A micro turbine generator

A technology of micro-generator and micro-turbine, which is applied in the field of micro-motors, can solve the problems of high misfire rate of bullets, complicated process, and inapplicability to mass production and processing, etc., so as to reduce the number of via holes, increase the number of coil turns, and improve the effective The effect of using the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

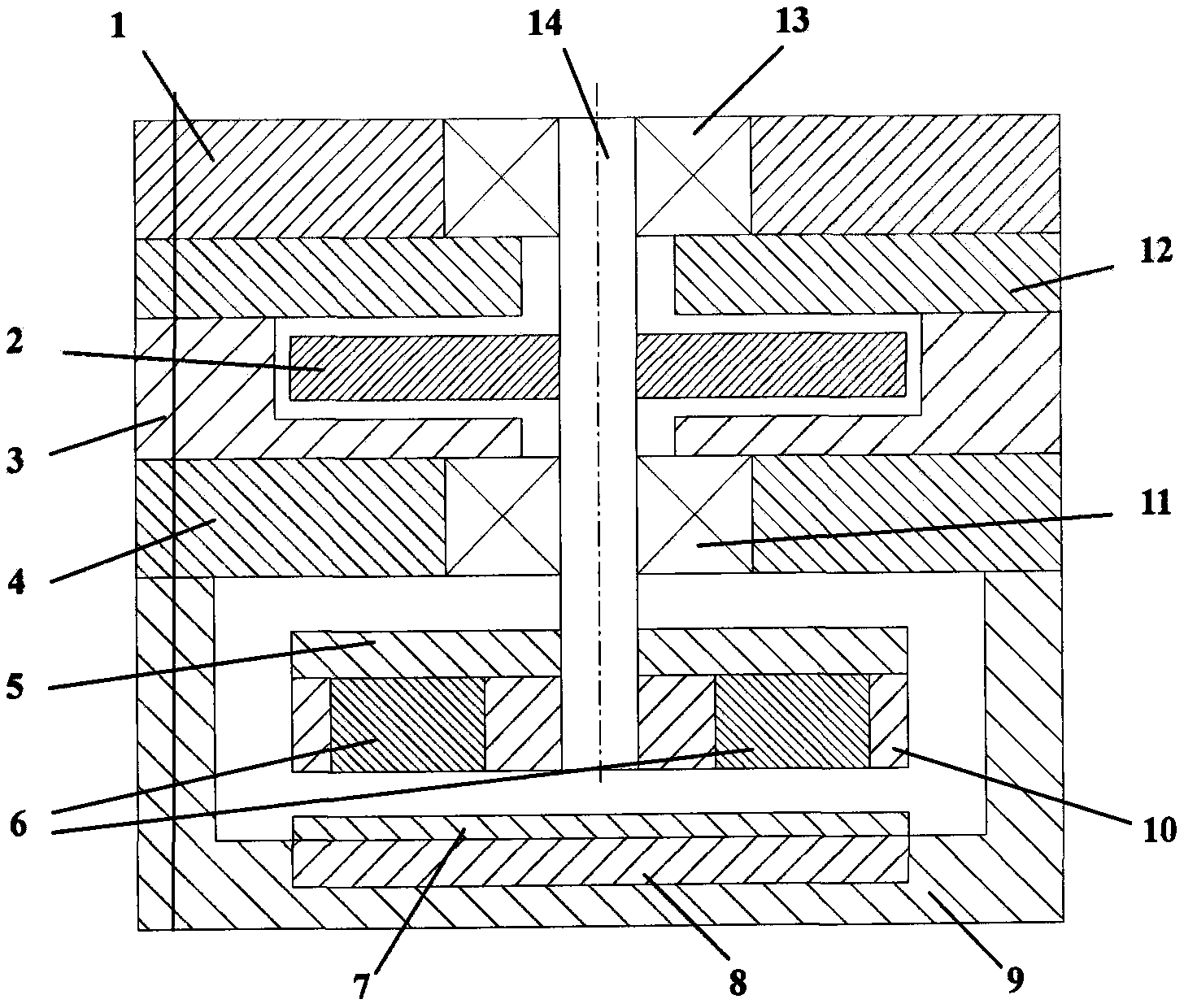

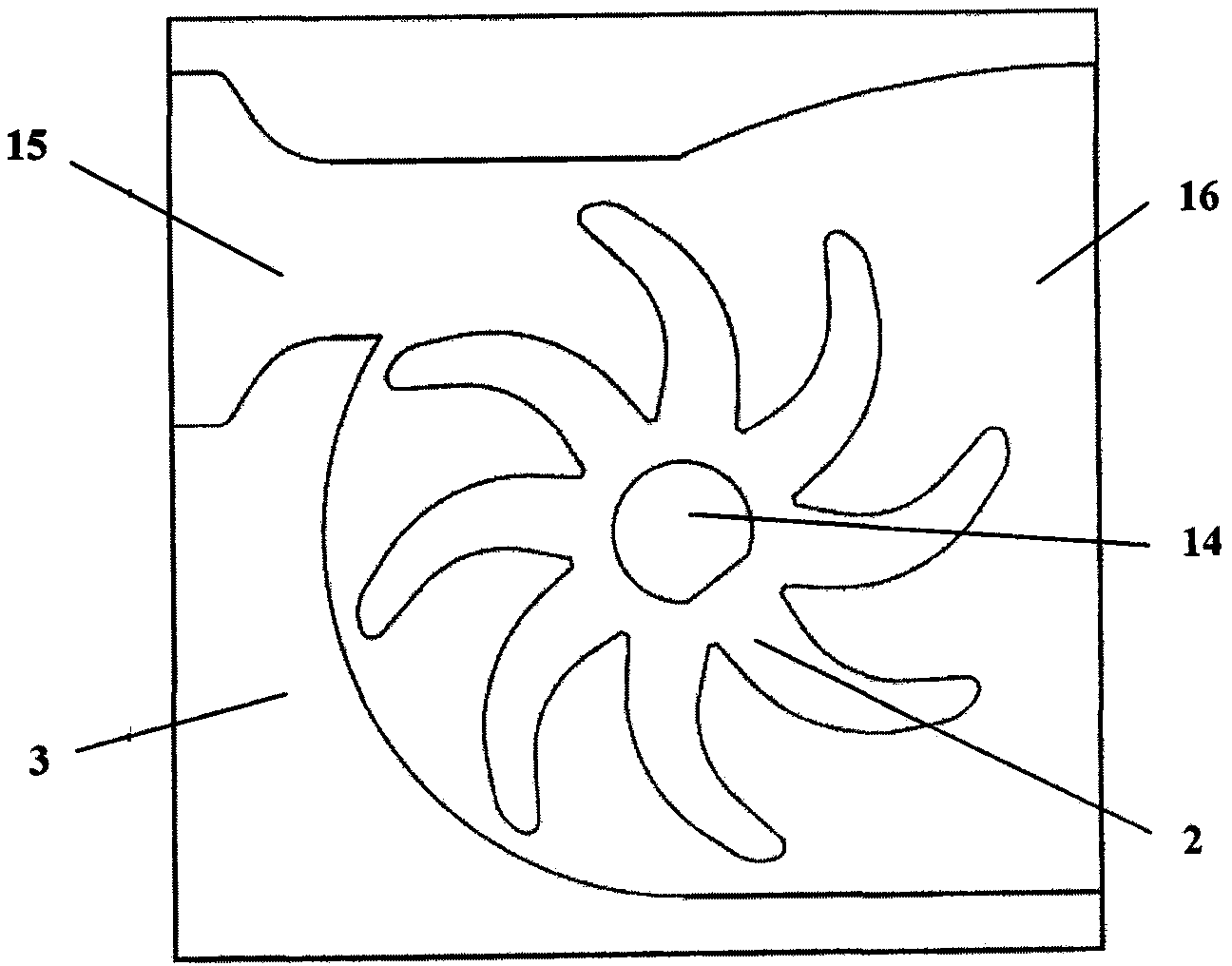

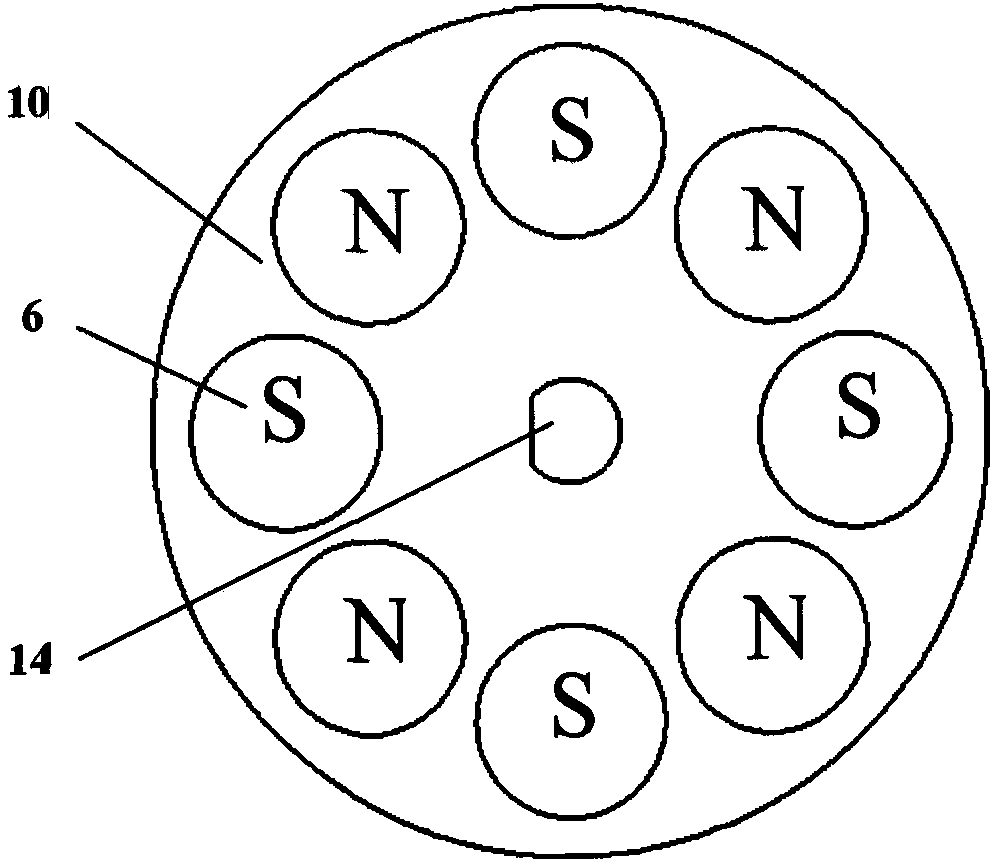

[0031] Install a micro-turbine generator in the bullet fuze of a certain sub-munition, and the volume needs to reach 1cm 3 Below, the output power reaches more than 1mW. To meet the above requirements, a micro-turbine generator is designed, such as figure 1 As shown, it includes: upper end cover 1, turbine 2, cavity 3, lower partition 4, rotor yoke 5, permanent magnet 6, flexible circuit board 7, stator yoke 8, lower end cover 9, rotor base plate 10, lower bearing 11. Upper partition 12, upper bearing 13, rotating shaft 14, air inlet 15, exhaust port 16, B-phase coil via hole 17, A-phase coil pad 18, C-phase coil via hole 19, A-phase coil 20, Through hole 21 , B-phase coil 22 , C-phase coil 23 .

[0032] A microturbine generator, such as Figure 1 to Figure 6 As shown, it includes four parts: a micro-pneumatic turbine, a mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com