Mobile Formwork Applicable to Multiple Beams and Its Construction Method

A technology of mobile formwork and construction methods, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of many times of passing holes, and achieve the effects of reducing the number of passing holes, saving materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a mobile formwork suitable for multi-width beams and a construction method, which reduces the number of passing holes, is simple to operate, and improves the safety of bridge construction. The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

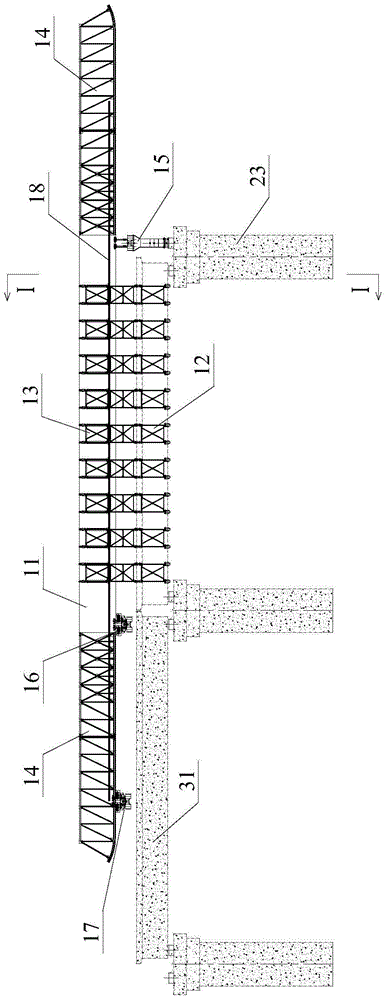

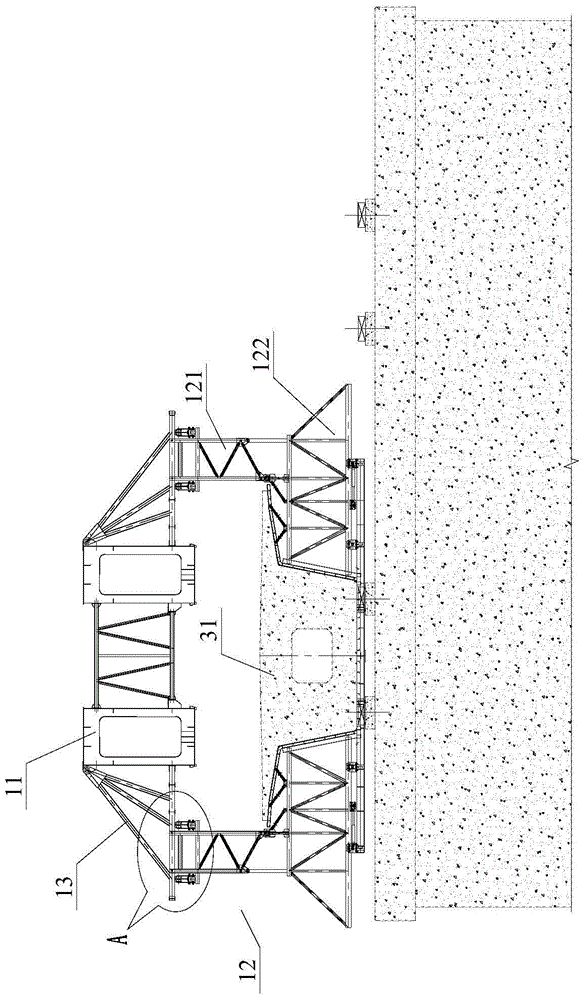

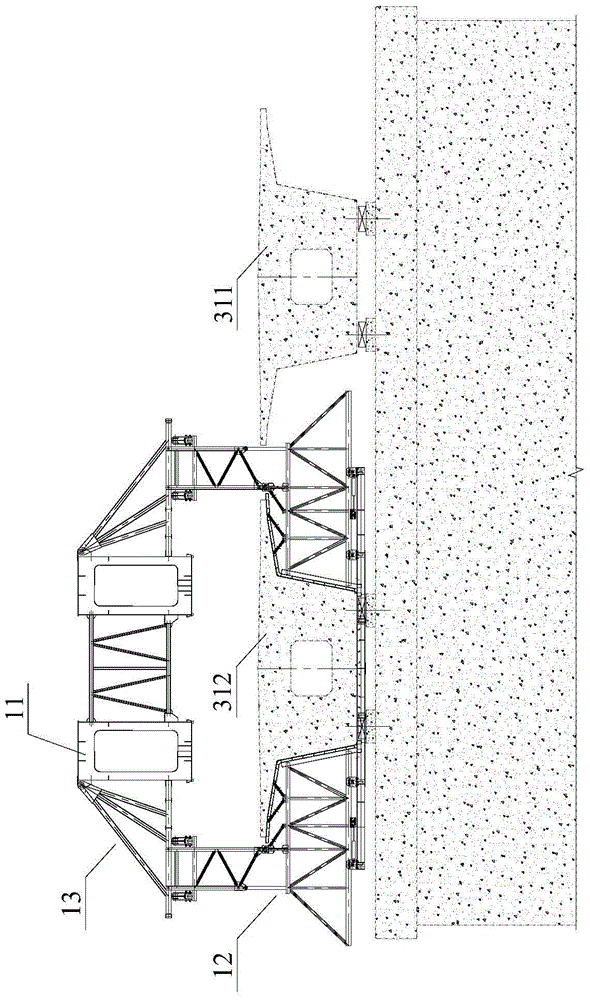

[0029] Such as figure 1 and Figure 5 As shown, the present invention provides a mobile formwork suitable for multiple beams, including a main beam 11 , a hanger 13 and a pouring form 12 .

[0030] A pair of main girders 11 that are consistent with the length direction of the bridge are fixedly connected, and guide beams 14 are provided at the front and rear ends, and front legs 15, middle legs 16 and rear legs 17 are slidably provided on the bottom surface.

[0031] Such as figure 2 , image 3 and Figure 4 As shown, the hanger 13 is arranged outside the two main girders 11, and the bottom surface of the hanger 13 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com