Small-sized LED lamp bead set and lamp beads

A technology of LED lamp beads and small size, which is applied in the direction of electrical components, electric solid devices, circuits, etc., which can solve the problems of poor electrical conductivity of products, huge process difficulty, and poor copper plating effect, so as to reduce density and process Difficulty, the effect of reducing the number of vias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described in conjunction with the following examples.

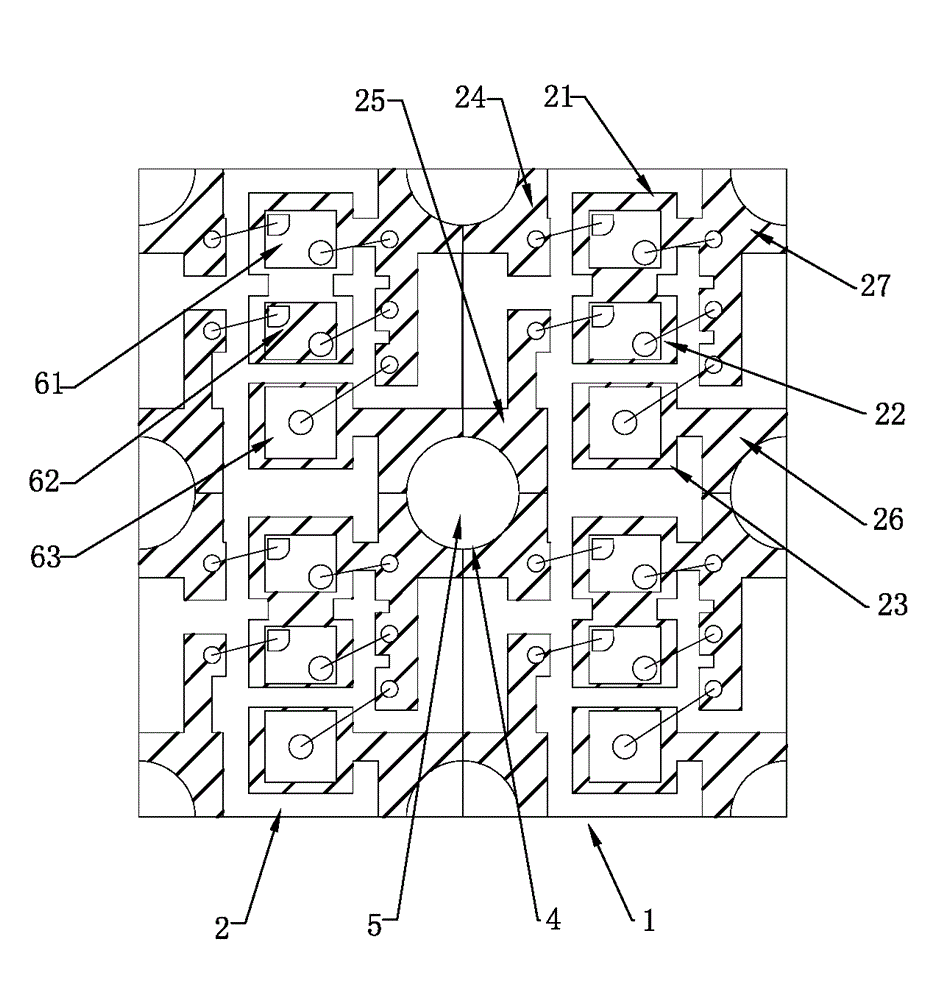

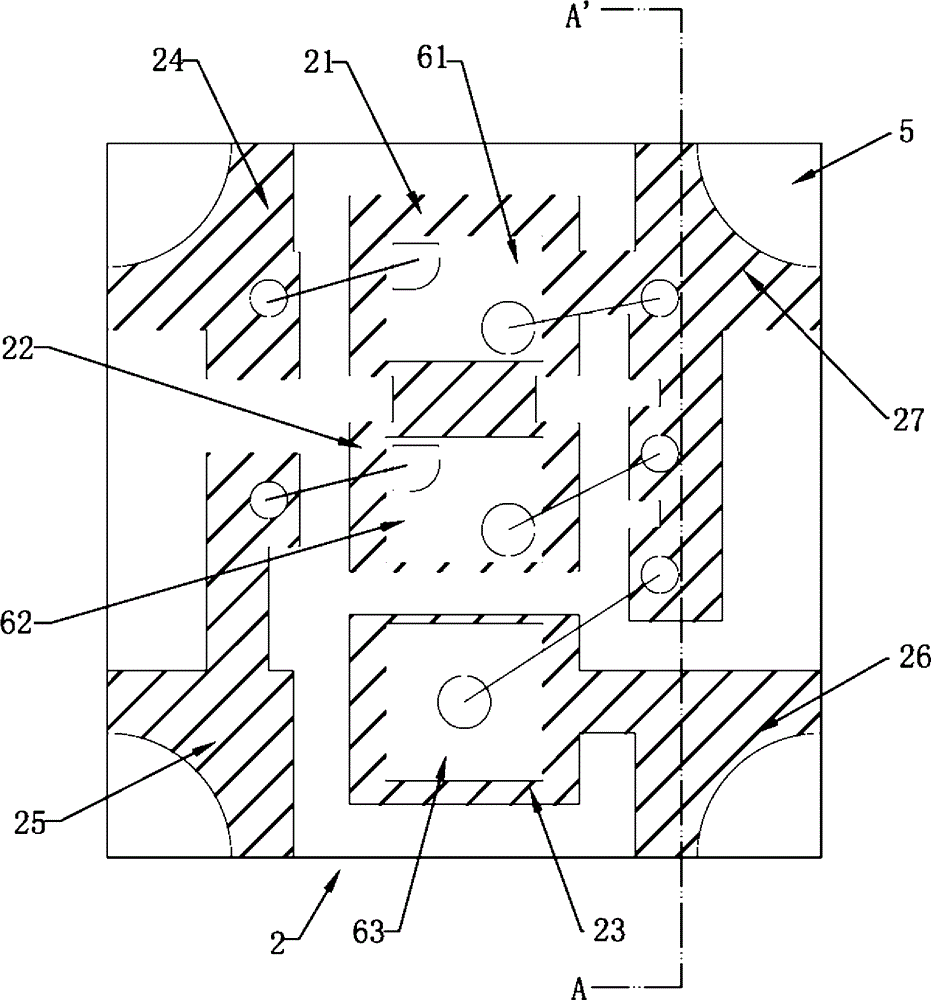

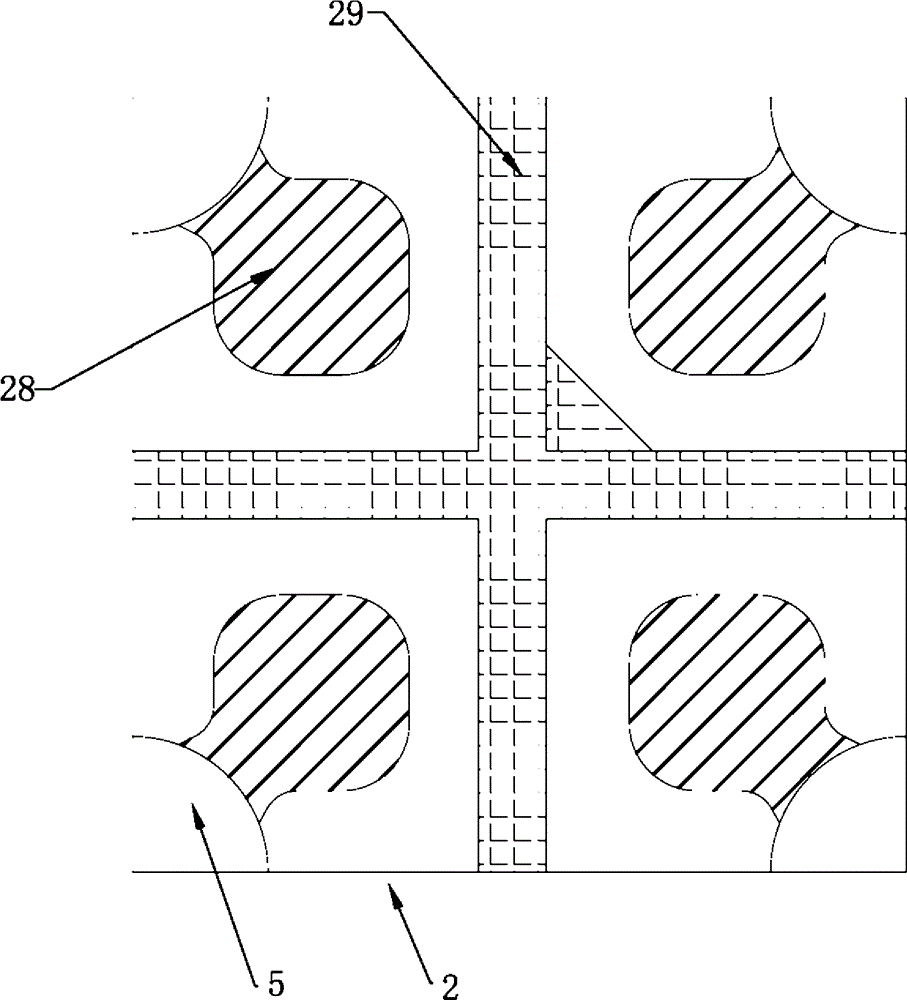

[0025] The present invention creates a specific embodiment of a small-sized LED lamp bead group, such as Figure 1 to Figure 3 As shown, it includes a bracket group and LED crystals fixed on the bracket group. The LED crystal includes a blue crystal 1, a green crystal 62 and a red crystal 63. The bracket group includes a square resin substrate 1 with a black upper surface. The resin substrate 1 Divide a plurality of quadrangular support substrates 2 (for ease of illustration, only four are shown in the figure), so that four adjacent quadrangular support substrates 2 share a vertex, and the front of each support substrate 2 is provided with roughly a The three crystal-bonding copper foils used to fix the LED crystal in a word arrangement are B crystal-bonding copper foil 21 for fixing blue light crystal 1, G crystal-bonding copper foil 22 for fixing green light crystal 62, and G crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com