Printing circuit board with modified power zone block

A technology of printed circuit boards and multi-layer circuit boards, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problem of reducing the service life of printed circuit boards, generating heat, and destroying the integrity and stability of the power layer and ground layer. and other problems to achieve the effect of improving integrity, increasing service life and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

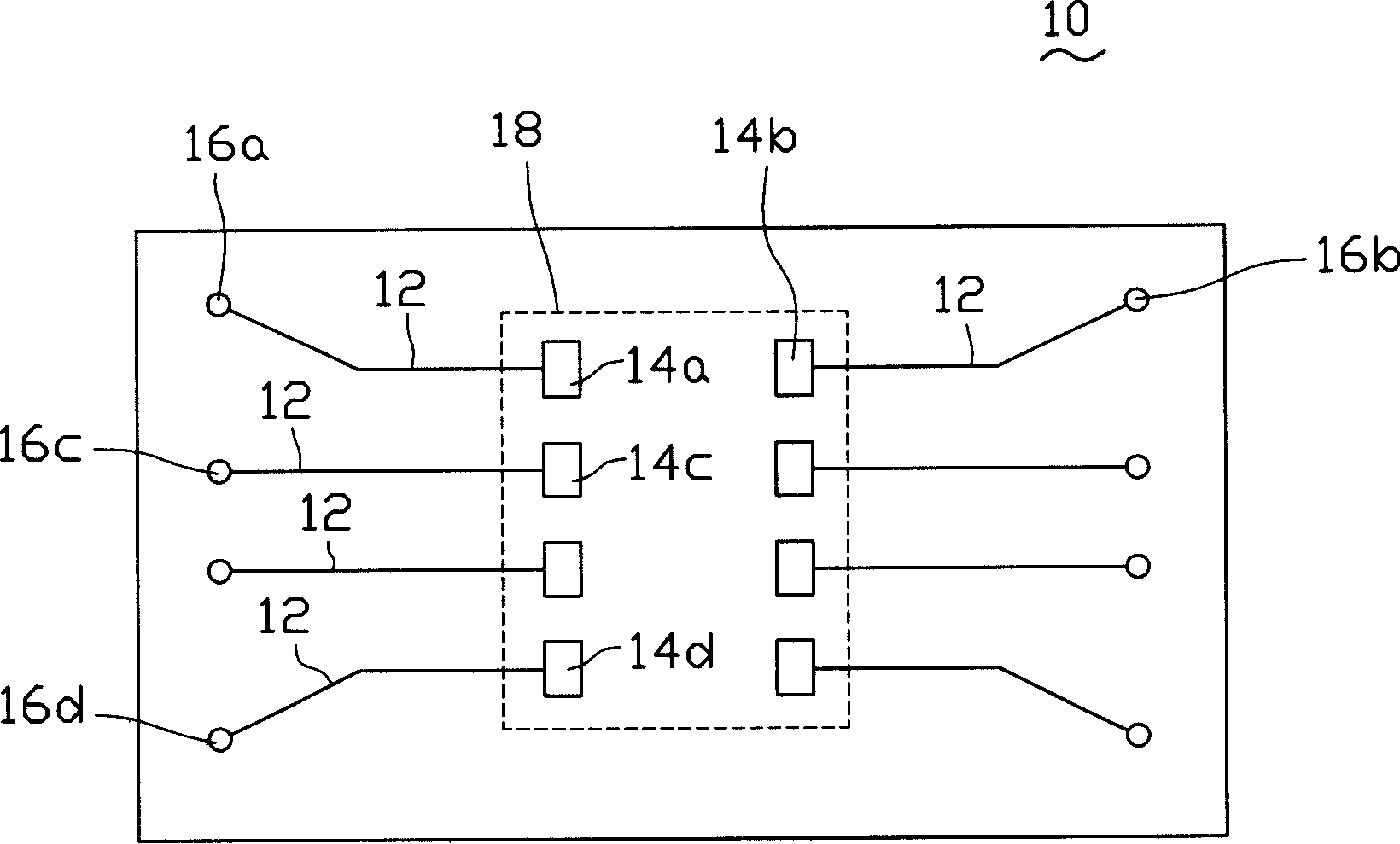

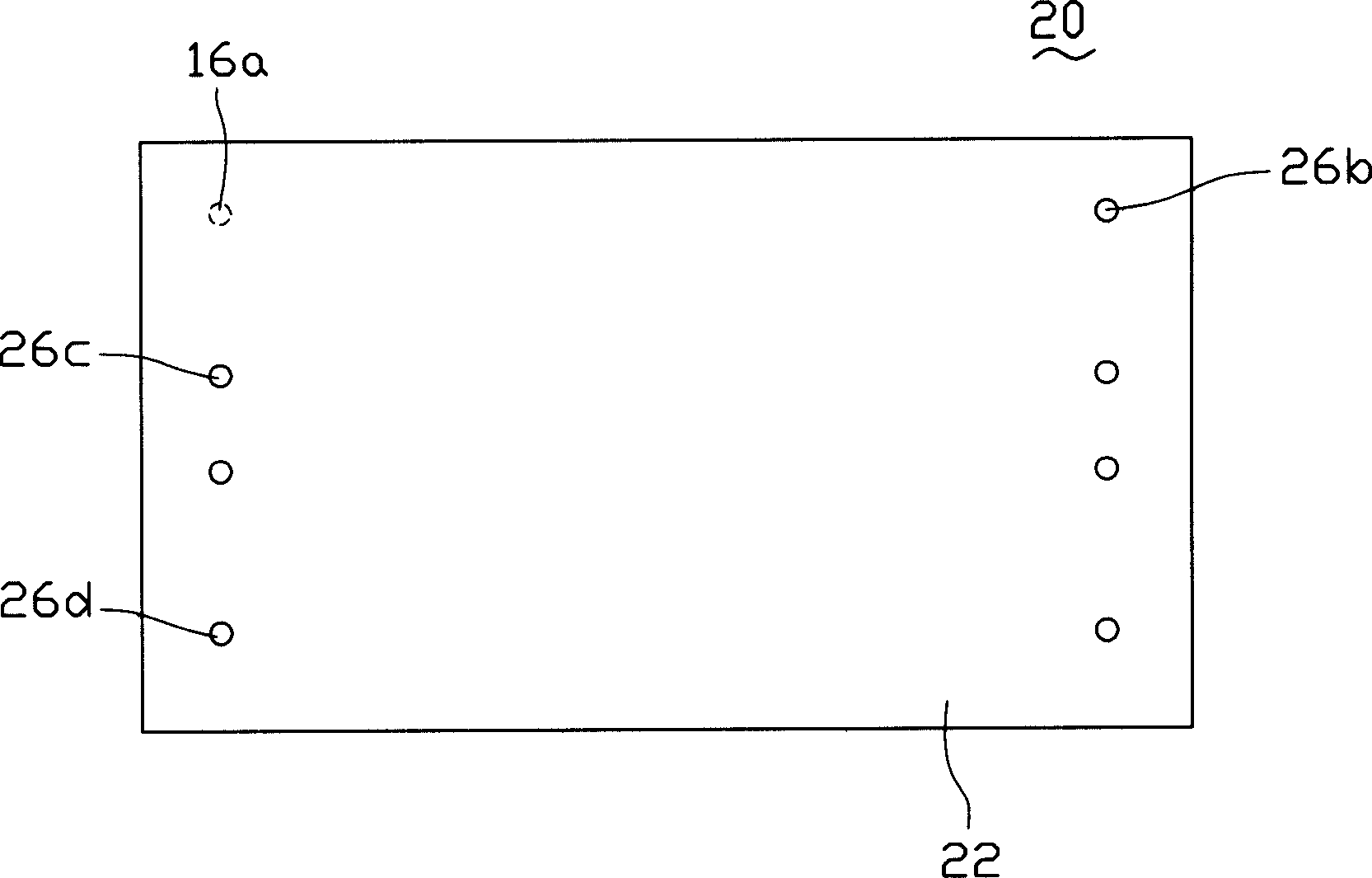

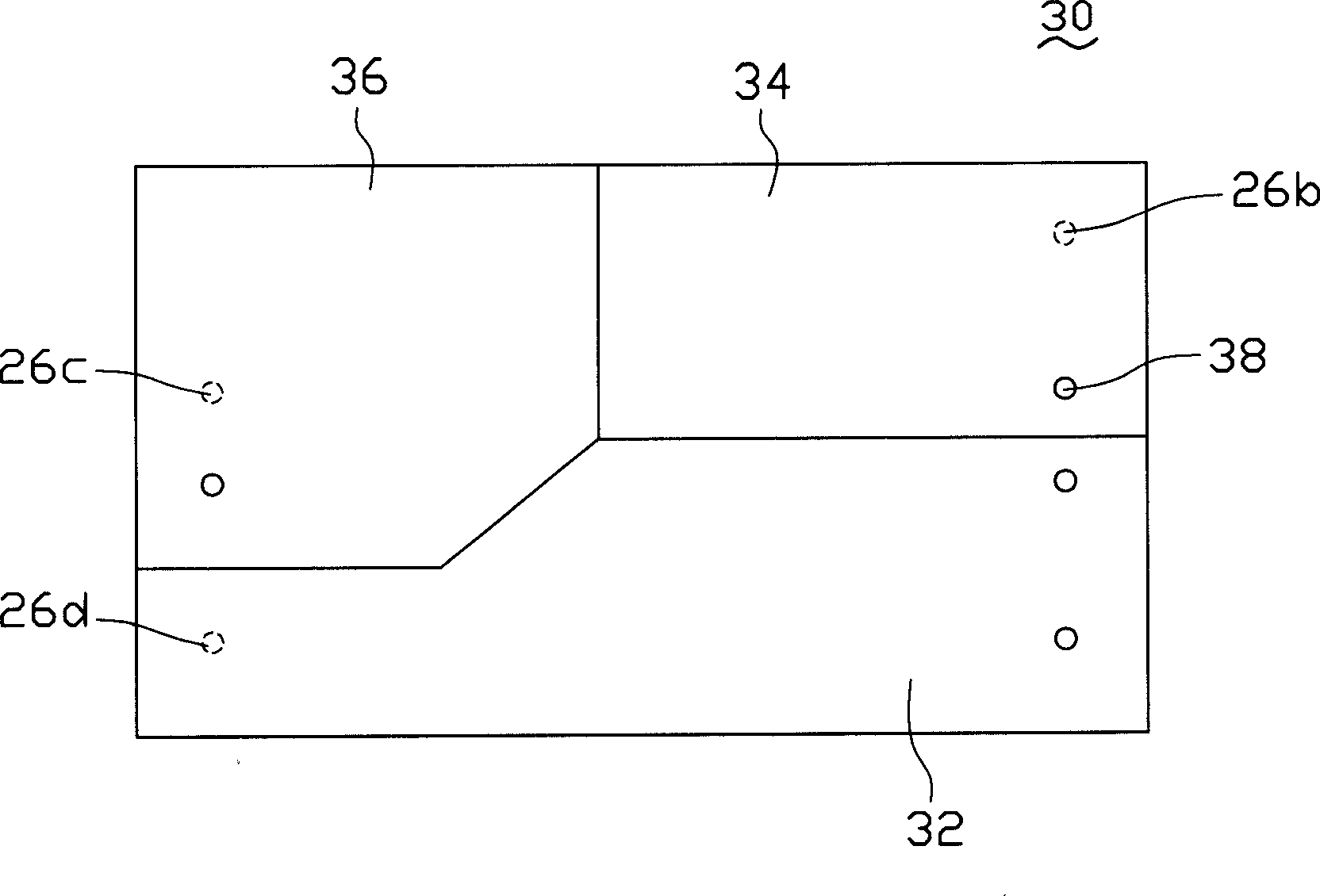

[0016] see Figure 4, a preferred embodiment of the present invention has a printed circuit board with an improved power supply block, the printed circuit board is a multilayer circuit board, which has a number of component contacts 40, a first power supply block 42, a second power supply block 44 and Several via holes 46 . The component contacts 40 are used to place a large current component (not shown); the first power supply block 42 and the second power supply block 44 are used to jointly provide the high current components installed on the component contacts 40 Working voltage and working current; the via hole 46 runs through and electrically connects the first power supply block 42 and the second power supply block 44 to keep the same voltage. The first power supply block 42 and the second power supply block 44 are all identical in purpose and property, and are located in different layers of the printed circuit board. When the multilayer printed circuit board is a four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com