B-dot probe based on PCB type magnetic induction coil, and current spatial distribution measuring system

A technology of magnetic induction coil and current probe, which is applied in the direction of measuring device, only measuring current, measuring electric variable, etc., can solve the problems of large difference in sensitivity of B-dot, inconvenient data analysis, and difficulty in ensuring the consistency of B-dot magnetic induction coil. , to achieve the effect of suppressing strong electromagnetic and high-energy electronic interference, simple structure design, and good electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

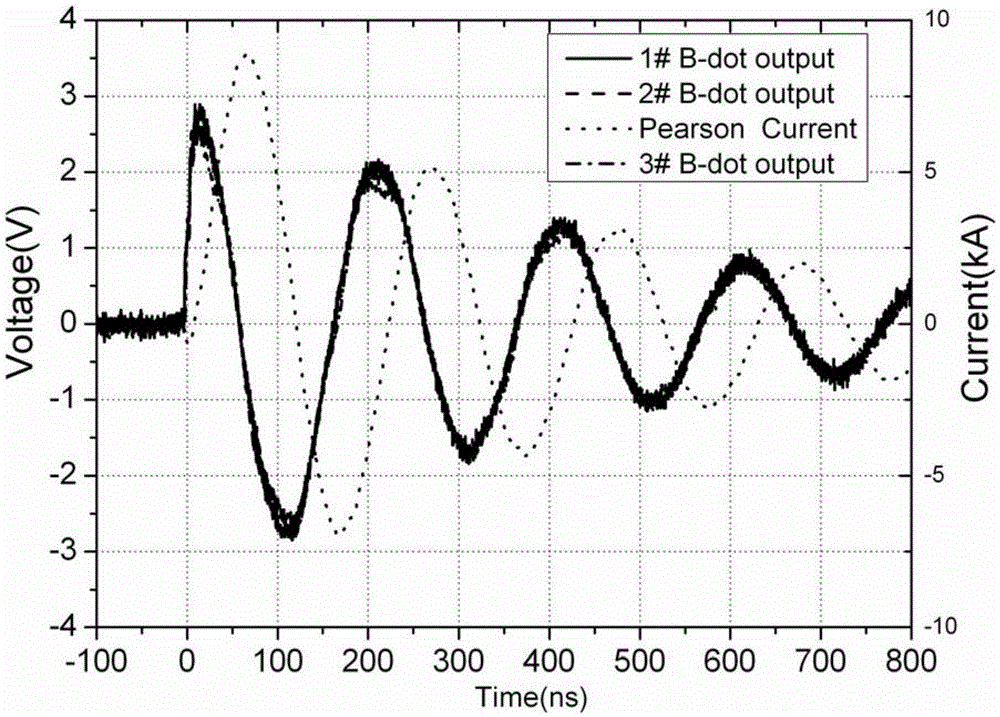

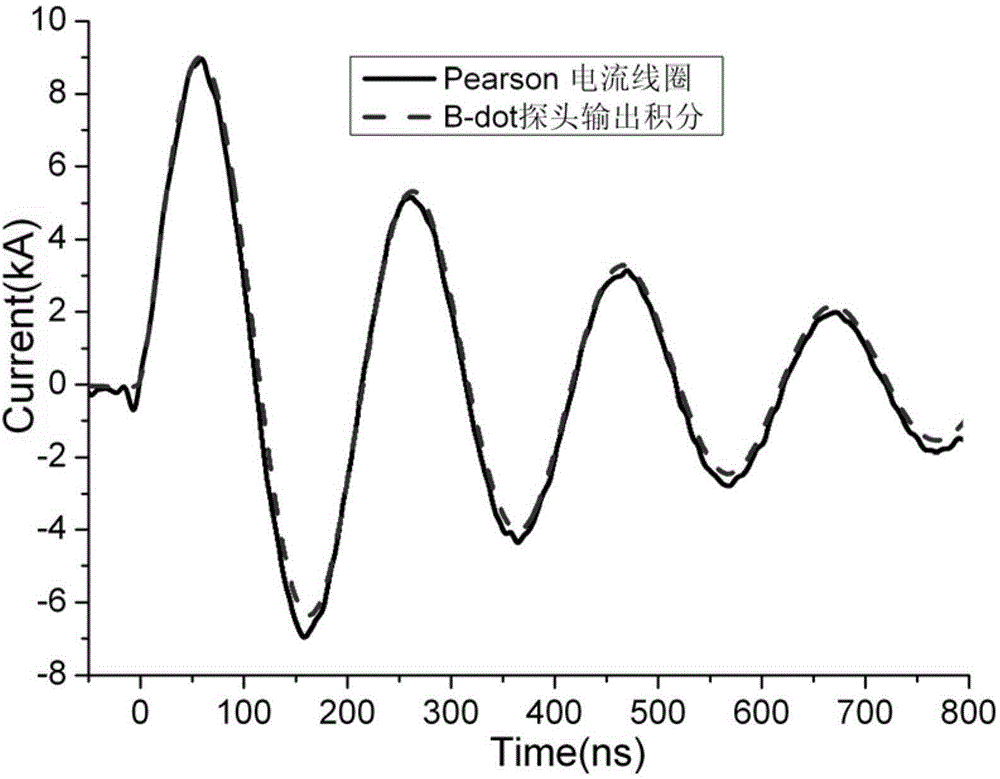

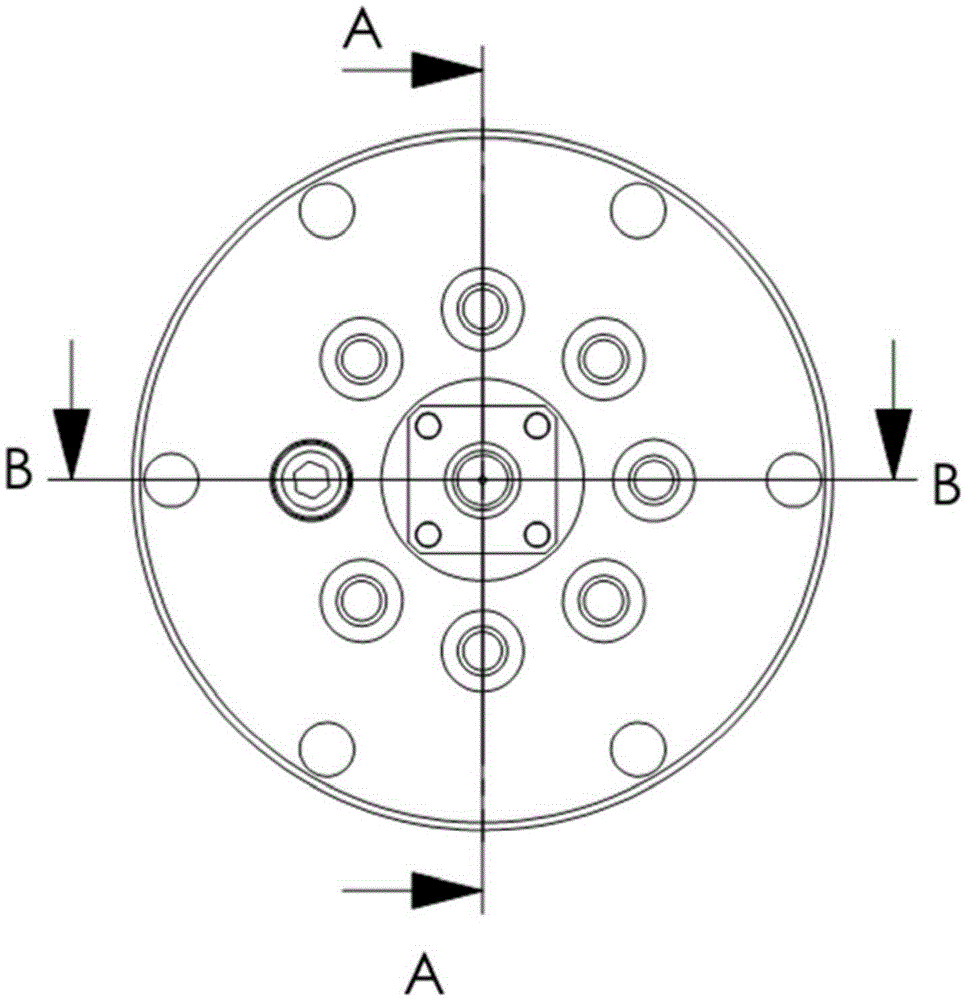

[0045] The present invention proposes a B-dot current probe using a small-sized printed circuit board (PCB) as a magnetic induction coil. tin. The wiring on the top layer of the coil starts at the center of the top layer of the PCB, and the wiring on the bottom layer of the coil terminates in the tinned area of the PCB board. The male TNC connector snaps into the recess of the PCB coil and leads out the measurement signal. The metal support ring 3 engraved with a rectangular groove and the metal shielding cover 2 press the PCB type magnetic induction coil 1 from the upper and lower sides to ensure good electrical contact. A slit 7 is opened on the top of the metal shielding cover 2, and the direction of the slit coincides with the normal direction of the PCB coil, allowing the magnetic field to enter the PCB coil. The connector mounting flange 4, the metal support ring 3 and the metal shielding cover 2 are fastened and connected by screws. The implementation technical sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com