Semiconductor plasma processing device capable of improving appearance of film at surface of wafer

A processing device and semiconductor technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of uneven plasma distribution, electric field bending, uneven edge film, etc., to avoid excessive growth, uniform growth, and reduce gas flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

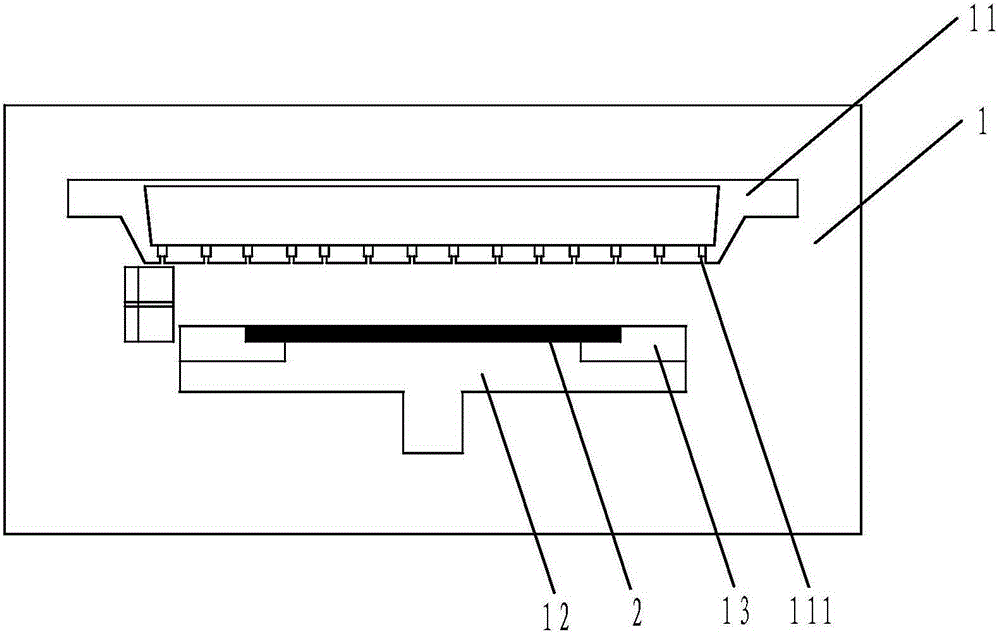

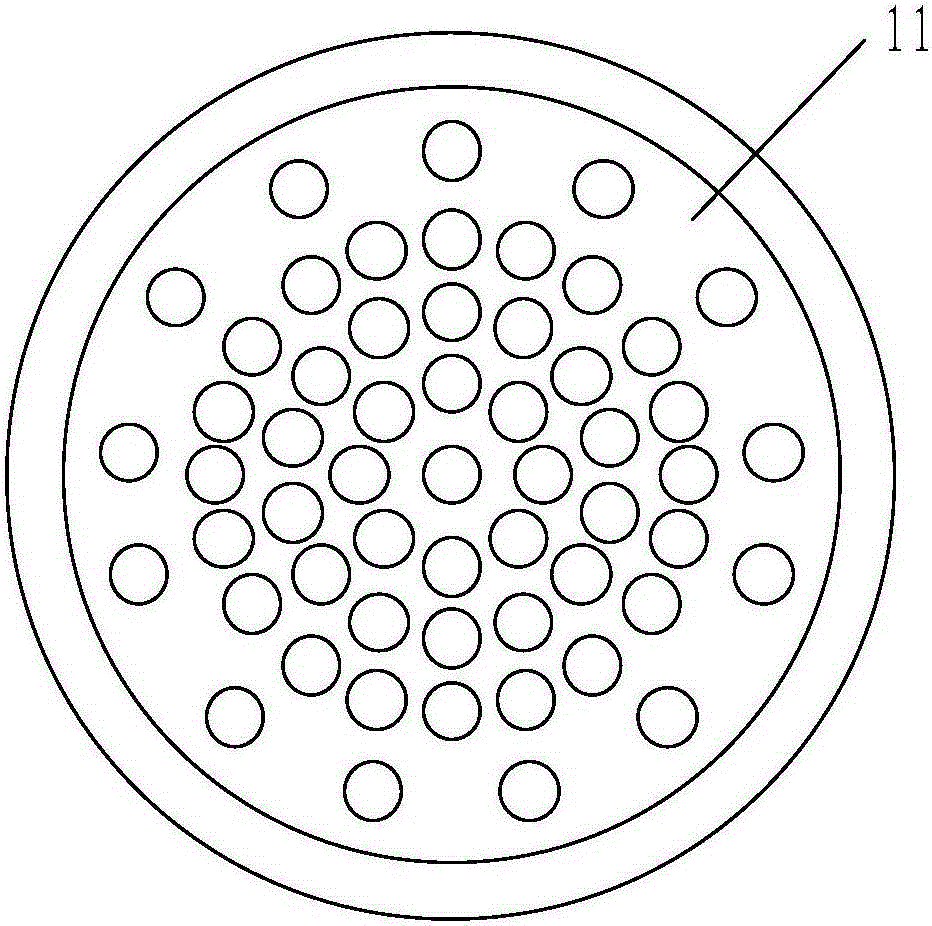

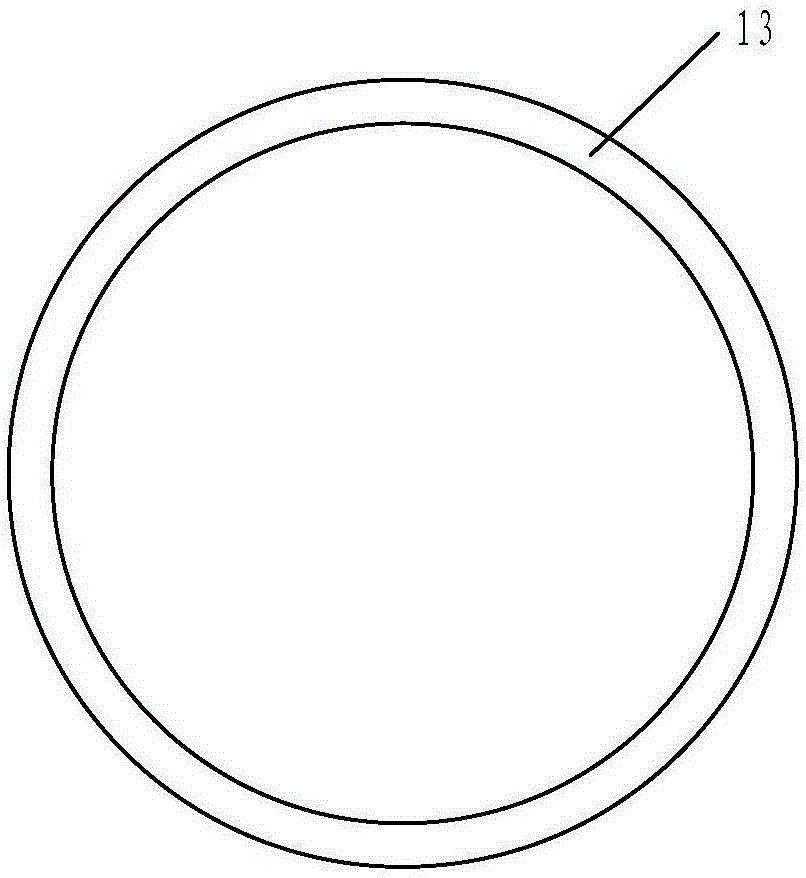

[0028] The process experiment was carried out using a semiconductor plasma processing device with 1 to 5 rings of through holes 111 reduced by 10% on the periphery of the shower head 11 and the air extraction hole 131 of the air extraction ceramic ring 13 moved down by 3 mm. The substrate used in the experiment was a 300 mm silicon wafer. During the experiment, the process gas was supplied to the stage 12 from the through hole 111 of the shower head 11, and the gas was exhausted from the exhaust hole 131 of the pumping ceramic ring 13 around the stage 12, and the pressure was stabilized by the control device. Afterwards, the shower head 11 and the stage 12 are used as the upper and lower electrodes to apply a voltage to form a plasma field between the shower head 11 and the stage 12 to perform plasma treatment on the loaded objects.

Embodiment 2

[0030] A semiconductor plasma processing device with 1 to 5 circles of through holes 111 reduced by 35% on the periphery of the shower head 11 and the air extraction hole 131 of the air extraction ceramic ring 13 moved down by 8 mm was used for the process experiment. The substrate used in the experiment was a 300 mm silicon wafer. During the experiment, the process gas was supplied to the stage 12 from the through hole 111 of the shower head 11, and the gas was exhausted from the exhaust hole 131 of the pumping ceramic ring 13 around the stage 12, and the pressure was stabilized by the control device. Afterwards, the shower head 11 and the stage 12 are used as the upper and lower electrodes to apply a voltage to form a plasma field between the shower head 11 and the stage 12 to perform plasma treatment on the loaded objects.

Embodiment 3

[0032] A process experiment was carried out using a semiconductor plasma processing device with 1 to 5 rings of through holes 111 reduced by 60% on the periphery of the shower head 11 and the air extraction holes 131 of the air extraction ceramic ring 13 moved down by 15 mm. The substrate used in the experiment was a 300 mm silicon wafer. During the experiment, the process gas was supplied to the stage 12 from the through hole 111 of the shower head 11, and the gas was exhausted from the exhaust hole 131 of the pumping ceramic ring 13 around the stage 12, and the pressure was stabilized by the control device. Afterwards, the shower head 11 and the stage 12 are used as the upper and lower electrodes to apply a voltage to form a plasma field between the shower head 11 and the stage 12 to perform plasma treatment on the loaded objects.

[0033] Figure 6 The results of Examples 1, 2, and 3 are counted, and the center of circle of the silicon wafer is obtained as the origin, the x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com