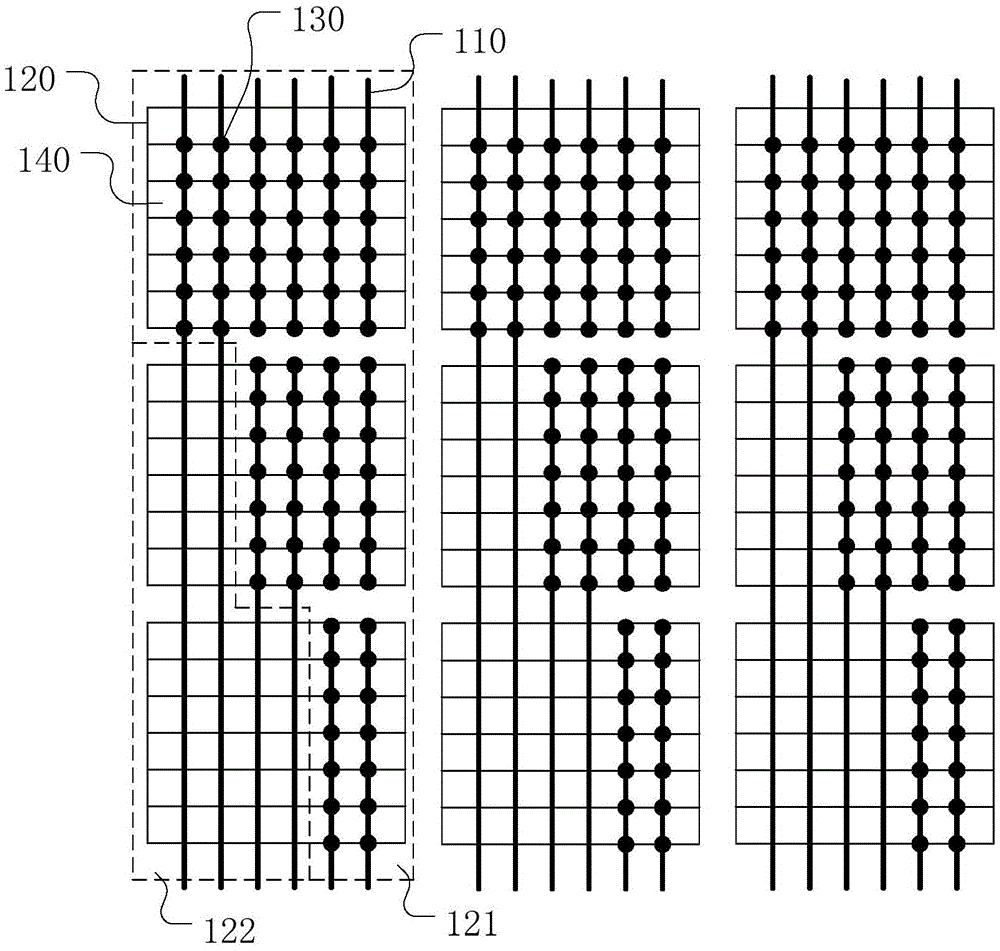

The present invention provides a touch control display device, a touch control display panel and an array substrate. The array substrate comprises a substrate; a plurality of pixel units arranged on the substrate; multiple rows of touch control electrodes, each touch control electrode covering the plurality of pixel units; a driving circuit driving the touch control electrodes; touch control leads which are respectively connected to the corresponding touch control electrode through a first through hole, and used for connecting the corresponding touch control electrode to the driving circuit; and at least one auxiliary lead which is positioned between the two adjacent touch control leads, is connected to the touch control electrode where a third through hole is located through the third through hole, and is broken between the two adjacent touch control electrodes, wherein for each row of the touch control electrodes, the touch control electrodes are provided with auxiliary through holes. According to the touch control display device, the touch control display panel and the array substrate, the problem of unevenly displayed strips visible to human eyes on display frames is solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

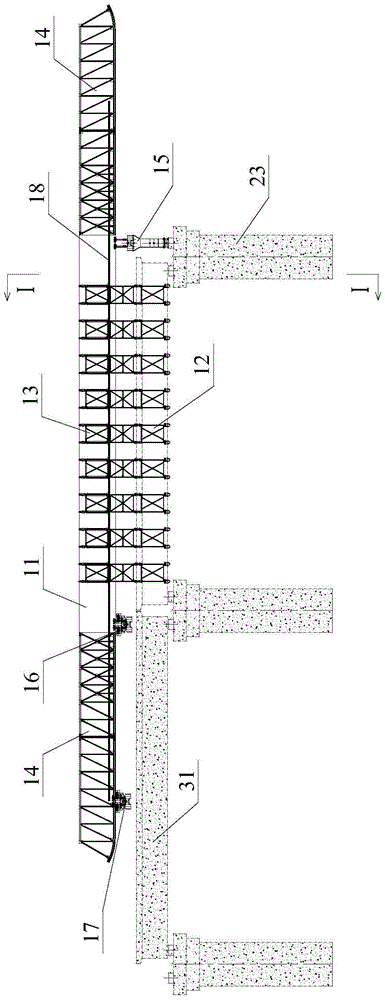

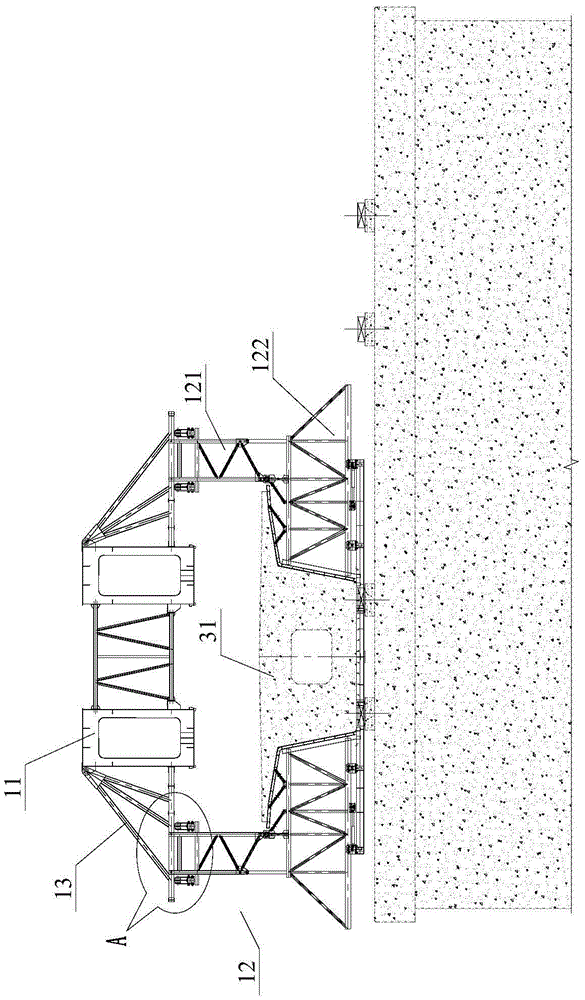

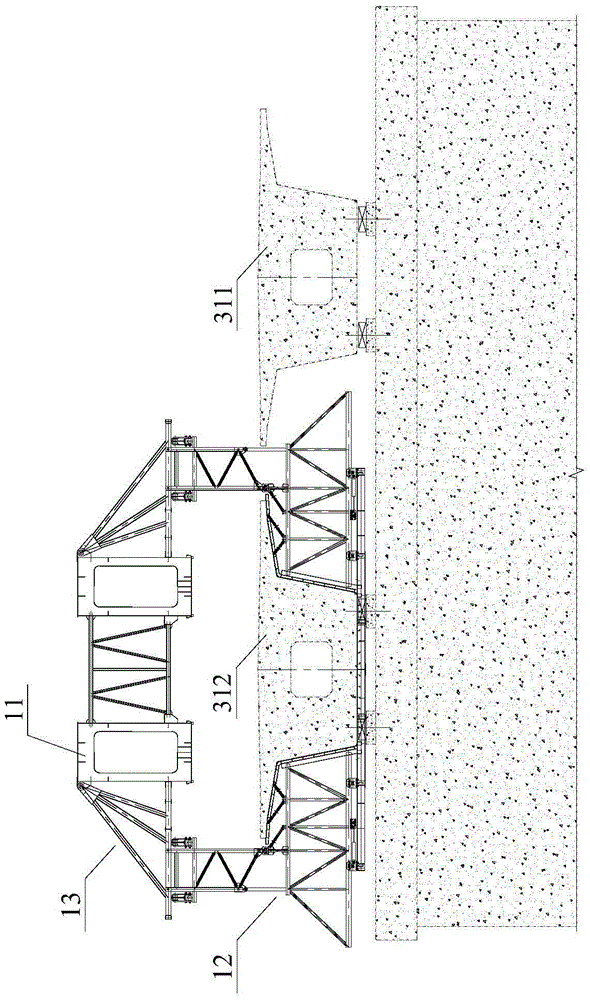

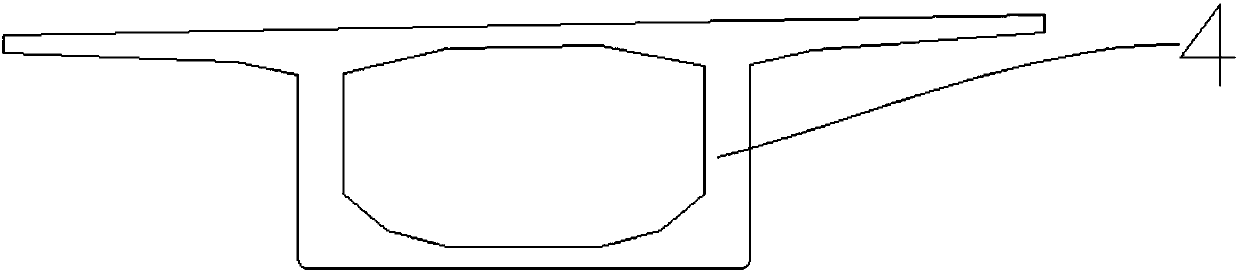

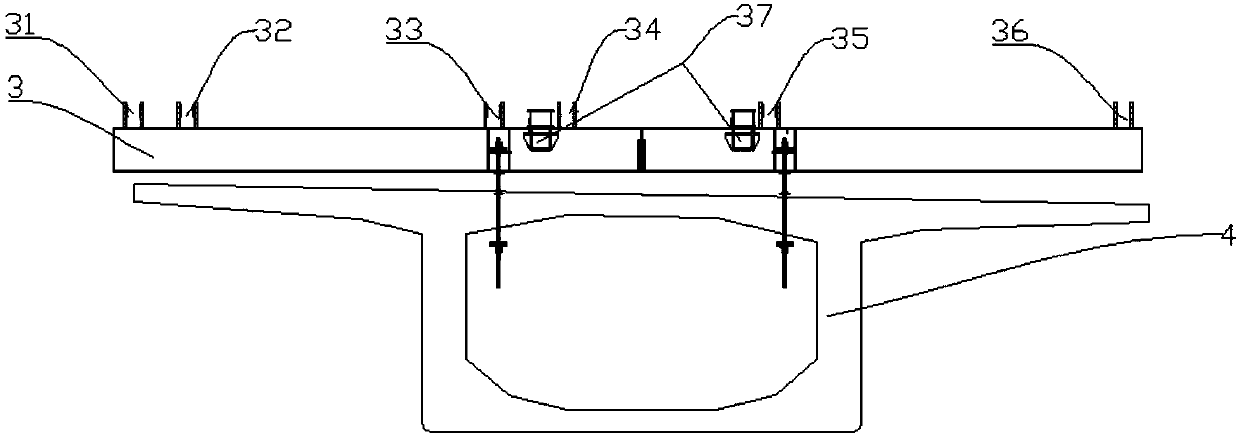

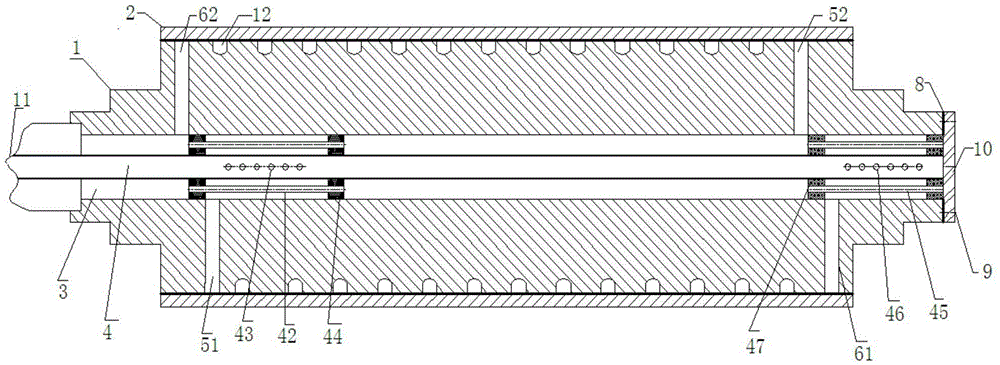

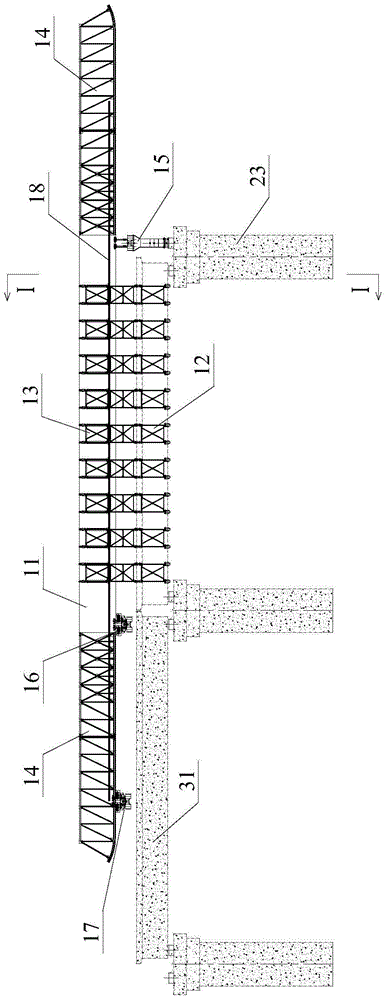

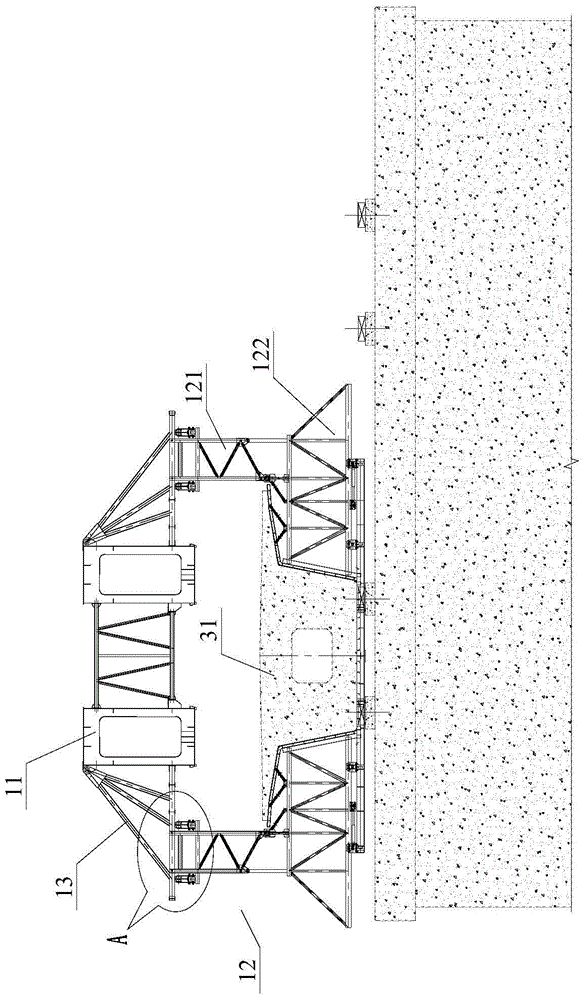

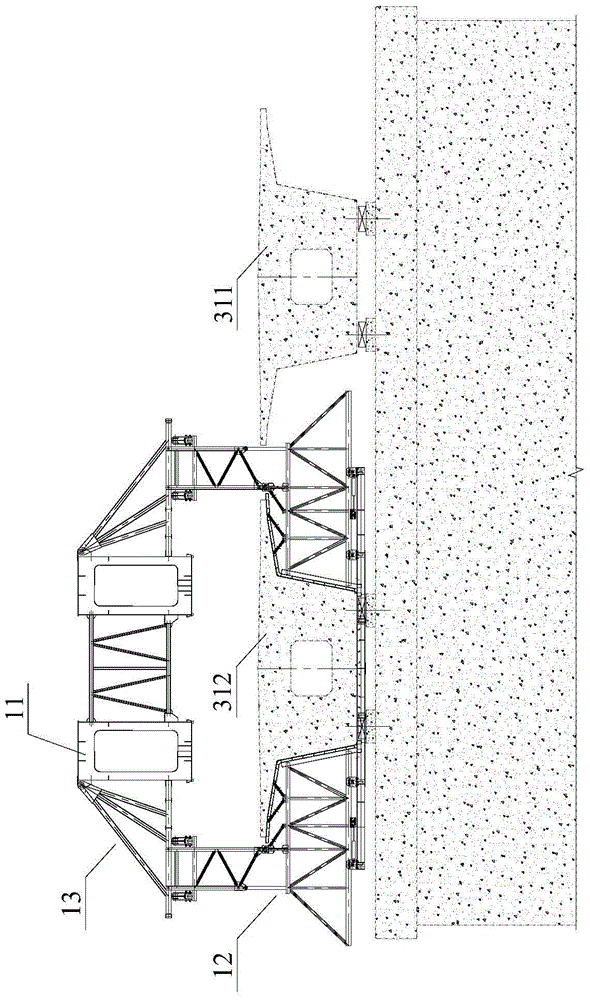

Movable formwork suitable for multiple beams and construction method

The invention discloses a movable formwork suitable for multiple beams and a construction method. The movable formwork comprises main beams, a hanging bracket and a casting mold. The direction of the pair of fixedly connected main beams is identical with the length direction of a bridge. Guide beams are arranged at the front end and the rear end of each main beam. A front supporting leg, a middle supporting leg and a rear supporting leg are arranged on the bottom face of each main beam in a sliding mode. The hanging bracket is arranged on the outer sides of the two main beams. A through track beam is arranged on the bottom face of the hanging bracket. The casting mold is movably arranged on the lower side of the hanging bracket and comprises a side mold body and a bottom mold body vertically arranged on the lower side of the side mold body. Reverse hooking wheels are arranged on the upper portion of the side mold body. The cross section of the track beam is in an I shape, and the reverse hooking wheels are movably arranged in an I-shaped cavity of the track beam. By the adoption of only one movable formwork, the multiple transverse beams are cast and transversely moved; besides, the position of the movable formwork does not need to be moved in the transverse direction, materials are saved, the number of hole passing times is reduced, operation is easier, and the safety of bridge construction is improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

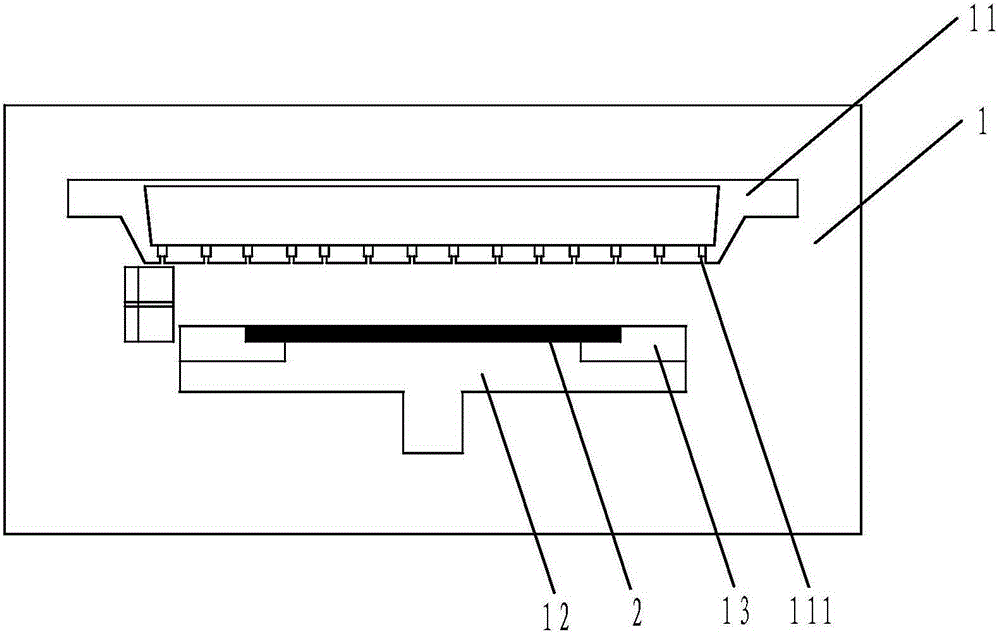

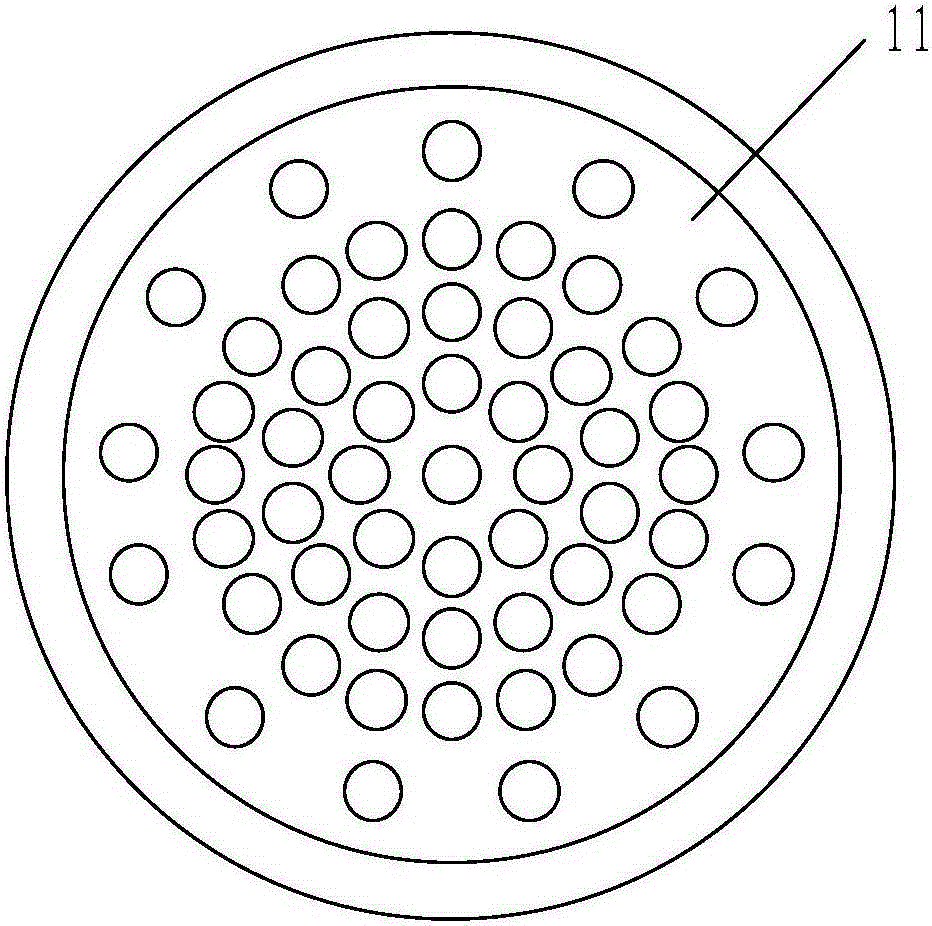

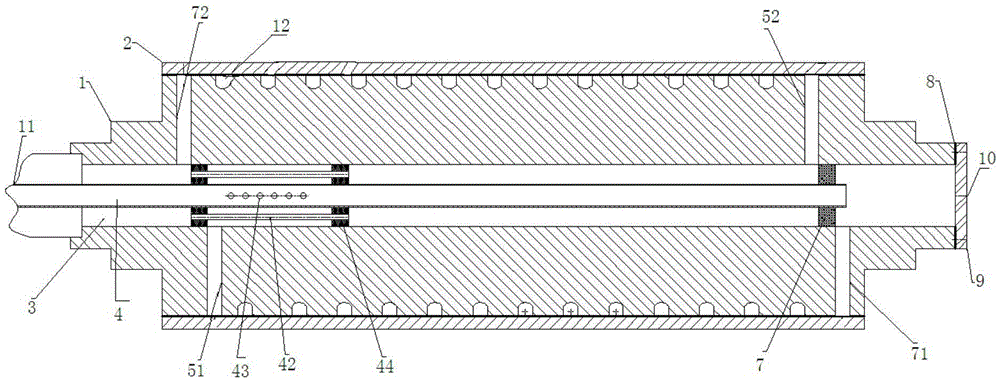

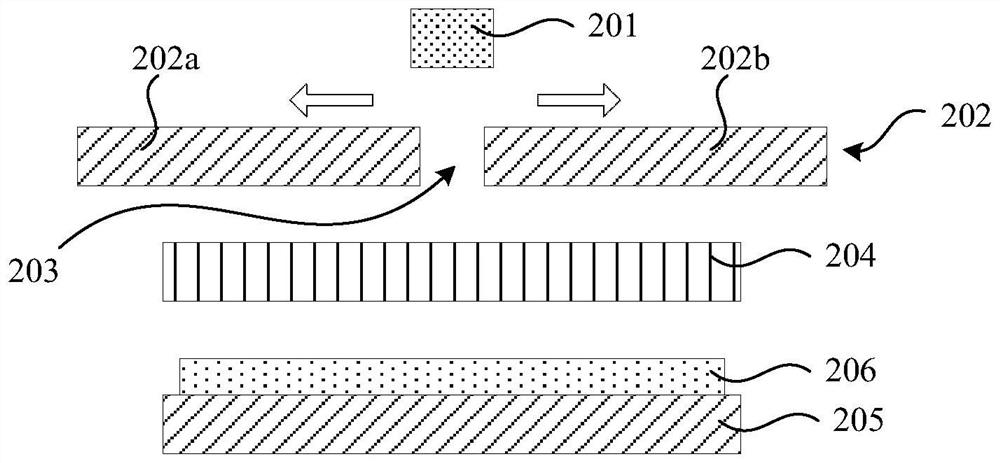

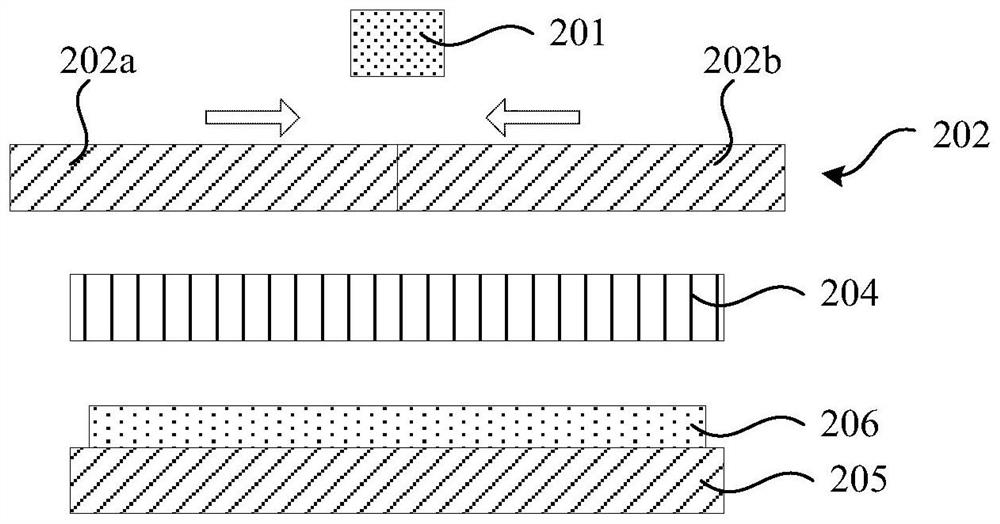

Semiconductor plasma processing device capable of improving appearance of film at surface of wafer

ActiveCN105225914AReduce the number of viasReduce gas flowElectric discharge tubesSemiconductor plasmaSubstrate surface

The invention provides a semiconductor plasma processing device capable of improving the appearance of a film at the surface of a wafer. The processing device comprises a reaction cavity and the wafer to be processed, the reaction cavity is internally provided with a spray head, an objective table and an exhausting ceramic ring, edge holes are distributed non-uniformly in the spray head, an exhausting hole of the exhausting ceramic ring moves downwardly, and the spray head is placed opposite to the objective table in the reaction cavity. The amount of edge holes of the spray head is reduced to reduce gas flow at the edge of the wafer, and the film at the edge of the wafer is avoided from too fast growth; the position of the exhausting hole of the exhausting ceramic ring moves downwardly to change the air flow path of exhausting and adjust the deposition effect of the substrate surface; and the film can grow uniformly on the substrate due to novel design of the spray head and exhausting ceramic ring in the device.

Owner:PIOTECH CO LTD

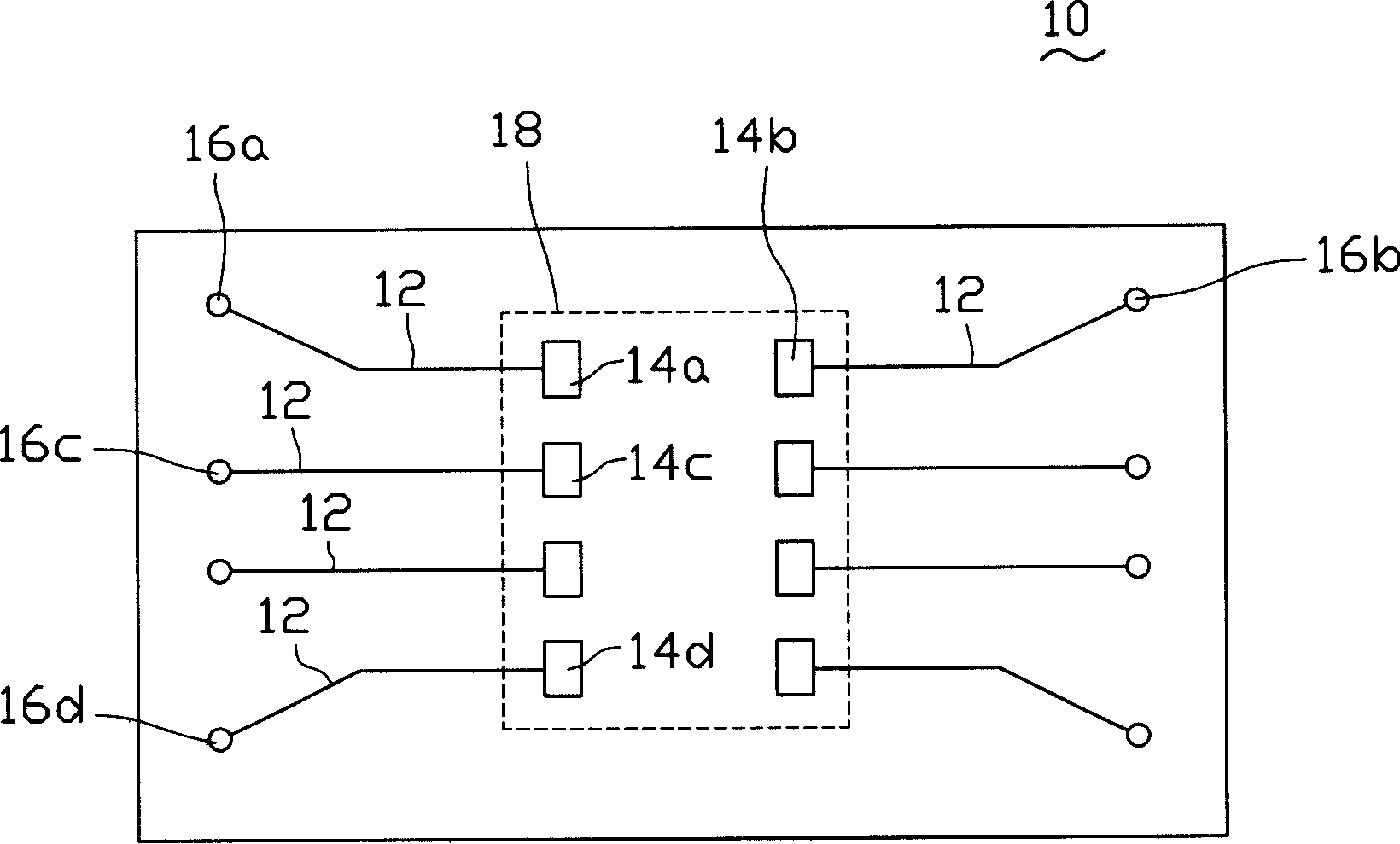

Semiconductor device with transistors and fabricating method therefor

InactiveUS20070077690A1Reduce the number of viasReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A semiconductor device with transistors and a fabricating method therefore are provided. The electrodes of the transistors are formed on the same layer, and they are coupled to one another by a conductor layer. Therefore, the requirement for the vias in whole circuit is reduced, and the cost is decreased.

Owner:IND TECH RES INST

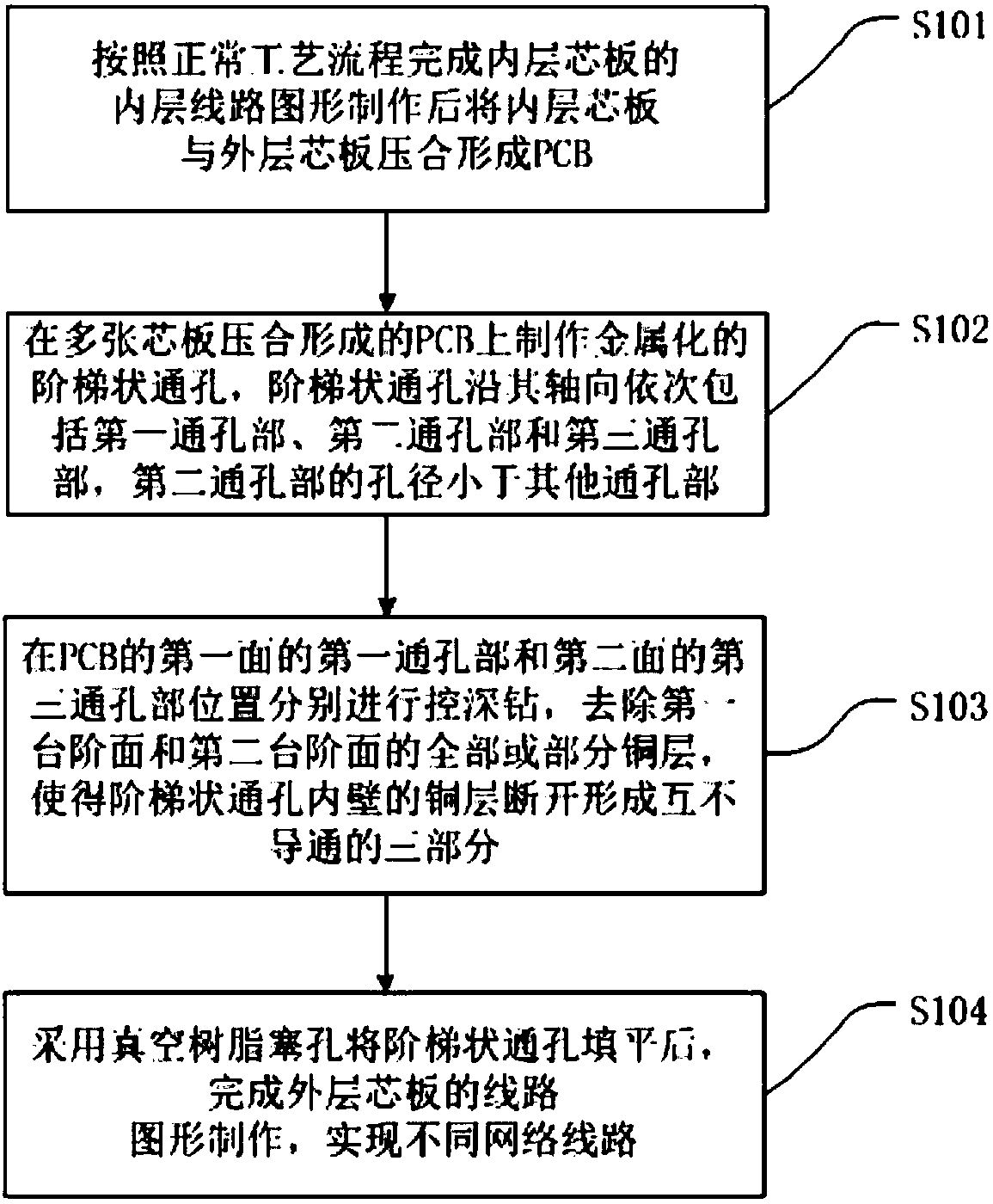

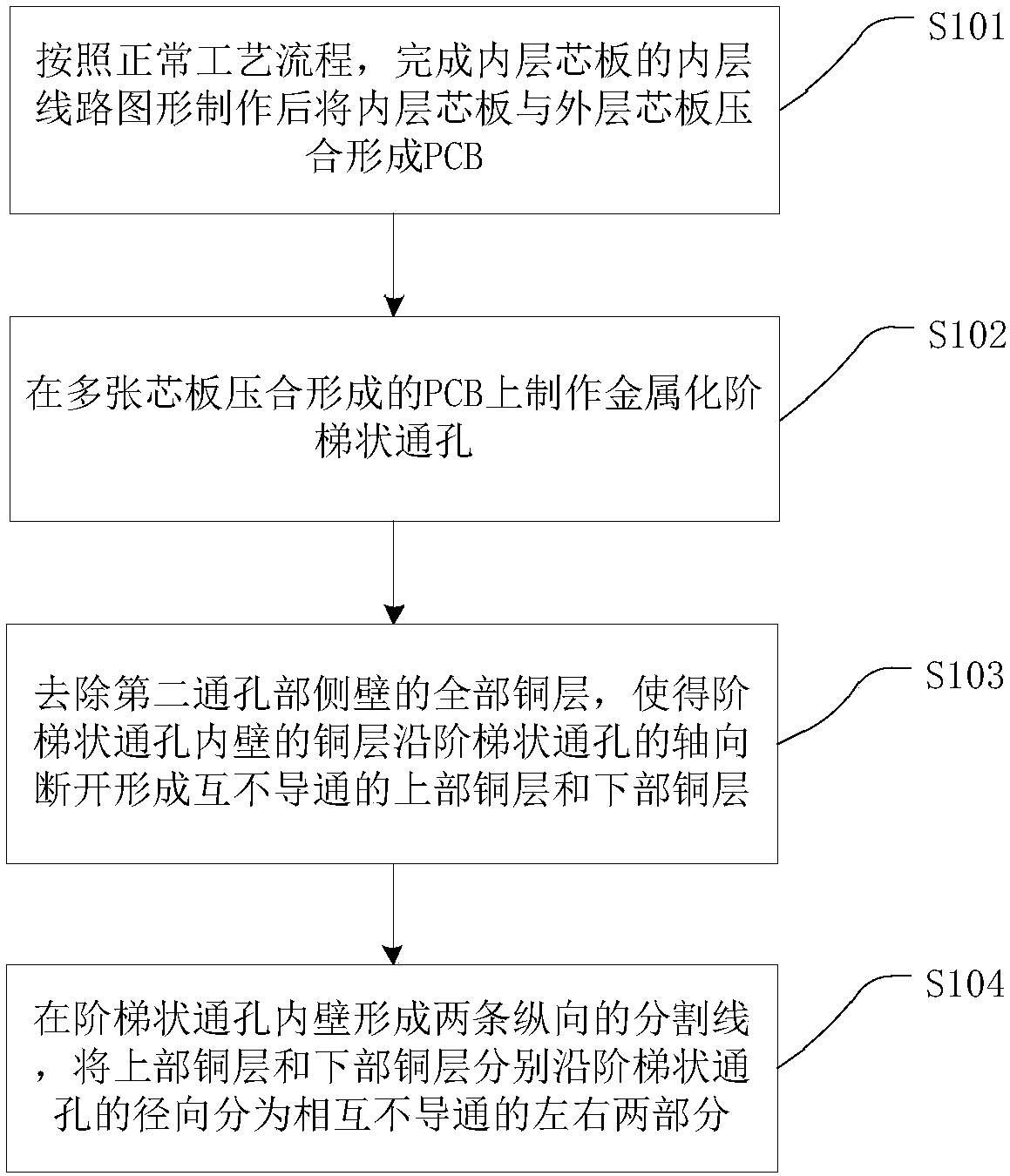

Processing method of PCB and PCB

InactiveCN107708298AImprove routing densityReduce the number of viasPrinted circuit aspectsElectrical connection printed elementsNetwork connectionEngineering

The invention discloses a processing method of a PCB and a PCB. The processing method comprises: an inner core plate and an outer core plate are pressed together to form a PCB; a stepped through holeis formed in the PCB and plated-through-hole electroplating is carried out on the through hole, wherein the stepped through hole includes a first through hole portion and a second through hole portionin an axial direction, the aperture of the first through hole portion is larger than that of the second through hole portion, and a first step surface is formed between the first through hole portionand the second through hole portion; and all the or the part of copper layer of the first step surface is removed or at least one part of copper layer o the side wall of the second through hole portion is removed, so that the copper layer of the inner wall of the stepped through hole is broken to form at least two parts not in conduction. According to the invention, the copper layer of the innerwall of the stepped through hole is divided into two parts or three parts not in conduction, so that two or three network connection layers are realized by one through hole part. Compared with the prior art, the method enables the via hole number to be reduced on the PCB with the same area, so that the wiring density of the PCB is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS

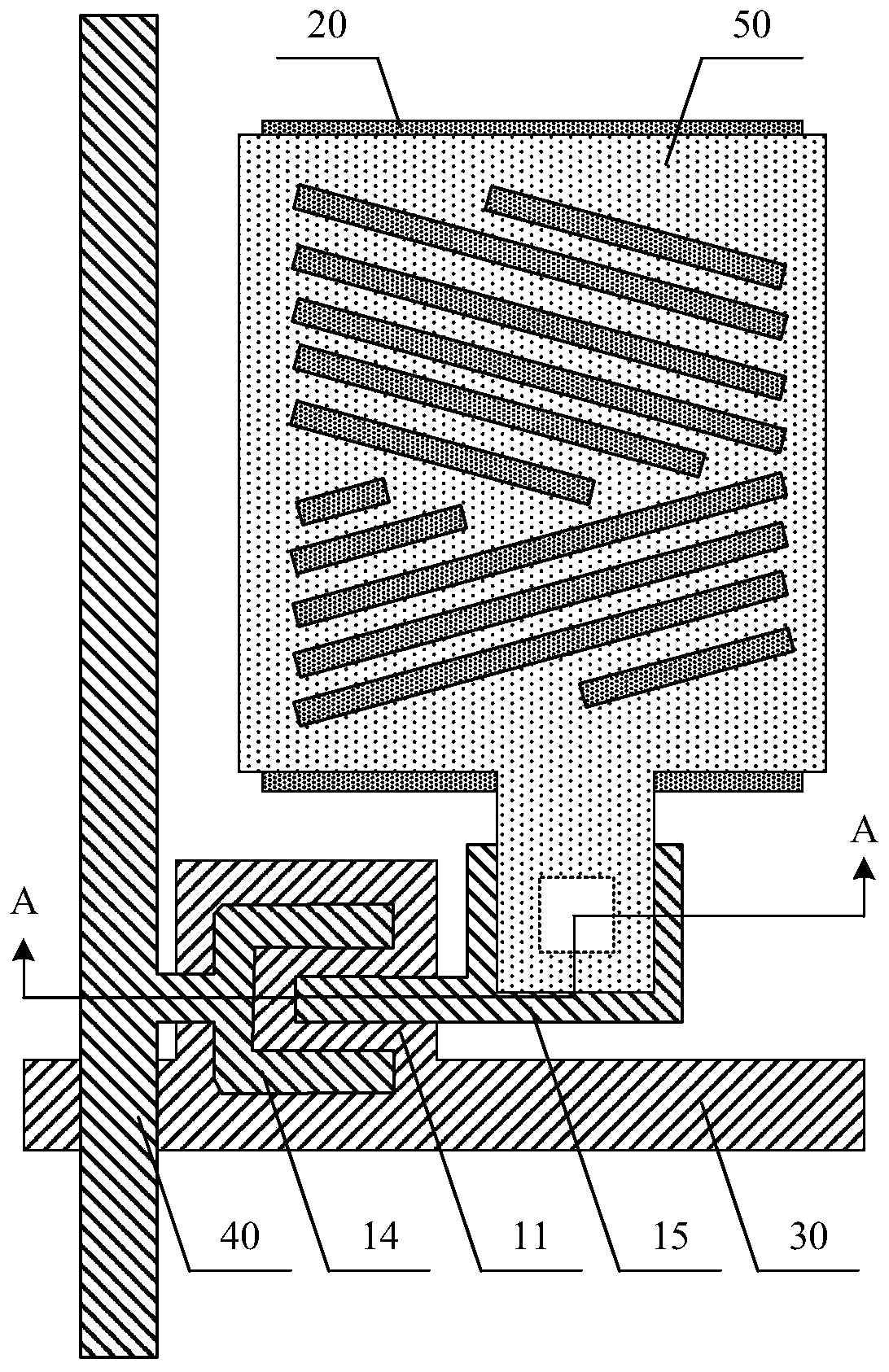

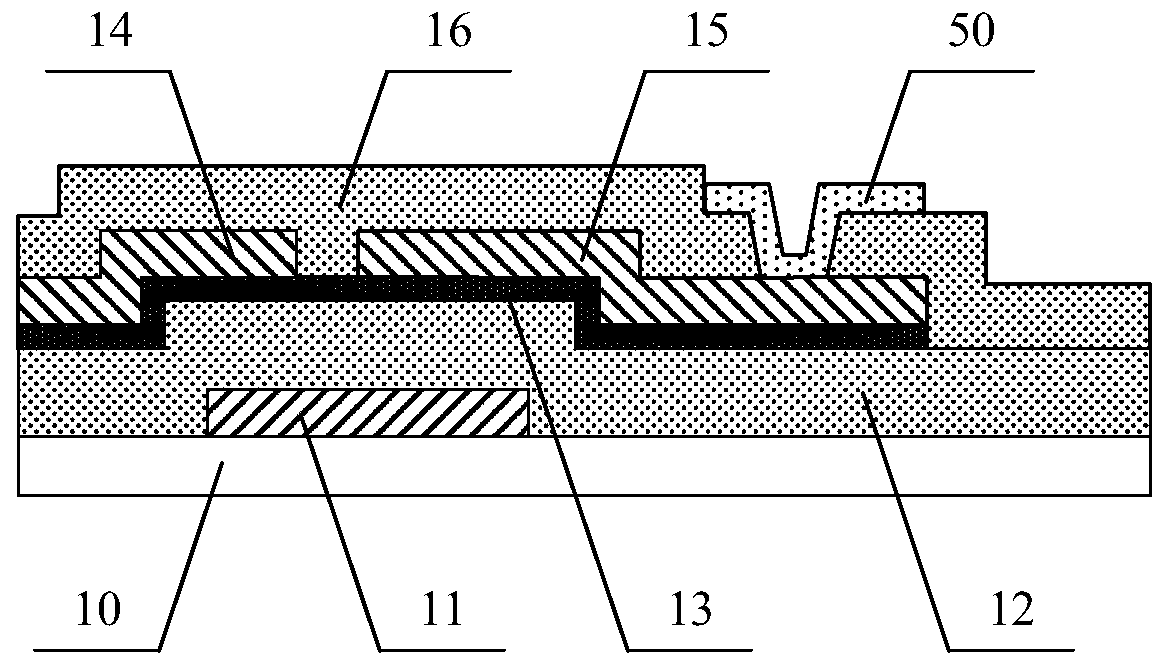

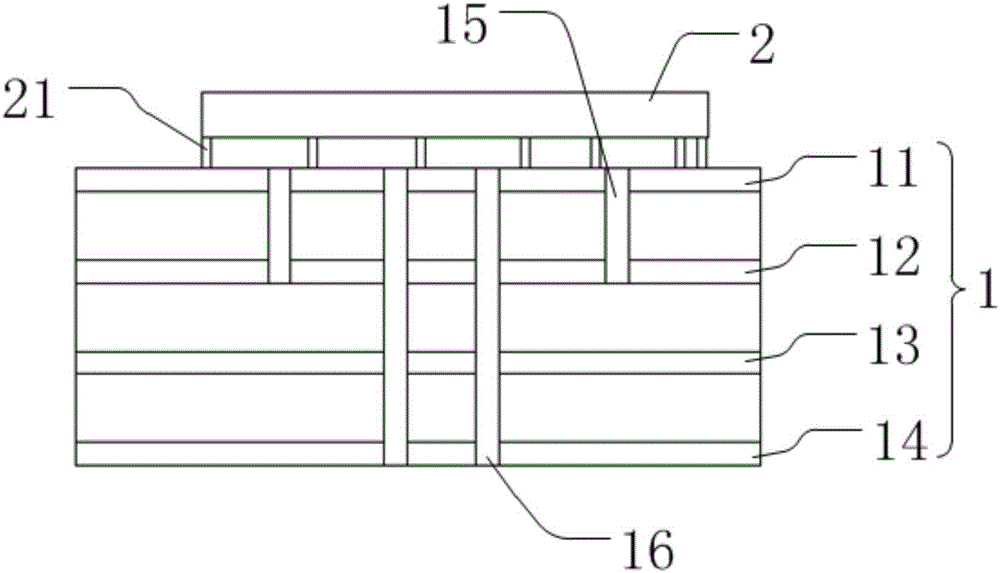

Array substrate, preparation method thereof, and display panel

ActiveCN109752891AReduce the number of viasIncrease opening ratioSemiconductor/solid-state device detailsSolid-state devicesEngineeringTransistor

The embodiment of the invention provides an array substrate, a preparation method thereof, and a display panel. The array substrate comprises a base, a pixel electrode, a film transistor, a passivation layer and a connecting electrode, wherein the pixel electrode and the film transistor are arranged on the base; the passivation layer covers the film transistor and is provided with a through connection through hole which simultaneously exposes the pixel electrode and the drain electrode of the film transistor; and the connecting electrode is arranged on the passivation layer and is simultaneously connected with the pixel electrode and the drain electrode through the through connection through hole. By use of the array substrate, through one through connection through hole, connection between the drain electrode and the pixel electrode is realized, the amount of through holes is effectively reduced, the aperture ratio of the display panel is increased, the quality of a product is improved, and a yield is improved.

Owner:BOE TECH GRP CO LTD +1

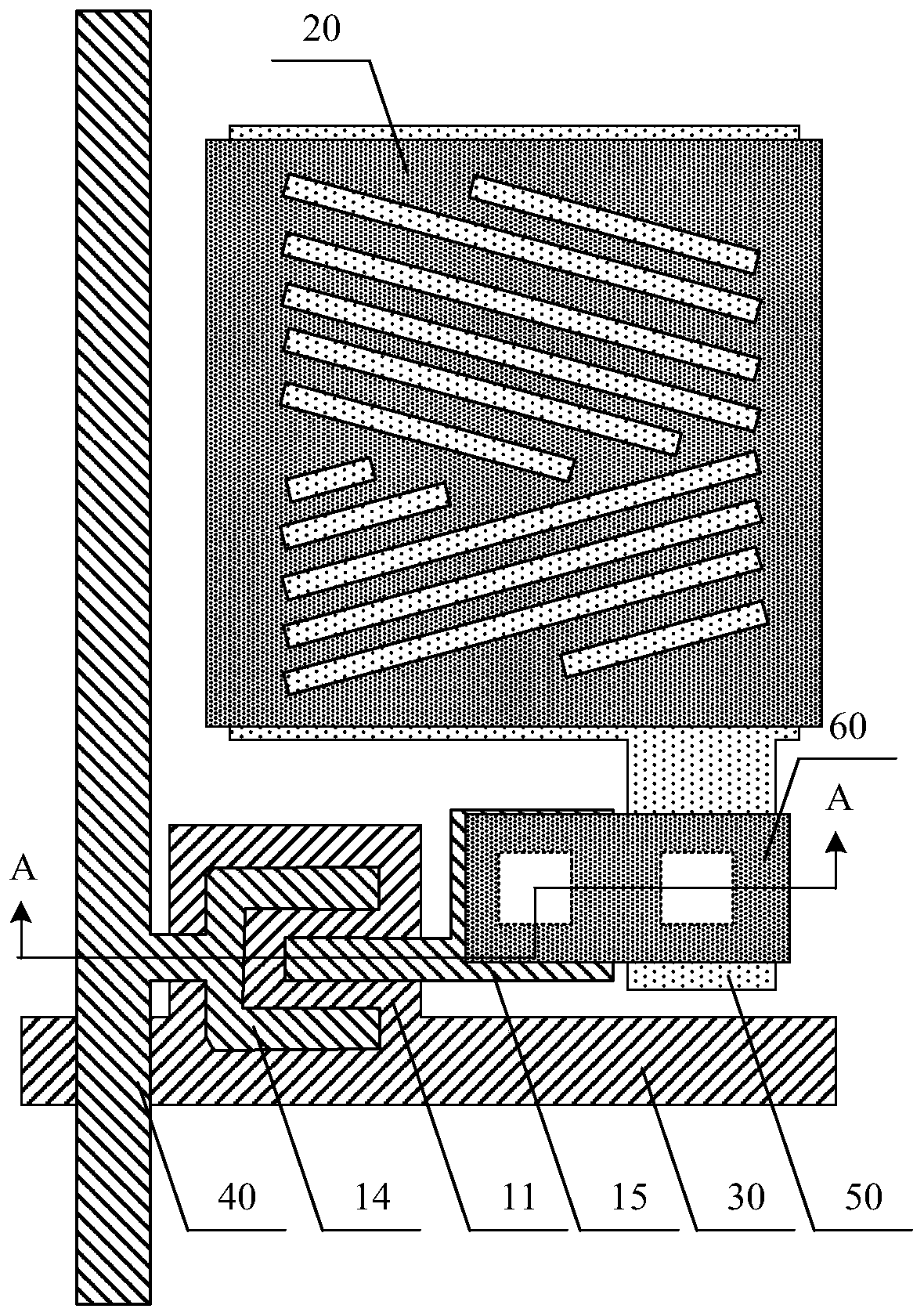

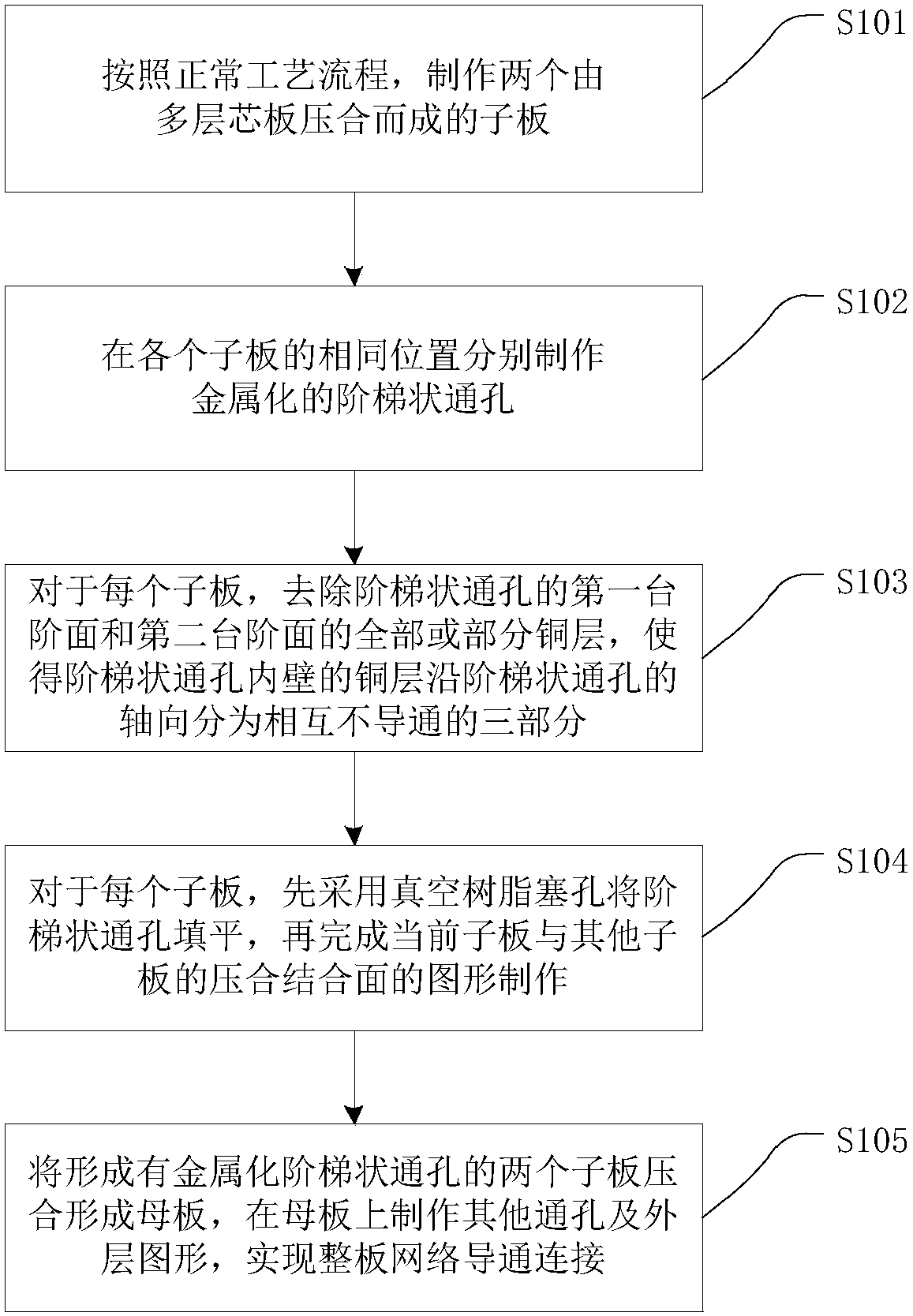

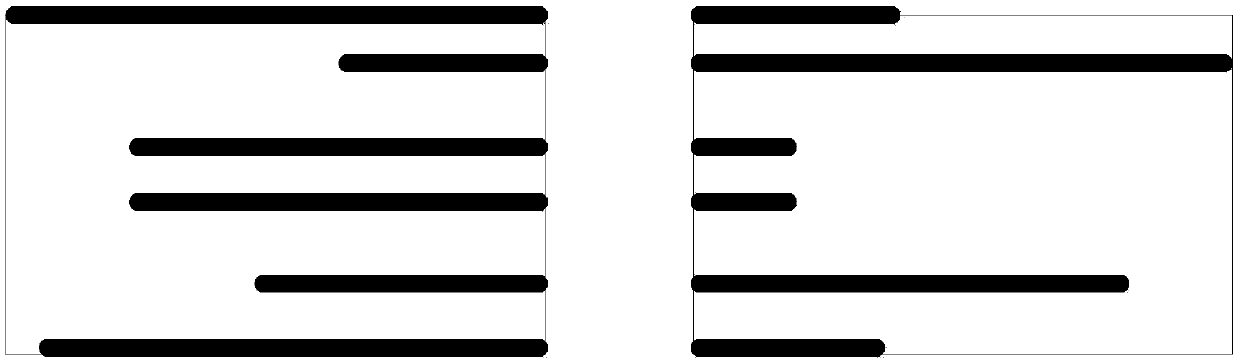

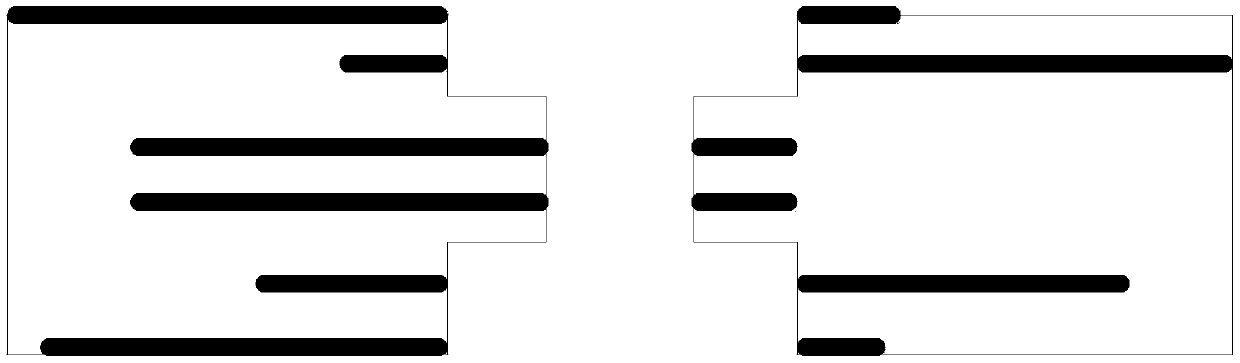

Multi-layer PCB manufacturing method and multi-layer PCB

InactiveCN107835588AImprove routing densityReduce the number of viasMultilayer circuit manufactureEngineeringSmall hole

The invention discloses a multi-layer PCB manufacturing method and a multi-layer PCB. The manufacturing method comprises the steps that at least two sub-boards are manufactured and at least two sub-boards are pressed to form a mother board. The manufacturing method of the sub-boards comprises the steps that a stepped through hole is manufactured and metallized at the same position on each sub-board; each stepped through hole comprises a first through hole part with a large hole diameter and a second through hole part with a small hole diameter along the axial direction, and a first step surface is formed between the first through hole part and the second through hole part; entire or part of the copper layer of each first step surface is removed, so that the copper layer on the inner wall of each stepped through hole is disconnected to form two parts which are non-conducting; and when at least two sub-boards are pressed to form a mother board, the position of the stepped through hole ofeach sub-board is kept the same from top to bottom. According to the embodiment of the invention, the copper layer on the inner wall of the stepped through hole of each sub-board is divided into twoparts or three parts; when the sub-boards of all layer are pressed together to form the mother board, more network connection layers are realized at the position of the same hole in the mother board;the number of vias is greatly reduced; and the PCB wiring density is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS

Synchronous construction method of double bridges at equal intervals by means of segmental assembly bridge girder erection machine

ActiveCN107687132AReduce the number of viasReduce operational riskBridge erection/assemblyCantileverBuilding construction

The invention provides a synchronous construction method of double bridges at equal intervals by means of a segmental assembly bridge girder erection machine. The method comprises the following stepsthat 1, a lifting crane is mounted on the bridge girder erection machine, wherein the lifting crane comprises a cross beam and two cantilever beams arranged below the cross beam, and two sets of girder hanging vehicles are arranged on the lower end surface of each cantilever beam; 2, a first set of hanging points and a sixth set of hanging points are arranged at both ends of a hanging cross beam,and two sets of hanging points are arranged relative between the first set of hanging points and the sixth set of hanging points; 3, multiple sets of segmental blocks are hoisted in sequence during bridge girder erection, hoisting of each set of segmental blocks includes hoisting of segmental blocks on the left side and hoisting of segmental blocks on the right side, the intervals of two adjacentsets of segmental blocks are adjusted to complete construction. According to the synchronous construction method of the double bridges at equal intervals by means of the segmental assembly bridge girder erection machine, through arrangement of the left and right cantilever beams on the cross beam of the lifting crane and multiple sets of hanging points on the hanging cross beam, the left bridge and right bridge of the double bridges can be transversely moved, beam feeding on the tail portion is achieved, so that construction of the double bridges is completed.

Owner:CCCC SECOND HARBOR ENG

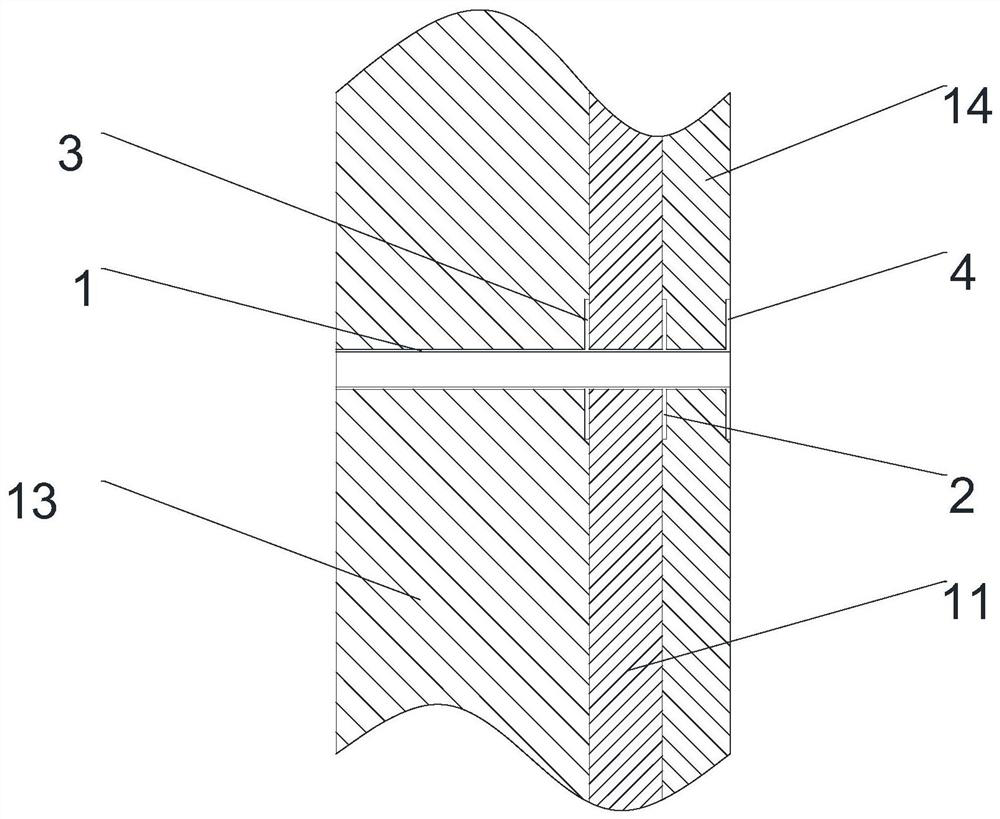

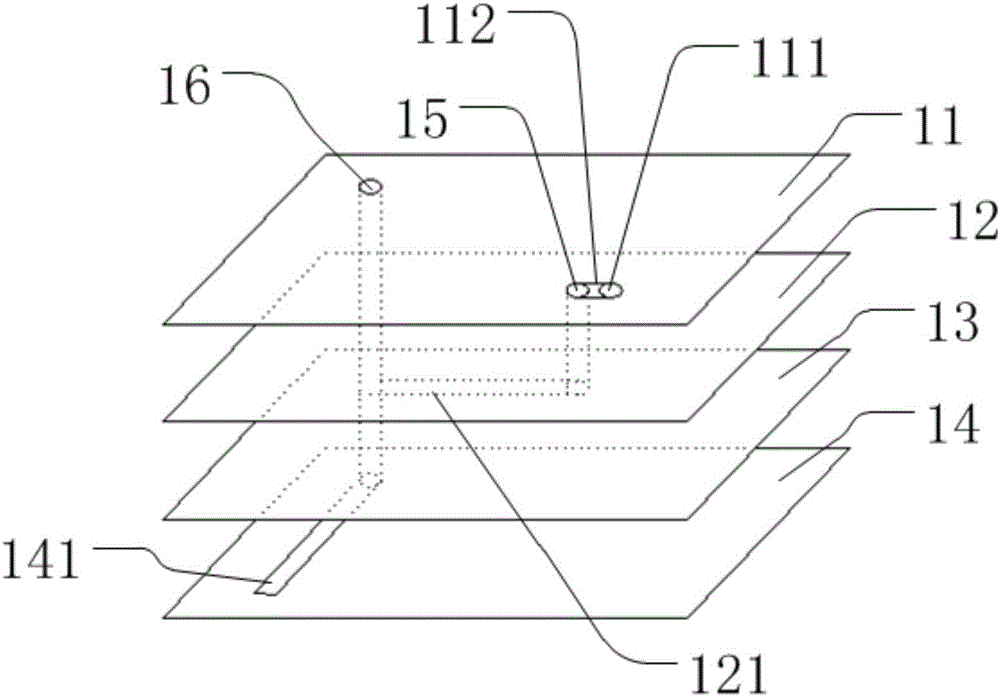

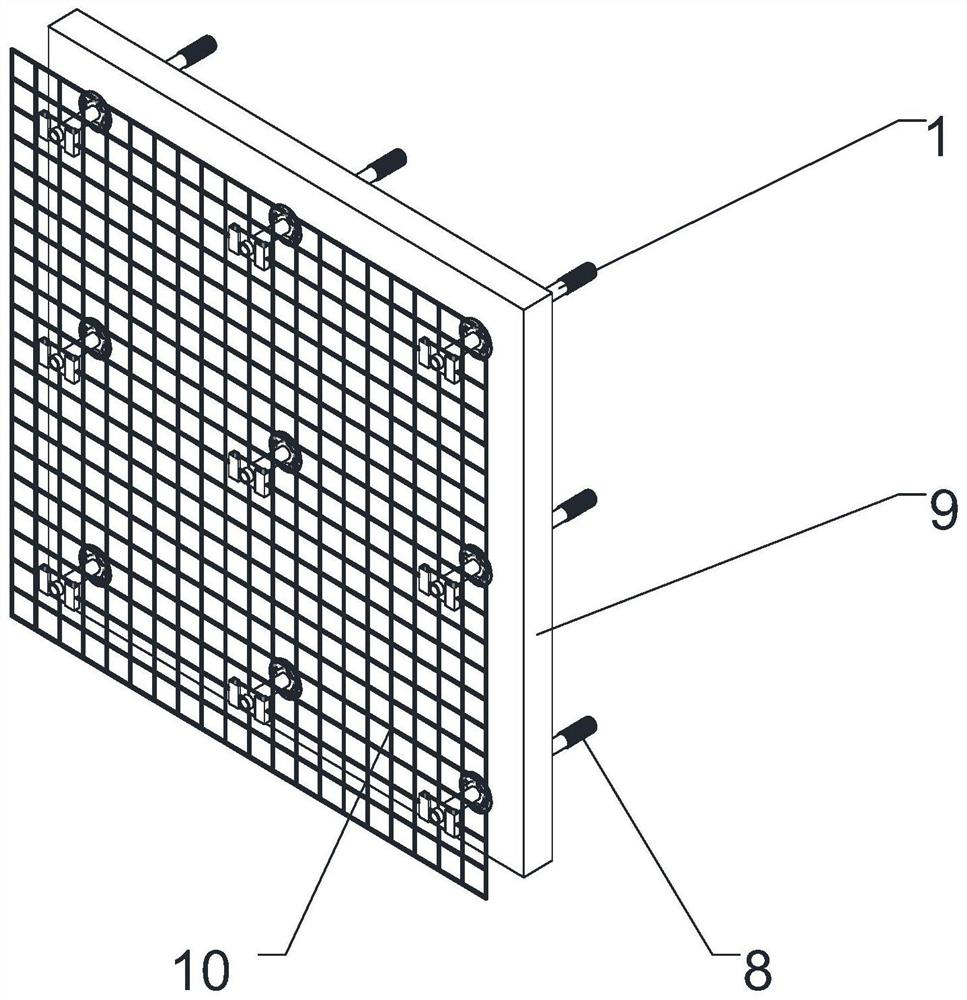

Cast-in-place concrete built-in thermal insulation wall structure

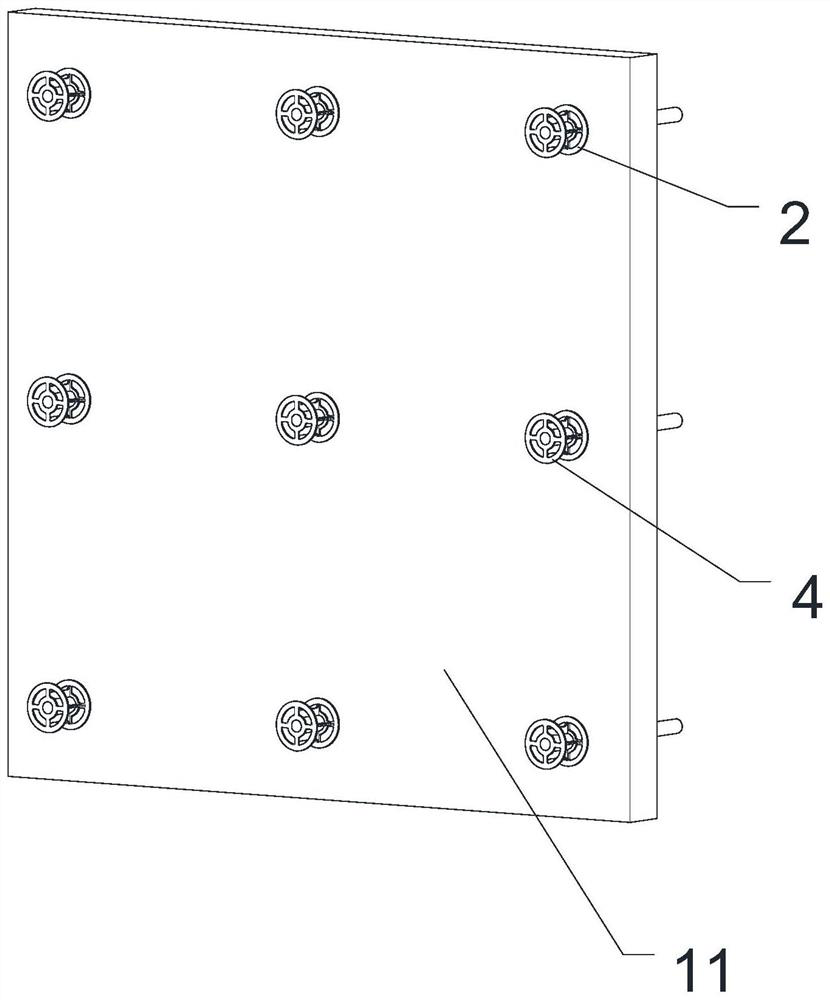

PendingCN111705964ASimple structureHigh strengthWallsClimate change adaptationInsulation layerThermal insulation

The invention relates to the field of building construction, and solves the problem of low thermal insulation performance of a concrete wall body caused by the fact that through holes for a connectingpiece and a split bolt to penetrate through are formed in a thermal insulation layer of the concrete wall body in the prior art. A cast-in-place concrete built-in thermal insulation wall structure comprises an inner wall layer, an outer wall layer, a thermal insulation layer located between the inner wall layer and the outer wall layer and a pipe body penetrating through the inner wall layer, thethermal insulation layer and the outer wall layer, an axial channel of the pipe body penetrates through the pipe body to form openings in the two ends of the pipe body, a first limiting piece and a second limiting piece are arranged on the outer side wall, and the thermal insulation layer is located between the first limiting piece and the second limiting piece. The split bolt penetrates throughthe pipe body to fasten an inner template and an outer template, and the tension of the split bolt and the supporting force of the connecting piece act synergistically to position the inner template and the outer template. Through holes cannot be formed in the cast-in-place concrete built-in thermal insulation wall structure due to the fact that split bolts are arranged, the number of the throughholes in the cast-in-place concrete built-in thermal insulation wall is reduced, heat loss is reduced, and the thermal insulation performance of the wall is improved.

Owner:山东赛昌新型材料有限公司

Circuit board

InactiveCN106231788AGuaranteed reliabilityReduce in quantityPrinted circuit aspectsHigh voltage circuit adaptationsGround layerEngineering

The invention relates to the technical field of circuit board production, in particular to a circuit board which comprises a substrate and first conductive parts. The substrate comprises a device layer, a signal layer and a ground layer which are arranged in an overlapped mode, the signal layer is located between the device layer and the ground layer, and the device layer is provided with multiple welding disks; the substrate is provided with blind holes which extend to the signal layer from the device layer, one first conductive part is arranged in each blind hole, and at least one welding disk is electrically conducted with the signal layer through the first conductive parts. According to the circuit board, the blind holes are arranged and each internally provided with one first conductive part, and the welding disks on the device layer can be electrically connected with the signal layer through the first conductive parts; therefore, the number of through holes in the circuit board can be decreased, destruction to the ground layer is reduced, the integrity of the ground layer is well guaranteed, when an ESD problem occurs, static electricity can be rapidly released, and the reliability of the system is guaranteed.

Owner:SHENZHEN TINNO WIRELESS TECH

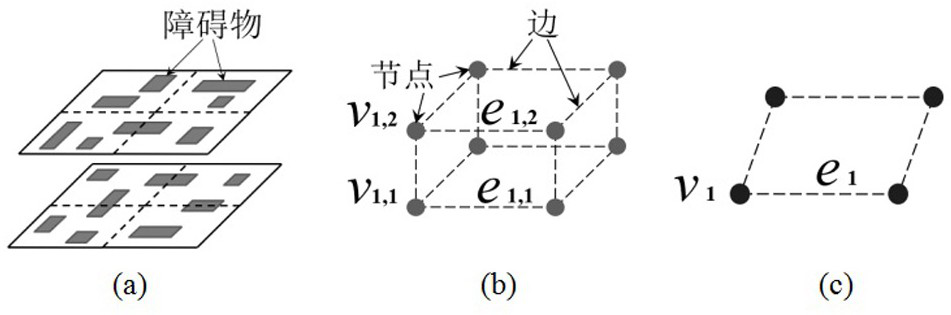

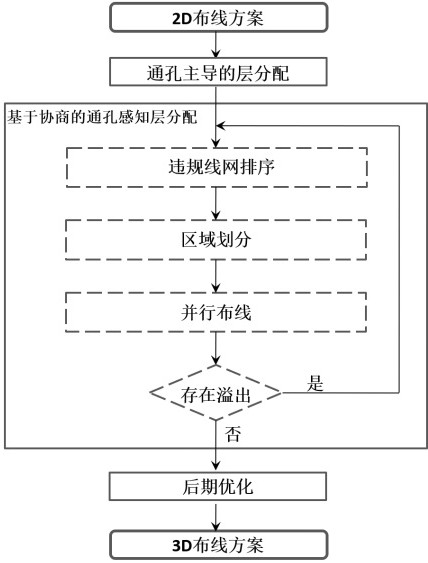

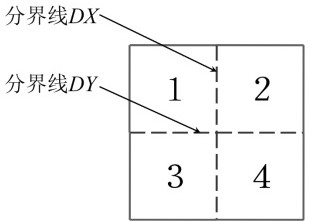

Parallel layer distribution method based on through hole perception under super-large-scale integrated circuit

ActiveCN111723545AReduce the number of viasLoad balancingComputer aided designSpecial data processing applicationsVery large scale integrated circuitsDistribution method

The invention relates to a parallel layer distribution method based on through hole perception under a super-large-scale integrated circuit. According to the method, a parallel strategy based on region division is provided, the load of each region can be balanced by sensing the number of line networks of each region, and thus the efficiency of the parallel strategy is improved; according to the method, a through hole optimization strategy based on wire network equivalent wiring scheme perception is provided, the priority of each wire network for wiring resource use is determined by utilizing the difference of the number of wire network 3D equivalent wiring schemes, and thus the number of through holes of a layer distribution scheme is effectively reduced.

Owner:FUZHOU UNIV

Printing circuit board with modified power zone block

InactiveCN1901777AReduce manufacturing costQuality improvementPrinted electric component incorporationPrinted circuit aspectsVoltageEngineering

This invention provides a multilayer PCB with improved supply blocks, which has several element contacts, a first supply block, a second supply block and several through holes, in which, said element contacts are used in setting a large current electronic element, said through holes pass through said first supply block, the second block and connect them to keep the voltage of them the same, and the shape of them is the same or similar, which can reduce numbers of the through holes.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Small-sized LED lamp bead set and lamp beads

InactiveCN104409620AReduce the number of viasLow densitySolid-state devicesSemiconductor devicesEngineeringLED lamp

The invention creatively provides a small-sized LED lamp bead set and lamp beads formed by cutting the lamp bead set. A bracket set forming the lamp bead set is formed by splicing a plurality of brackets; the brackets share a top point, and a through hole is formed in the top point shared by the brackets and used for allowing a conductive layer to be plated in, so that one conductive through hole can be shared by the brackets, the number of required through holes is effectively reduced, and the density of the through holes is reduced; moreover, the apertures of the through holes can be set to be relatively large, so that the process difficulty can be effectively lowered and the product yield can be increased.

Owner:MLS

Emitter circulating type solar cell and preparation thereof

InactiveCN101383386BReduce the number of viasHigh mechanical strengthPhotovoltaic energy generationSemiconductor devicesSolar cellIrradiation

The invention relates to a surrounding-emitting electrode solar cell and a preparation method thereof. The cell contains arrays which are arranged in a hexagonal lattice way and penetrate through holes 2 of an irradiation surface and a backlight surface of a silicon chip 1 in the silicon chip 1, therefore, the quantity of the through holes is minimized, and the breakage ratio of the silicon chip in the process of the hole drilling technology is reduced; a heavily doped emitting electrode 6 included on the back surface of the silicon chip 1 partially enters into the through holes, and a first conductive metal electrode 5 is arranged on the heavily doped emitting electrode 6, and plays the role of collecting minority carriers. A groove is arranged at the circumference of the first conductive metal electrode 5 by etching, a second conductive metal electrode 7 is arranged in the groove and plays the role of collecting majority carriers, and the first conductive metal electrode 5 and the second conductive metal electrode 7 deposited in the groove are insulated and isolated through the step of the groove.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

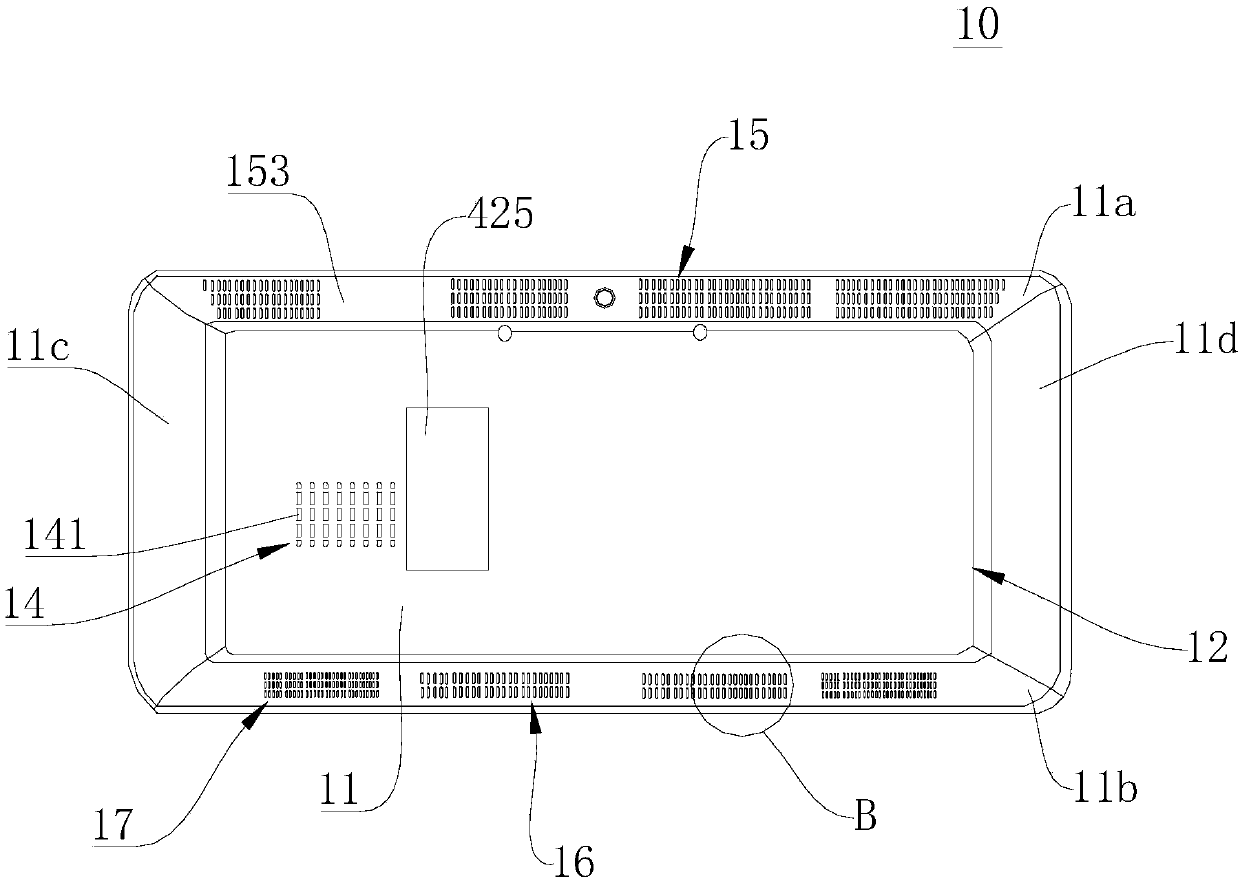

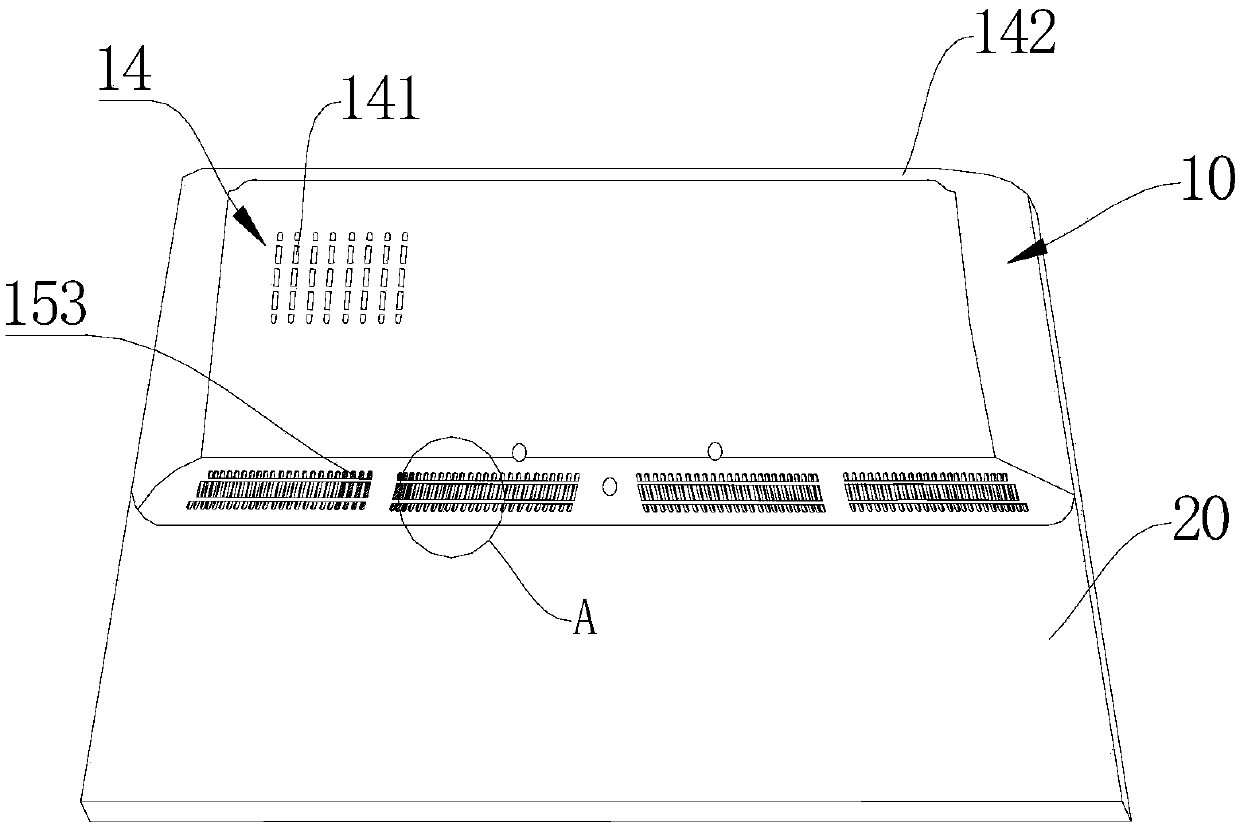

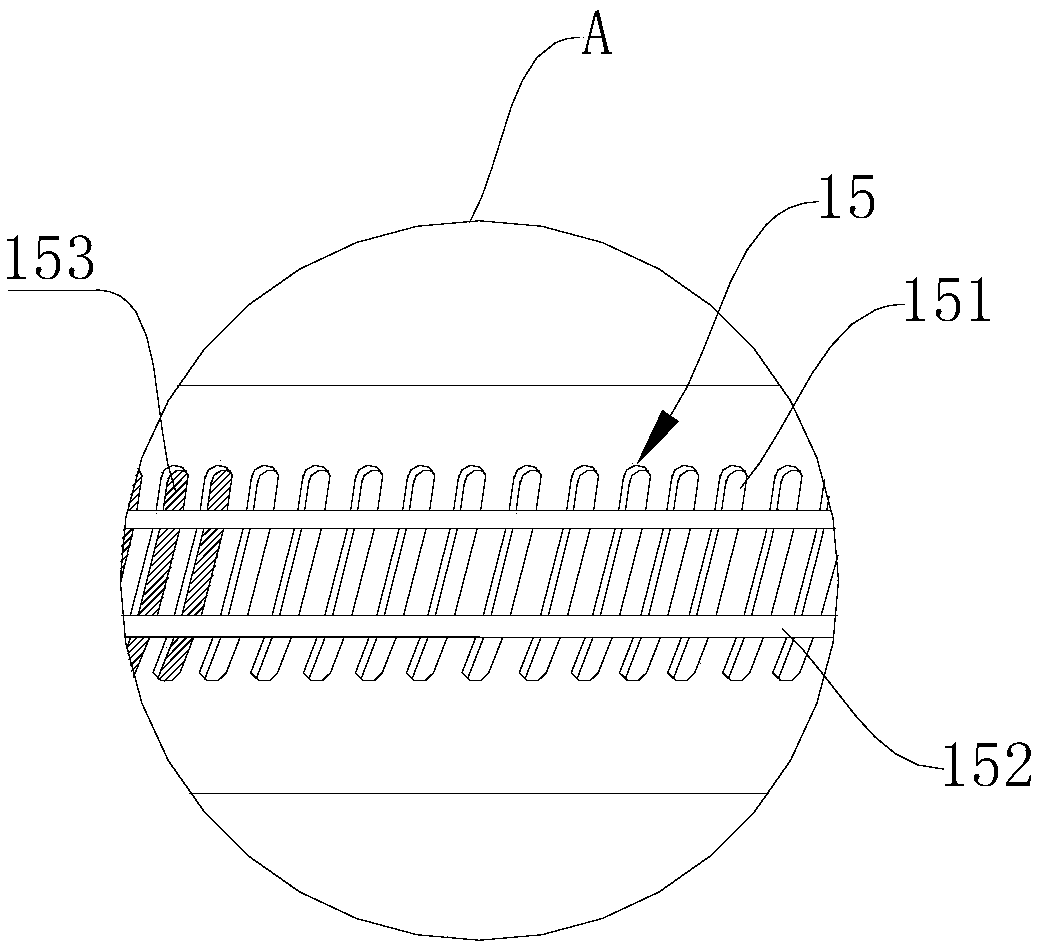

Display device and housing structure therefor

PendingCN107896435ADoes not affect strengthHeat dissipationCasings with display/control unitsCasings/cabinets/drawers detailsDisplay deviceHemt circuits

The invention discloses a display device and a housing structure therefor. The housing structure comprises a top cover, a first side wall, a second side wall, a third side wall and a fourth side wall,wherein the four side walls are set around the top cover, so as to form an accommodation space of the housing structure. A circuit mainboard is disposed in the accommodation space. The structure alsocomprises a first heat dissipation structure which is disposed on the top cover and comprises a plurality of first heat dissipation holes corresponding to the circuit mainboard, so as to timely dissipate the heat of the circuit mainboard; a second heat dissipation structure which is disposed on the first side wall. According to the invention, a back plate is provided with a plurality of heat dissipation through hole structures, and the plurality of heat dissipation through hole structures are arranged according to a predetermined layout. A region, corresponding to the circuit mainboard, of the back plate is provided with the heat dissipation structures, thereby facilitating the improvement of the heat dissipation performance of the circuit mainboard in a display screen.

Owner:HKC CORP LTD

Straight pipe type hot and cold water valve

ActiveCN103047443AReduce the number of viasMixing ratio adjustmentOperating means/releasing devices for valvesMultiple way valvesMagnetic polesEngineering

The invention provides a straight pipe type hot and cold water valve which comprises an inner straight pipe and an outer straight pipe, wherein a mixed water cavity is formed between the inner straight pipe and the outer straight pipe, and a water outlet is extracted from the mixed water cavity. Through holes are bestrewed on one half circumferential wall of the inner straight pipe, and two ends of the inner straight pipe are respectively connected with a hot and cold water pipe. A separation sleeve capable of rotating around the inner straight pipe is encircled on the outer side of the inner straight pipe, and through holes are bestrewed on one half circumferential wall of the separation sleeve. A sliding sleeve is sleeved on the outer side of the outer straight pipe. A pair of magnetic poles with the magnetic interaction direction facing to the sliding sleeve diameter direction is arranged in the sliding sleeve. Two magnetic stripes along a cylindrical bus bar of the separation sleeve are arranged on the separation sleeve, and the acting force direction between the two magnetic stripes faces to the separation sleeve diameter direction. A magnetic sliding plug is further arranged in the inner straight pipe. The straight pipe type hot and cold water valve can be operated by users conveniently and can adjust water temperature continuously and accurately.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

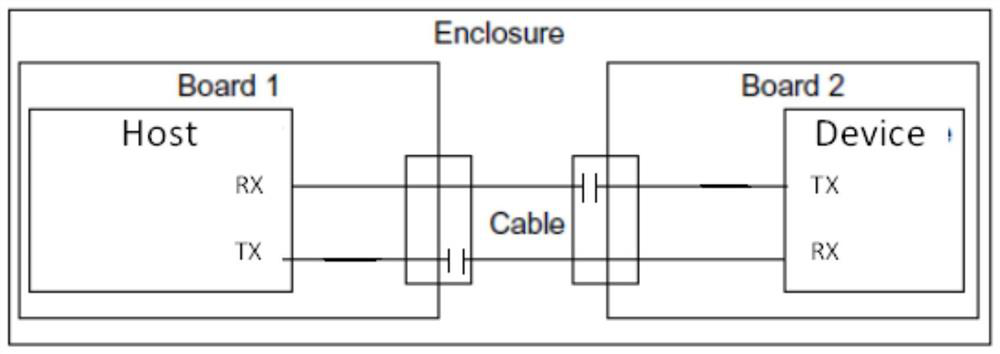

PCIe circuit board

InactiveCN114051312AReduce the number of viasImprove routing efficiencyElectrical connection printed elementsCircuit electrical arrangementsComputer hardwareCapacitance

The invention relates to the technical field of servers, and particularly provides a PCIe circuit board which comprises a first PCIe board and a second PCIe board. The first PCIe board and the second PCIe board are connected through a high-speed connector, the high-speed connector comprises a first sub-connector and a second sub-connector, and the first sub-connector is electrically connected with the second sub-connector; the first sub-connector is connected with a first PCIe board, and the second sub-connector is connected with a second PCIe board; the first sub-connector and the second sub-connector are respectively provided with an AC coupling capacitor. According to the invention, the number of the via holes in the PCIe board can be effectively reduced, so that the routing efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

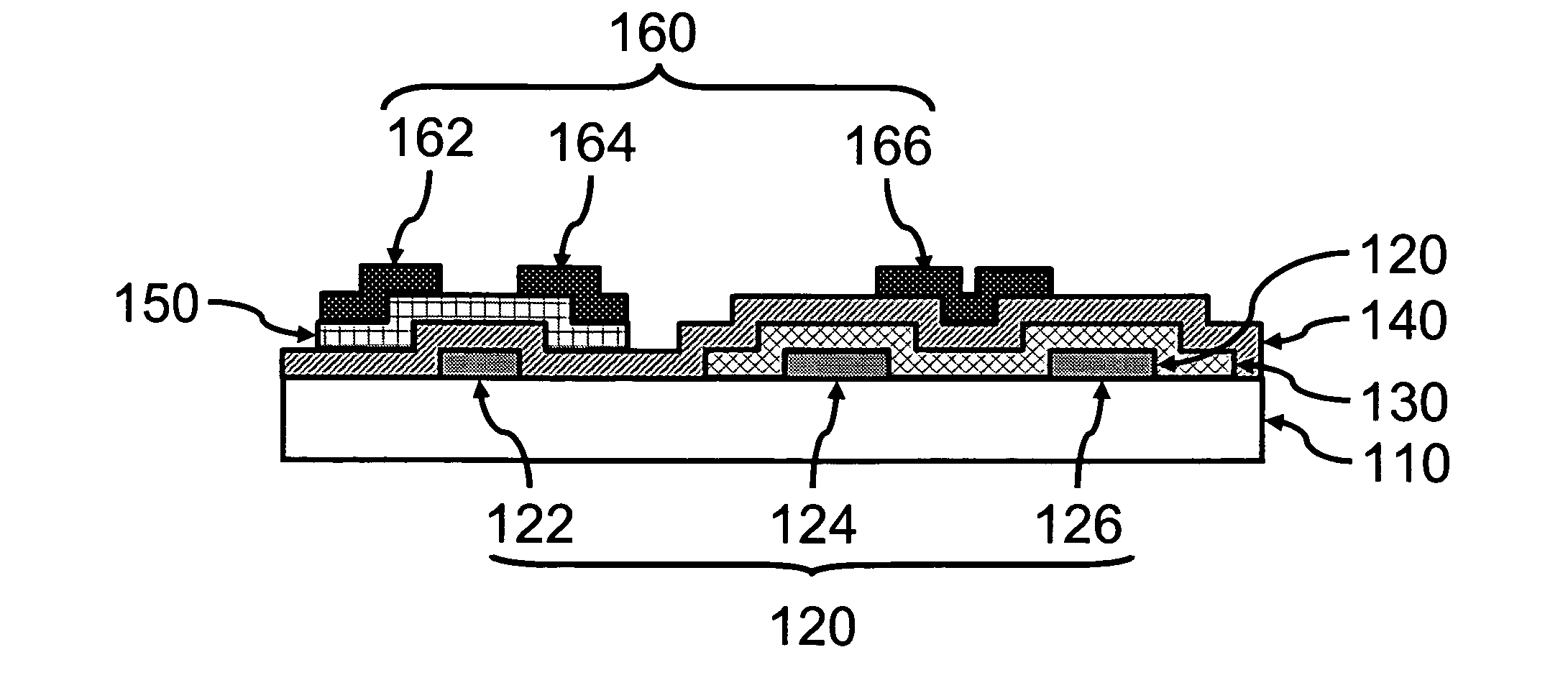

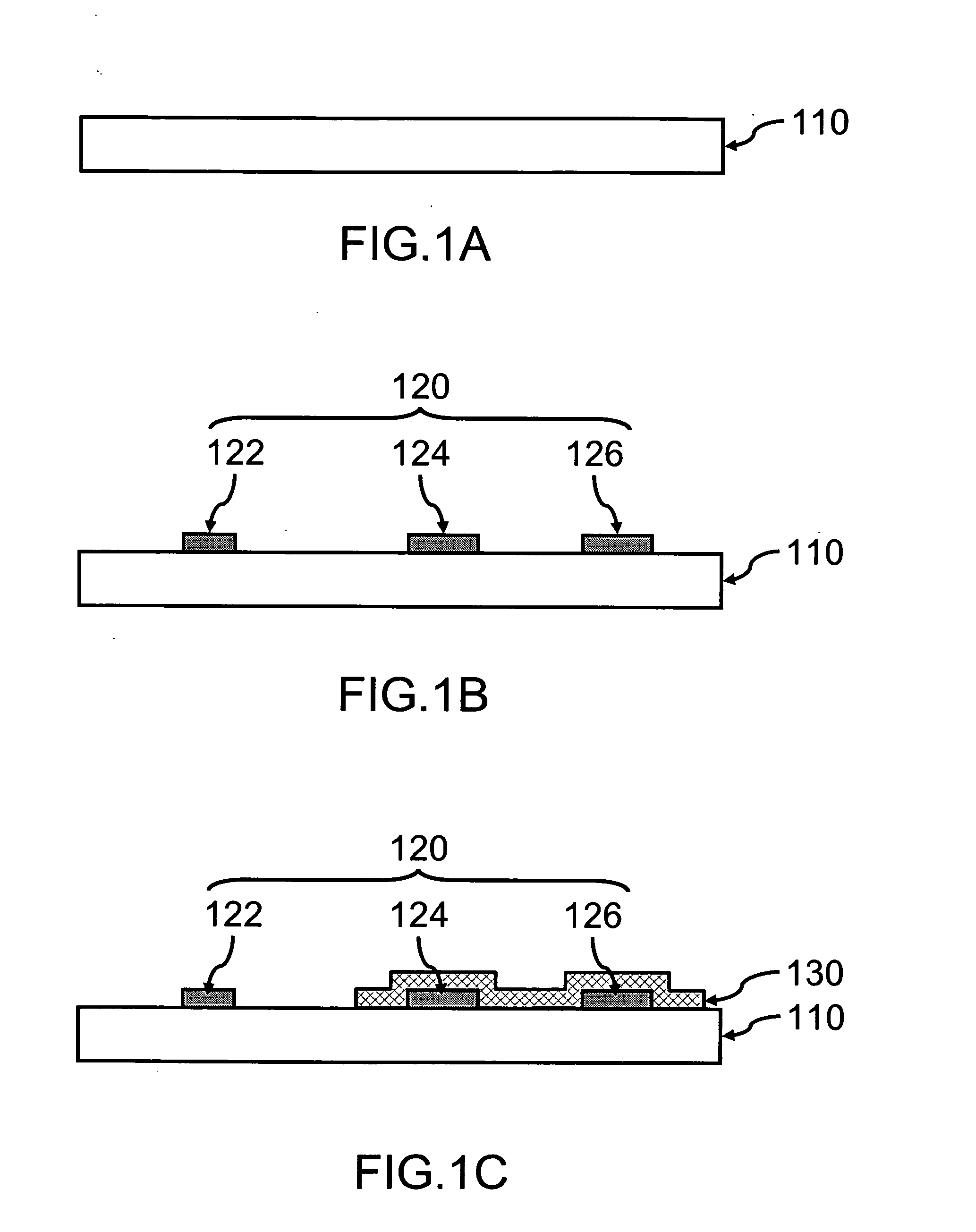

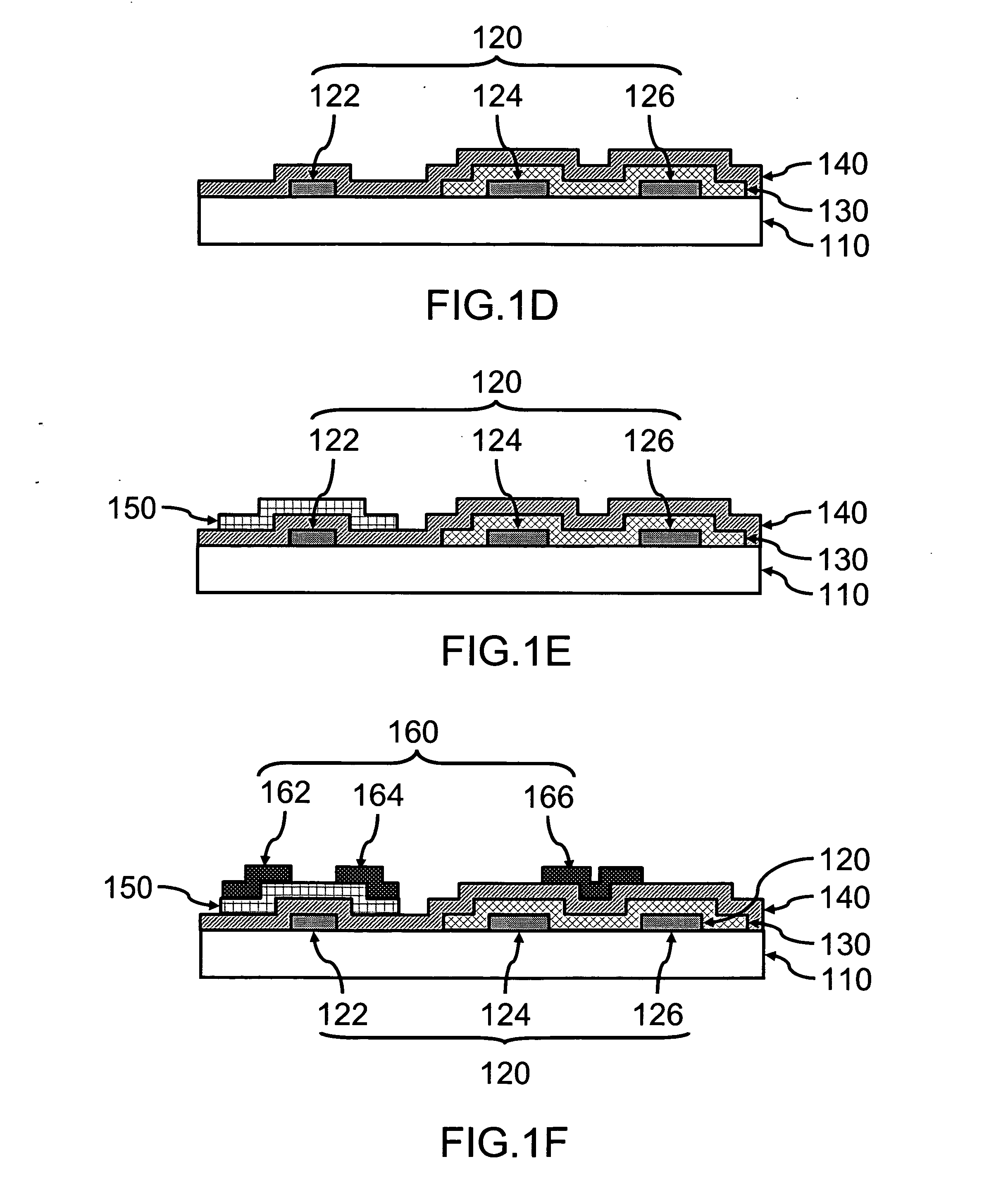

Manufacturing method of PCB and PCB

InactiveCN107708334AImprove routing densityReduce the number of viasPrinted circuit aspectsElectrical connection printed elementsNetwork connectionEngineering

The invention discloses a manufacturing method of a PCB and a PCB. The manufacturing method includes: an inner circuit pattern is manufactured at an inner core plate and then the processed inner coreplate is pressed with an outer core plate to form a PCB; a step-shaped through hole is formed in the PCB and plated-through-hole electroplating is carried out on the through hole, wherein the step-shaped through hole includes a first through hole portion and a second through hole portion in an axial direction and the aperture of the first through hole portion is larger than that of the second through hole portion; and the copper layer of the inner wall of the stepped through hole is broken along the radial direction of the step-shaped through hole to form at least two parts not in conduction.According to the invention, the copper layer of the inner wall of the stepped through hole of the PCB is divided into four parts not in conduction by two-times disconnection and each part of copper layer serves as a network connection layer separately, so that four network connection layers is realized by one step-shaped through hole. Therefore, the via hole number is reduced and the wiring density of the PCB is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS

A micro turbine generator

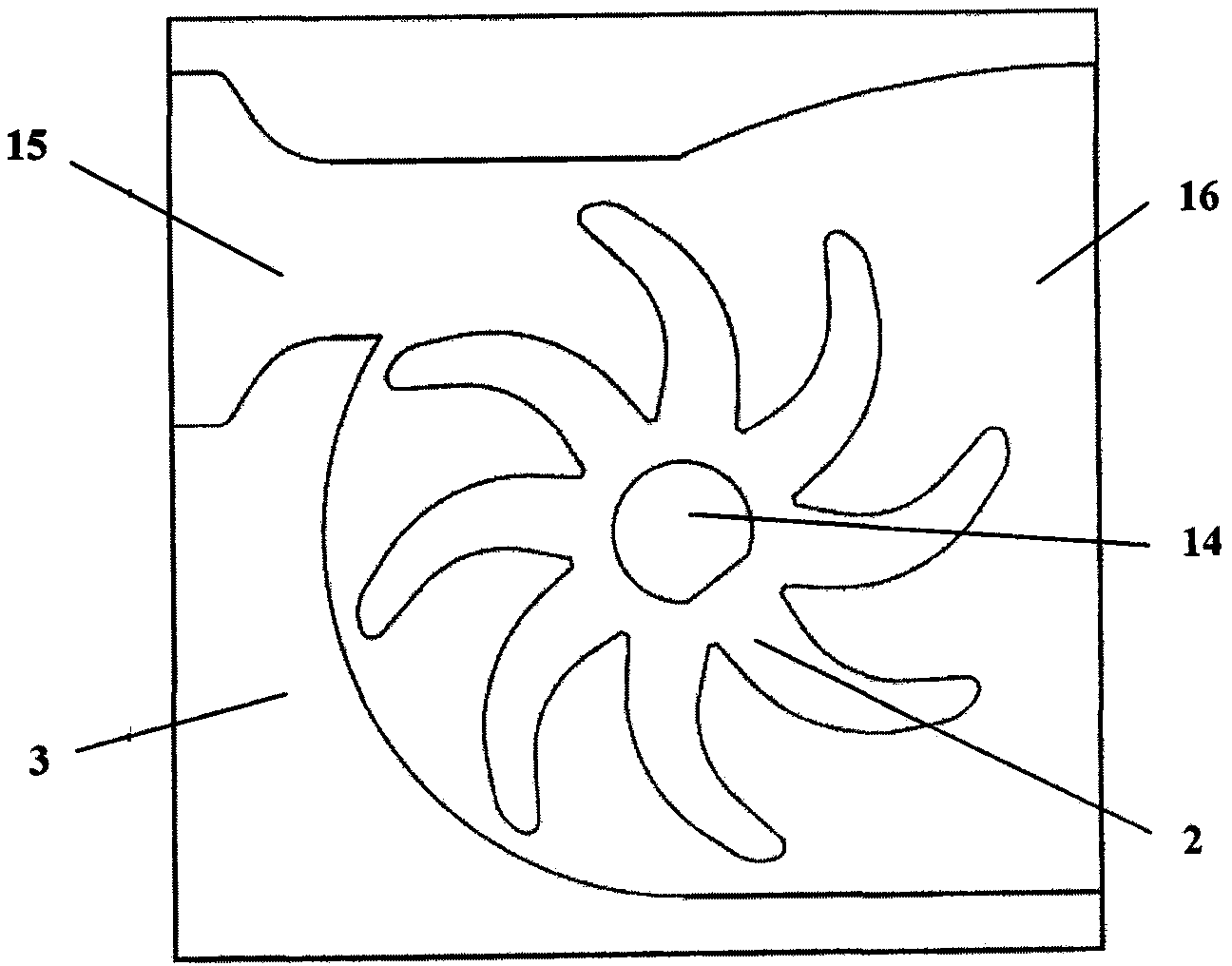

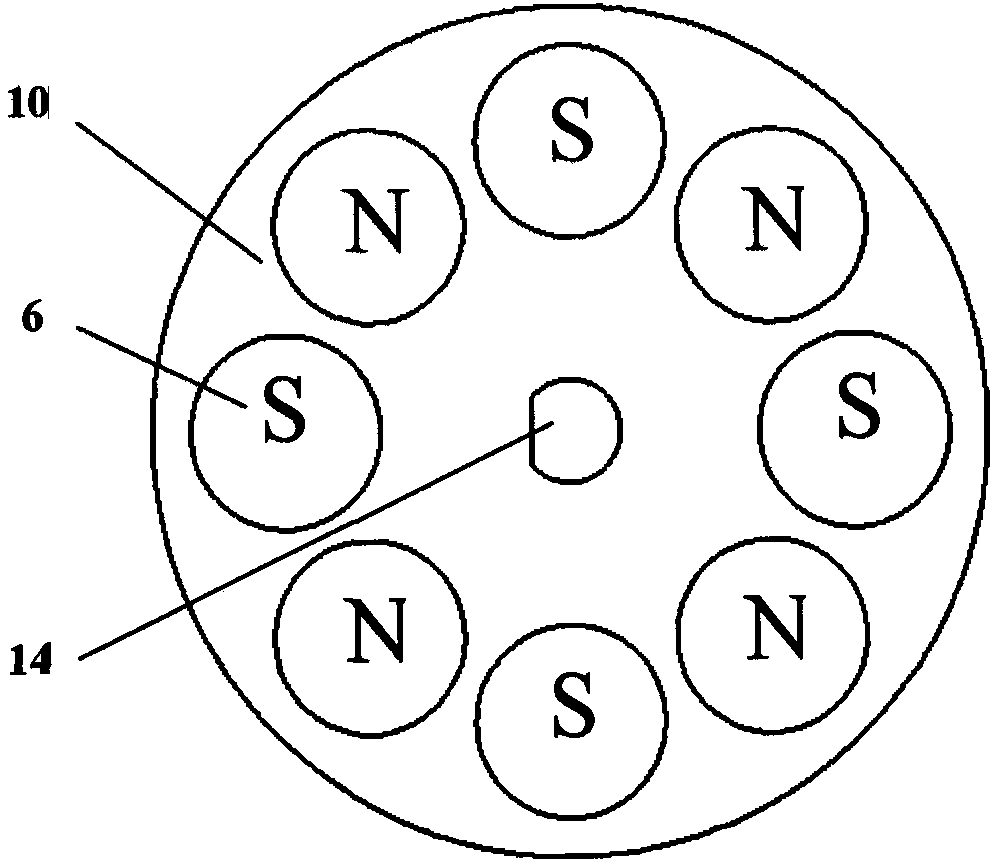

InactiveCN105659774BLarge input energyIncrease the number of turnsWind motor combinationsMachines/enginesFlexible circuitsEngineering

The present invention relates to a microturbine generator, comprising: ① micro pneumatic turbine: including a cavity, a turbine, and an upper baffle; the cavity and the upper baffle form a gas passage; ② micro generator: including a stator and a rotor; Composed of circuit board and stator yoke, the stator yoke is embedded in the lower end cover, the coil is processed on the flexible circuit board, and the flexible circuit board is attached to the exposed side surface of the stator yoke: the rotor is composed of the rotor yoke, the rotor base plate and the permanent magnet Composition; ③ transmission device: including rotating shaft, upper bearing and lower bearing; the fixed connection between the turbine and the rotating shaft, and the fixed connection between the rotating shaft and the rotor; ④ housing: the rotating shaft is connected to the upper end cover of the housing through the upper bearing, and the It is connected with the lower partition of the casing, and plays the role of fixing the rotating shaft and transmitting the power of the rotating shaft. The invention is suitable for the power supply device of the bullet fuze of the artillery sub-communication ammunition and other equipments requiring the miniature power supply device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

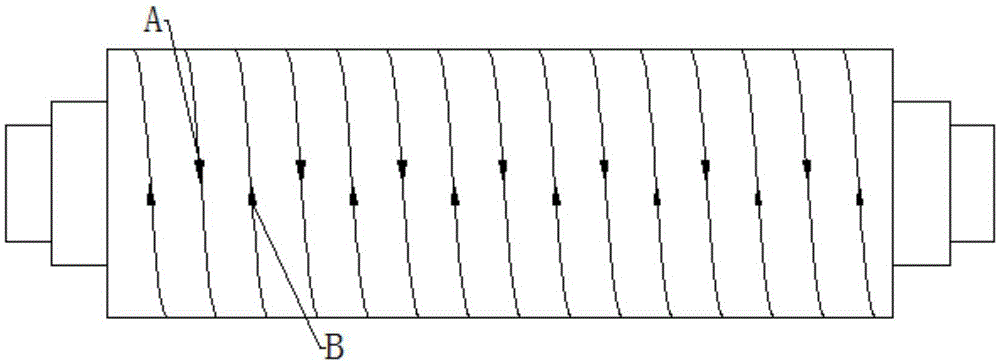

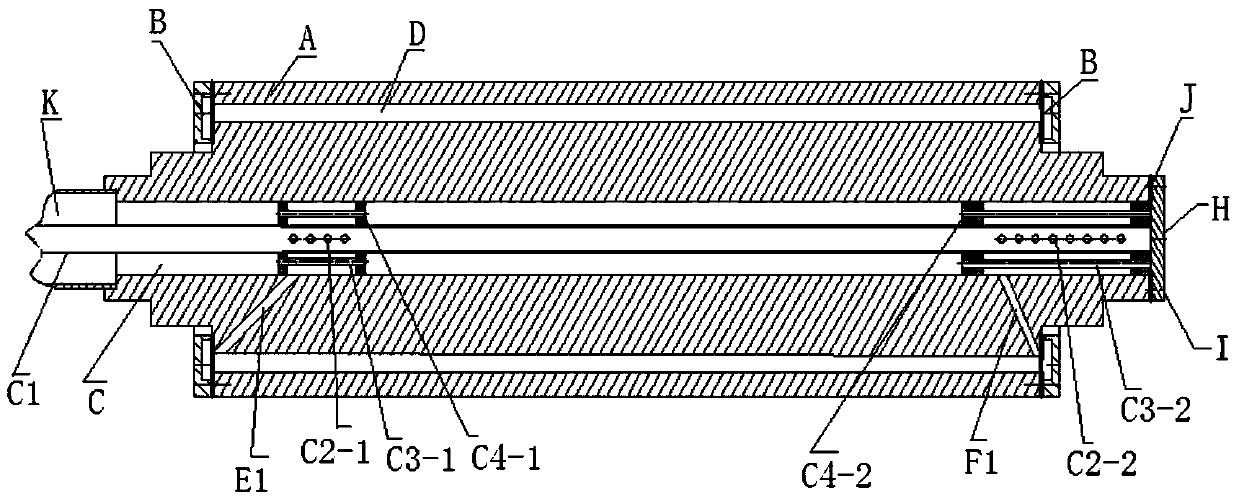

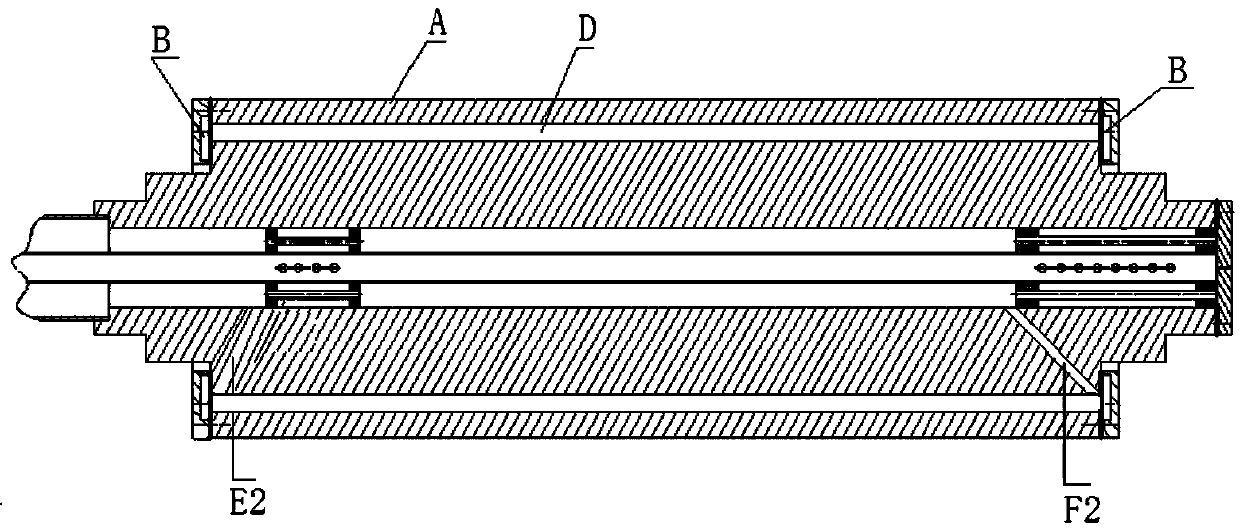

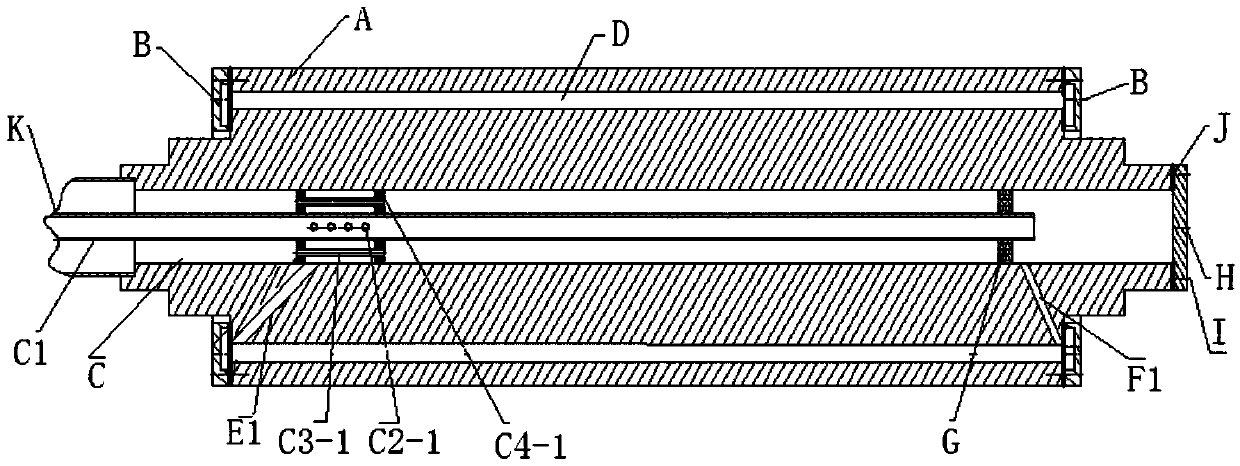

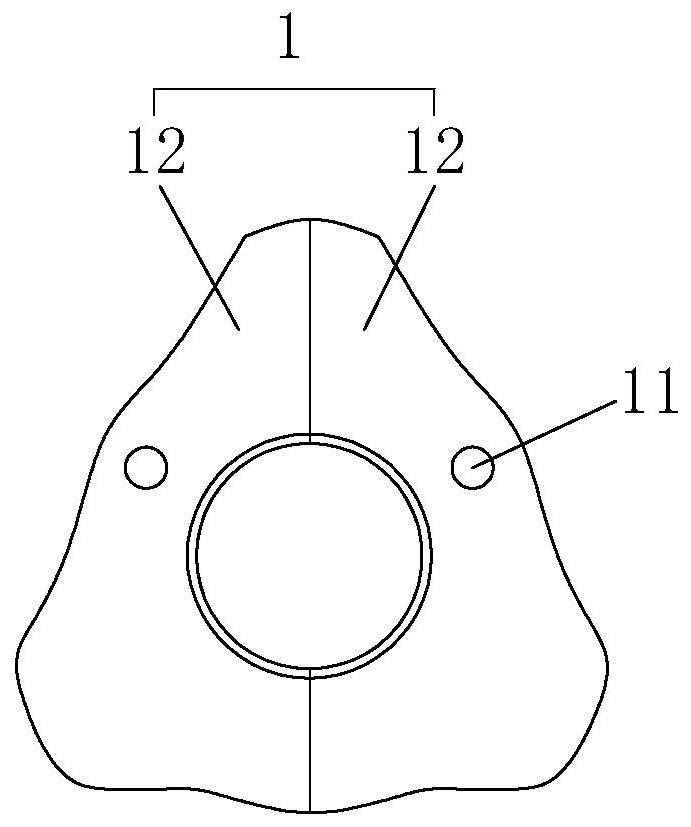

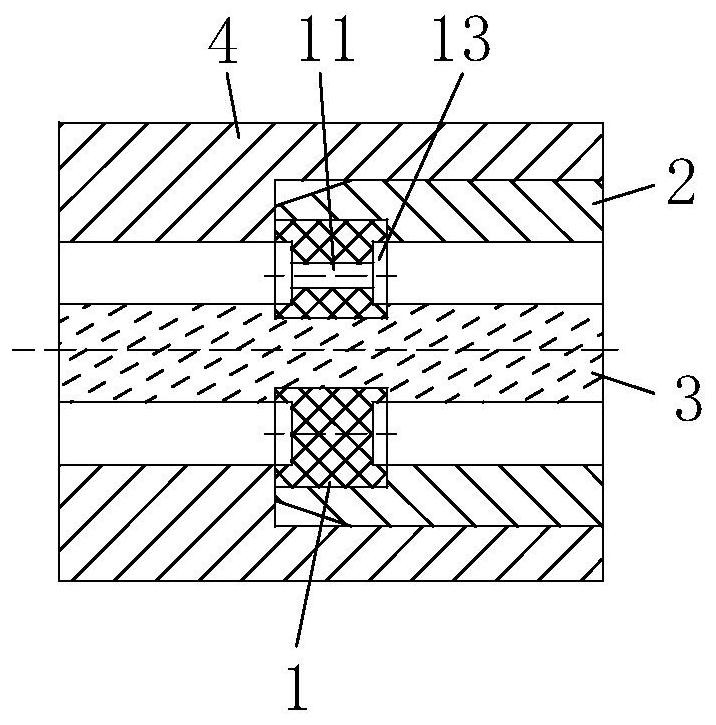

Combined roller of open mill or calender

The invention belongs to the field of roller structures of open mills or calenders, and discloses a combined roller of an open mill or a calender. The roller comprises a mandrel and a sleeve coating the mandrel; the mandrel includes an inner cavity and two parallel spiral medium runners formed in the surface of the mandrel; and the inner cavity includes a mandrel through hole, an inner pipe arranged in the mandrel through hole and a shunt backflow device. A medium of the roller synchronously flows in from two ends, and flows in two directions, so that the heating and cooling uniformity of a cylinder working surface of the calender or the open mill is guaranteed, the problems of high roller temperature difference and nonuniform heating and cooling are solved, and the roller heating or cooling effect is improved; the number of the through hole of the roller is few; the structure is simple; enough mechanical strength and rigidity of the roller are guaranteed; and under the precondition of guaranteeing the mechanical strength, the roller can change the pipe diameter size of a liquid inlet pipe, the number and the size of the through hole and the size of a medium access port to control the flow of the heating or cooling medium so as to influence the temperature control effect.

Owner:青岛首科新材料有限公司

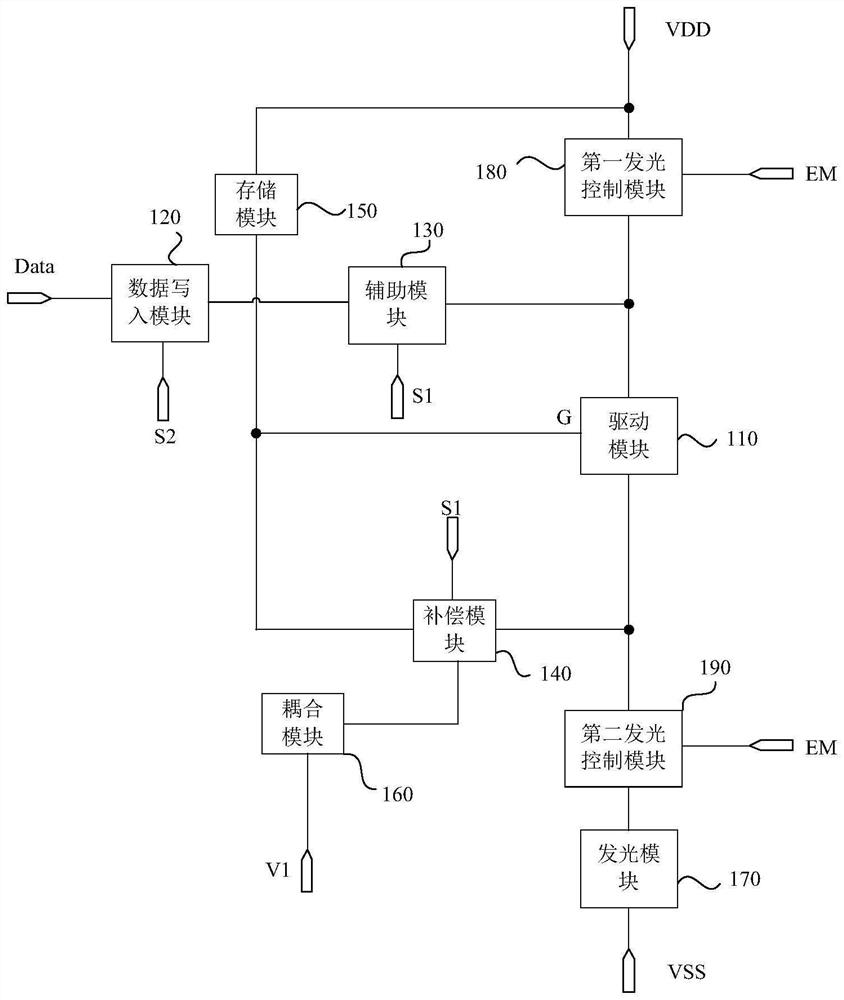

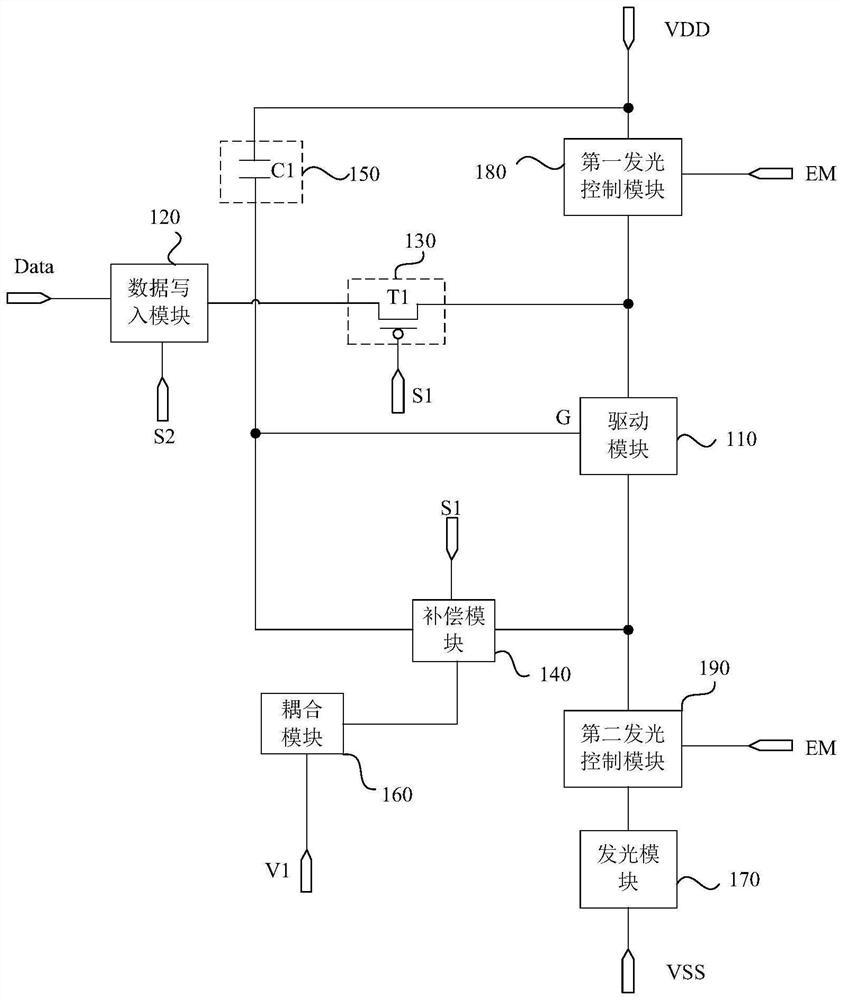

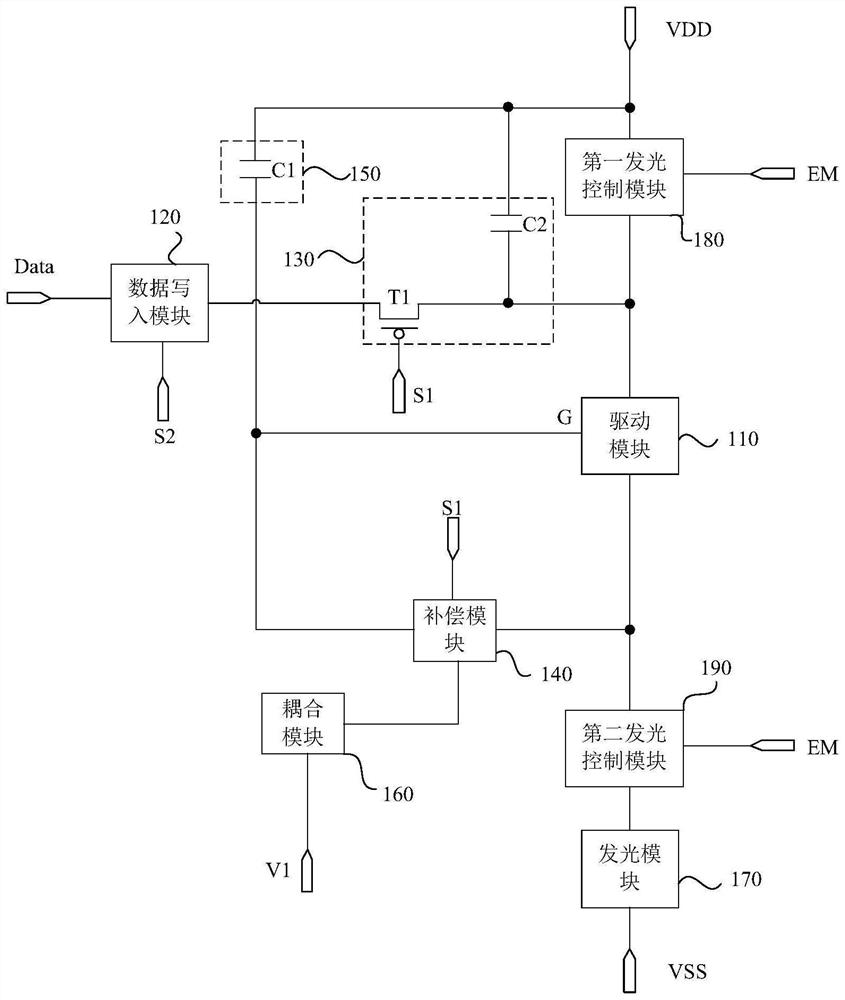

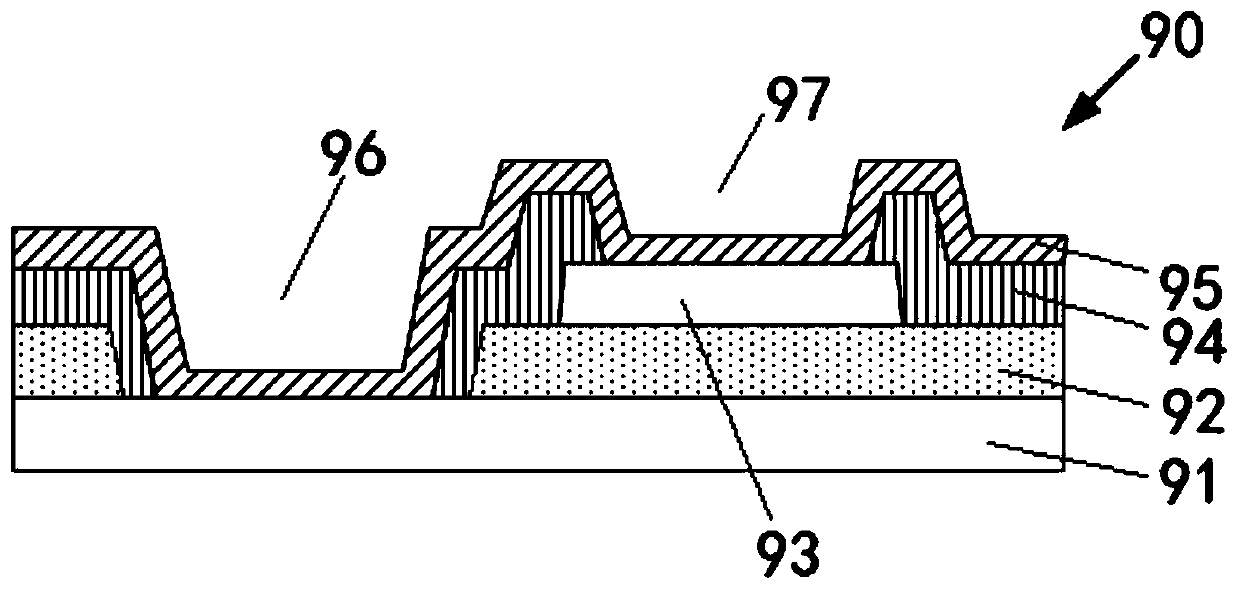

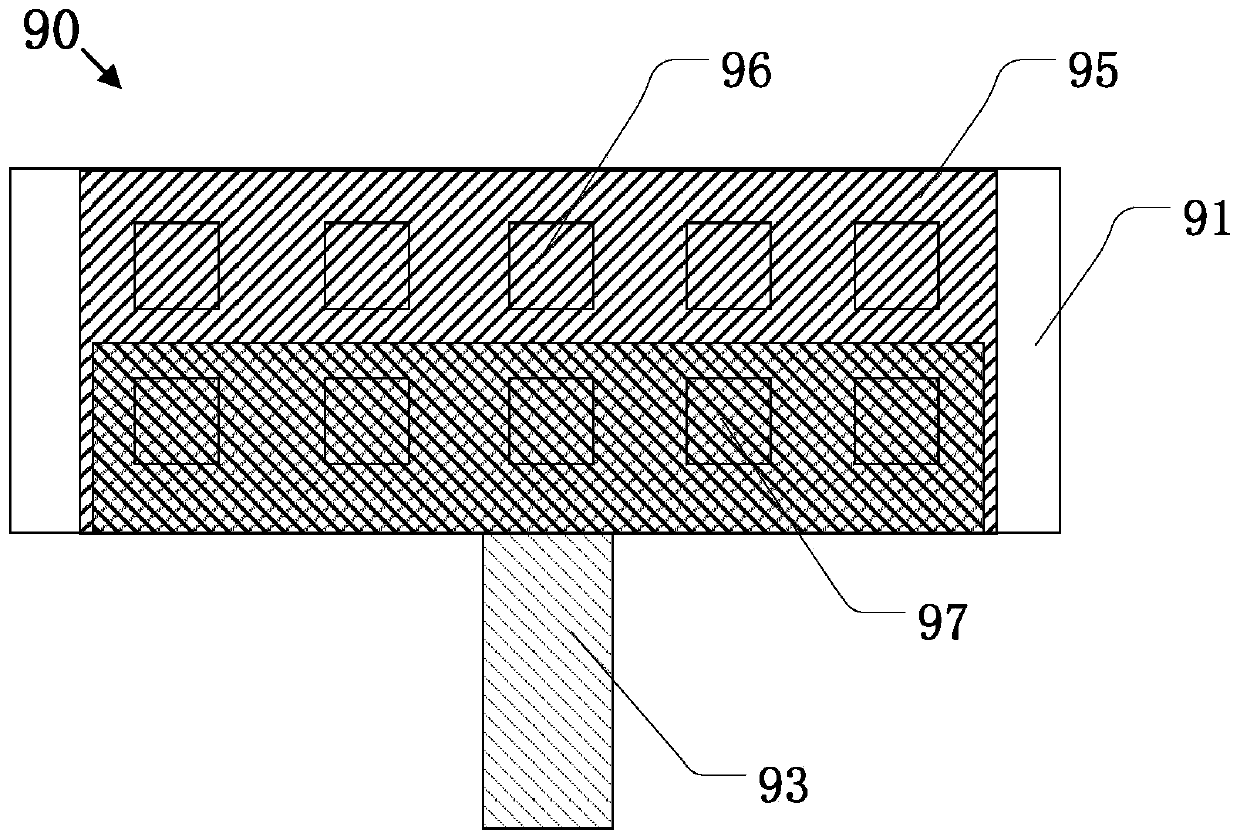

Pixel circuit, driving method thereof and display panel

PendingCN114708832AReduce layout areaImprove threshold compensation effectStatic indicating devicesHemt circuitsComputer science

The embodiment of the invention discloses a pixel circuit, a driving method thereof and a display panel. The pixel circuit comprises a driving module, a data writing module, an auxiliary module, a compensation module, a storage module, a coupling module and a light emitting module, the data writing module is used for writing data voltage into the control end of the driving module through the auxiliary module; the compensation module is connected between the first end and the control end of the driving module and is used for compensating the threshold voltage of the driving module; the coupling module is connected with the compensation module and is used for adjusting the voltage of the control end of the driving module through the compensation module according to the received jump voltage; the storage module is connected with the control end of the driving module, and the driving module is used for providing driving signals for the light-emitting module according to the voltage of the control end and driving the light-emitting module to emit light. According to the pixel circuit provided by the embodiment of the invention, the compensation effect can be improved, and meanwhile, the number of via holes is reduced, so that the layout area of pixels is reduced, and high PPI can be realized.

Owner:YUNGU GUAN TECH CO LTD

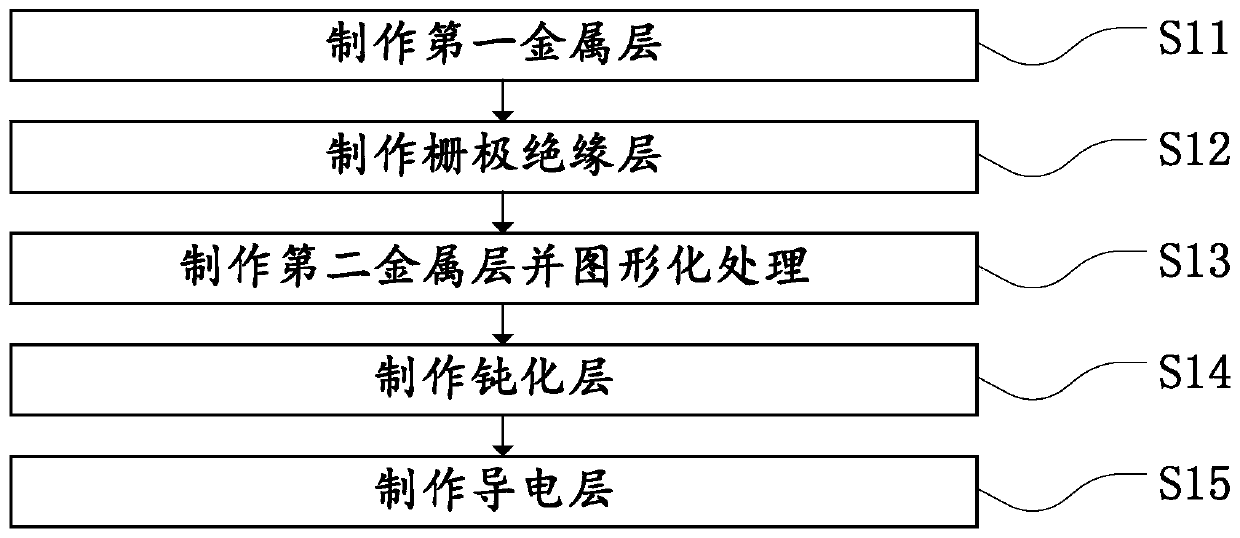

Array substrate, display panel and manufacturing method of array substrate

InactiveCN110993623AImprove reliabilityLower impedanceSolid-state devicesSemiconductor/solid-state device manufacturingHemt circuitsEngineering

The invention discloses an array substrate, a display panel and a manufacturing method of the array substrate. The array substrate is provided with a row driving region, and the row driving region comprises a first metal layer, a gate insulating layer and a second metal layer; the gate insulating layer is located on the first metal layer, and the gate insulating layer is provided with a through hole; and the second metal layer is located on the gate insulating layer and extends to the inner side wall of the first through hole and the surface of the first metal layer corresponding to the through hole. Impedance is reduced through direct contact between the first metal layer and the second metal layer, so that hole burning abnormity is not liable to occur, and the panel yield and the panel reliability are improved; and moreover, the number of through holes in the gate insulating layer can be relatively reduced, the circuit space limitation of the row driving region is reduced, and a narrow frame is favorably realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

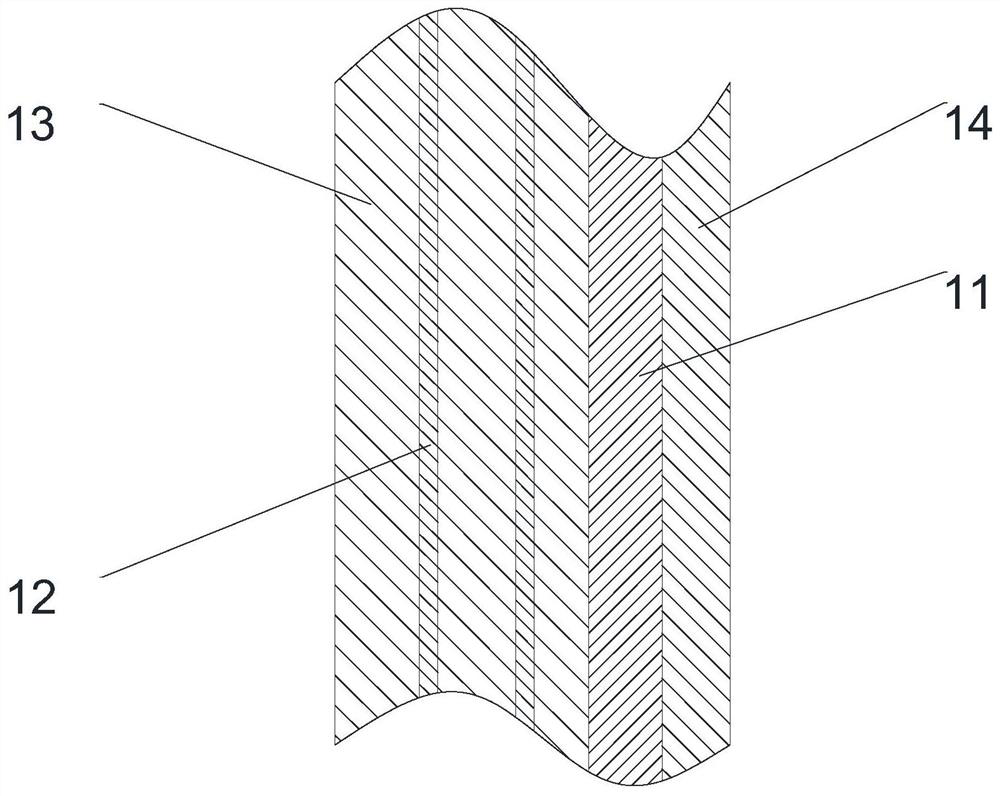

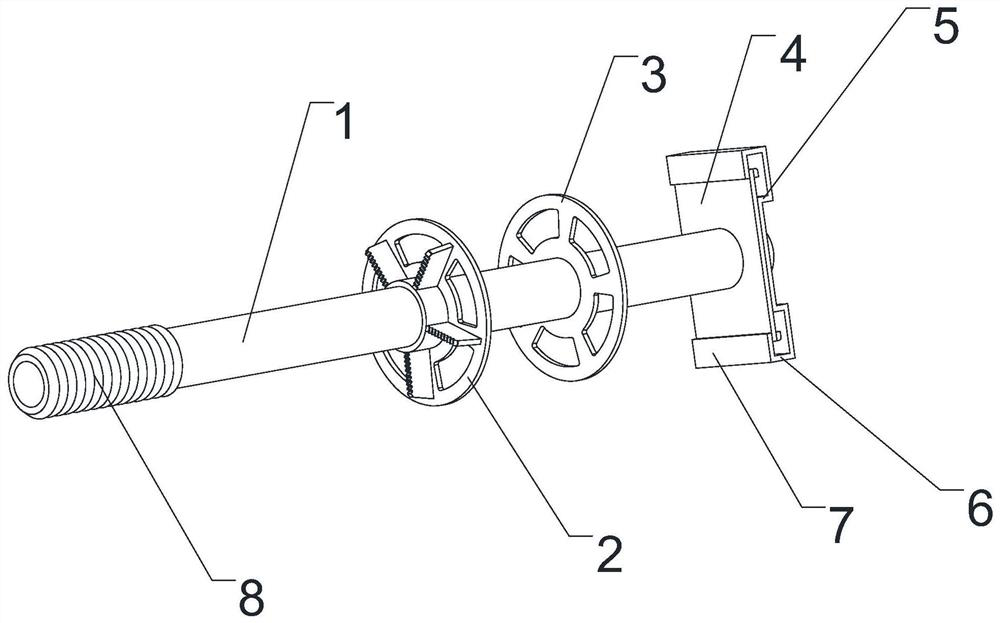

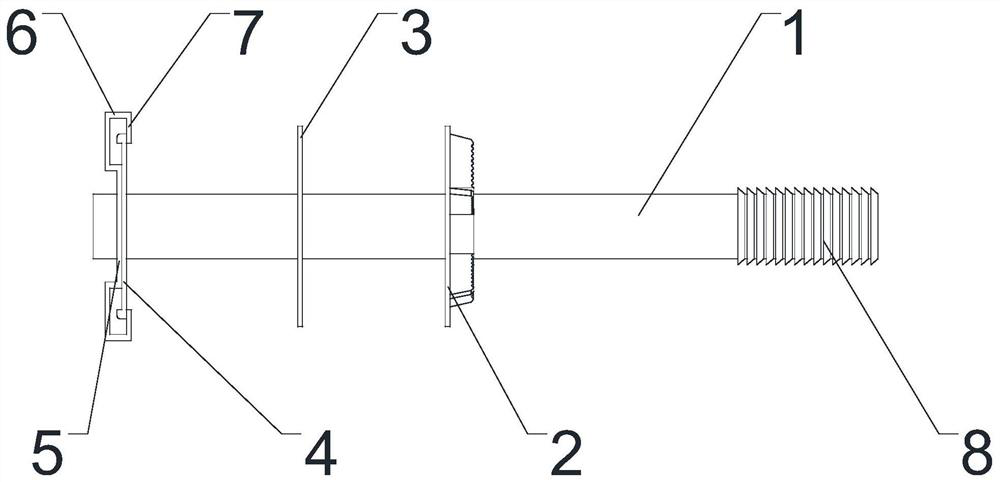

Tubular connecting piece and cast-in-place concrete built-in thermal insulation wall body

PendingCN111705963APrevent disengagementImprove smoothnessWallsHeat proofingInsulation layerThermal insulation

The invention relates to the field of building template connection supporting, and relates to a tubular connecting piece. The tubular connecting piece solves the problem that a tubular connecting piece is not connected with a steel wire mesh piece in the prior art. The tubular connecting piece comprises a pipe body. An axial channel of the pipe body penetrates through the pipe body to form openings in the two ends of the pipe body. A first limiting piece, a second limiting piece and a connecting mechanism are arranged on the outer side wall of the pipe body. The connecting mechanism and the first limiting piece are correspondingly located on two sides of the second limiting piece. The steel wire mesh piece can apply a tensile force to an outer wall layer, the firmness of the combination ofthe outer wall layer and a thermal insulation layer is enhanced, and the outer wall layer is prevented from being separated from the thermal insulation layer. The cast-in-place concrete built-in thermal insulation wall body comprises the inner wall layer, the outer wall layer, the thermal insulation layer located between the inner wall layer and the outer wall layer and a tubular connecting piece. The pipe body penetrates through the inner wall layer, the thermal insulation layer and the outer wall layer. The steel wire mesh piece is arranged in the outer wall layer. A first end piece and a second end piece are located on the two sides of the steel wire mesh piece correspondingly. The thermal insulation layer is located between the first limiting piece and the second limiting piece.

Owner:山东赛昌新型材料有限公司

Etching equipment and etching method

InactiveCN111668081AImprove effective utilizationReduce physical size non-uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingWaferPlasma generator

The invention provides etching equipment and an etching method. The etching equipment comprises a plasma generator, a flow homogenization disc, a baffle assembly and a wafer moving assembly, wherein the baffle assembly is arranged between a plasma generator and the flow homogenization disc in an openable and closable manner, when the baffle assembly is opened, a window is formed to expose one partof the flow homogenization disc so as to allow plasma to reach the flow homogenization disc through the window, and the wafer moving assembly is arranged below the flow homogenization disc and is used for bearing a to-be-etched wafer and driving the to-be-etched wafer to move, so that the to-be-etched region of the wafer passes through a region below the part, exposed by the window, of the flow homogenization disc according to a preset path and is etched by plasmas passing through the flow homogenization disc. According to the invention, the etching uniformity can be improved, the spare partcost and the equipment maintenance workload can be reduced to a certain extent, and the radio frequency power consumption is reduced.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Bi-directional temperature-controlling roller of open mill or calendaring machine

The invention belongs to the field of roller structures of open mills or calendaring machines, and discloses a bi-directional temperature-controlling roller of an open mill or calendaring machine. The roller comprises a roller body, end covers which are installed at the two ends of the roller body and provided with track grooves and a plurality of temperature-controlling through holes formed in the roller body, and the temperature-controlling through holes are communicated through the track grooves of the end covers in a spaced mode to form two snake-shaped through holes. According to the roller, a medium flows bi-directionally and is fully distributed on the surface of the whole roller, therefore, uniform heating or cooling of the working surface of the roller body of the open mill or calendaring machine is guaranteed, the problems that the roller temperature difference is large, and temperature controlling is not uniform are solved, and the heating or cooling effect of the roller is improved; the quantity of the through holes is small, the structure is simple, and therefore it is guaranteed that the roller has the enough mechanical strength and rigidity; on the premise that the mechanical strength is guaranteed, the roller can control the flow of the medium by changing the pipe diameter of a liquid inlet pipe, the size of through holes and the size of a medium inlet and a medium outlet, and then the heating or cooling effect is influenced.

Owner:青岛众屹科锐工程技术有限公司

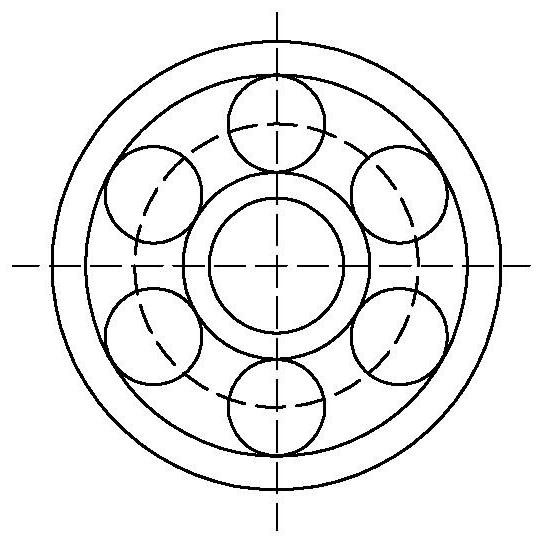

Insulator structure for power transmission and transformation project and installation method

ActiveCN112992438AImprove insulation support strengthReduce volumeSuspension arrangements for electric cablesSuspension/strain insulatorsInterference fitElectrical conductor

The invention relates to an insulator structure for a power transmission and transformation project and an installation method. The insulator structure for the power transmission and transformation project comprises an insulator body with a triangular end face, a pressing sleeve, a connector inner conductor and a connector outer conductor, wherein two air holes are uniformly formed in the insulator body, the insulator body is clamped and fixed on the connector inner conductor, the insulator body and the connector inner conductor are detachably fixed in the pressing sleeve, the pressing sleeve is detachably fixed in the connector outer conductor, an outer wall of the connector inner conductor is in interference fit with an inner wall of the insulator body, and an outer wall of the insulator body is in interference fit with an inner wall of the connector outer conductor. The number of the insulator through holes is reduced to two, so the risk can be effectively avoided, the insulation support strength of the insulator is improved, and the part assembly process performance is good.

Owner:福建榕灿电气科技有限公司

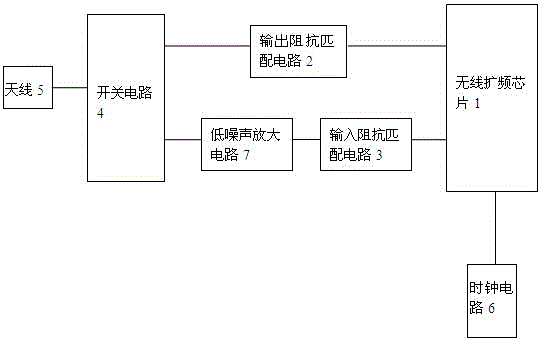

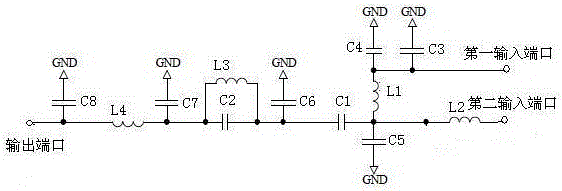

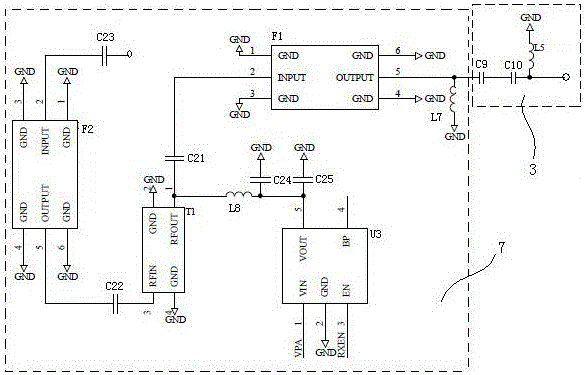

Gas meter wireless spread spectrum transceiver system and its pcb layout structure

ActiveCN104868934BImprove stabilityImprove anti-interference abilityTransmissionTransceiverInput impedance

The invention relates to the design field of radio-frequency circuits, and particularly relates to an improved gas meter wireless spread spectrum transceiving system and a printed circuit board (PCB) layout structure thereof. In the improved gas meter wireless spread spectrum transceiving system, an output impedance matching circuit is arranged between an output end of a wireless spread spectrum chip and a switch circuit, and an input impedance matching circuit and a low noise amplifier circuit are arranged between an input end of the wireless spread spectrum chip and the switch circuit. Through arrangement of the input impedance matching circuit and the output impedance matching circuit, matching of impedances of an input link and an output link is guaranteed, the low noise amplifier (LNA) circuit is arranged in a receiving link, so that the communication distance is lengthened by times when a module has the same transmitting power; in addition, the PCB layout structure provided by the invention adopts a four-layer layout manner, all components and parts are arranged on the same layer of the PCB so as to form an integral unified reference ground, so that the stability of the wireless spread spectrum transceiving system is further improved.

Owner:CHENGDU QIANJIA TECH CO LTD

Mobile Formwork Applicable to Multiple Beams and Its Construction Method

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Bracket set of small-sized LED lamp beads and brackets

InactiveCN104409451ALow densityLarge apertureSolid-state devicesSemiconductor devicesEngineeringLED lamp

The invention creatively provides a bracket set of small-sized LEDs and brackets formed by cutting the bracket set. The bracket set is formed by splicing a plurality of brackets; the brackets share a top point, and a through hole is formed in the top point shared by the brackets and used for allowing a conductive layer to be plated in, so that one conductive through hole can be shared by the brackets, the number of required through holes is effectively reduced, and the density of the through holes is reduced; moreover, the apertures of the through holes can be set to be relatively large, so that the process difficulty can be effectively lowered and the product yield can be increased.

Owner:MLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com