Patents

Literature

67 results about "Semiconductor plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating packaged chamber parts for semiconductor plasma apparatus

ActiveUS20140120312A1Improve service performanceImprove processing qualityVacuum evaporation coatingSurface reaction electrolytic coatingSemiconductor plasmaPhysical chemistry

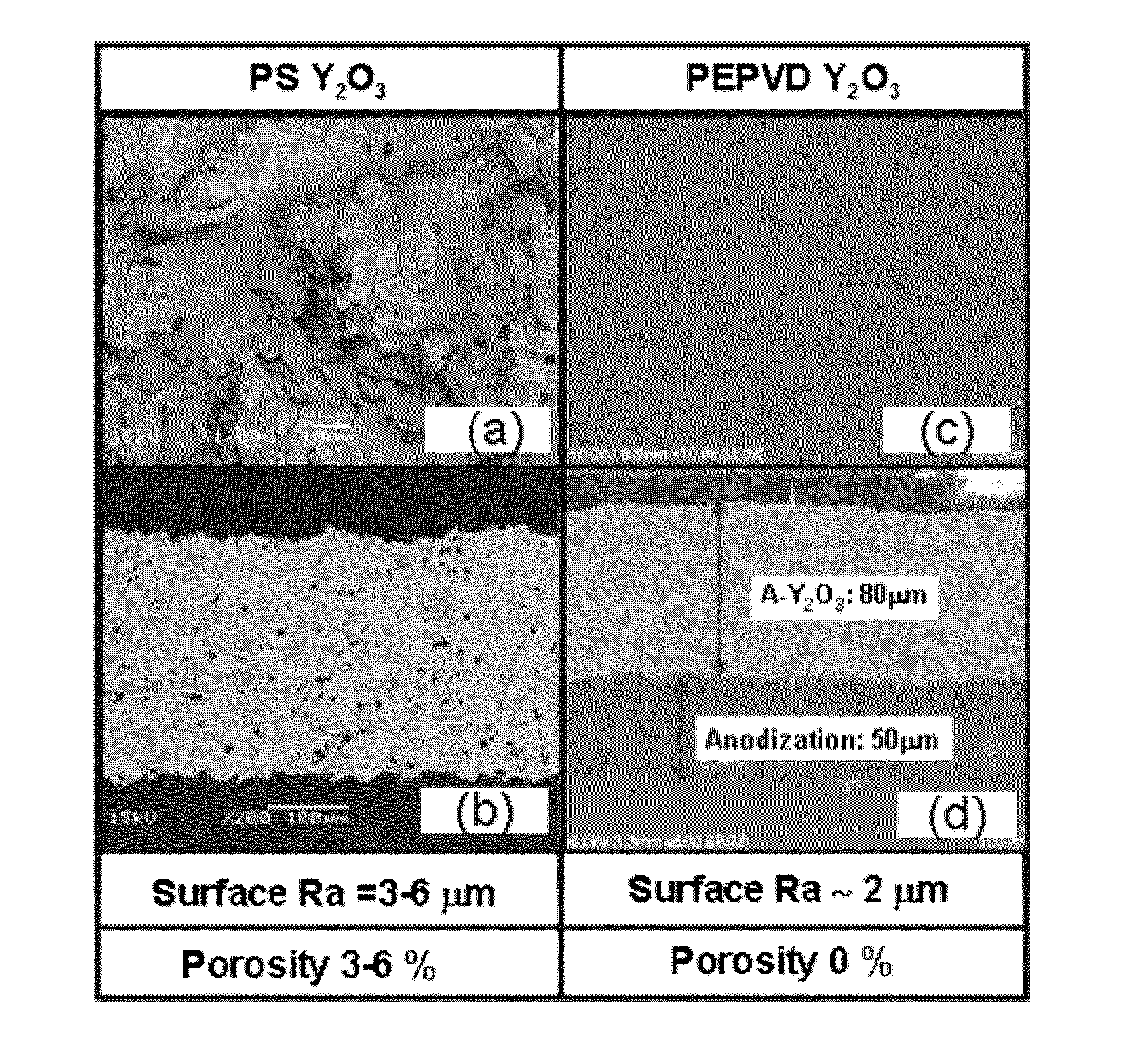

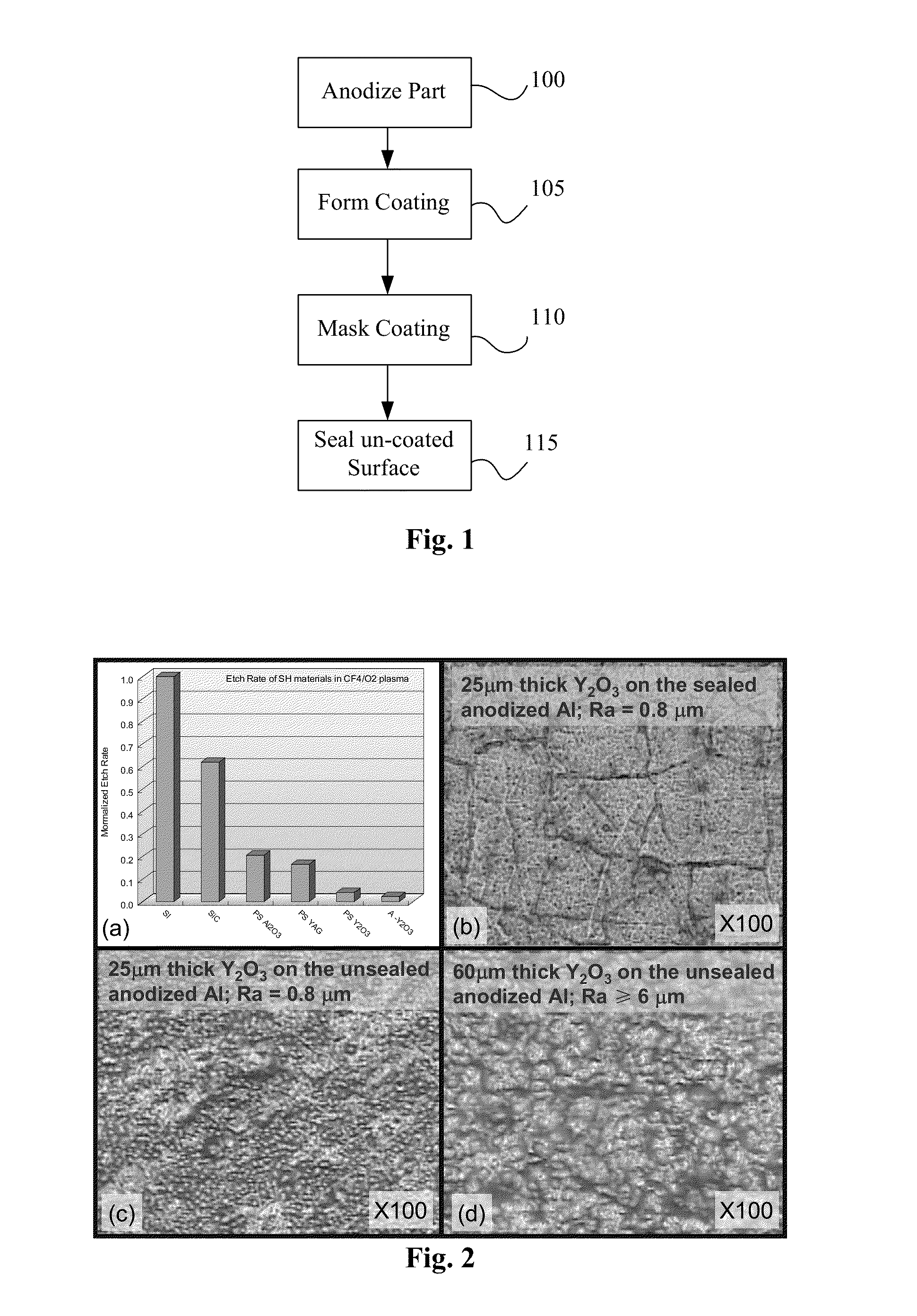

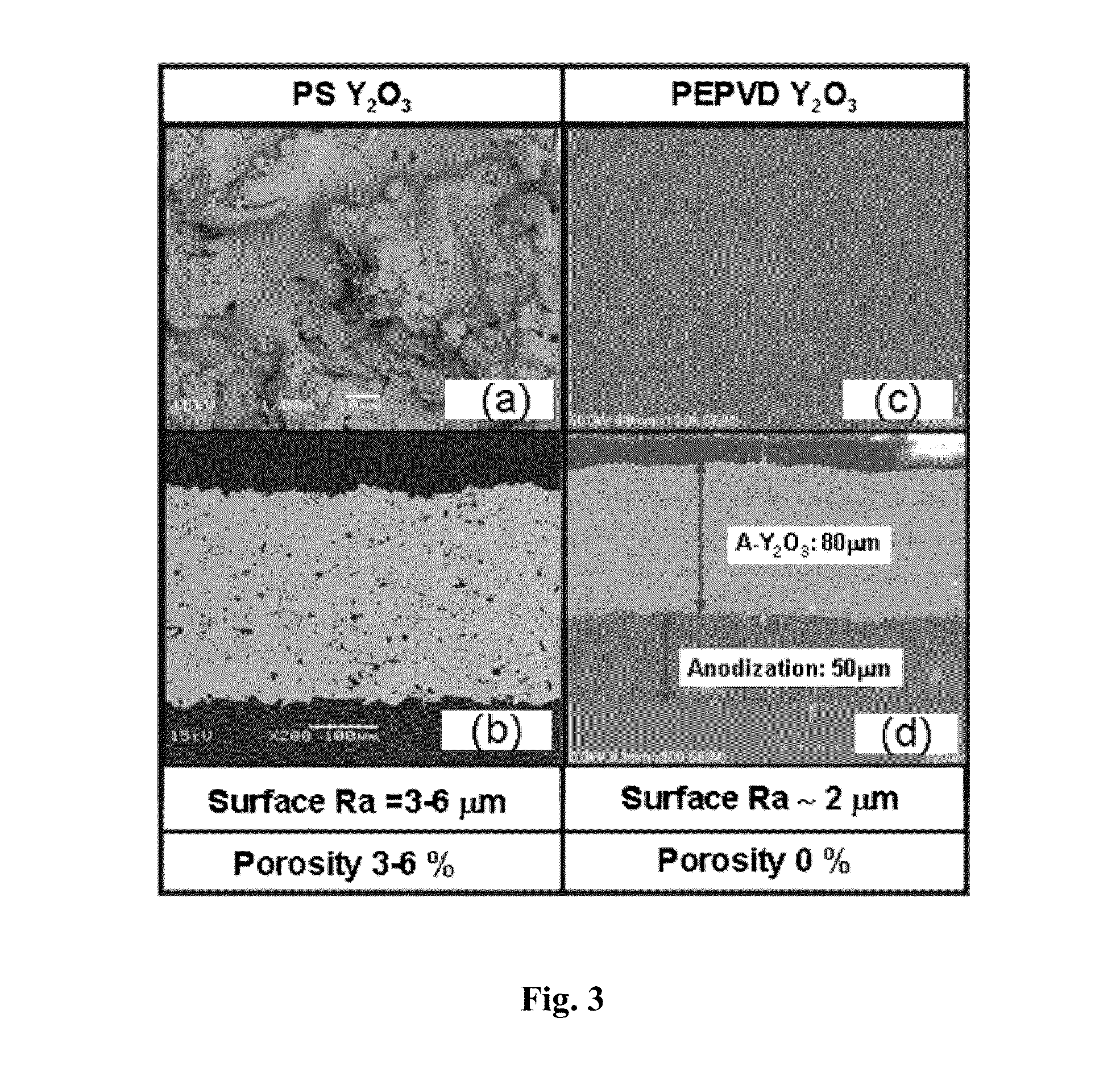

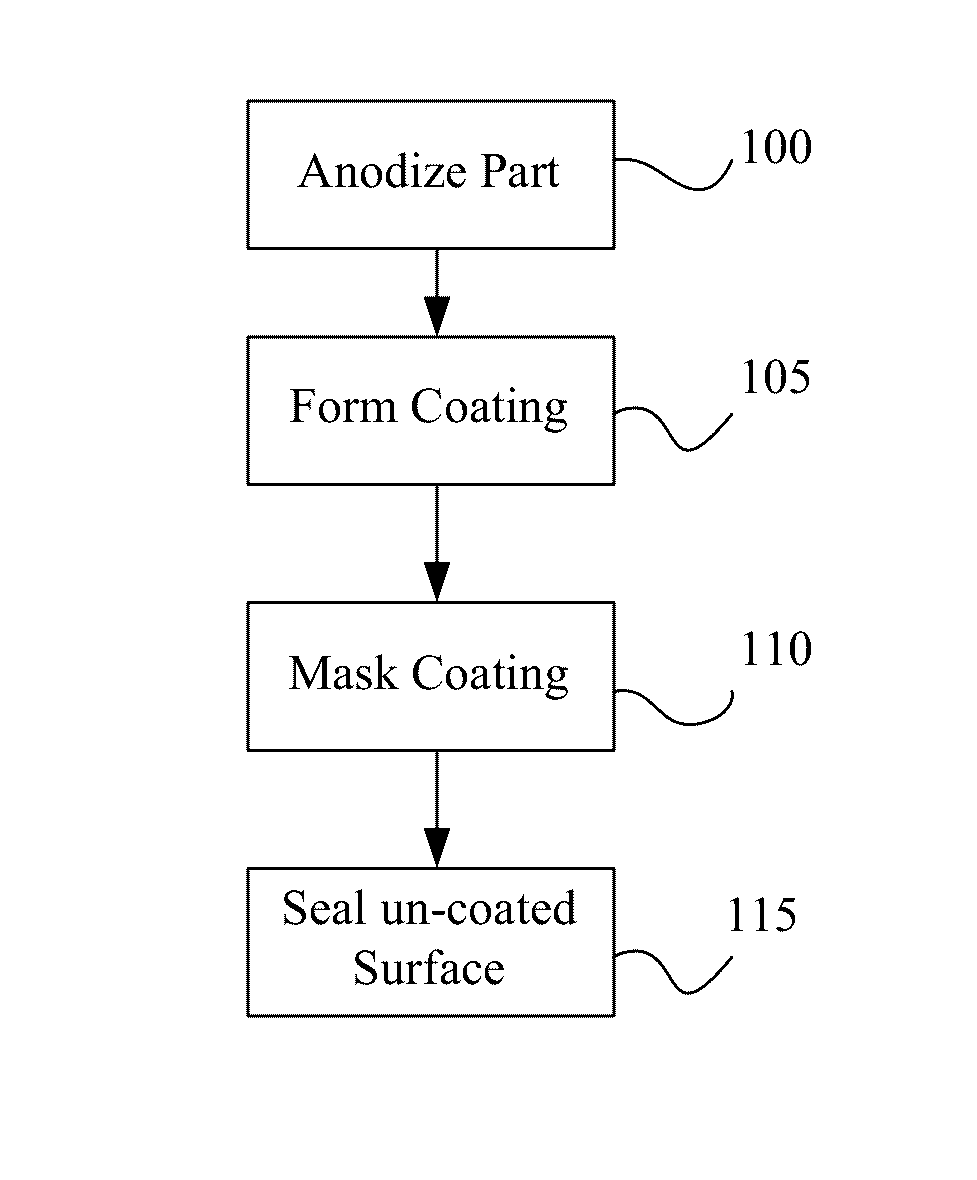

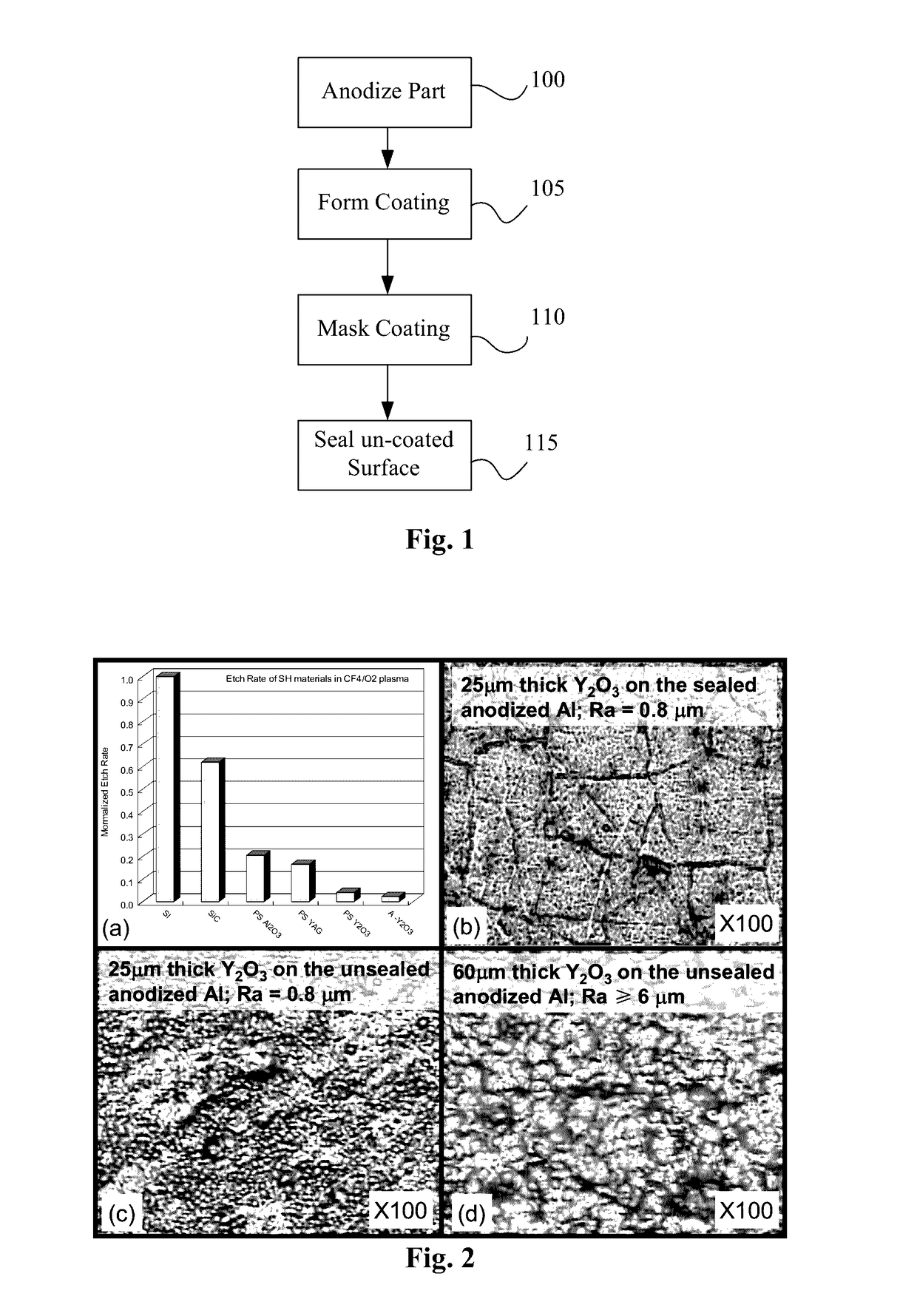

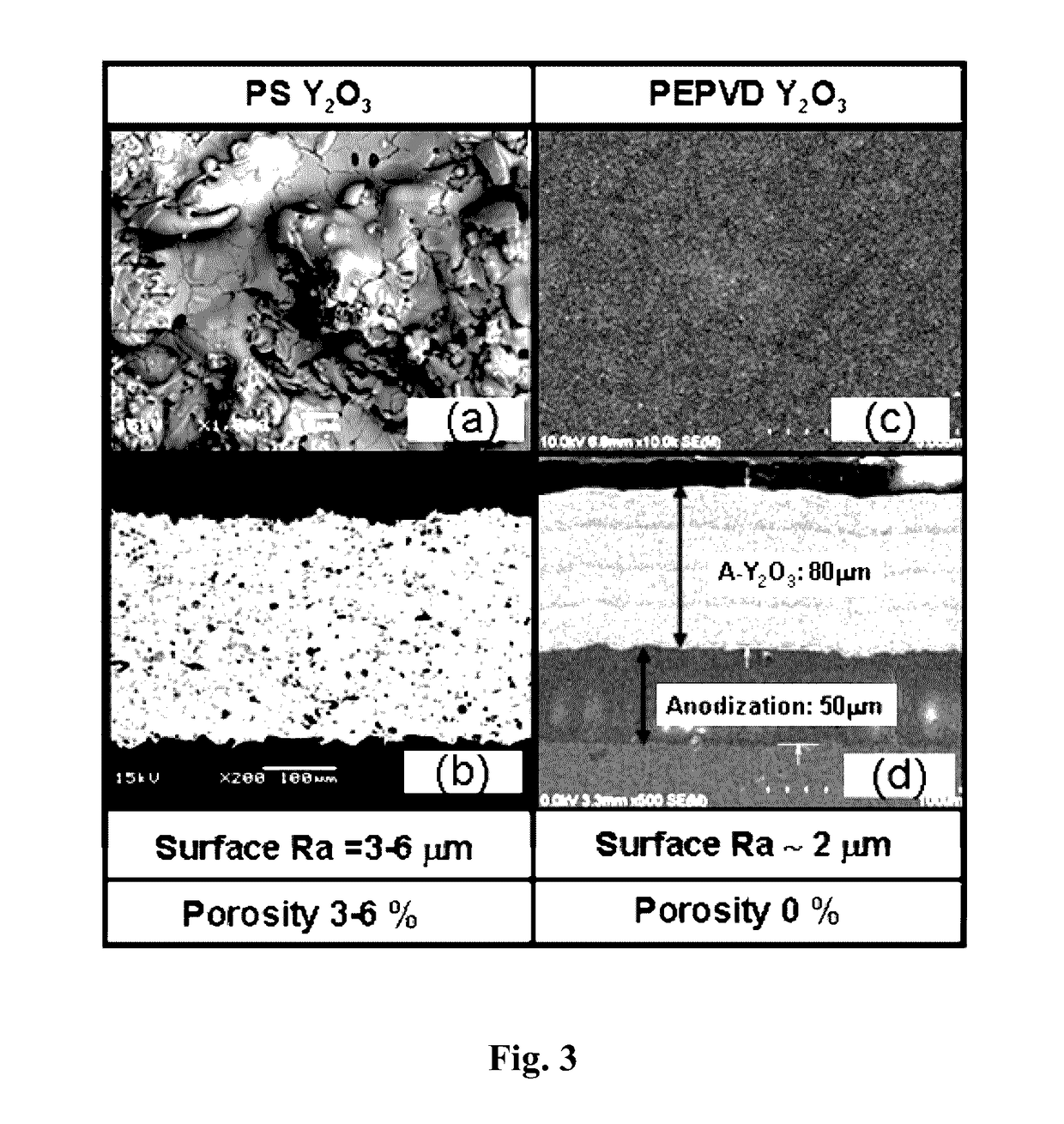

An advanced coating for parts used in plasma processing chamber. The advanced coating is formed over an anodized surface that has not been sealed. After the coating is formed, the coated area is masked, and the remaining anodized surface is sealed. The porous and rough structure of the anodized but un-sealed aluminum enhances adhesion of the coating. However, to prevent particle generation, the exposed anodized surface is sealed after formation of the coating. The coating can be of yttria, formed by plasma enhanced atomic deposition techniques which results in a dense and smooth coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

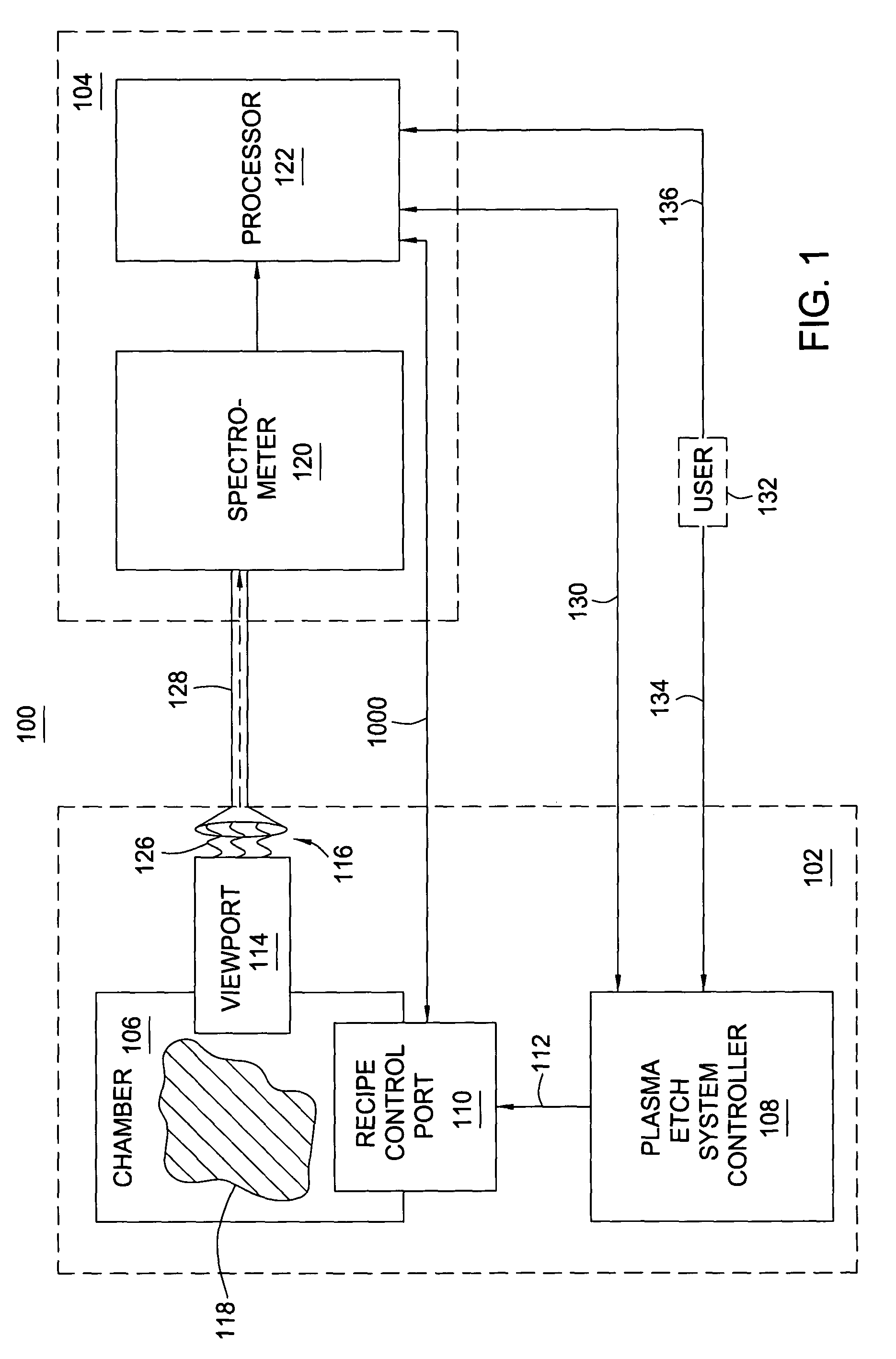

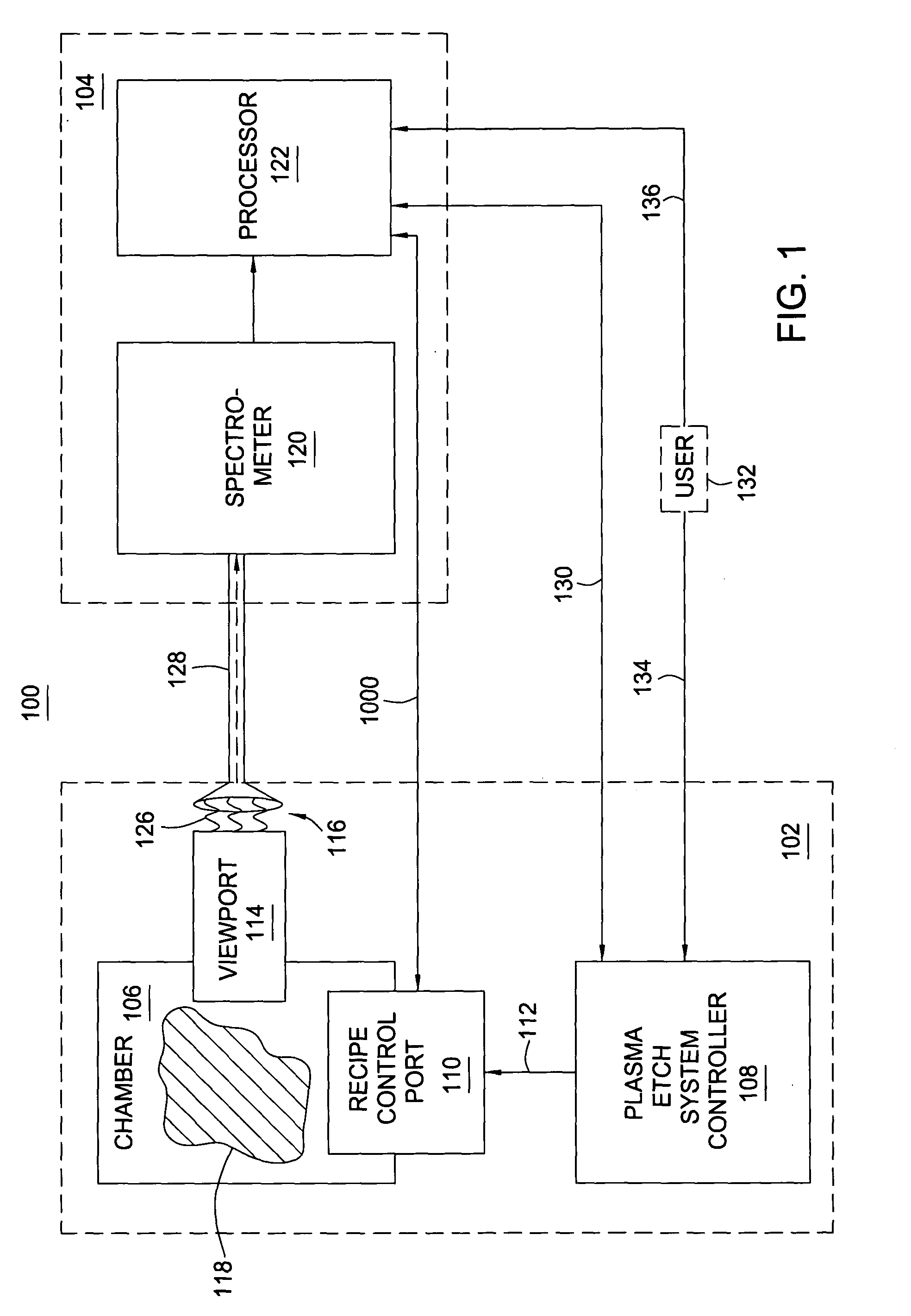

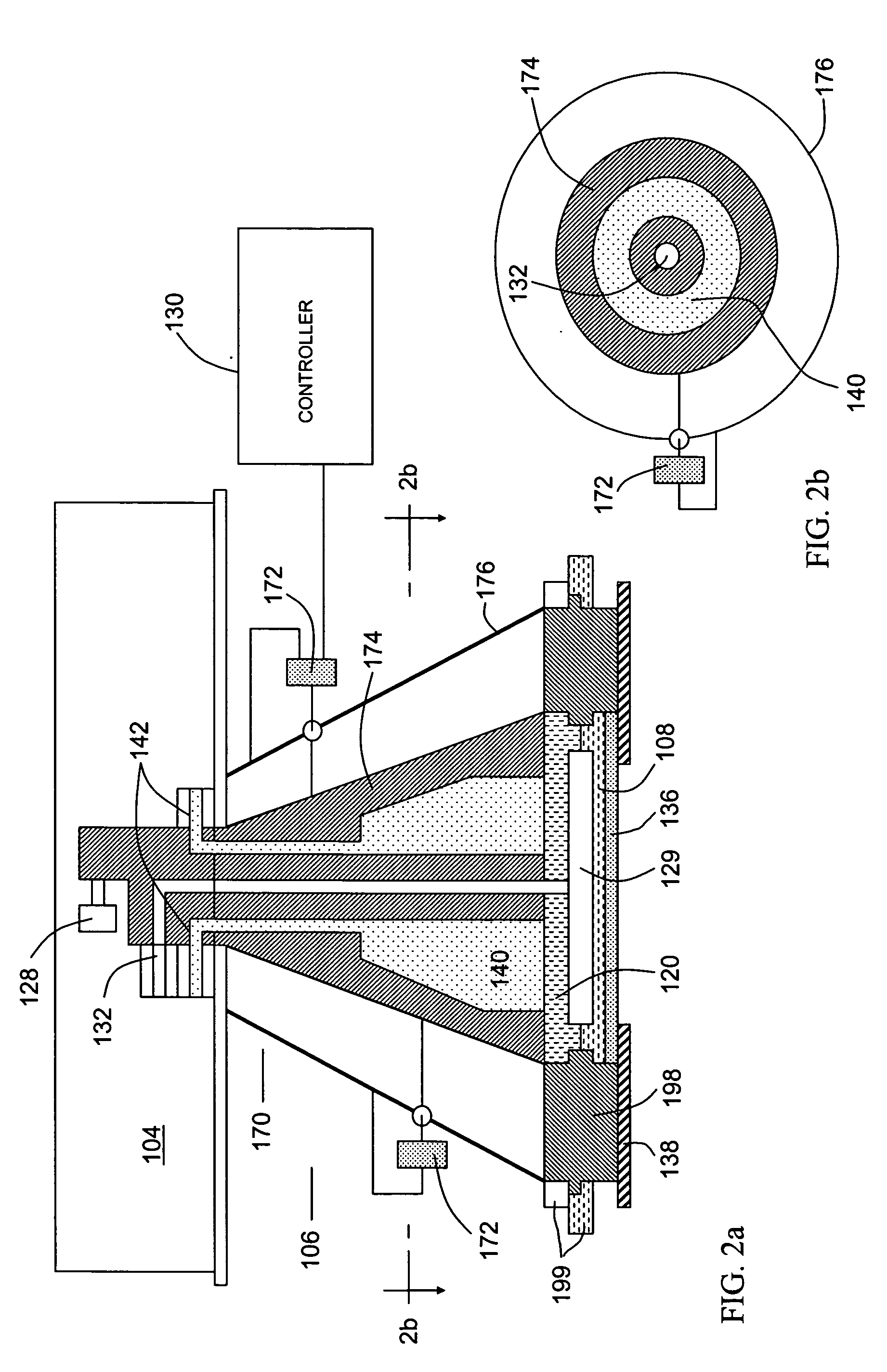

Method for automatic determination of semiconductor plasma chamber matching and source of fault by comprehensive plasma monitoring

InactiveUS7169625B2Electric discharge tubesSemiconductor/solid-state device manufacturingSemiconductor plasmaProcedural parameter

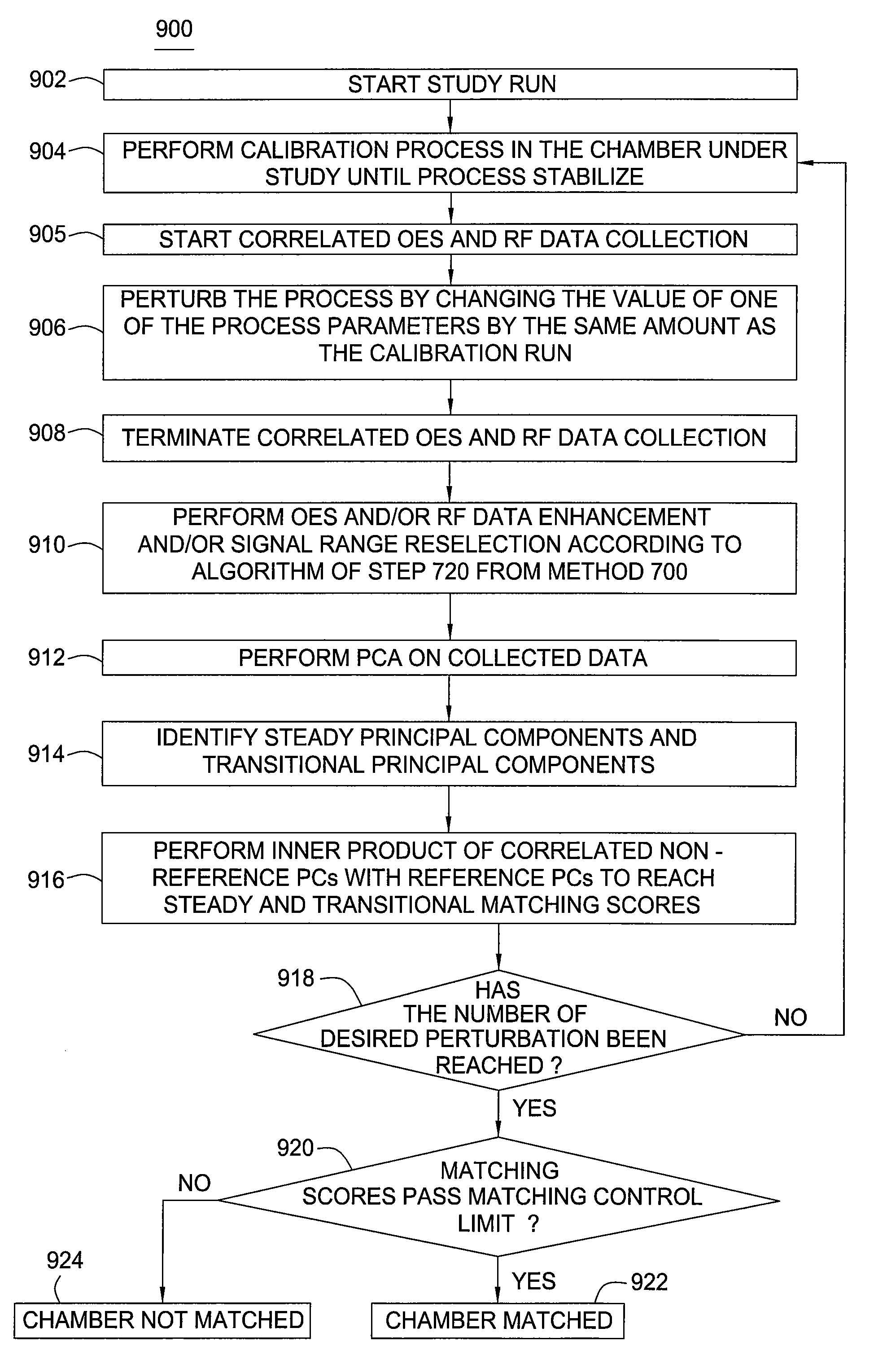

A method and apparatus for automatic determination of semiconductor plasma chamber matching a source of fault are provided. Correlated plasma attributes are measured for process used for calibration both in a chamber under study and in a reference chamber. Principal component analysis then is performed on the measured correlated attributes so as to generate steady principal components and transitional principal components; and these principal components are compared to reference principal components associated with a reference chamber. The process used for calibration includes a regular plasma process followed by a process perturbation of one process parameter. Similar process perturbation runs are conducted several times to include different perturbation parameters. By performing inner products of the principal components of chamber under study and the reference chamber, matching scores can be reached. Automatic chamber matching can be determined by comparing these scores with preset control limits. The potential source(s) of chamber fault can also be identified by the lowest matching score(s).

Owner:APPLIED MATERIALS INC

Method for automatic determination of semiconductor plasma chamber matching and source of fault by comprehensive plasma monitoring

InactiveUS20050019961A1Electric discharge tubesSemiconductor/solid-state device manufacturingPrincipal component analysisSemiconductor plasma

A method and apparatus for automatic determination of semiconductor plasma chamber matching a source of fault are provided. Correlated plasma attributes are measured for process used for calibration both in a chamber under study and in a reference chamber. Principal component analysis then is performed on the measured correlated attributes so as to generate steady principle components and transitional principle components; and these principal components are compared to reference principal components associated with a reference chamber. The process used for calibration includes a regular plasma process followed by a process perturbation of one process parameter. Similar process perturbation runs are conducted several times to include different perturbation parameters. By performing inner products of the principle components of chamber under study and the reference chamber, matching scores can be reached. Automatic chamber matching can be determined by comparing these scores with preset control limits. The potential source(s) of chamber fault can also be identified by the lowest matching score(s).

Owner:APPLIED MATERIALS INC

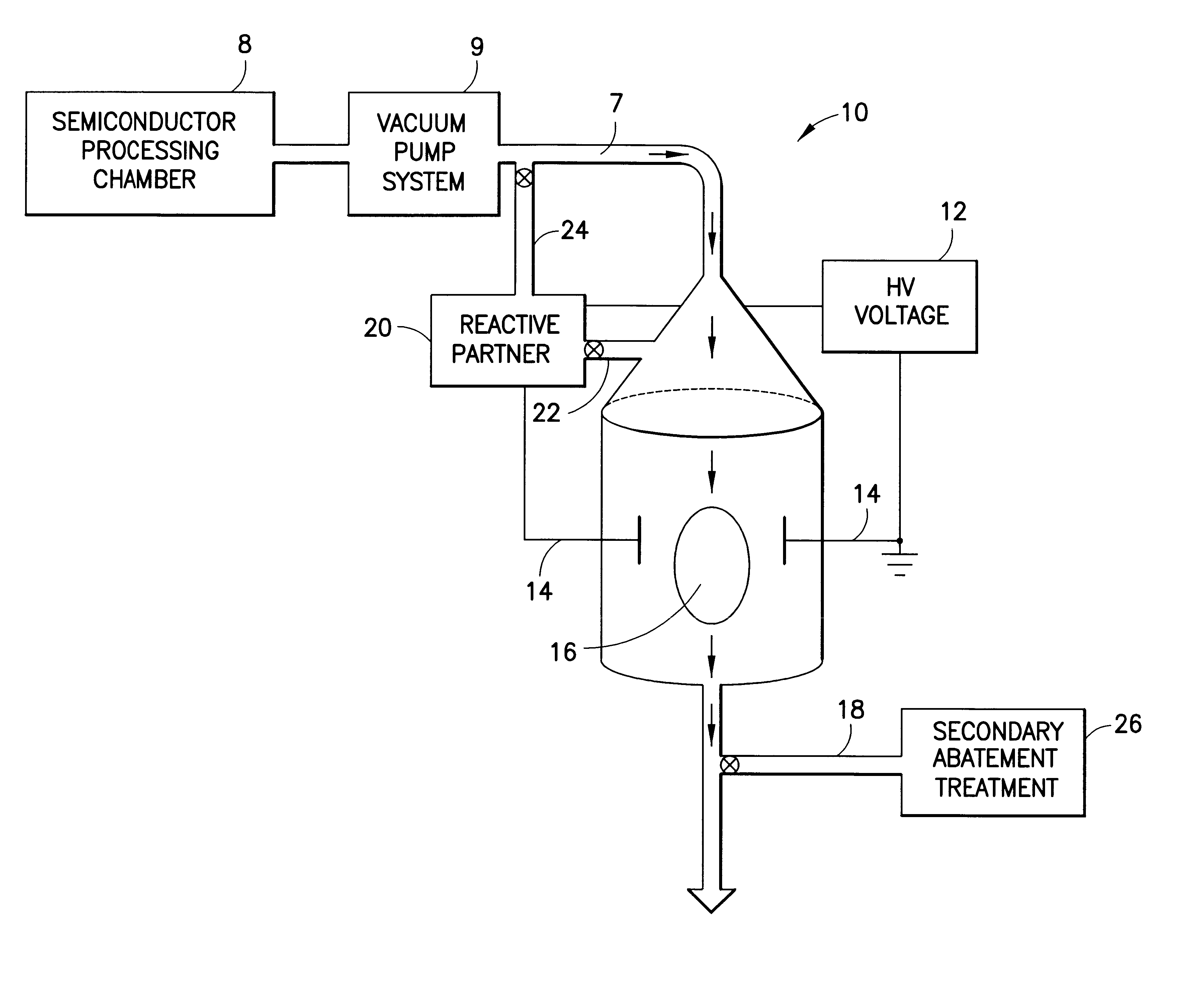

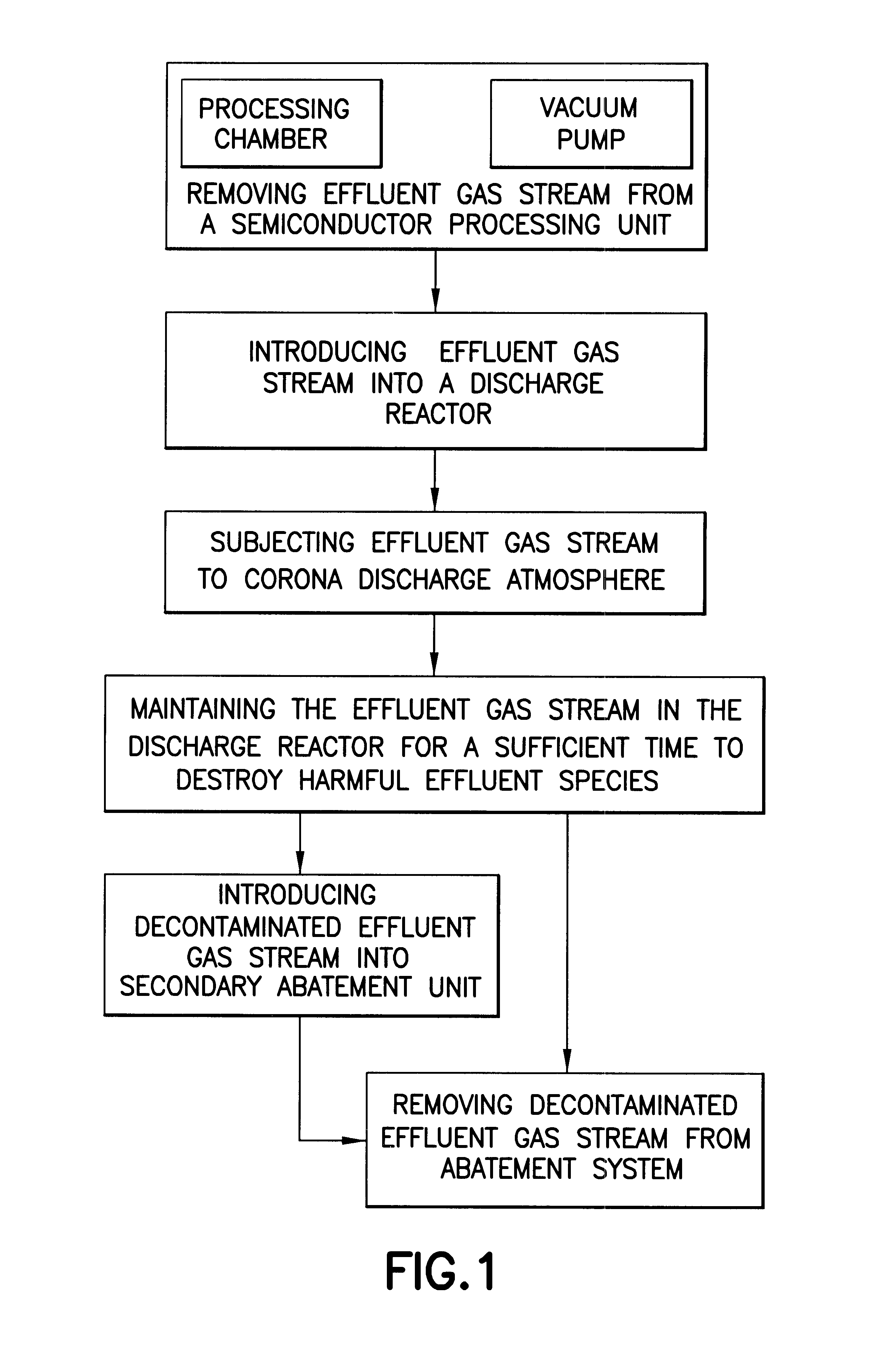

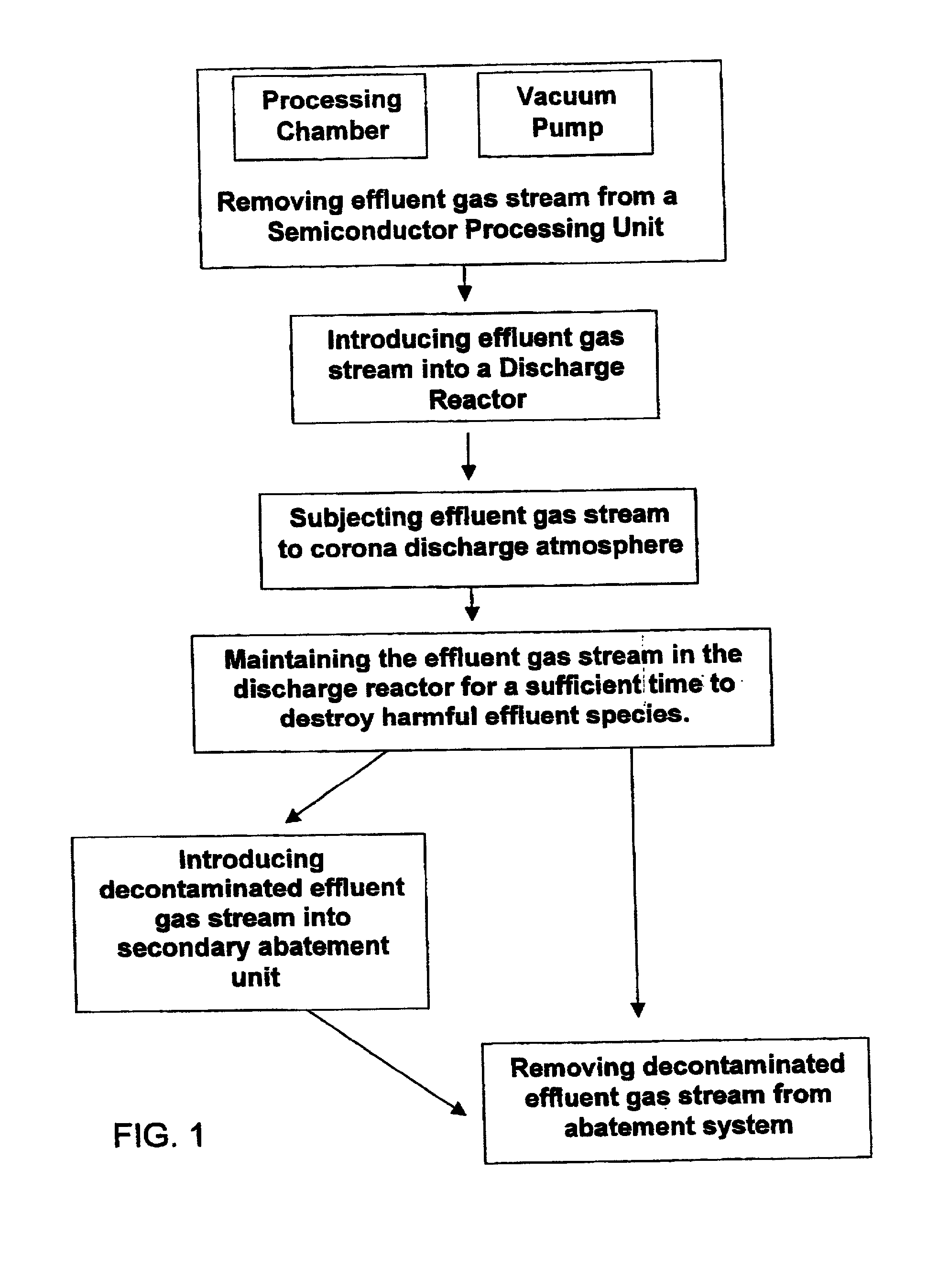

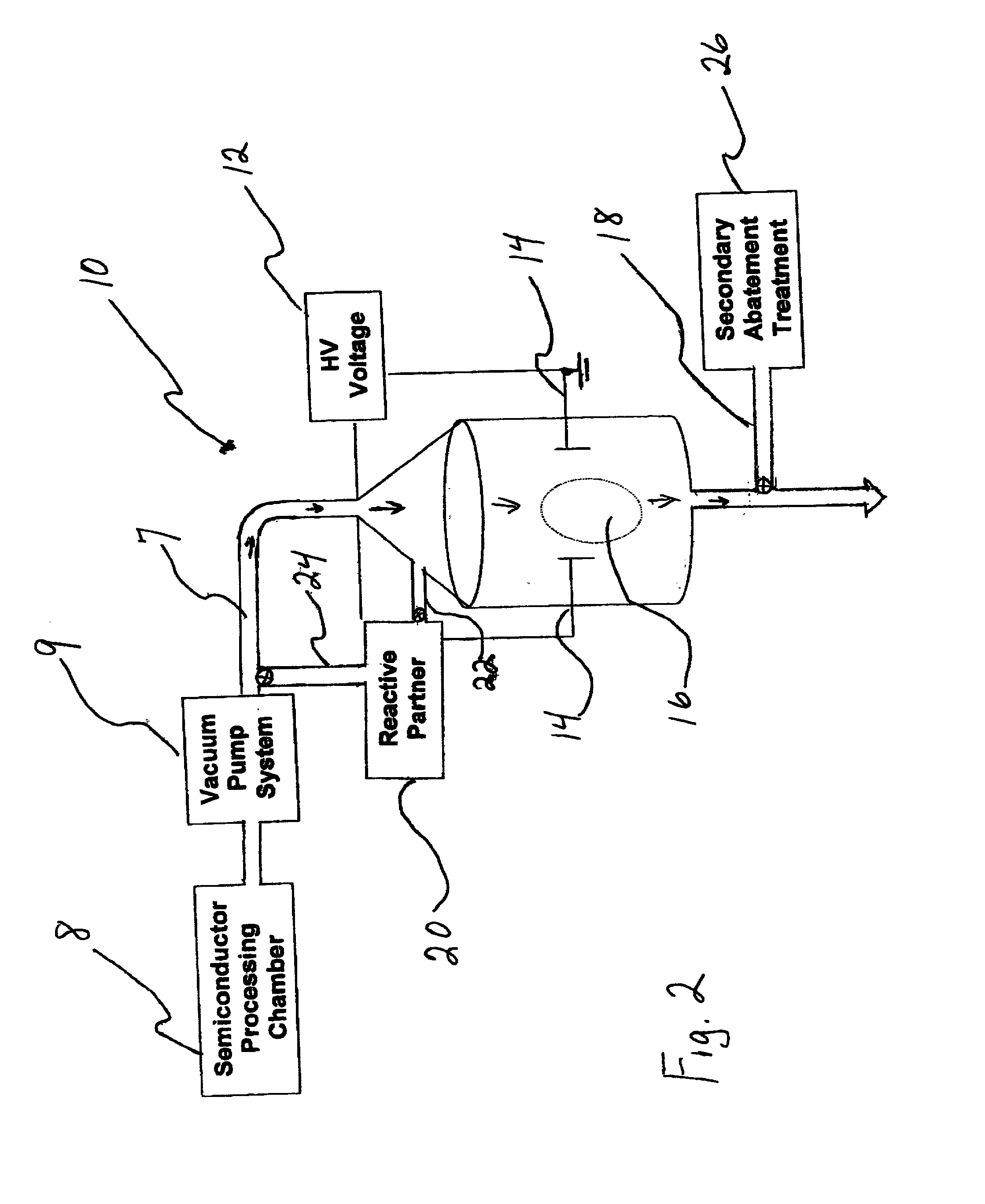

Atmospheric pressure plasma enhanced abatement of semiconductor process effluent species

InactiveUS6576573B2Combination devicesSemiconductor/solid-state device manufacturingSufficient timeSemiconductor plasma

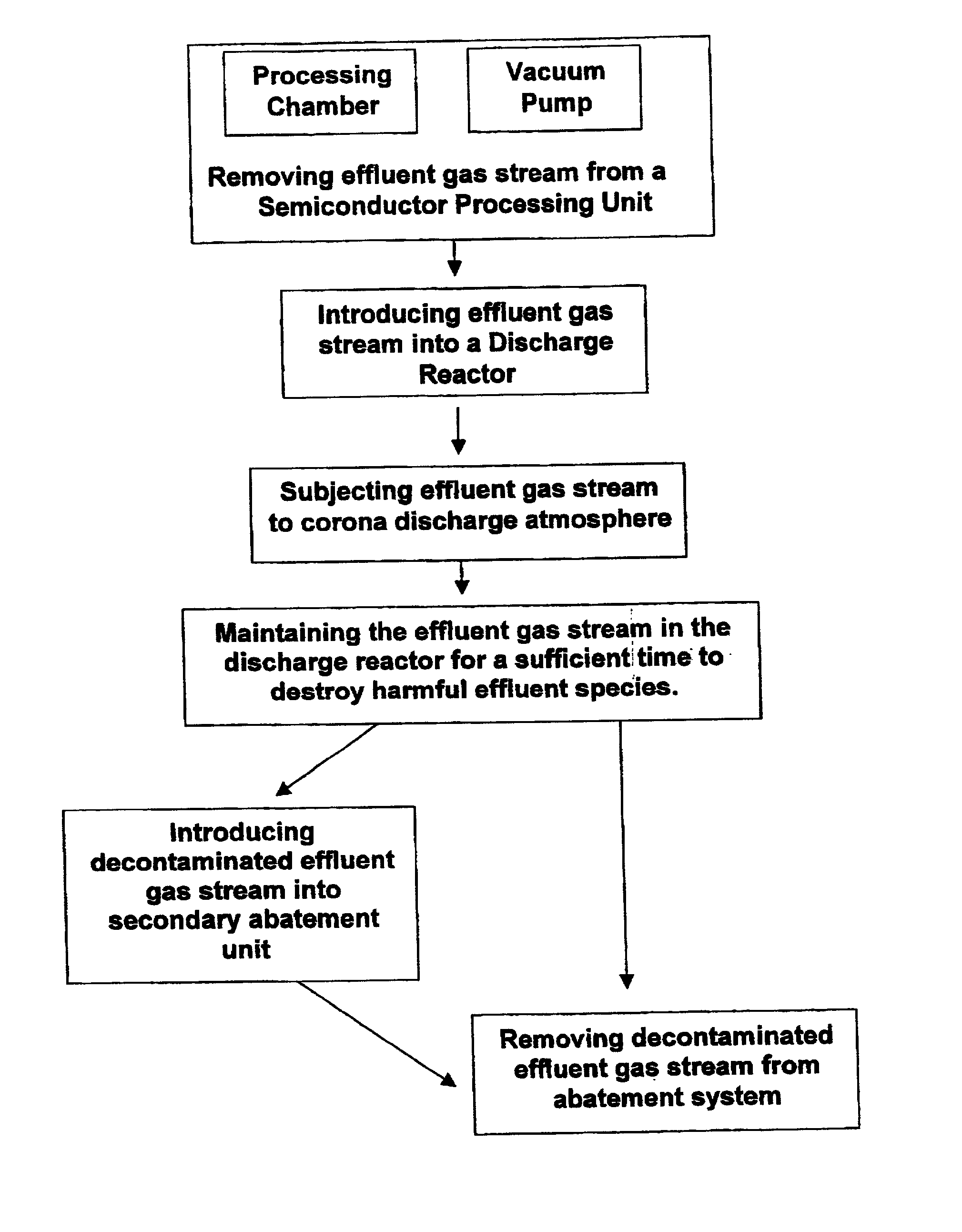

The present invention relates to a method and system for non-thermal abatement of effluent species generated in a semiconductor processing unit. In the method, an effluent stream is introduced into a discharge reactor wherein the components of the effluent stream are subjected to a corona discharge and maintained therein for a sufficient time to detoxify and / or dissociate the harmful components of the effluent stream. The discharge reactor, maintained at approximately atmospheric pressure, is positioned after the low-pressure semiconductor processing chamber and connecting vacuum pump system to limit interference with the semiconductor plasma processing tool.

Owner:APPLIED MATERIALS INC

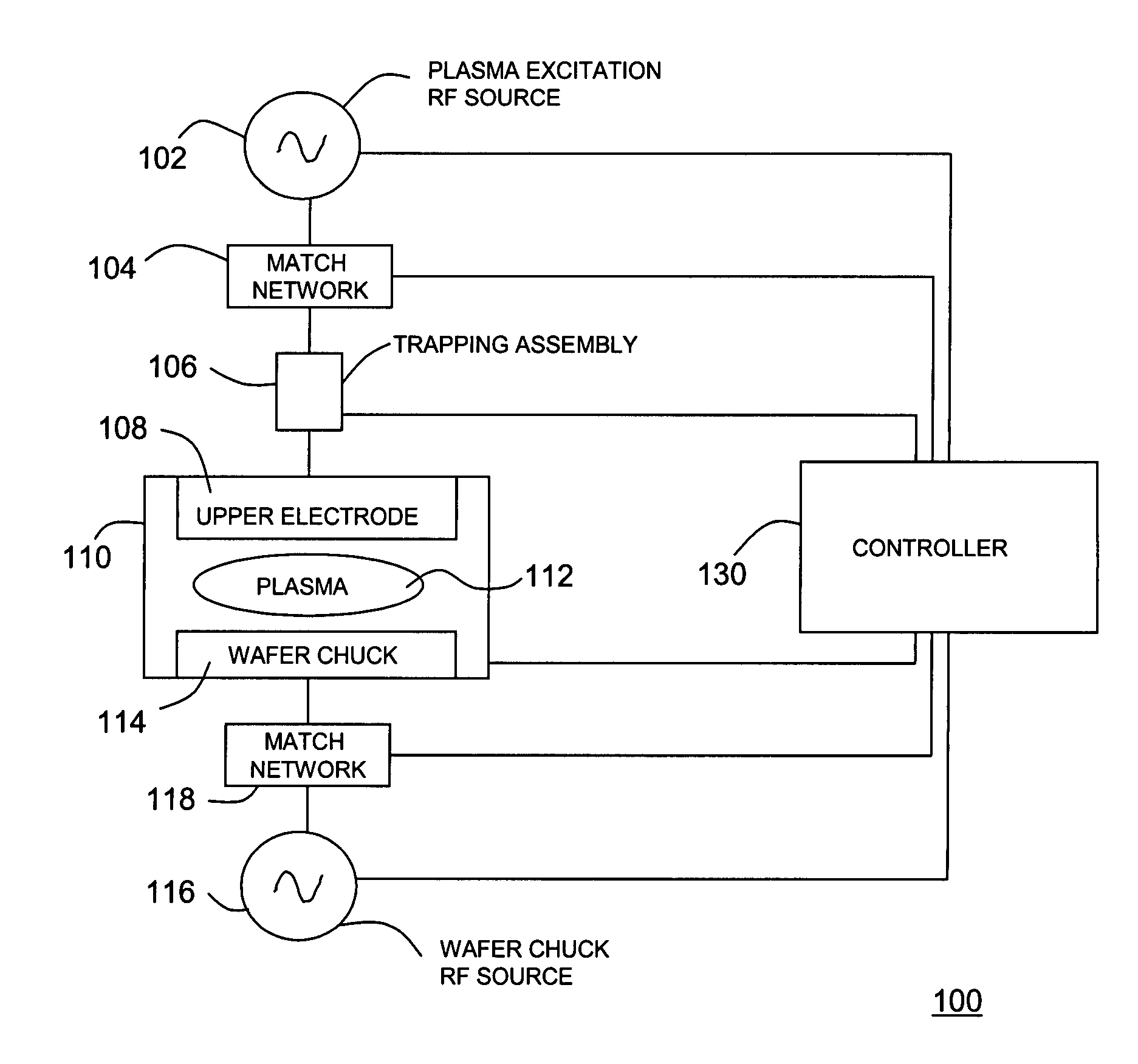

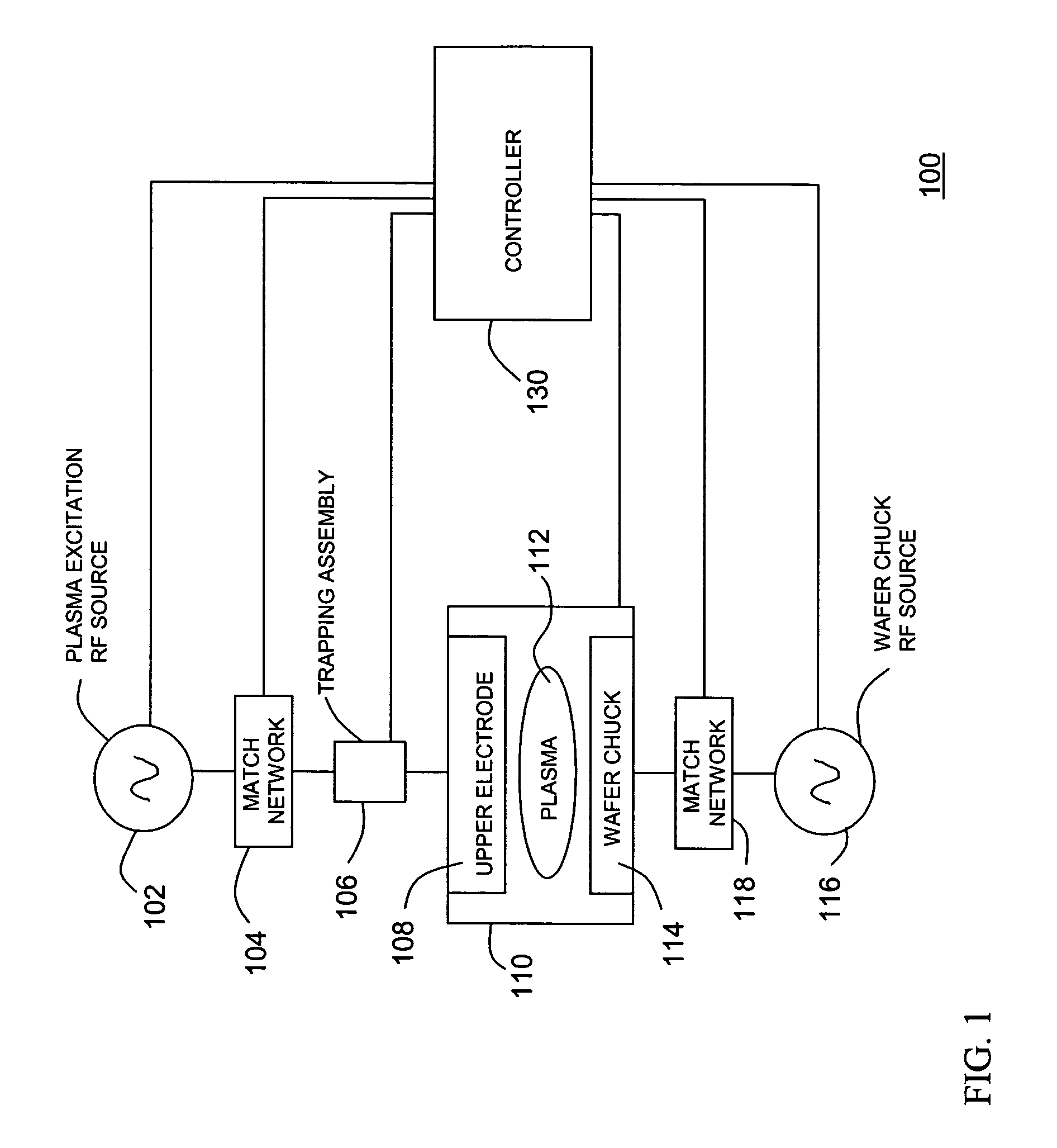

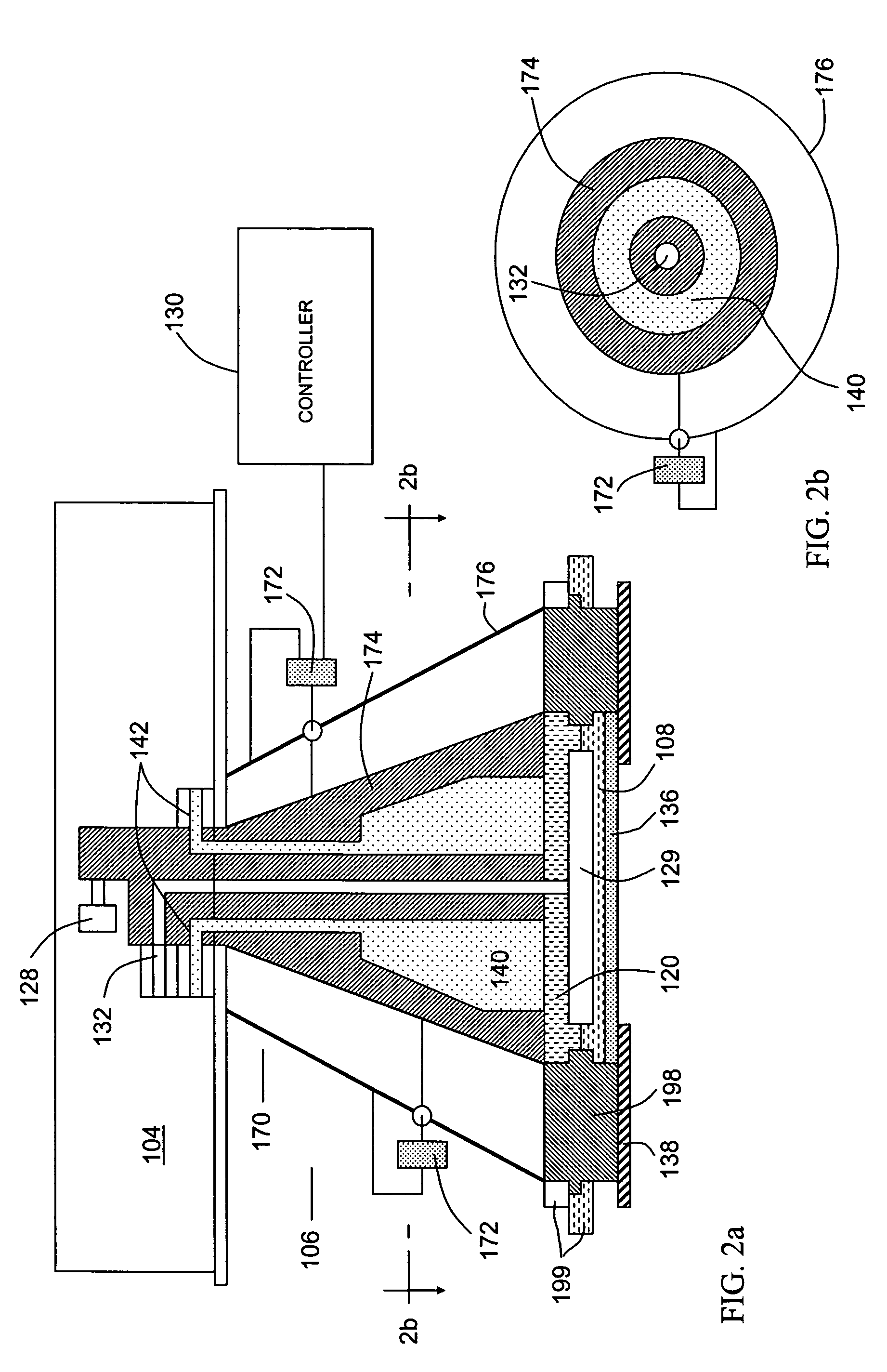

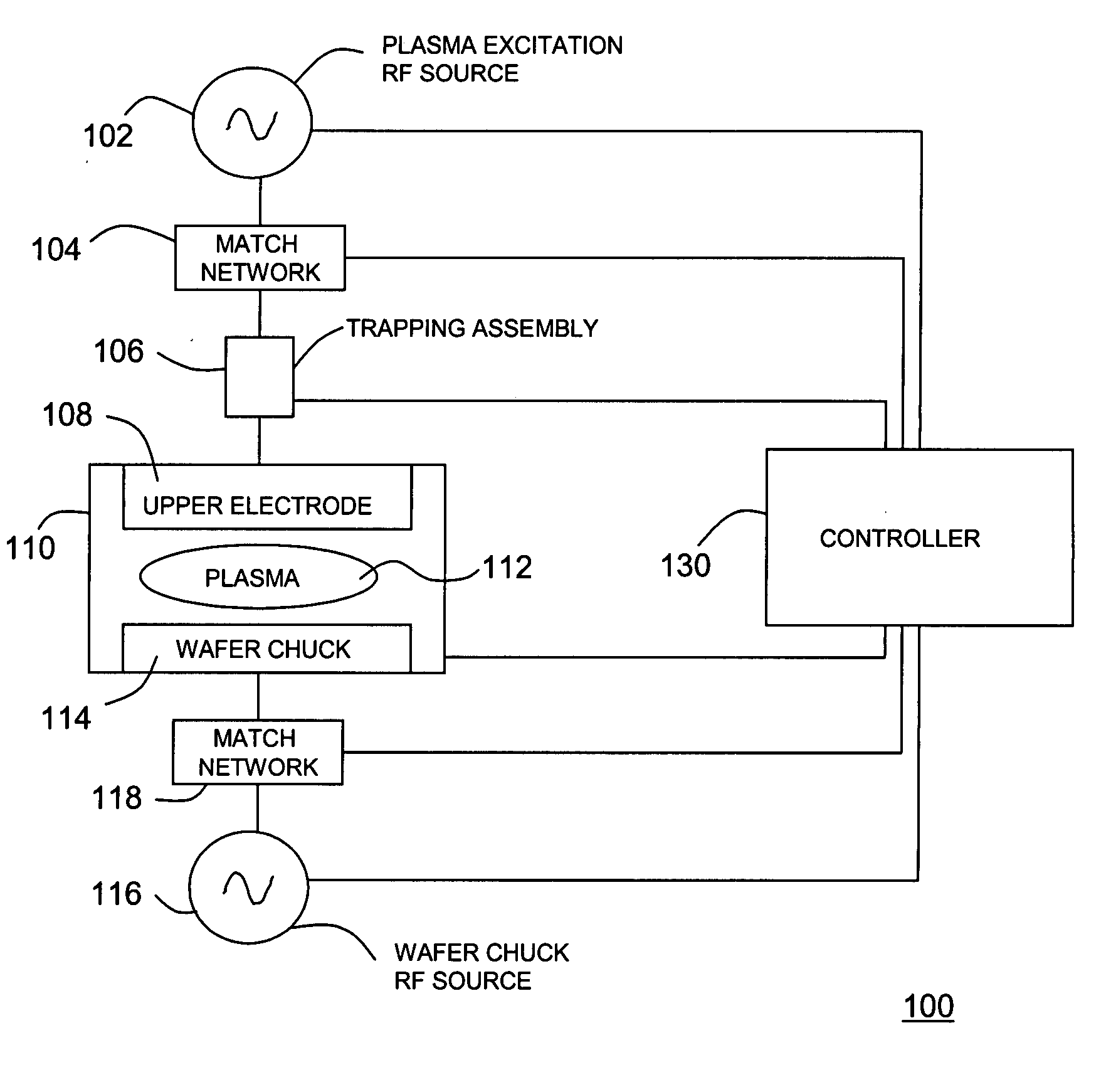

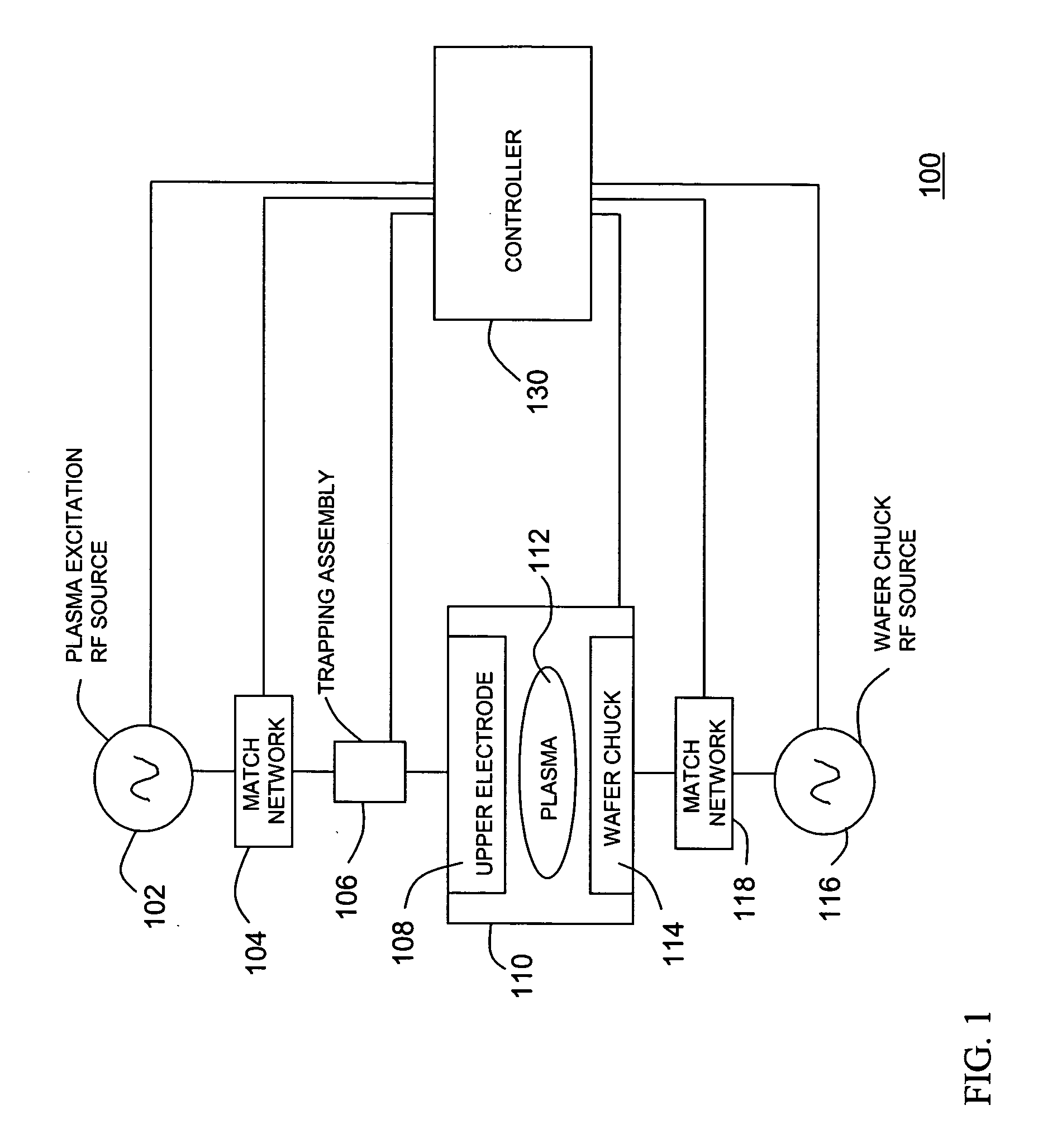

Method and device for removing harmonics in semiconductor plasma processing systems

A system and method for maintaining a plasma in a plasma region by supplying RF power at a fundamental frequency to the plasma region together with a gas in order to create an RF electromagnetic field which interacts with the gas to create a plasma that contains electromagnetic energy components at frequencies that are harmonics of the fundamental frequency. The components at frequencies that are harmonics of the fundamental frequency are reduced by placing RF energy absorbing resistive loads in energy receiving communication with the plasma, the resistive loads having a frequency dependent attenuation characteristic such that the resistive loads attenuate electrical energy at frequencies higher than the fundamental frequency more strongly than energy at the fundamental frequency.

Owner:TOKYO ELECTRON LTD

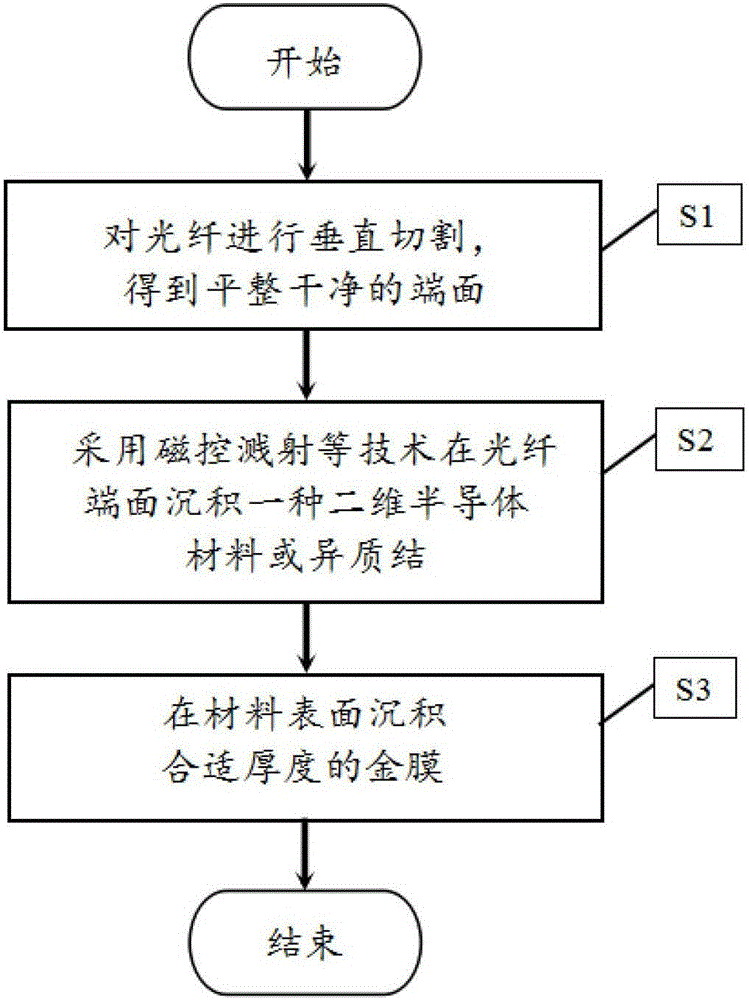

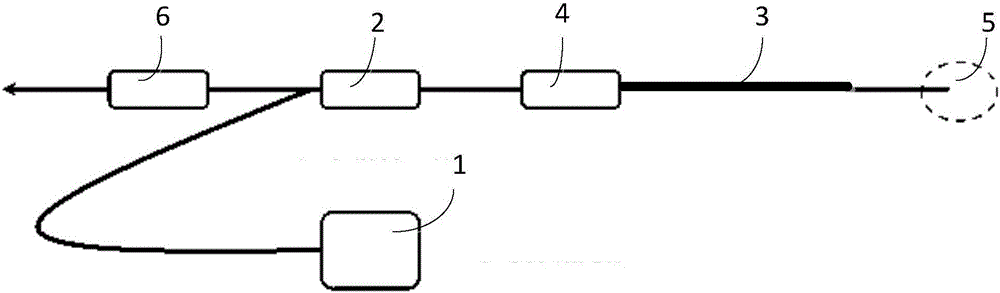

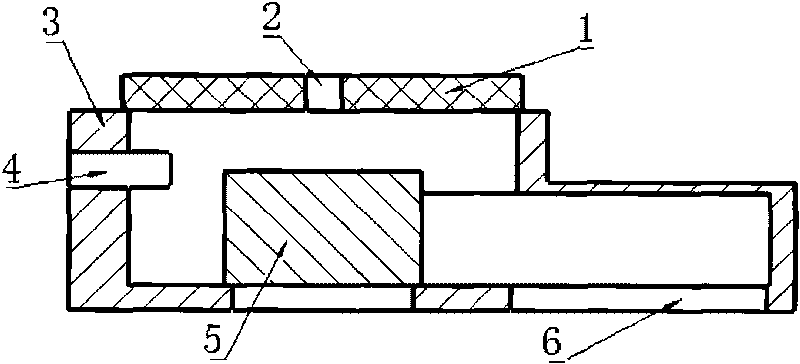

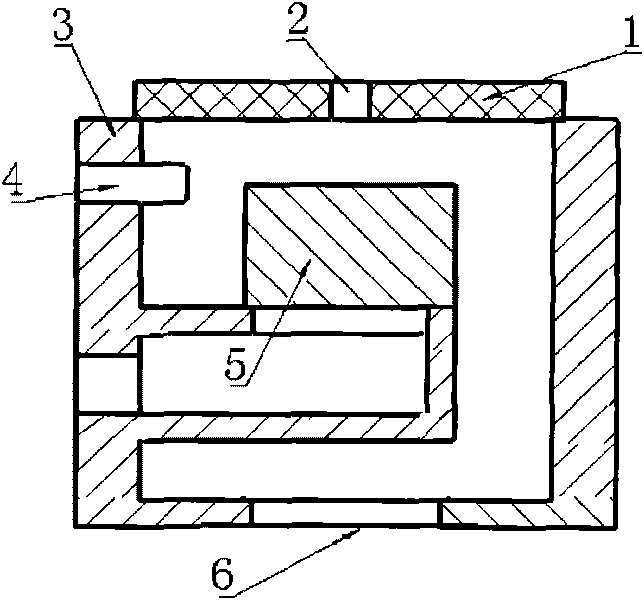

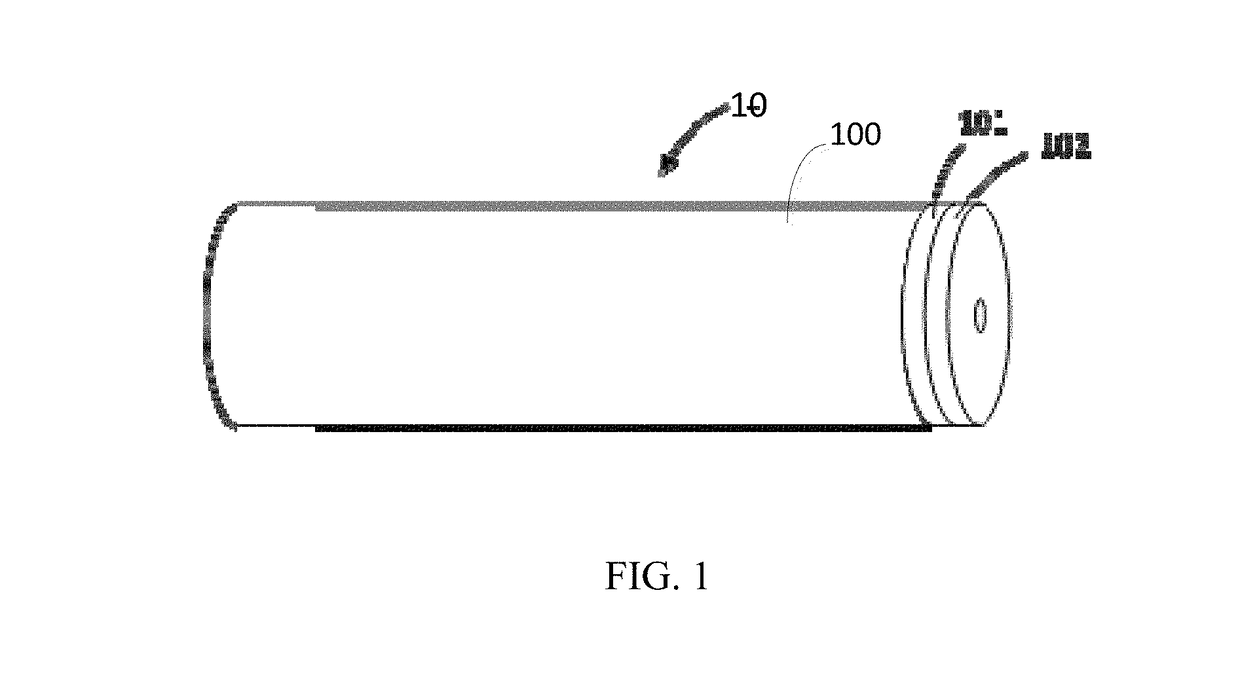

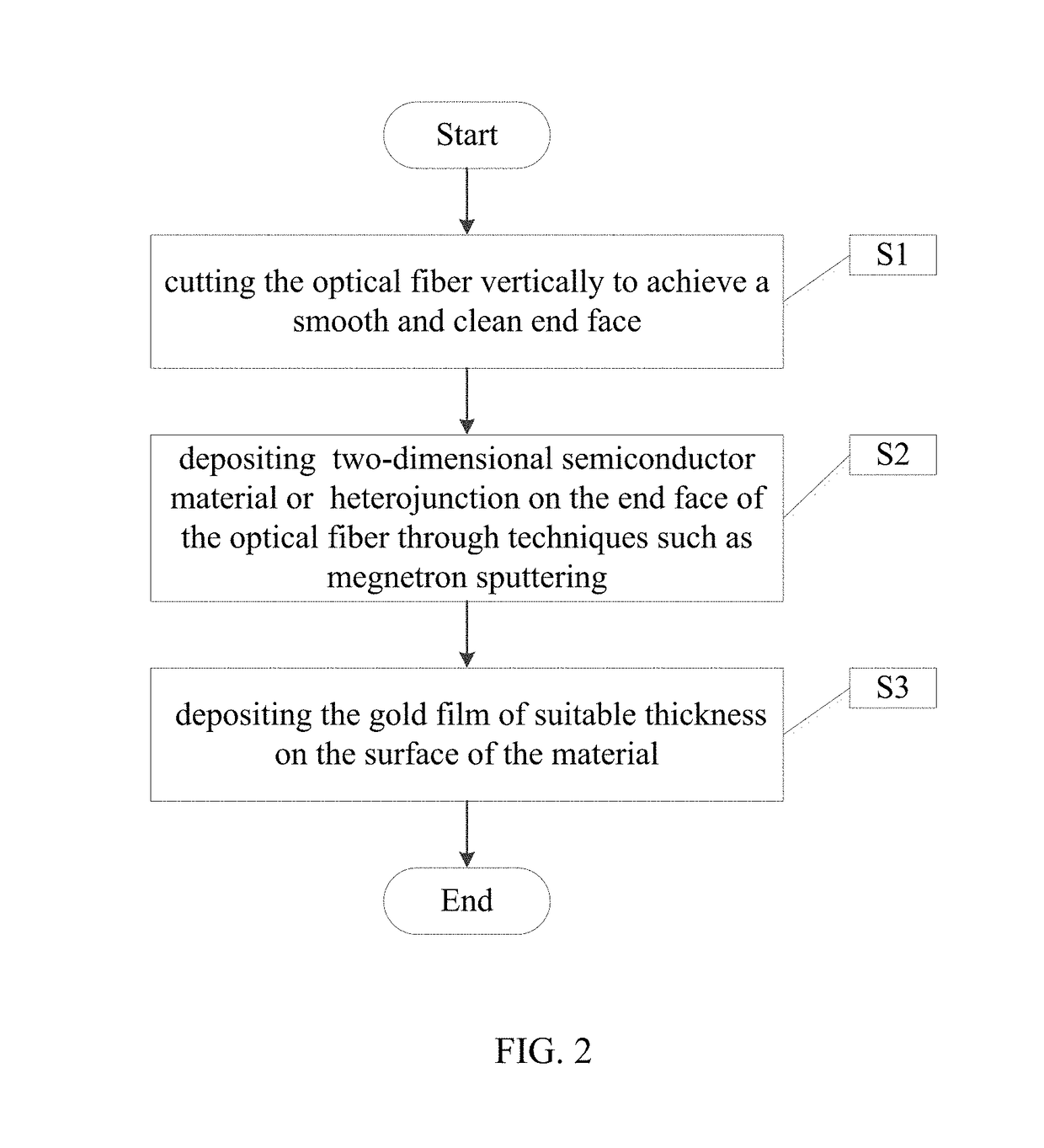

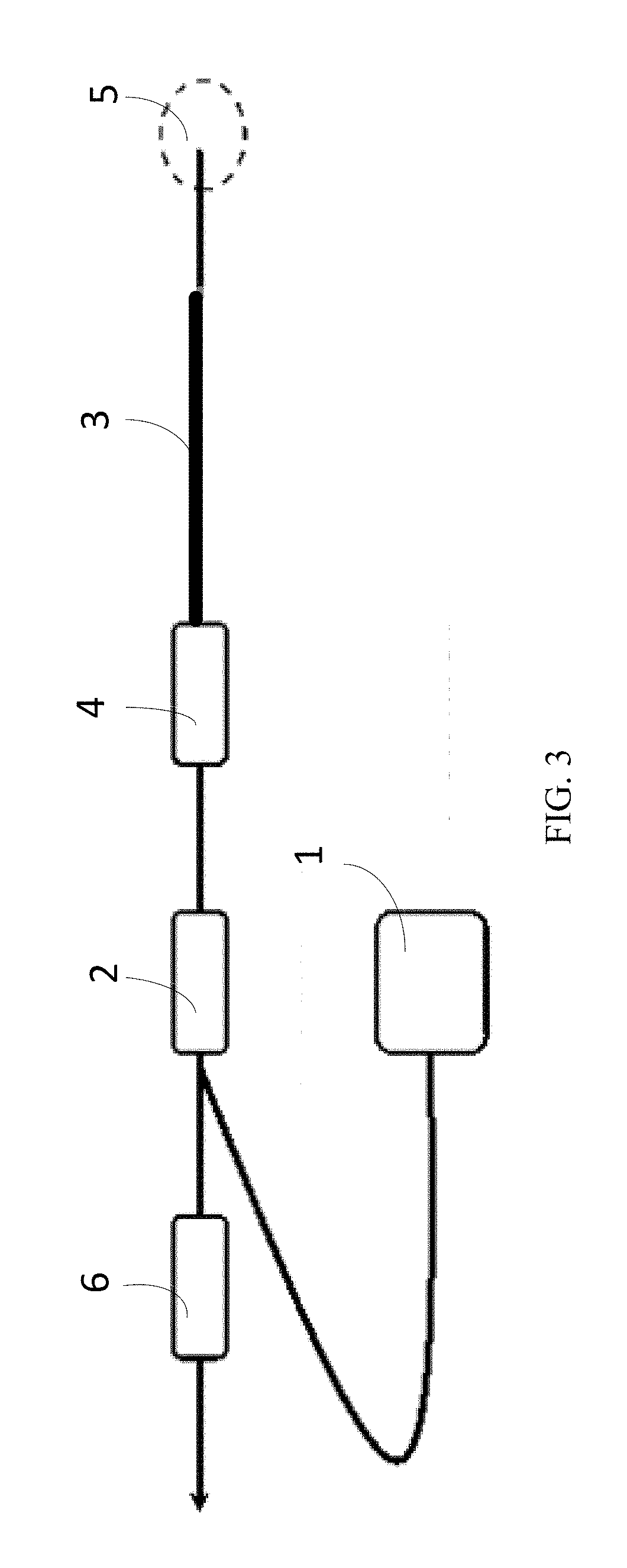

Two-dimensional semiconductor saturable absorber mirror and preparation method thereof, and pulse fiber laser

InactiveCN105896258AHigh damage thresholdNot easy to damageActive medium shape and constructionDeposition temperatureSemiconductor plasma

The invention relates to the technical field of lasers, and provides a two-dimensional semiconductor saturable absorber mirror. The two-dimensional semiconductor saturable absorber mirror comprises an optical fiber, a two-dimensional semiconductor film attached to the optical fiber end face and a gold film attached to the two-dimensional semiconductor film. The invention further provides a preparation method of the two-dimensional semiconductor saturable absorber mirror. The preparation method comprises the steps of: cutting the optical fiber; placing the cut optical fiber and a two-dimensional semiconductor target material in a vacuum chamber, depositing two-dimensional semiconductor plasma on the optical fiber end face, forming the two-dimensional semiconductor film, and enabling the two-dimensional semiconductor film to reach the required thickness by controlling the deposition time and / or the deposition temperature; and plating the gold film on the obtained two-dimensional semiconductor film. The novel two-dimensional semiconductor saturable absorber mirror provided by the invention is composed of the optical fiber end face, the two-dimensional semiconductor film and the gold film, and has the advantages of being high in damage threshold, simple in structure, low in cost, and high in reliability.

Owner:SHENZHEN UNIV

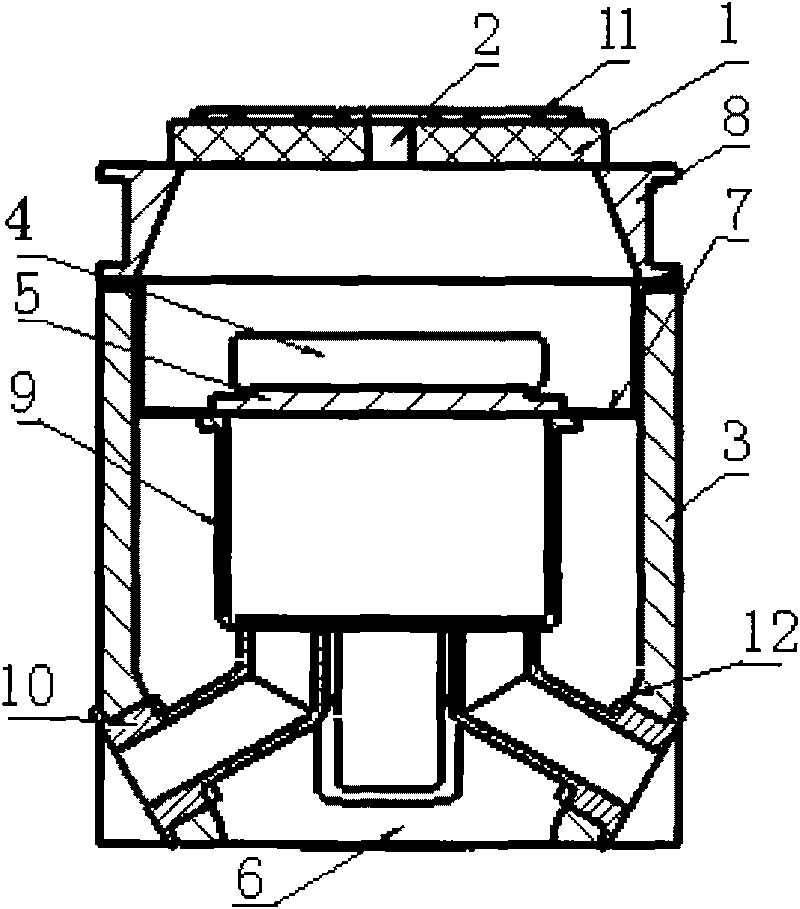

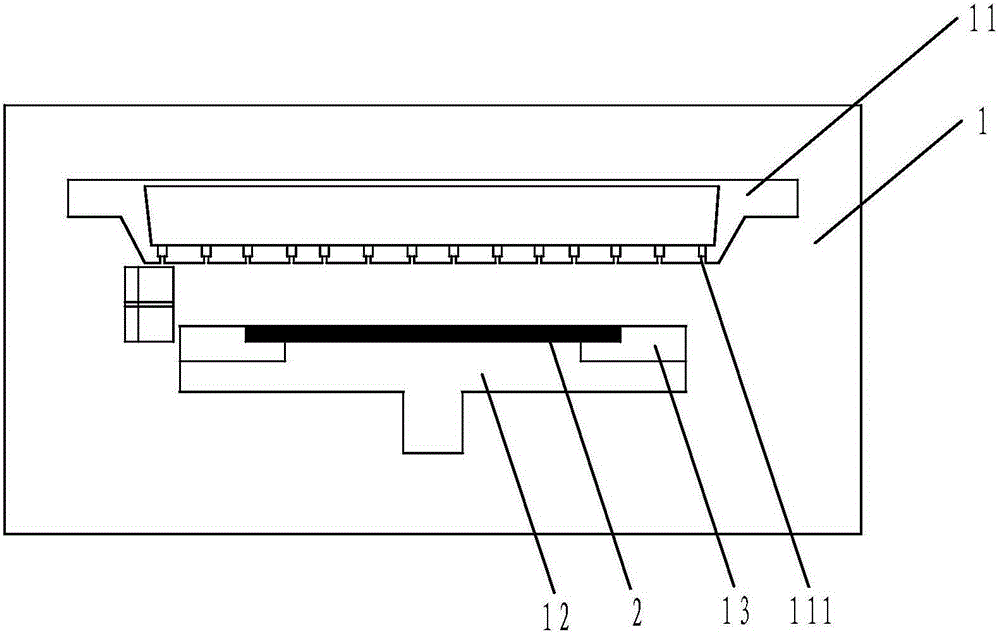

Reaction chamber and semiconductor processing device

ActiveCN101740340AEvenly distributedSimple structureElectric discharge tubesSemiconductor/solid-state device manufacturingSemiconductor plasmaProduct gas

The invention discloses a reaction chamber and a semiconductor processing device, in the reaction chamber, a lower electrode box body is supported on the chamber wall through a plurality of channels, and an inner cavity of the lower electrode box body is communicated with the outside of the reaction chamber through the plurality of channels; the plurality of channels are evenly distributed around the circumferential direction of the longitudinal axial line of the reaction chamber; and an air extraction port is formed at the lower part of the chamber wall. On the one hand, a centrally symmetric distribution structure is formed on an air extraction air passage, thereby forming even distribution of air flow; on the other hand, a variety of air pipelines, electrical lines, cooling pipelines, radio frequency lines and the like can be arranged through the plurality of channel, thereby realizing simple structure and flexible arrangement. The reaction chamber can be used for different types of semiconductor plasma processing, such as etching, deposition and the like.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

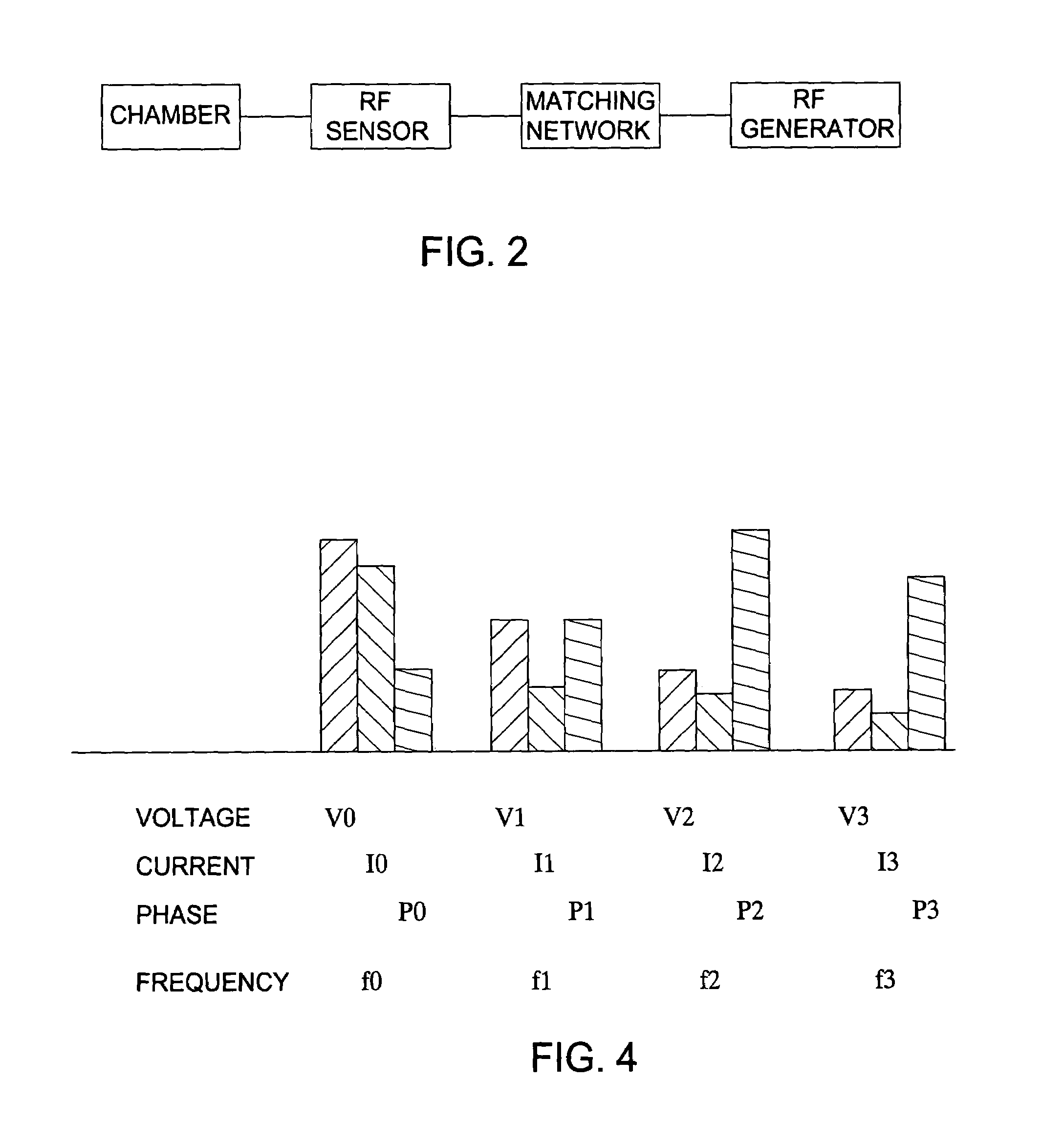

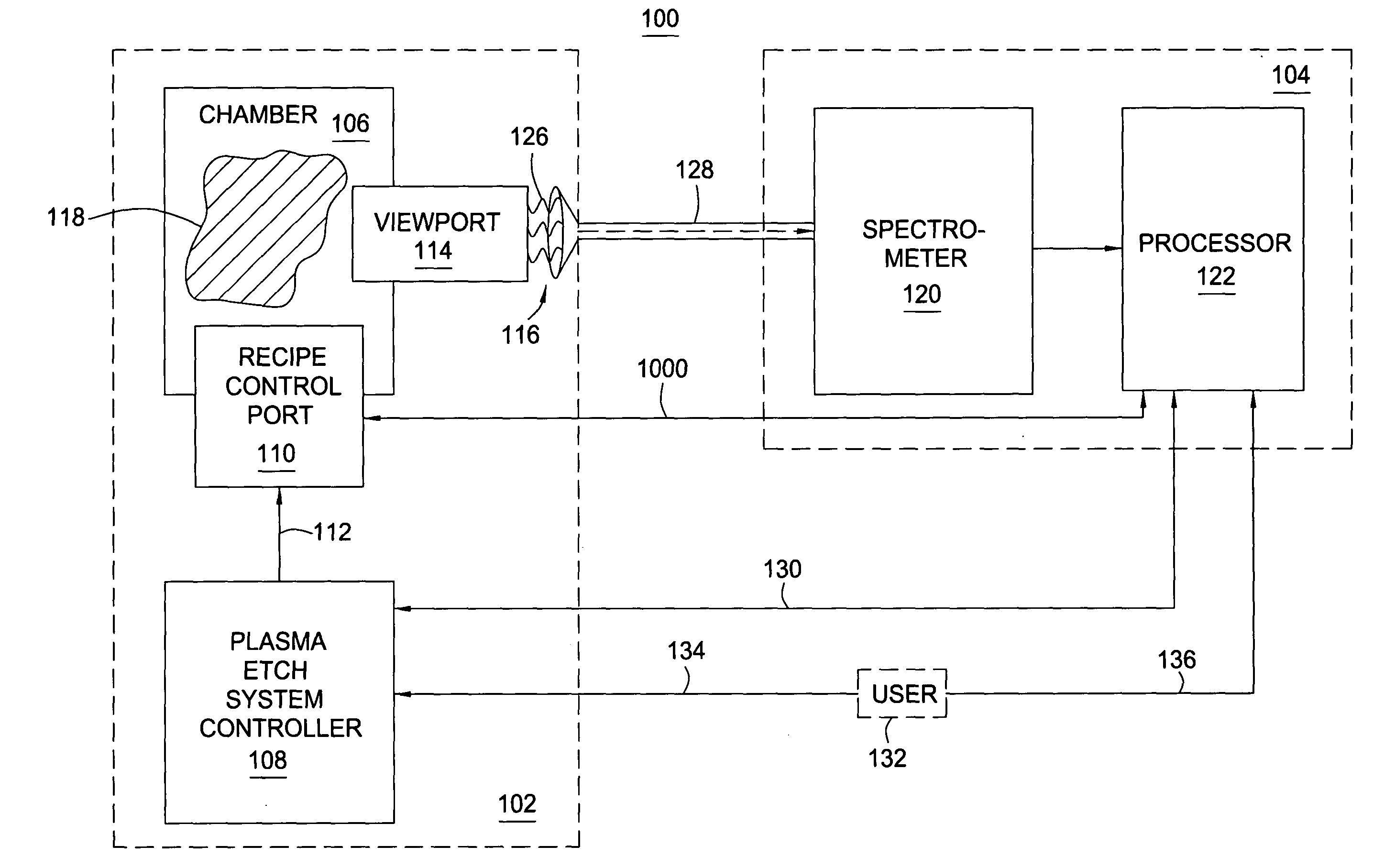

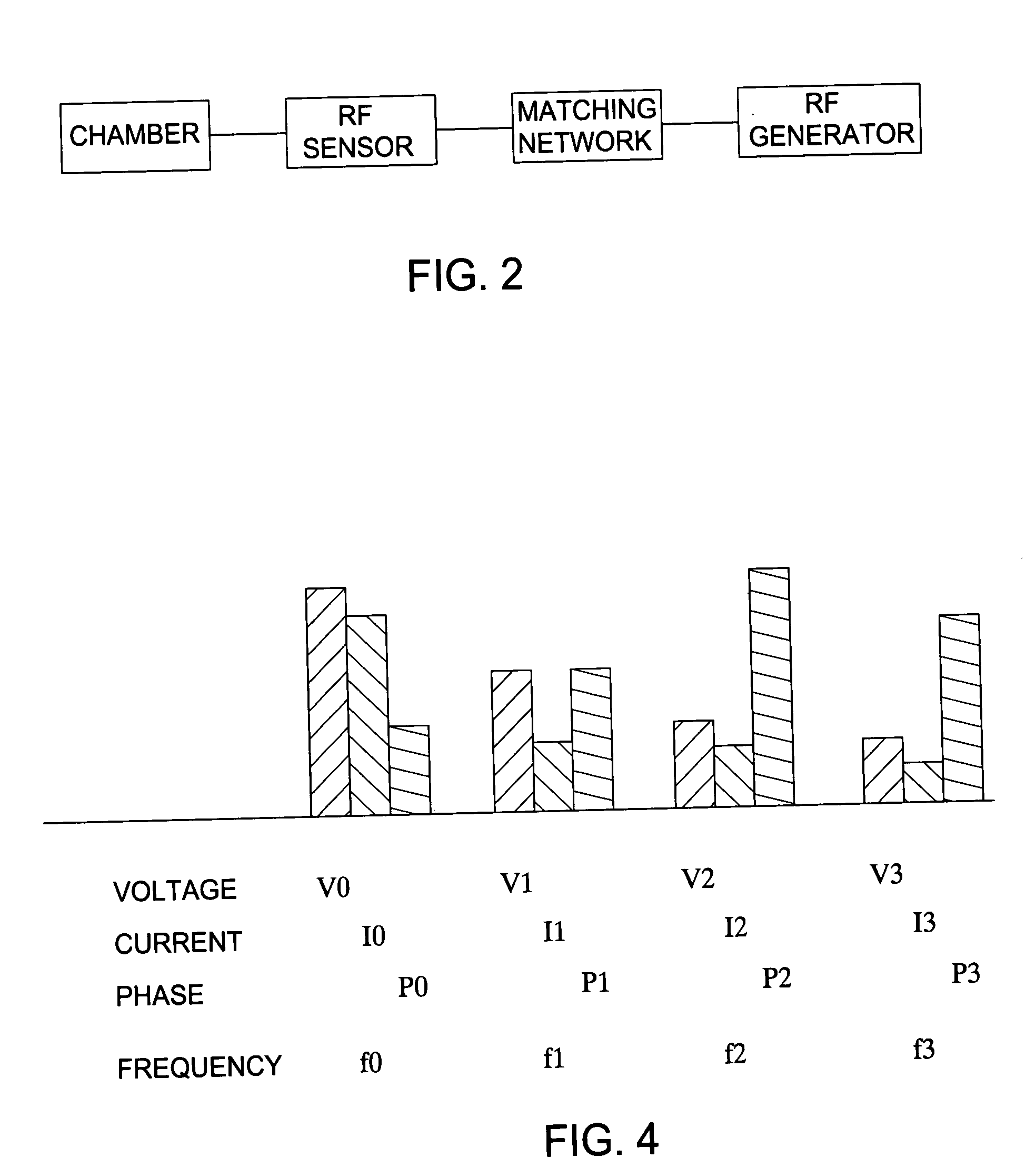

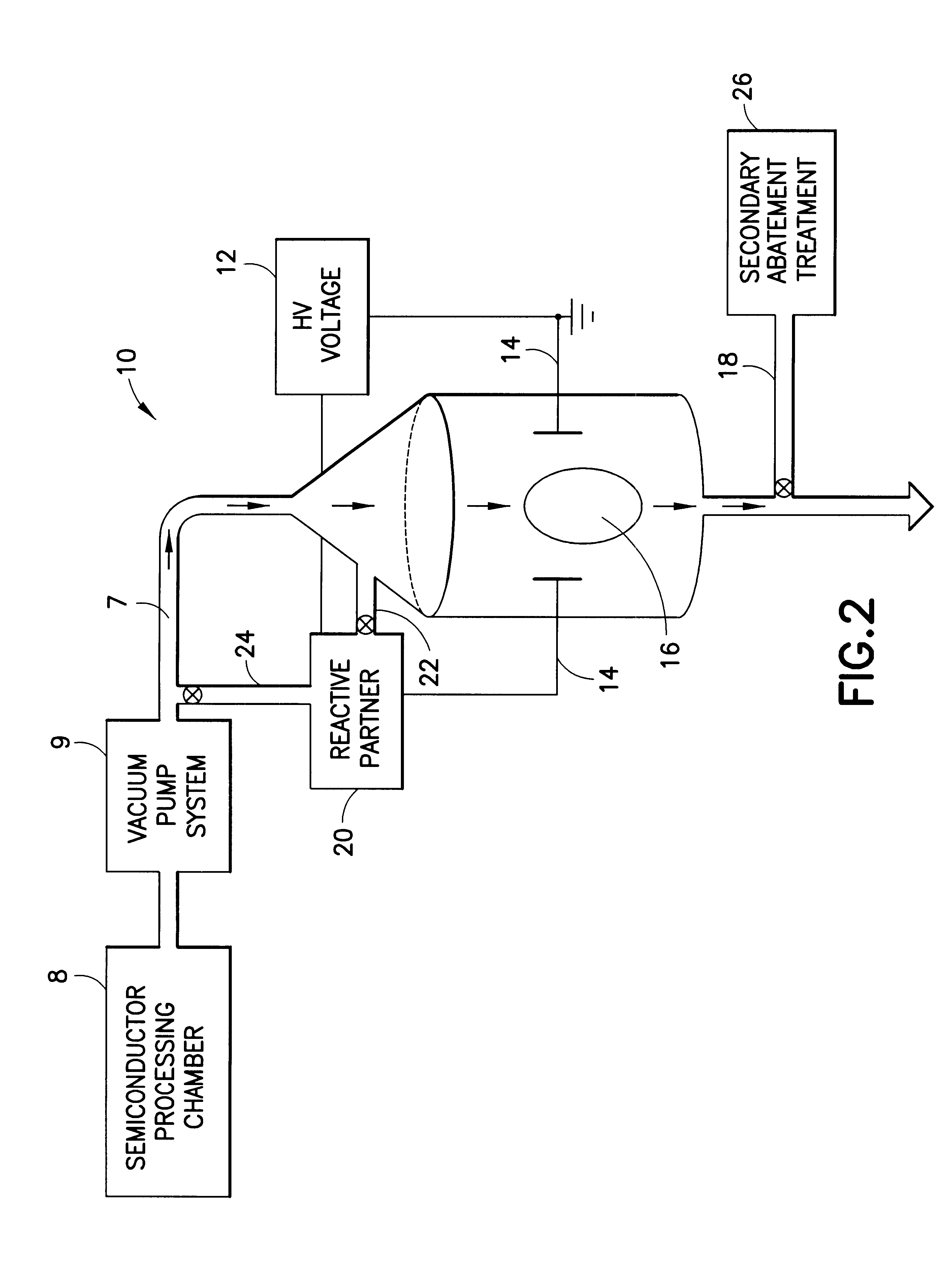

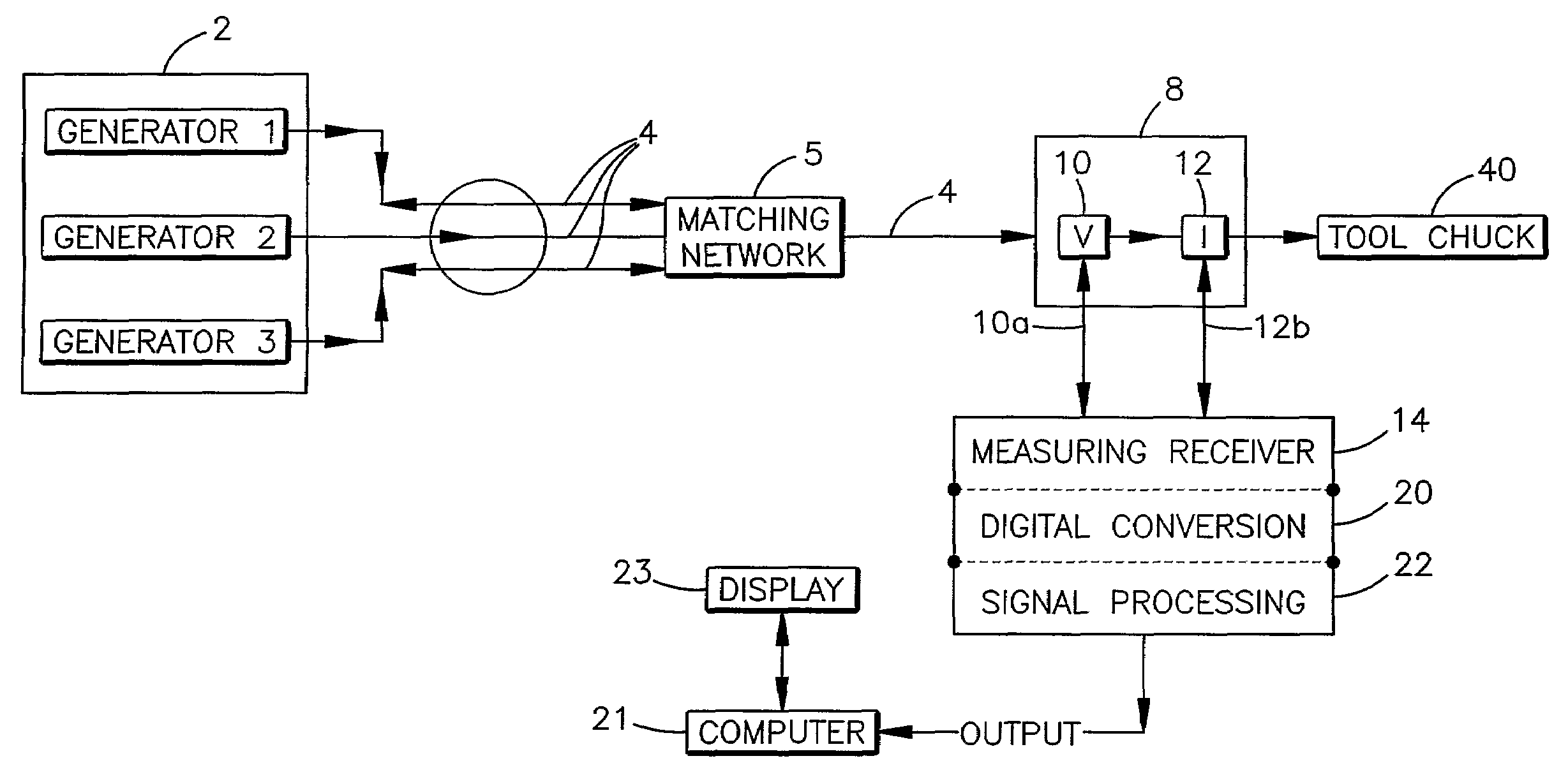

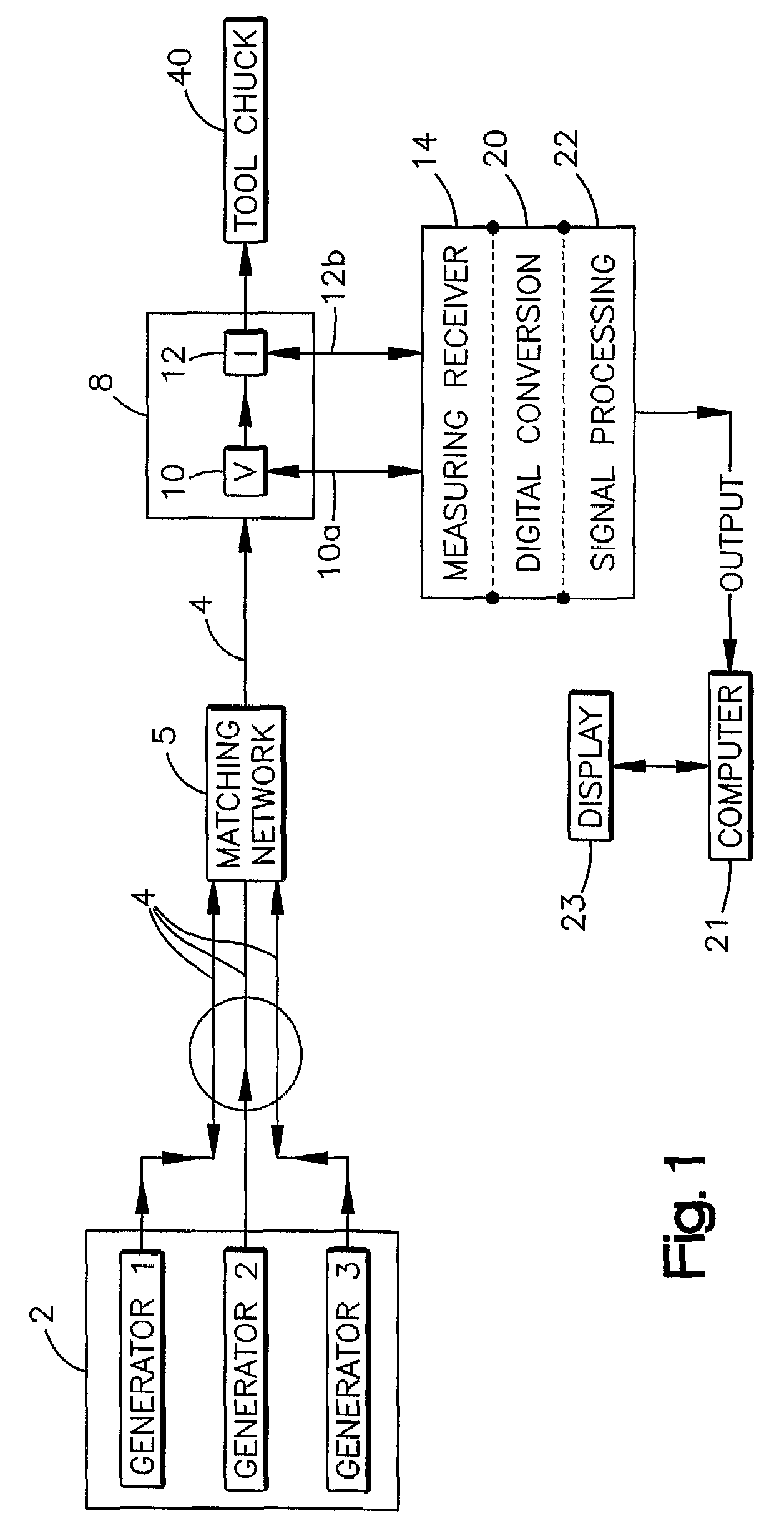

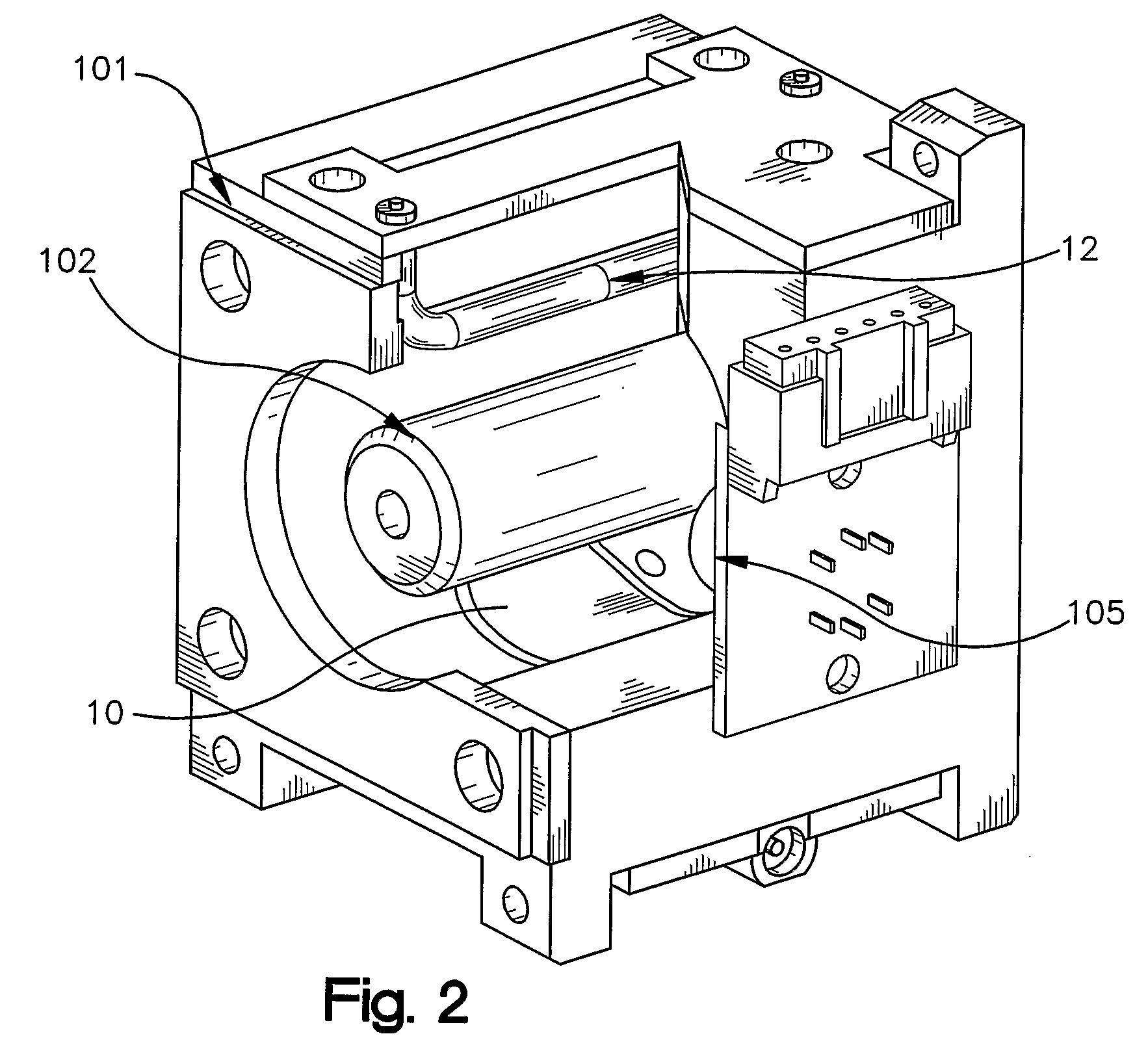

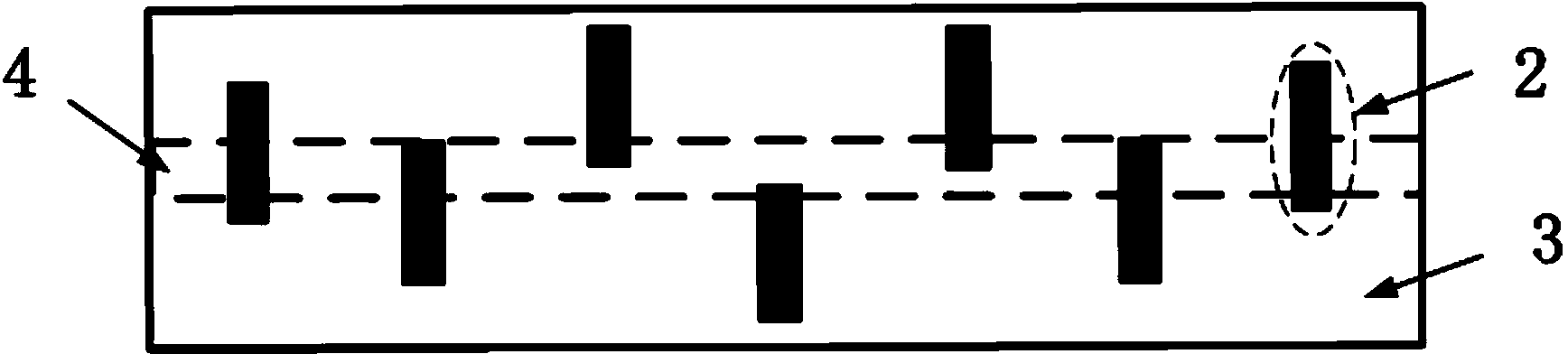

System and method for analyzing power flow in semiconductor plasma generation systems

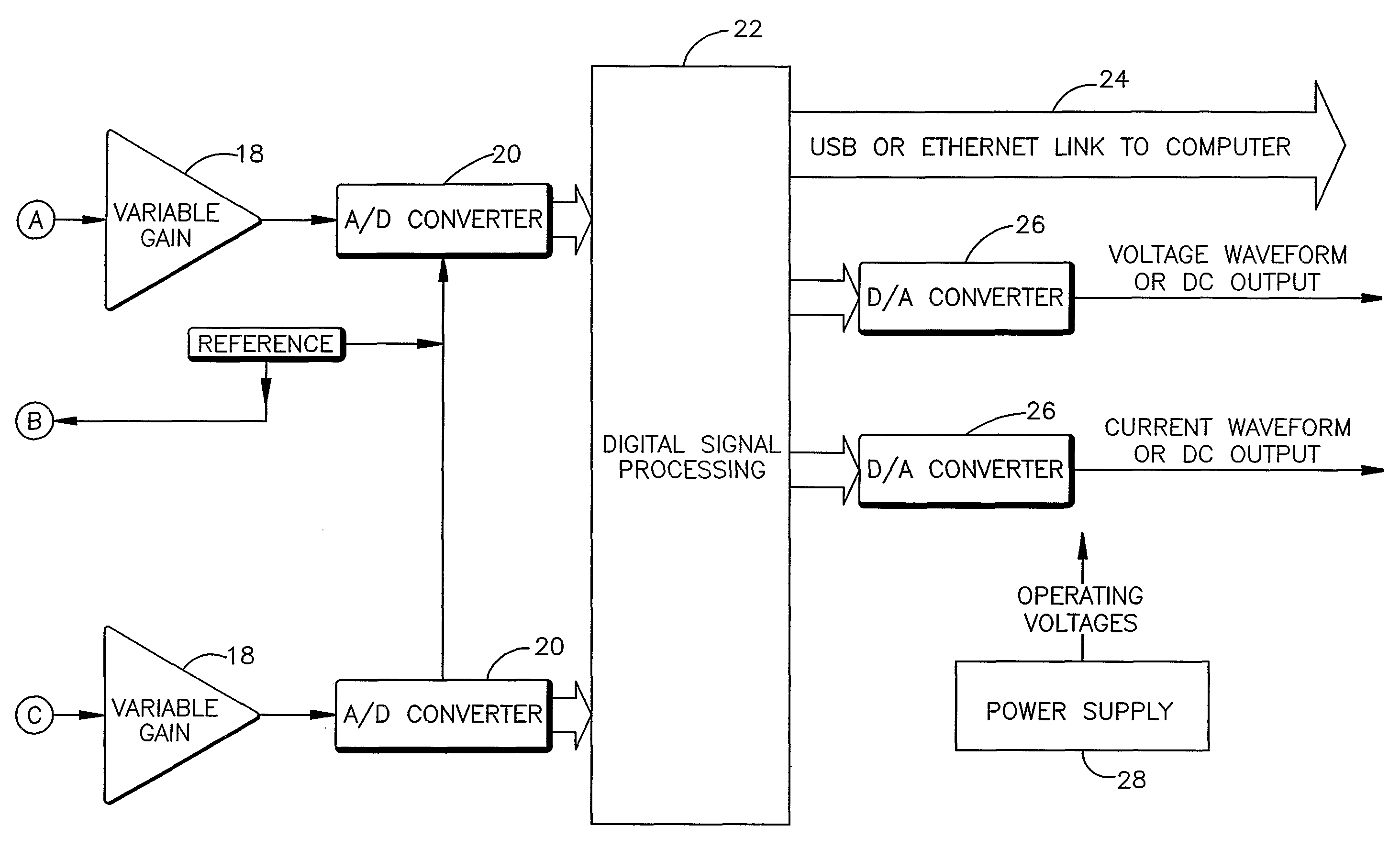

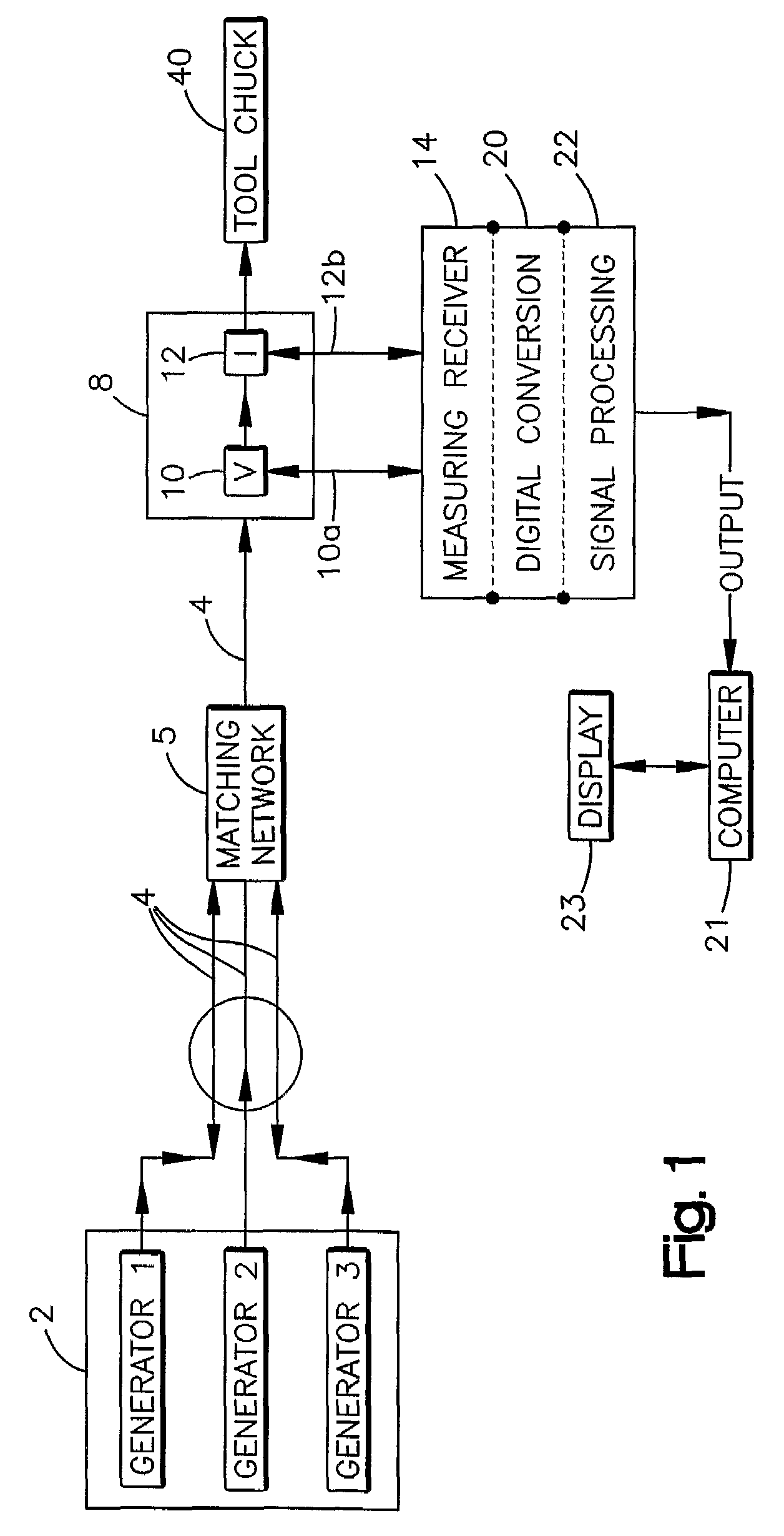

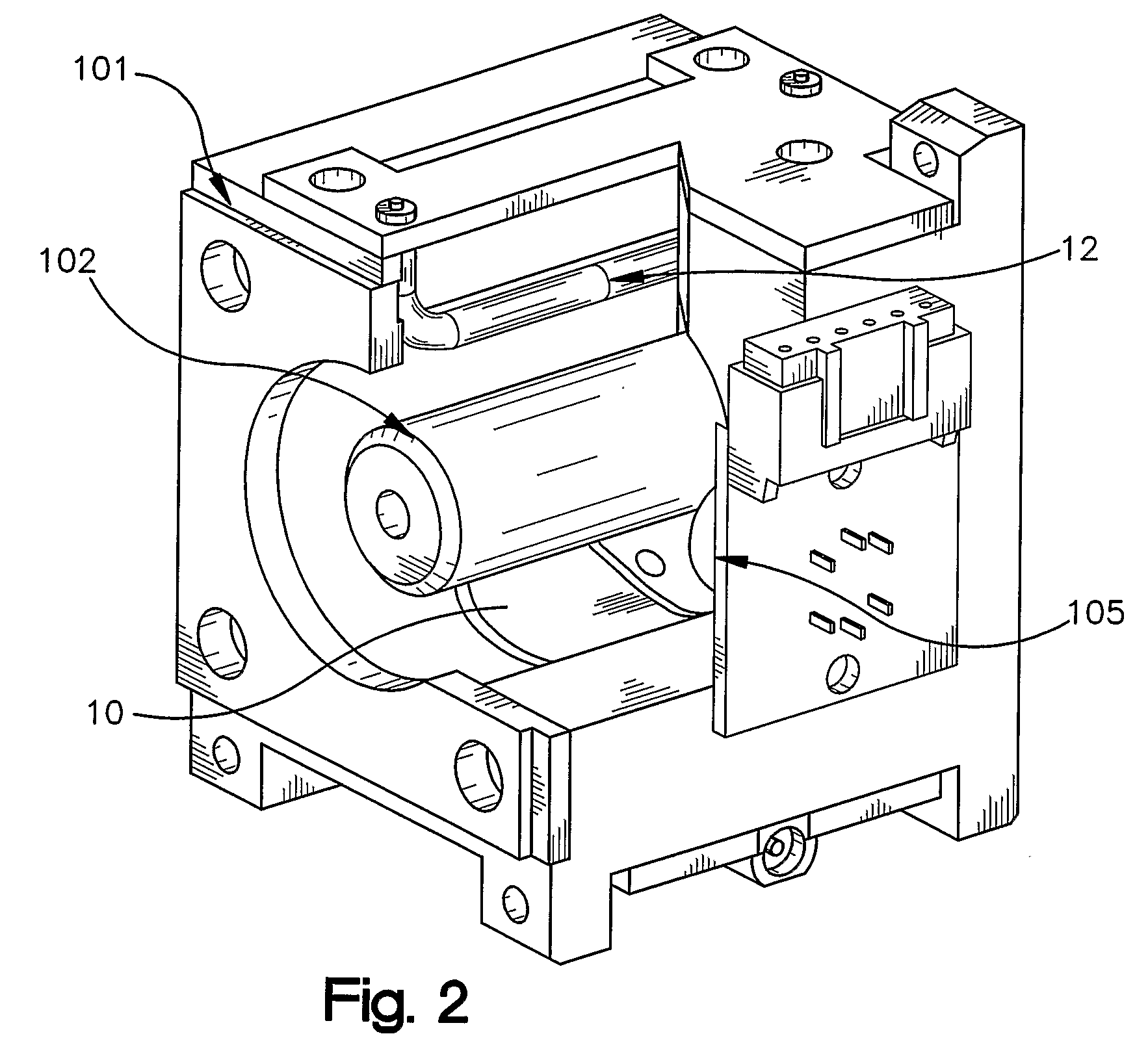

ActiveUS20090210181A1Spectral/fourier analysisNoise figure or signal-to-noise ratio measurementElectric power transmissionPlasma generator

A system and method for measuring and analyzing power flow parameters in RF-based excitation systems for semi-conductor plasma generators. A measuring probe (8) is connected to an RF transmission line for receiving and measuring voltage (10) and current signals (12) from the transmission line (4). A high-speed sampling process converts the measured RF voltage and current signals into digital signals. The digital signals are then processed so as to reveal fundamental and harmonic amplitude and phase information corresponding to the original RF signals. Multiple measuring probes may be inserted in the power transmission path to measure two-port parameters, and the networked probes may be interrogated to determine input impedance, output impedance, insertion loss, internal dissipation, power flow efficiency, scattering, and the effect of plasma non-linearity on the RF signal.

Owner:BIRD TECH GROUP

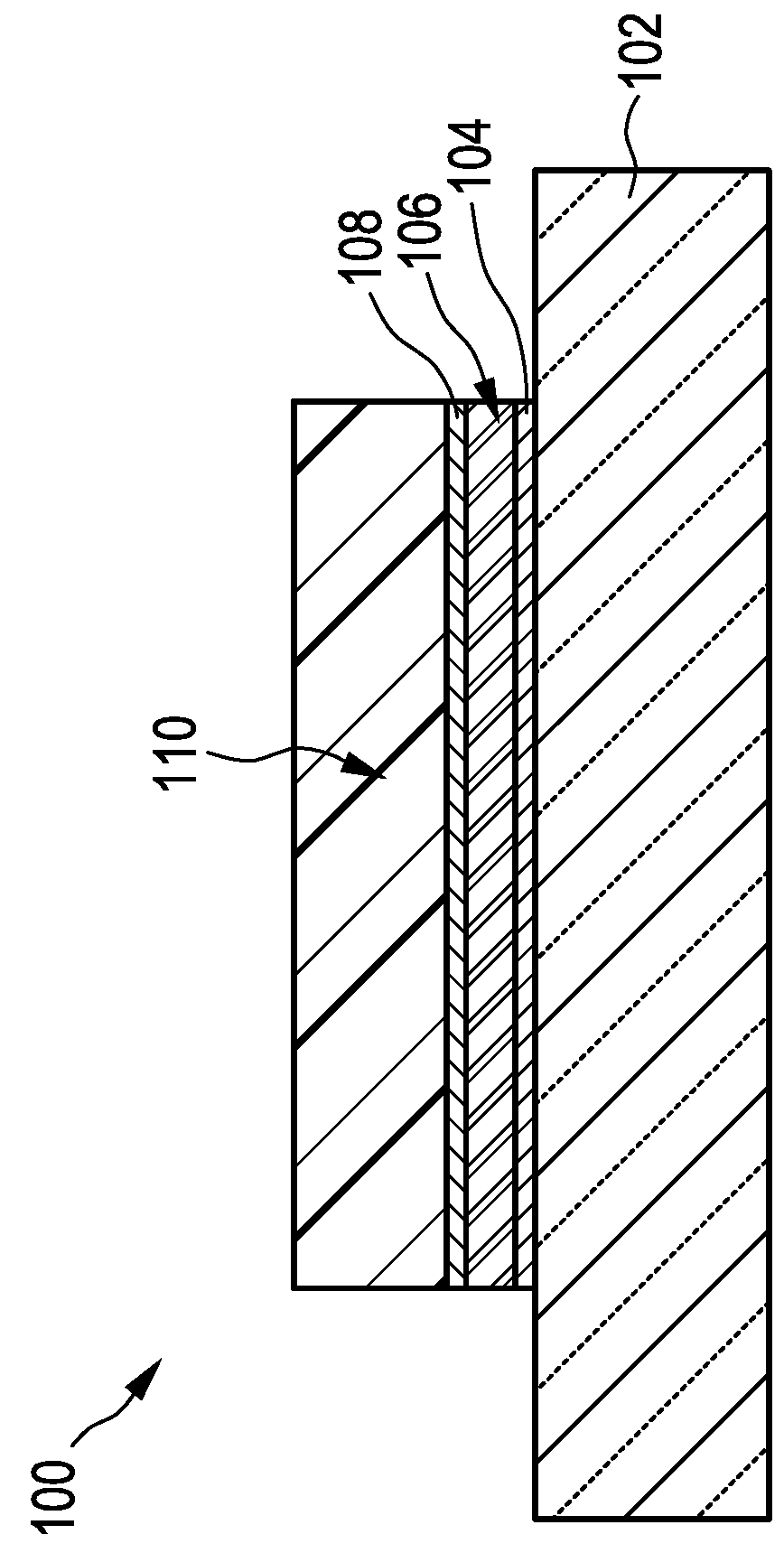

Coating packaged chamber parts for semiconductor plasma apparatus

ActiveUS9617633B2Improve service performanceImprove processing qualityAnodisationVacuum evaporation coatingSemiconductor plasmaParticle generation

An advanced coating for parts used in plasma processing chamber. The advanced coating is formed over an anodized surface that has not been sealed. After the coating is formed, the coated area is masked, and the remaining anodized surface is sealed. The porous and rough structure of the anodized but un-sealed aluminum enhances adhesion of the coating. However, to prevent particle generation, the exposed anodized surface is sealed after formation of the coating. The coating can be of yttria, formed by plasma enhanced atomic deposition techniques which results in a dense and smooth coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Atmospheric pressure plasma enhanced abatement of semiconductor process effluent species

InactiveUS20020111045A1Combination devicesSemiconductor/solid-state device manufacturingSemiconductor plasmaCorona discharge

The present invention relates to a method and system for non-thermal abatement of effluent species generated in a semiconductor processing unit. In the method, an effluent stream is introduced into a discharge reactor wherein the components of the effluent stream are subjected to a corona discharge and maintained therein for a sufficient time to detoxify and / or dissociate the harmful components of the effluent stream. The discharge reactor, maintained at approximately atmospheric pressure, is positioned after the low-pressure semiconductor processing chamber and connecting vacuum pump system to limit interference with the semiconductor plasma processing tool.

Owner:APPLIED MATERIALS INC

Method and device for removing harmonics in semiconductor plasma processing systems

ActiveUS20050001555A1Level of power controlElectric discharge tubesElectric arc lampsElectrical resistance and conductanceRadio frequency energy

A system and method for maintaining a plasma in a plasma region by supplying RF power at a fundamental frequency to the plasma region together with a gas in order to create an RF electromagnetic field which interacts with the gas to create a plasma that contains electromagnetic energy components at frequencies that are harmonics of the fundamental frequency. The components at frequencies that are harmonics of the fundamental frequency are reduced by placing RF energy absorbing resistive loads in energy receiving communication with the plasma, the resistive loads having a frequency dependent attenuation characteristic such that the resistive loads attenuate electrical energy at frequencies higher than the fundamental frequency more strongly than energy at the fundamental frequency.

Owner:TOKYO ELECTRON LTD

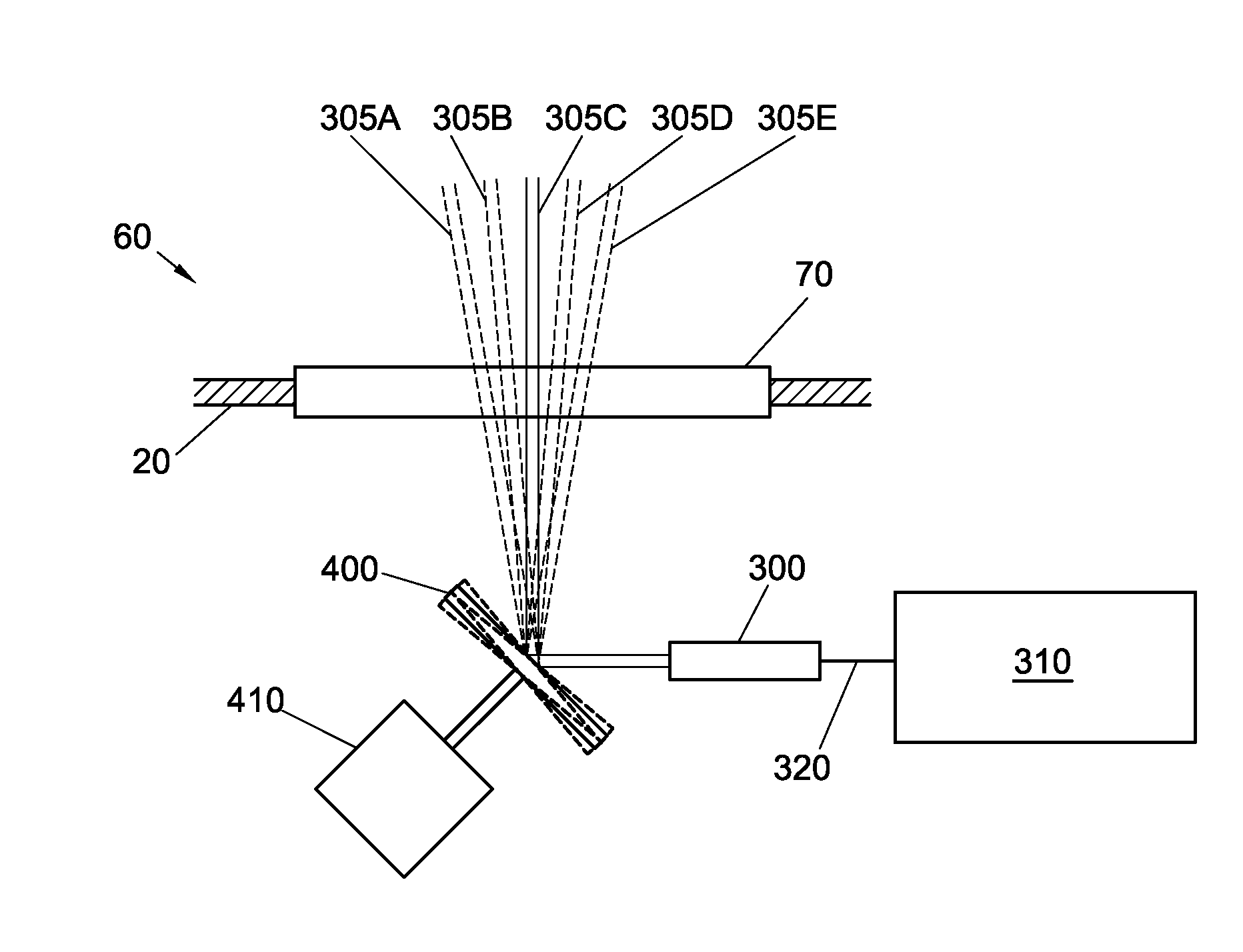

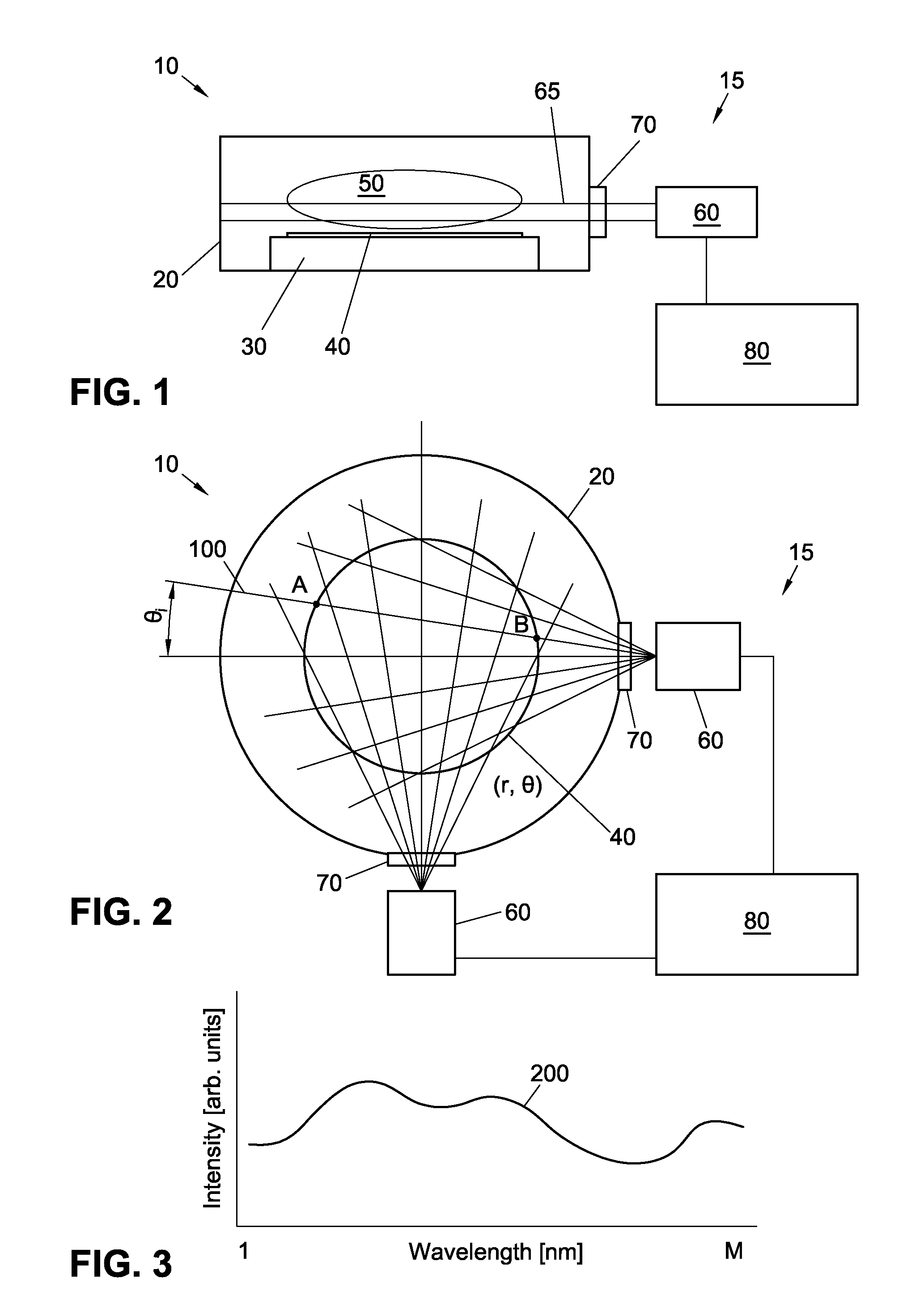

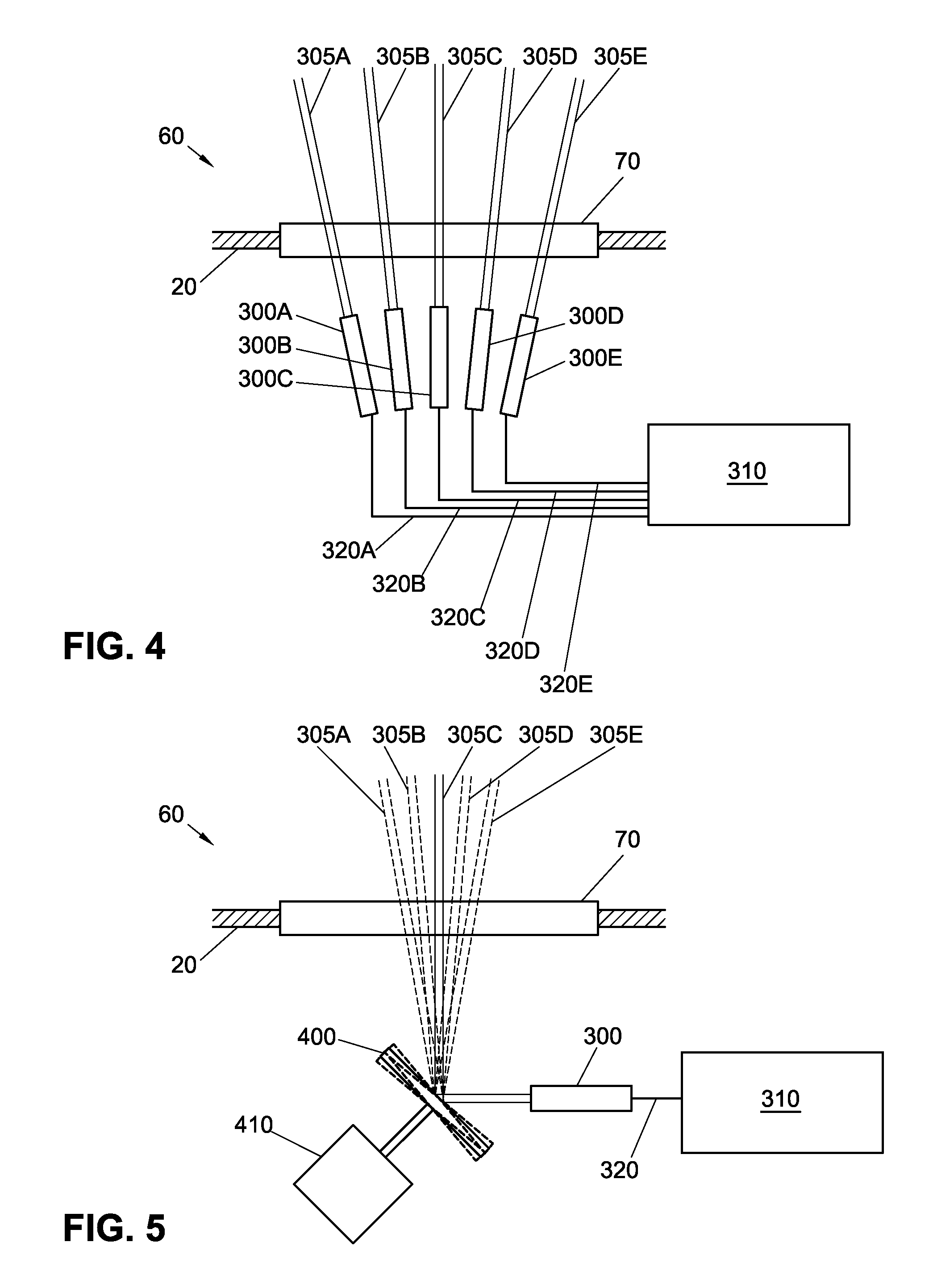

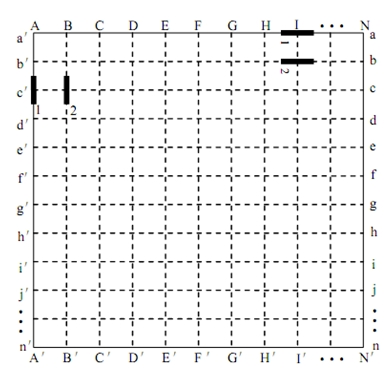

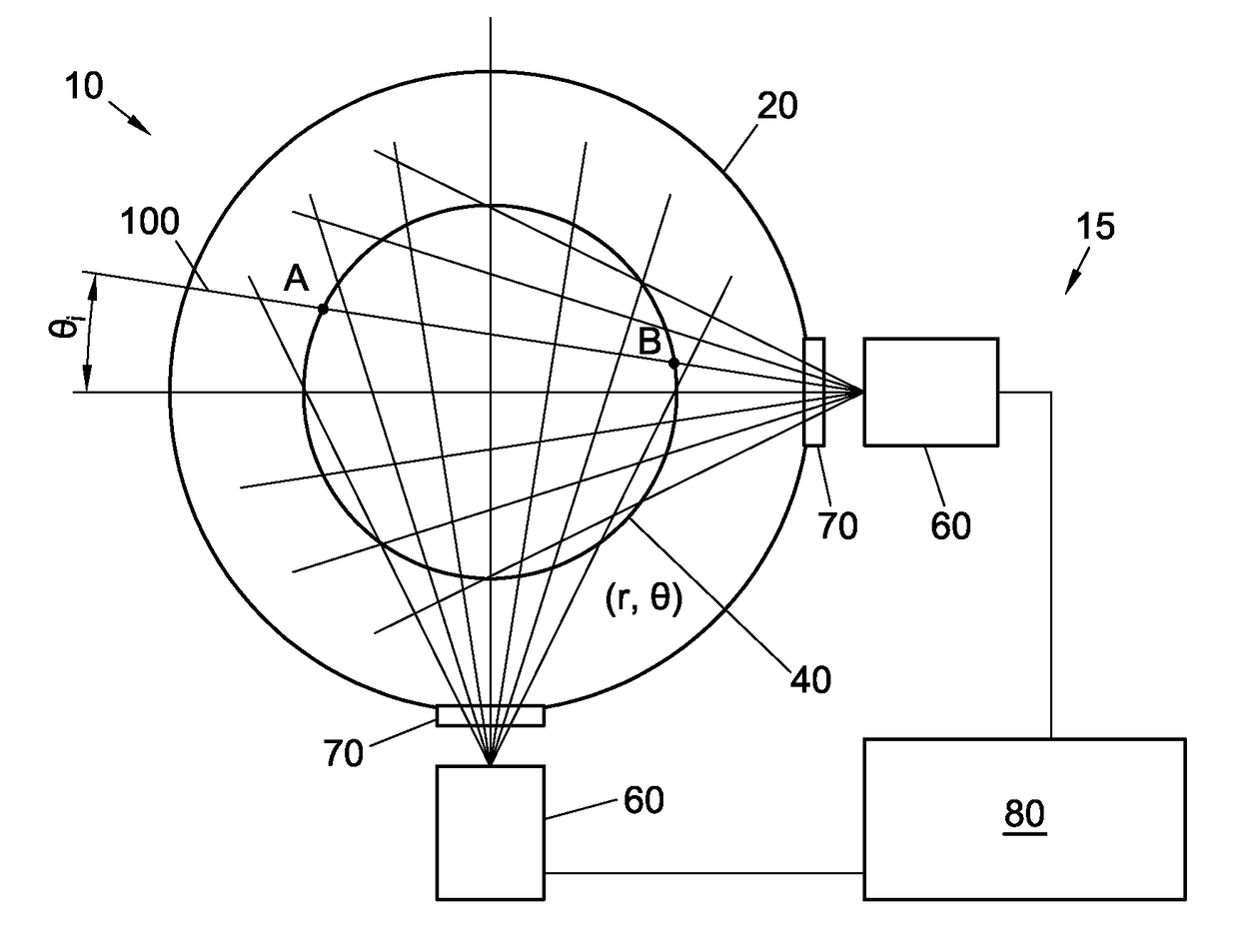

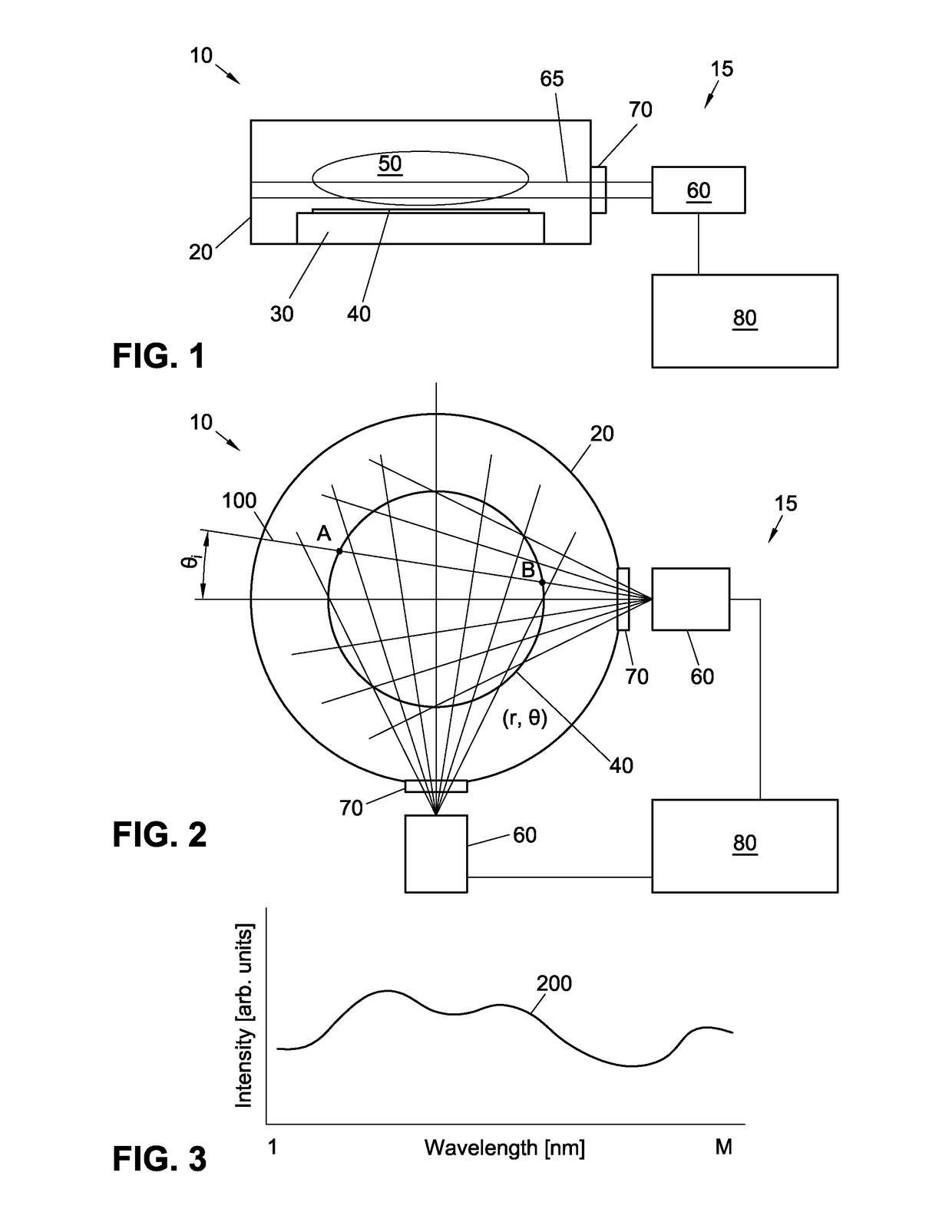

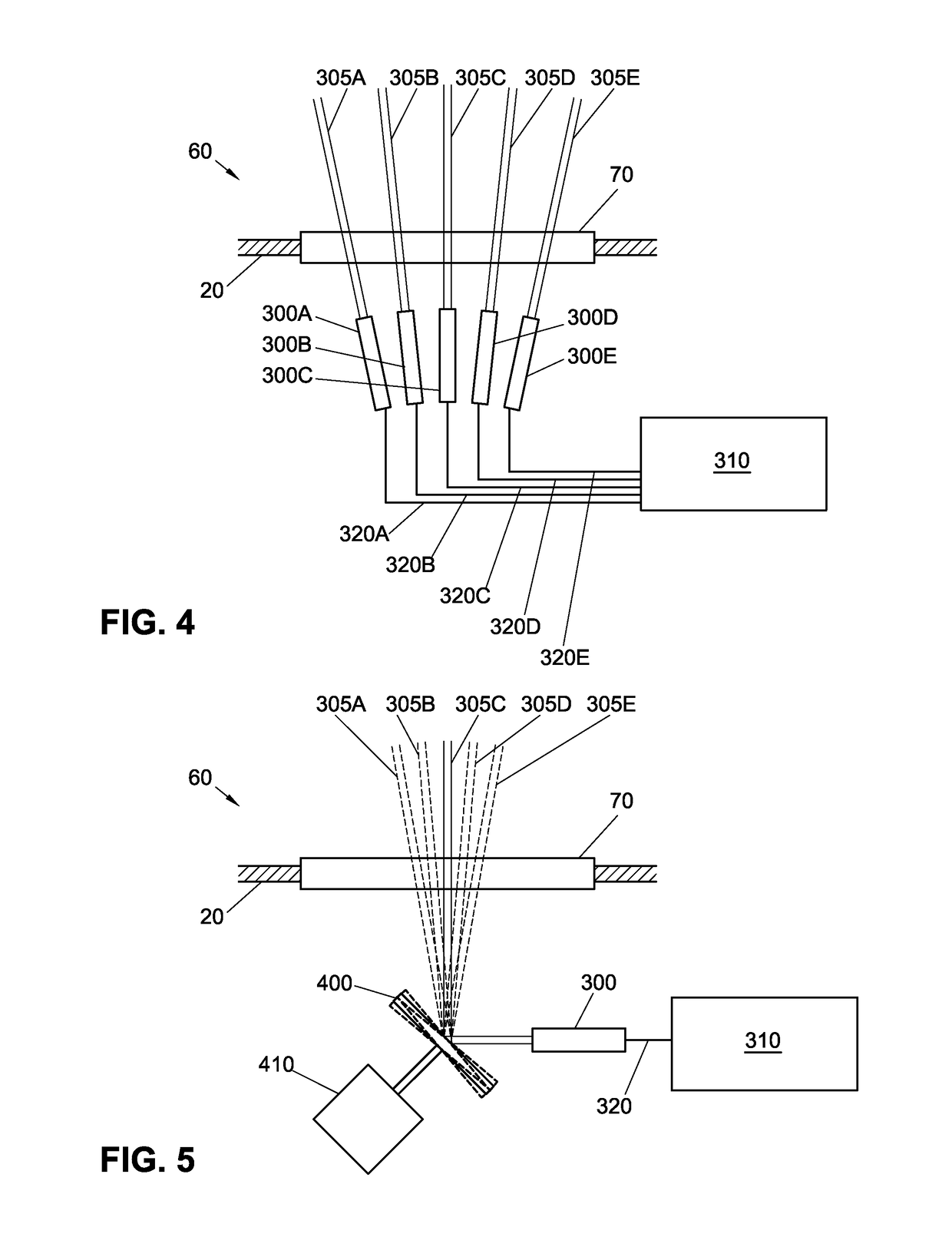

Spatially resolved optical emission spectroscopy (OES) in plasma processing

ActiveUS20150124250A1Emission spectroscopyRadiation pyrometryProcess developmentOptical emission spectrometry

Disclosed is a method, computer method, system, and apparatus for measuring two-dimensional distributions of optical emissions from a plasma in a semiconductor plasma processing chamber. The acquired two-dimensional distributions of plasma optical emissions can be used to infer the two-dimensional distributions of concentrations of certain chemical species of interest that are present in the plasma, and thus provide a useful tool for process development and also for new and improved processing tool development. The disclosed technique is computationally simple and inexpensive, and involves the use of an expansion of the assumed optical intensity distribution into a sum of basis functions that allow for circumferential variation of optical intensity. An example of suitable basis functions are Zernike polynomials.

Owner:TOKYO ELECTRON LTD

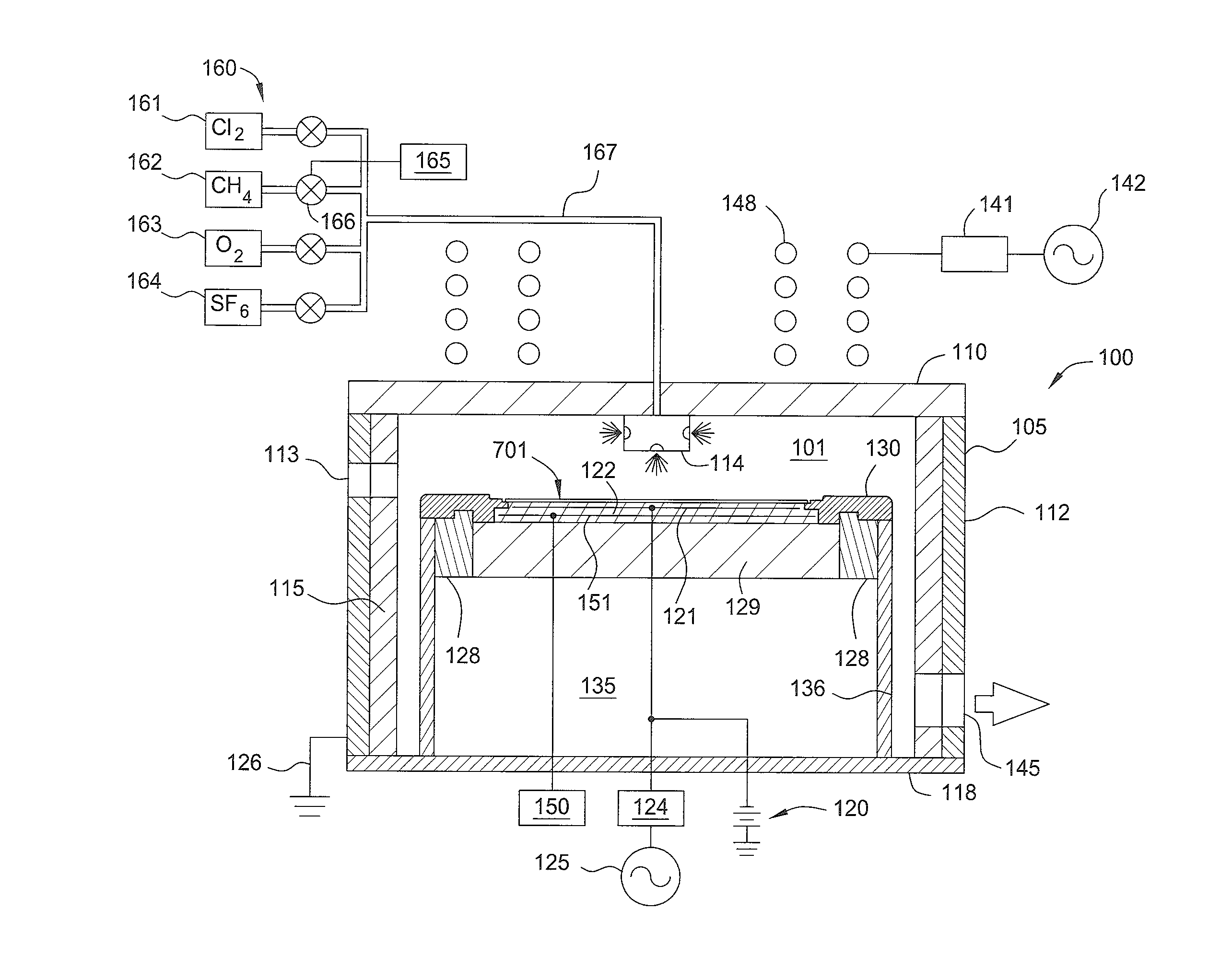

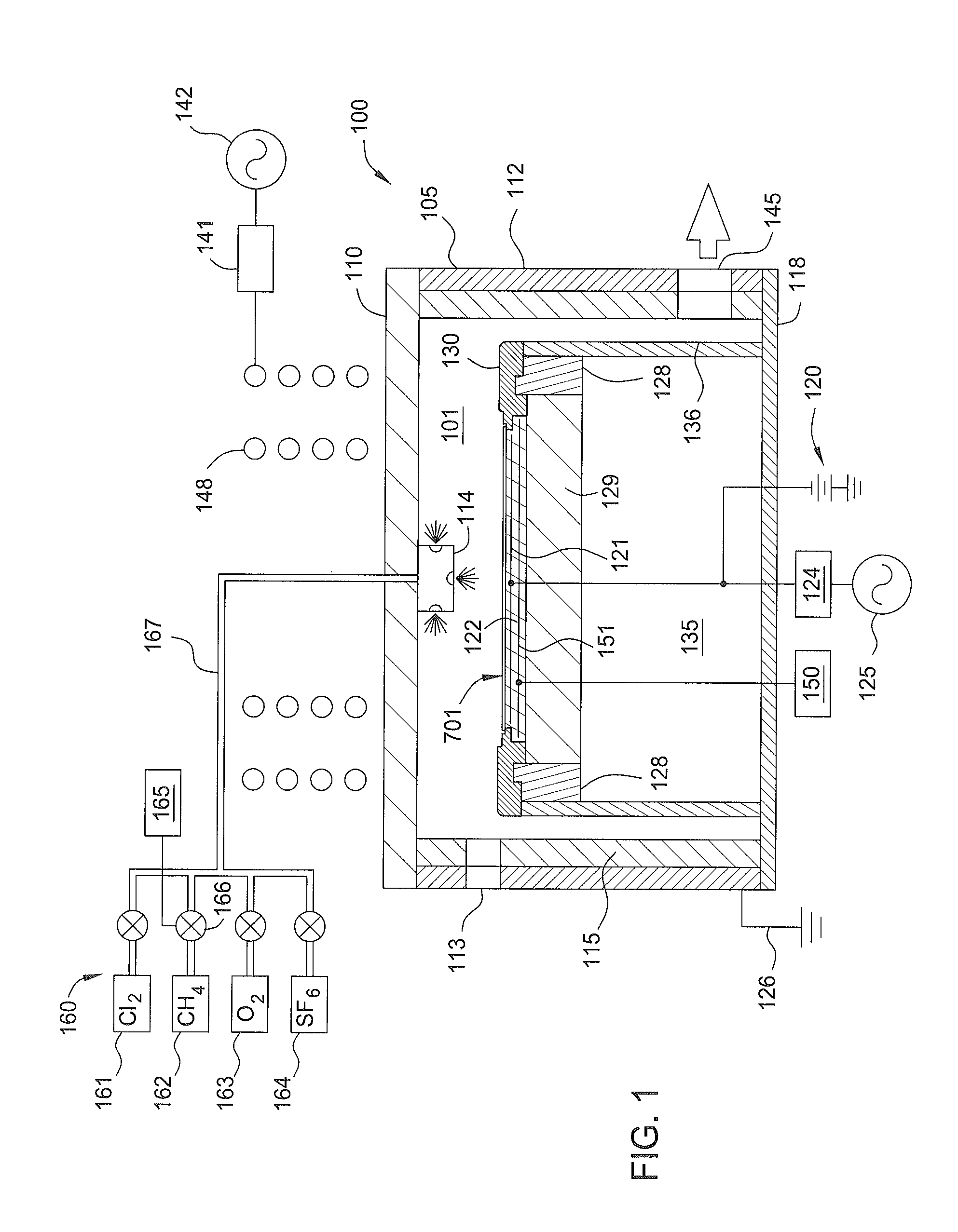

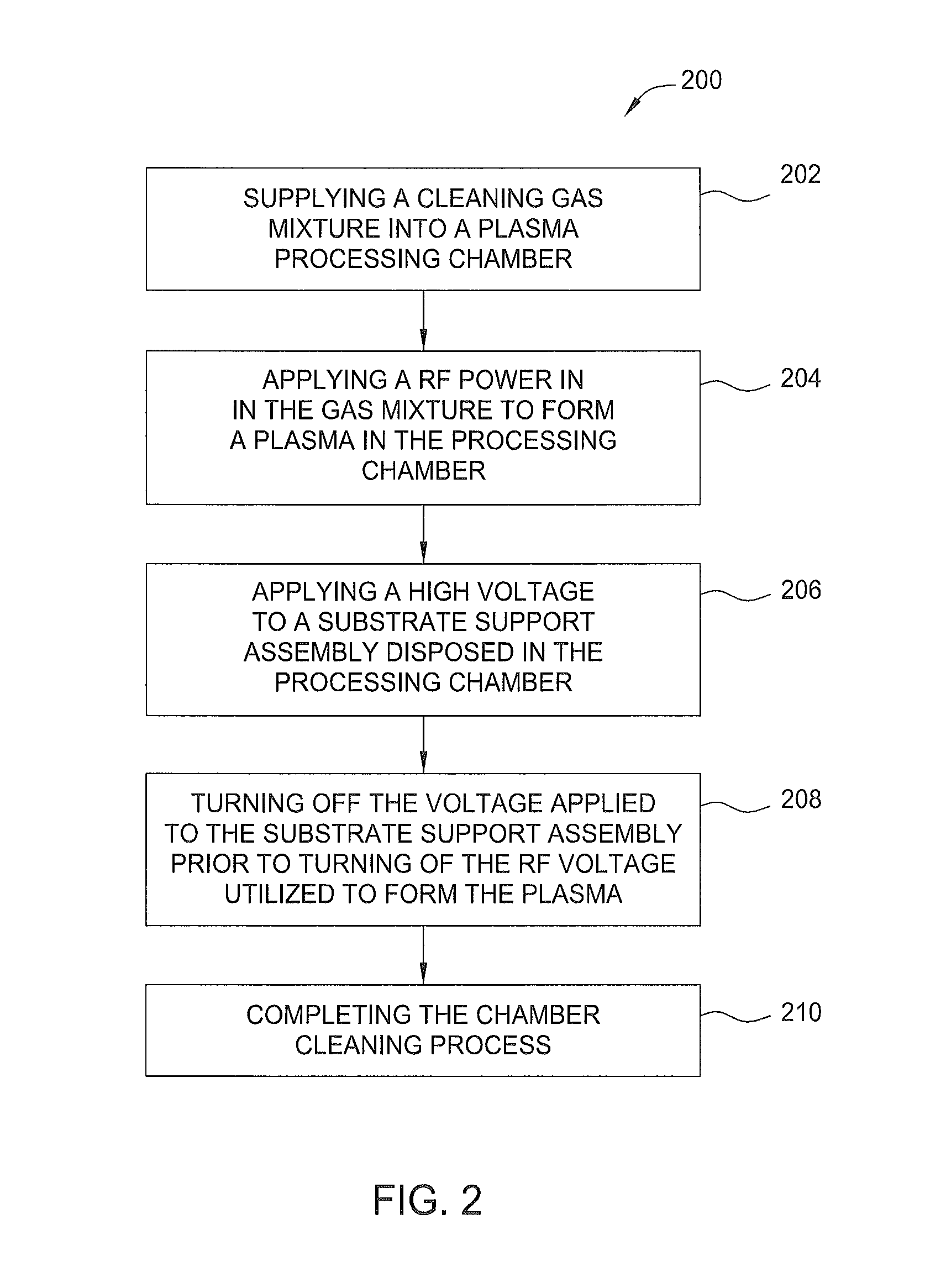

Methods for extending chamber component life for plasma processing semiconductor applications

InactiveUS20150294843A1Minimal erosionExtended service lifeElectric discharge tubesElectrostatic cleaningSemiconductor plasmaEngineering

Embodiments of the present invention generally provide chamber cleaning methods for cleaning a plasma processing chamber with minimum likelihood of erosion occurred on the chamber components so as to extend service life of chamber components for semiconductor plasma applications. In one embodiment, a method of extending chamber component life in a processing chamber includes supplying a cleaning gas mixture into a plasma processing chamber, applying a RF source power to the plasma processing chamber, and applying a voltage to a substrate support assembly disposed in the processing chamber during cleaning.

Owner:APPLIED MATERIALS INC

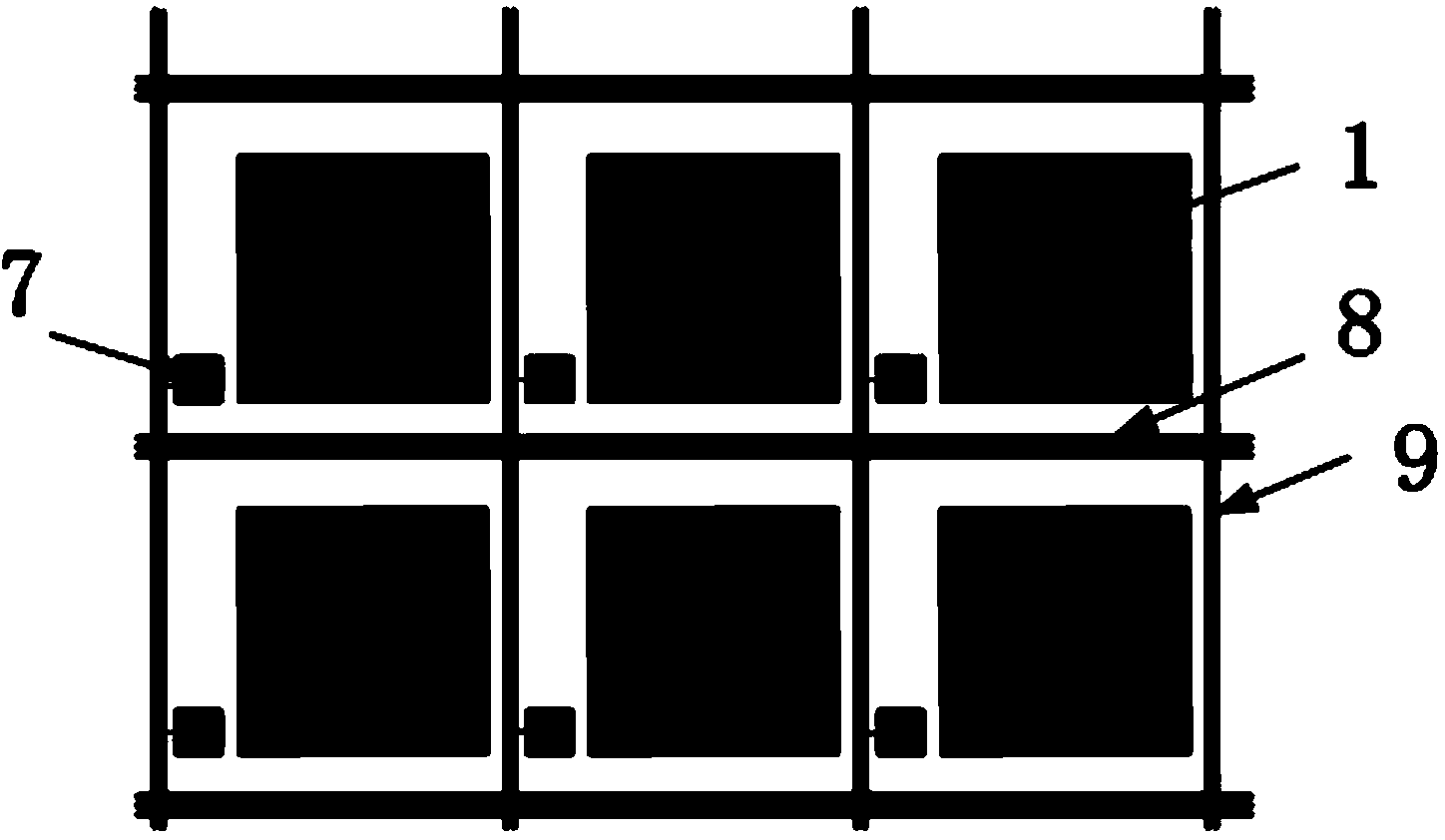

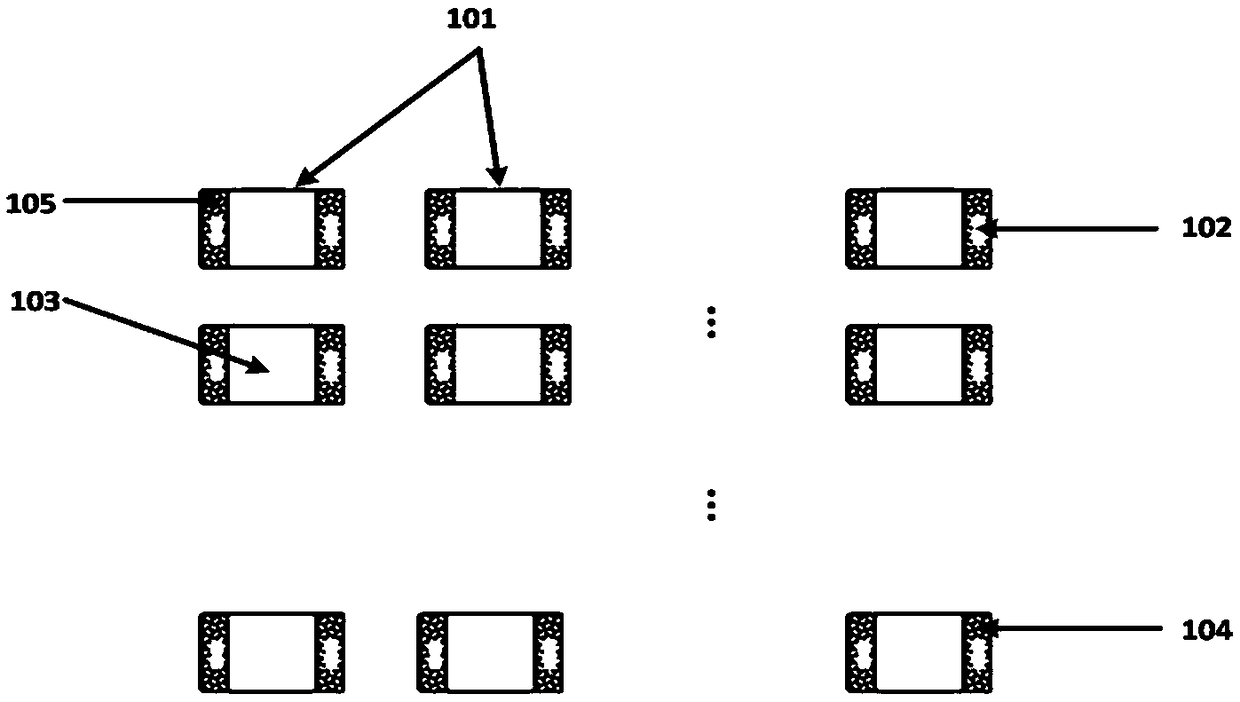

All solid-state plasma near coupling cloaking antenna array and control method thereof

InactiveCN104241851AIncreased Design FreedomPlay the role of stealthAntenna arraysAntenna couplingsPlasma antennaDielectric substrate

The invention discloses an all solid-state plasma near coupling cloaking antenna array and a control method thereof. The all solid-state plasma near coupling cloaking antenna array comprises solid-state plasma antenna units, an upper layer dielectric substrate, a micro-strip coupling feeder line, a bottom layer dielectric substrate and a grounding metal plate. The solid-state plasma antenna units comprise semiconductor plasma units, plasma unit control chips, line control wires and queue control wires. All the plasma units are controlled independently through a peripheral control circuit, the plasma antenna units of different shapes are formed, and reconstruction of an antenna structure is achieved. The antenna structure is compact and simple, the cost is low, the antenna structure can work in a 1 GHz-100GHz wave band, the limitation that a traditional gas plasma antenna can not work in a high frequency band easily is broken through, and the advantages of being capable of achieving beam scanning, good in cloaking performance and the like are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

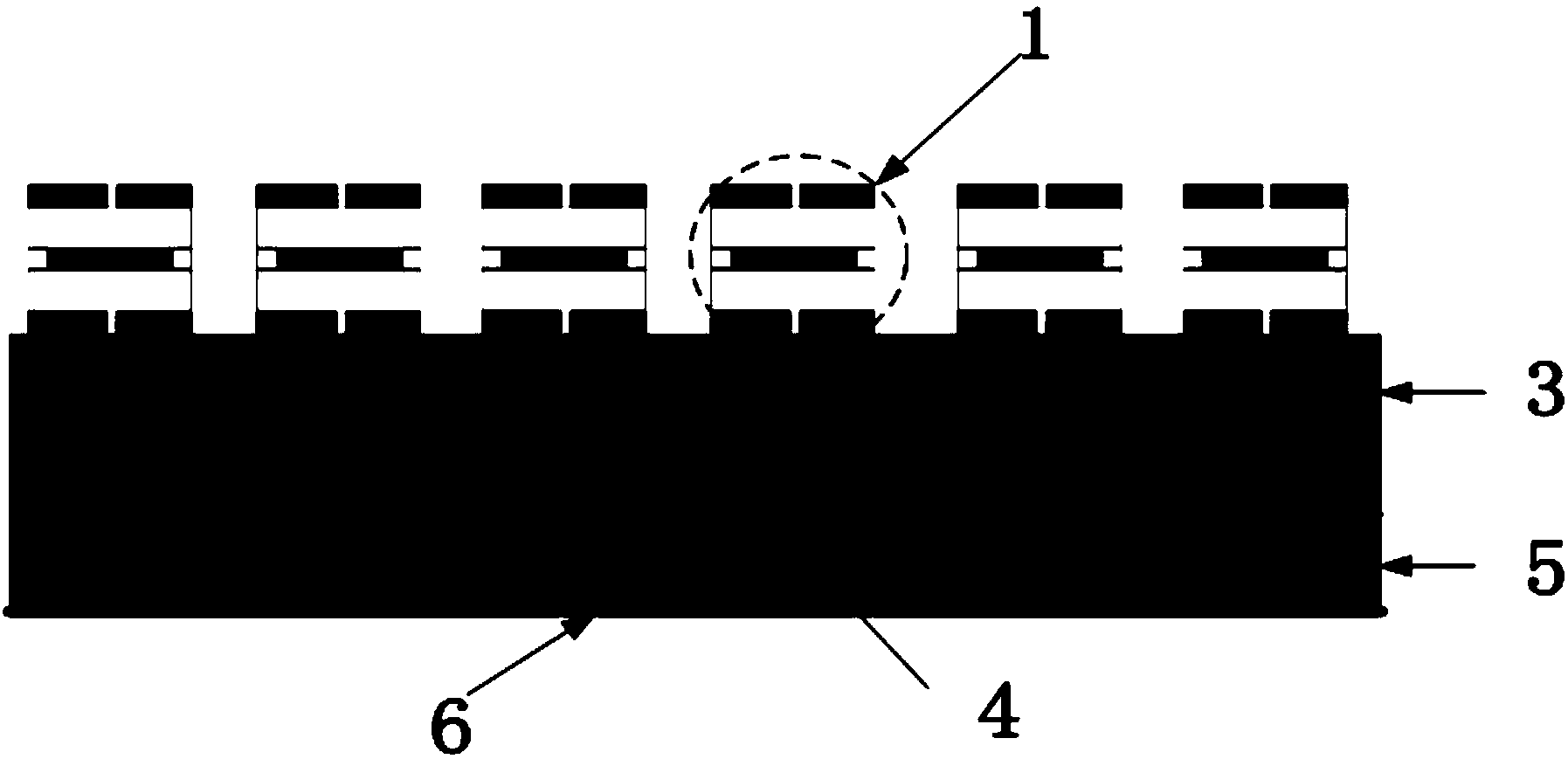

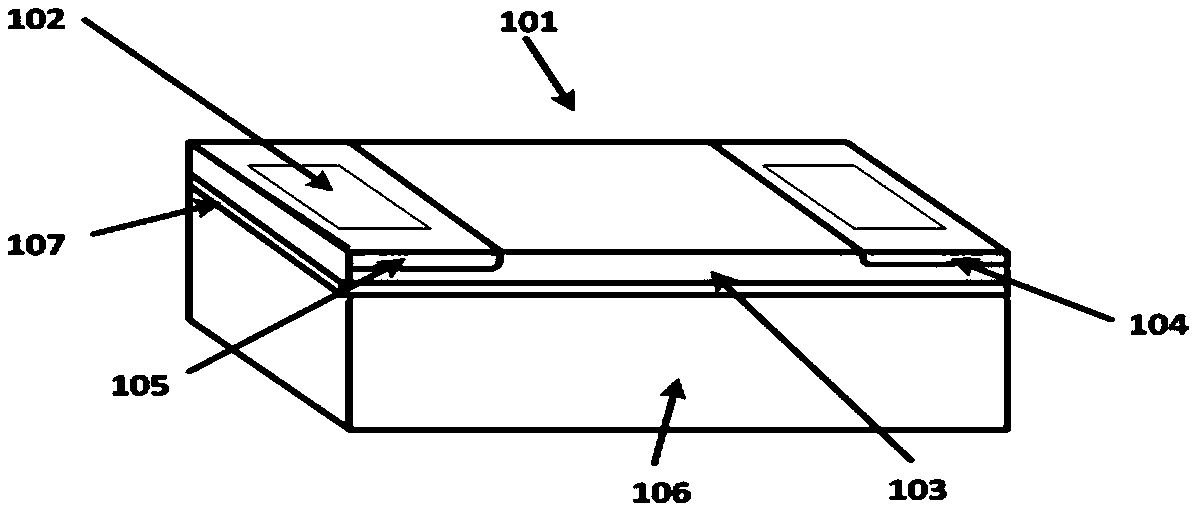

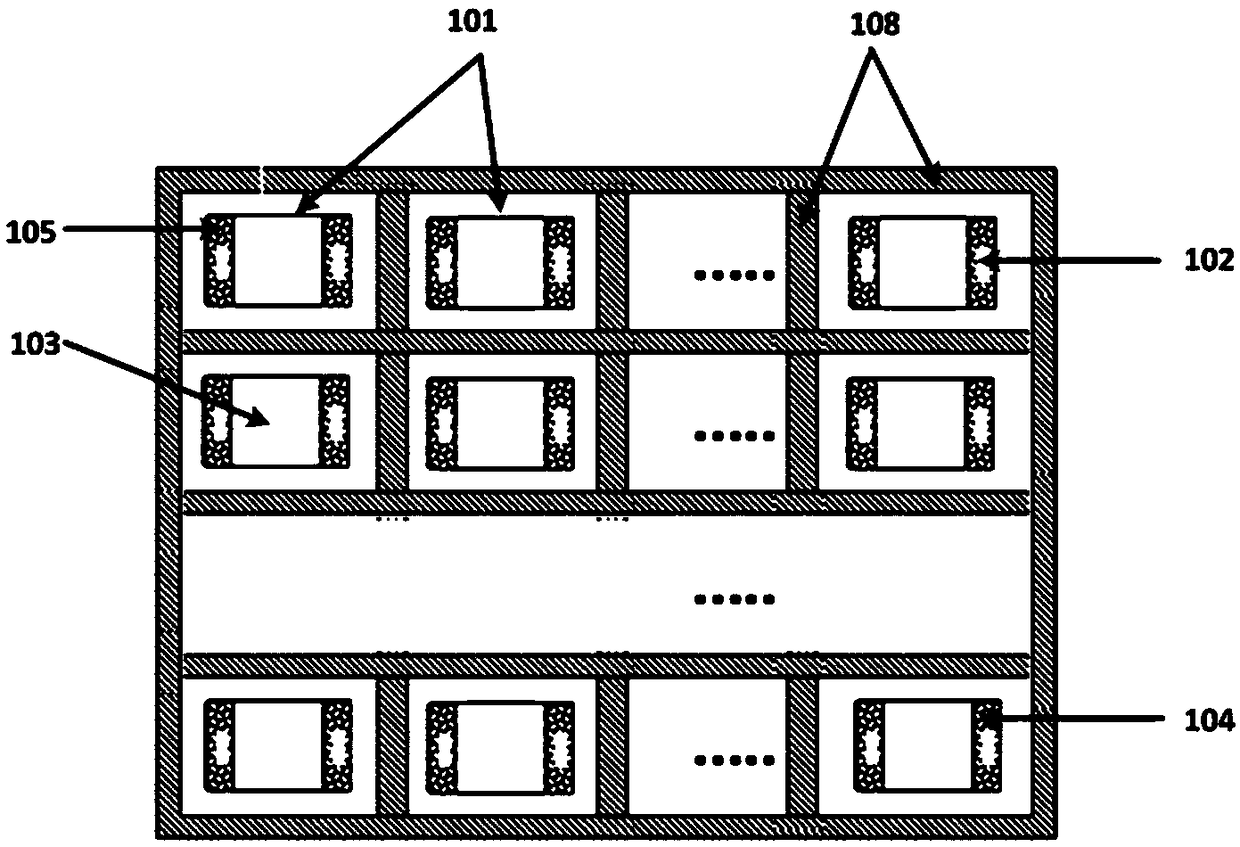

Reconfigurable multi-functional antenna based on distributed direct drive arrays

PendingCN108767445AChange shapeShort switching timeAntenna arraysRadiating elements structural formsDielectric substrateEngineering

The invention mainly belongs to the technical field of antennas and relates to a fast agile multi-functional planar and quasi-three-dimensional antenna, in particular to a reconfigurable multi-functional antenna. The multi-function antenna is composed of the semiconductor plasma and the fast, large current, simple TFT matrix driving technology distributed direct drive arrays integrated into silicon, glass, sapphire, silicon carbide and other planar or curved dielectric substrates, the multi-function antenna can quickly, dynamically control the shape, size and the correct position to be in of the radiating elements constituting the planar array, the antenna frequency is reconfigurable, polarization reconfigurability, beam control and gain agility reconfigurability, sidelobe position and relative level reconfigurability, and combinations of these, like a two-dimensional printer, rapidly and agilely change the antenna from one function to another, transforming a planar or quasi-three-dimensional antenna into a multi-function planar or quasi-three-dimensional antenna.

Owner:北京神舟博远科技有限公司

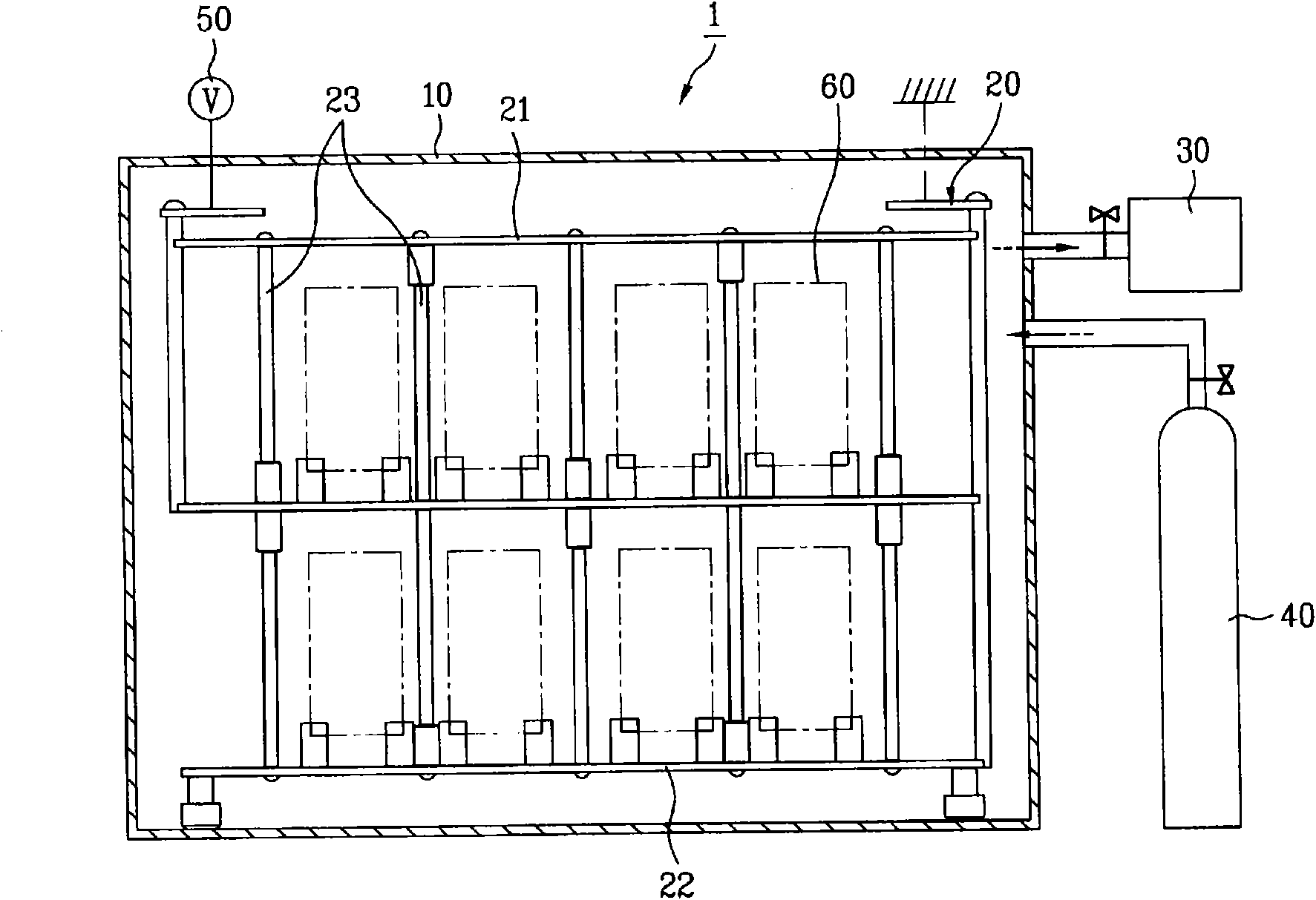

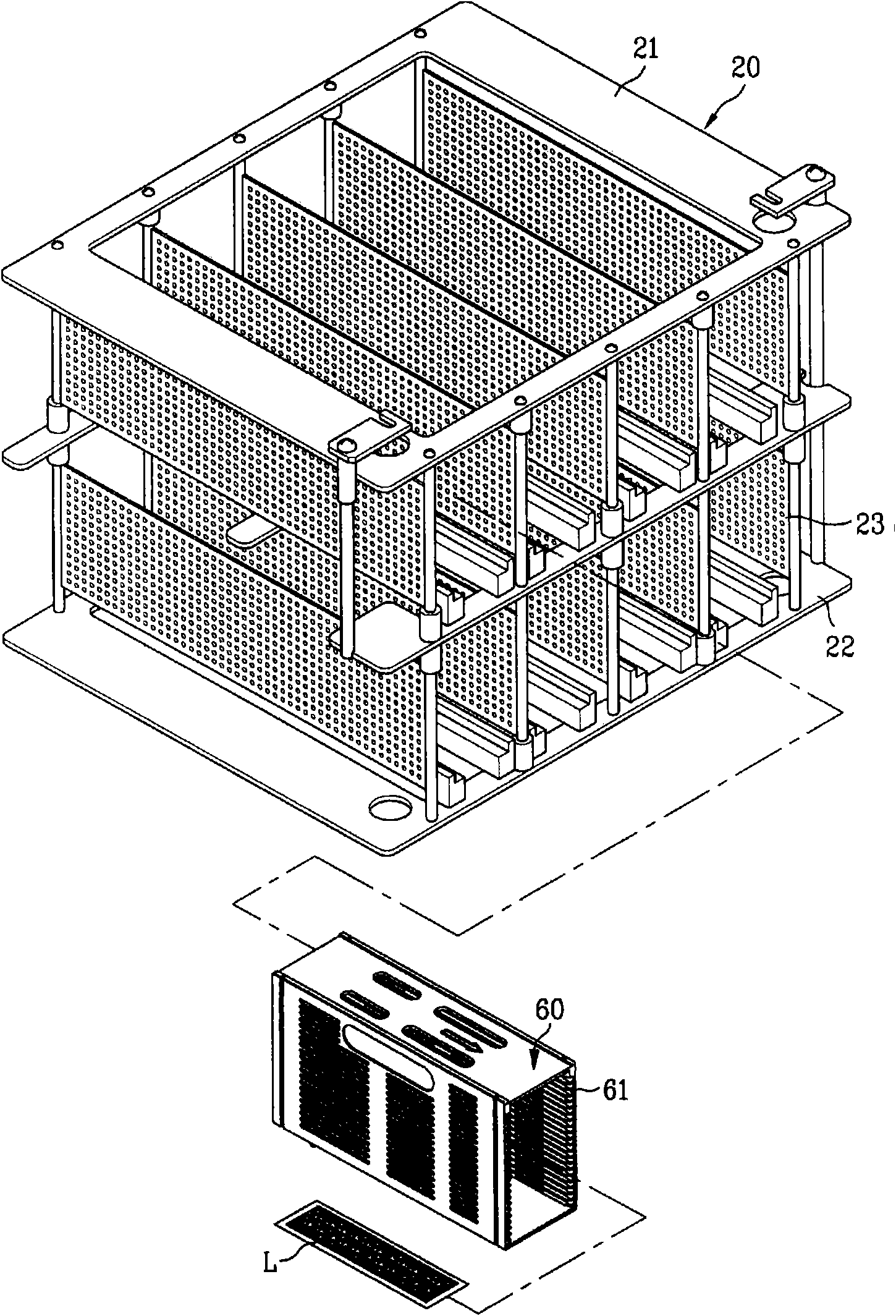

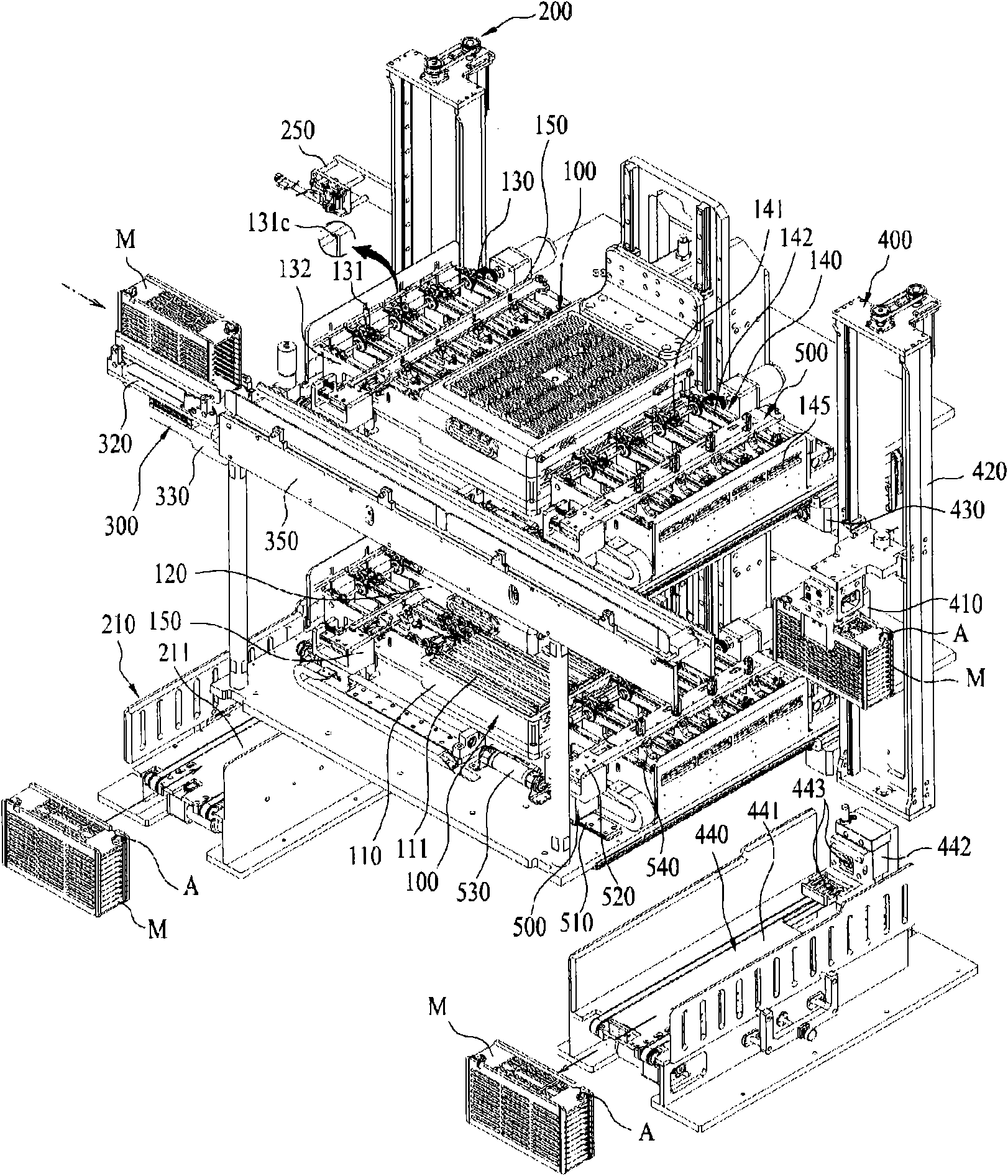

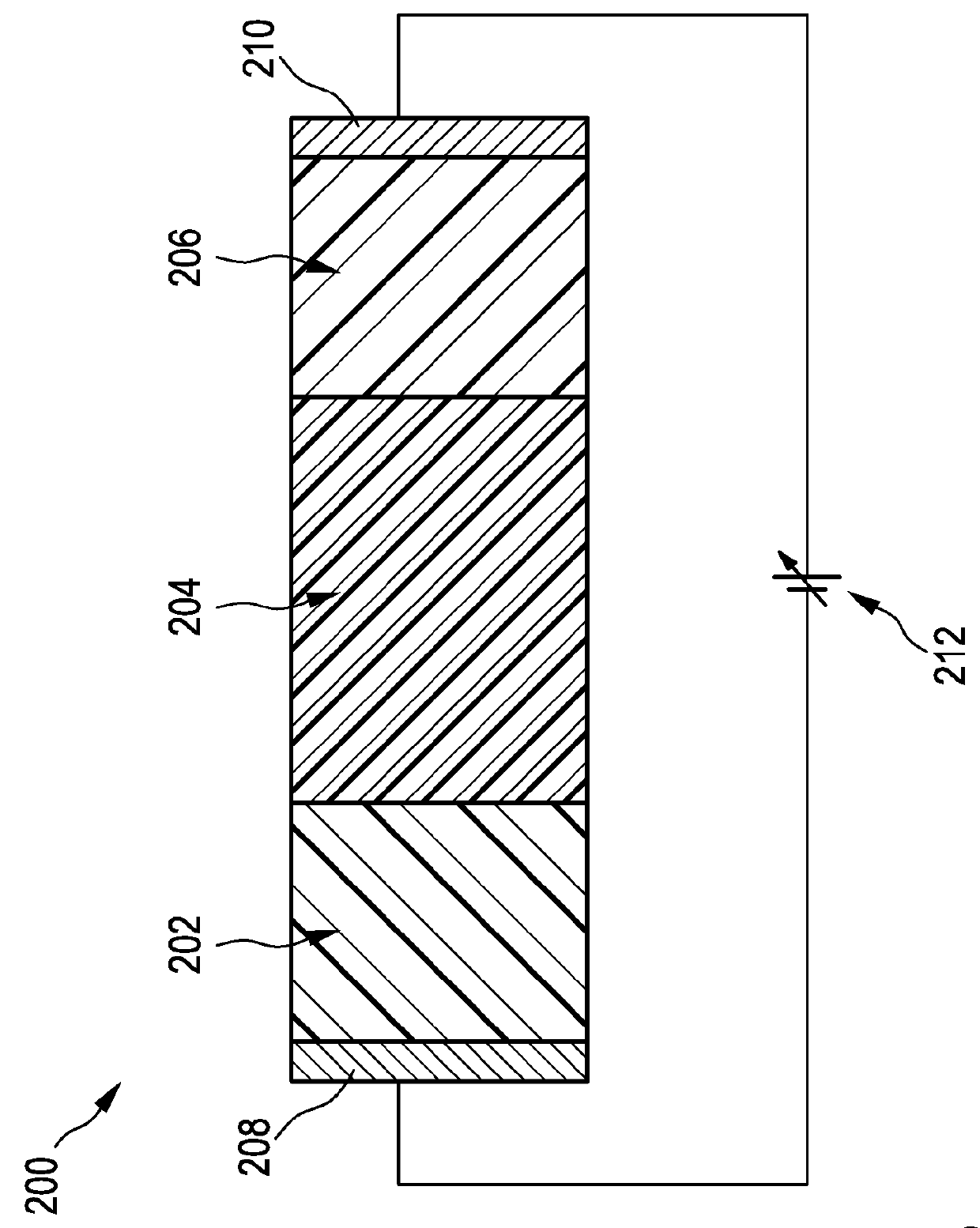

Plasma cleaning apparatus for a semiconductor panel with cleaning chambers

InactiveCN101980798ASmall footprintImprove work performanceSemiconductor/solid-state device manufacturingCleaning processes and apparatusSemiconductor plasmaEngineering

The present invention relates to plasma cleaning apparatuses for cleaning semiconductor components (a cleaning object or a PCB board) with plasma discharge in a semiconductor fabrication process. More specifically, the present invention relates to a semiconductor plasma cleaning apparatus with cleaning chambers (100) for improving working efficiency by making continuous plasma cleaning of cleaning objects placed in magazines. The semiconductor plasma cleaning apparatus having a plurality of cleaning chambers (100), includes the plurality of cleaning chambers (100) arranged in parallel vertically, an unloading unit (200) movable in up / down direction according to a cleaning progress Situation for transferring magazines having cleaning objects loaded thereon to front of each of the cleaning chambers (100) in succession, a plurality of first pushers (250) mounted to the unloading unit (200) for pushing and discharging the cleaning object loaded in the magazine being transferred by the unloading unit (200) toward the cleaning chamber one by one, a rotatable transfer unit (300) for receiving an empty magazine having all the cleaning objects discharged from the unloading unit (200), rotating the empty magazine by 180 horizontally, and transferring the empty magazine to rear of the plasma cleaning chamber, a loading unit (400) for receiving the empty magazines from the rotatable transfer unit (300), and transferring the empty magazines to rear of each of the plasma cleaning chambers (100) in succession while moving from an lower side to an upper side according to the cleaning progress situation, and a second pusher (500) for pushing and loading the cleaning objects having cleaning thereof finished into the empty magazine at the loading unit (400).

Owner:VISIONSEMICON CO LTD

System and method for analyzing power flow in semiconductor plasma generation systems

ActiveUS7885774B2Spectral/fourier analysisMagnetic measurementsElectric power transmissionPlasma generator

A system and method for measuring and analyzing power flow parameters in RF-based excitation systems for semi-conductor plasma generators. A measuring probe (8) is connected to an RF transmission line for receiving and measuring voltage (10) and current signals (12) from the transmission line (4). A high-speed sampling process converts the measured RF voltage and current signals into digital signals. The digital signals are then processed so as to reveal fundamental and harmonic amplitude and phase information corresponding to the original RF signals. Multiple measuring probes may be inserted in the power transmission path to measure two-port parameters, and the networked probes may be interrogated to determine input impedance, output impedance, insertion loss, internal dissipation, power flow efficiency, scattering, and the effect of plasma non-linearity on the RF signal.

Owner:BIRD TECH GROUP

Semiconductor plasma etching technology

ActiveCN101615579AImprove the selection ratioIncrease topSemiconductor/solid-state device manufacturingSemiconductor plasmaShielding gas

The invention provides a plasma etching technology comprising a dielectric layer penetrating and etching step and a silicon main etching step, wherein, technical gas in the dielectric layer penetrating and etching step comprises fluorine-base etching gas, first light resistance protection gas and dilution gas; technical gas in the silicon main etching step comprises main etching gas, carbon-base by-product removing gas and second light resistance protection gas. In a preferable embodiment, the fluorine-base etching gas is CF4 or SF6, the first light resistance protection gas is CH2F2 or CHF3 or HBr, and the dilution gas is He, Ar or N2; the main etching gas is Cl2, the carbon-base by-product removing gas is O2, and the second light resistance protection gas is HBr. In semiconductor plasma etching, the invention can improve sidewall steepness in figure etching and prevent the upper edge and the lower edge of a line from producing fillets.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

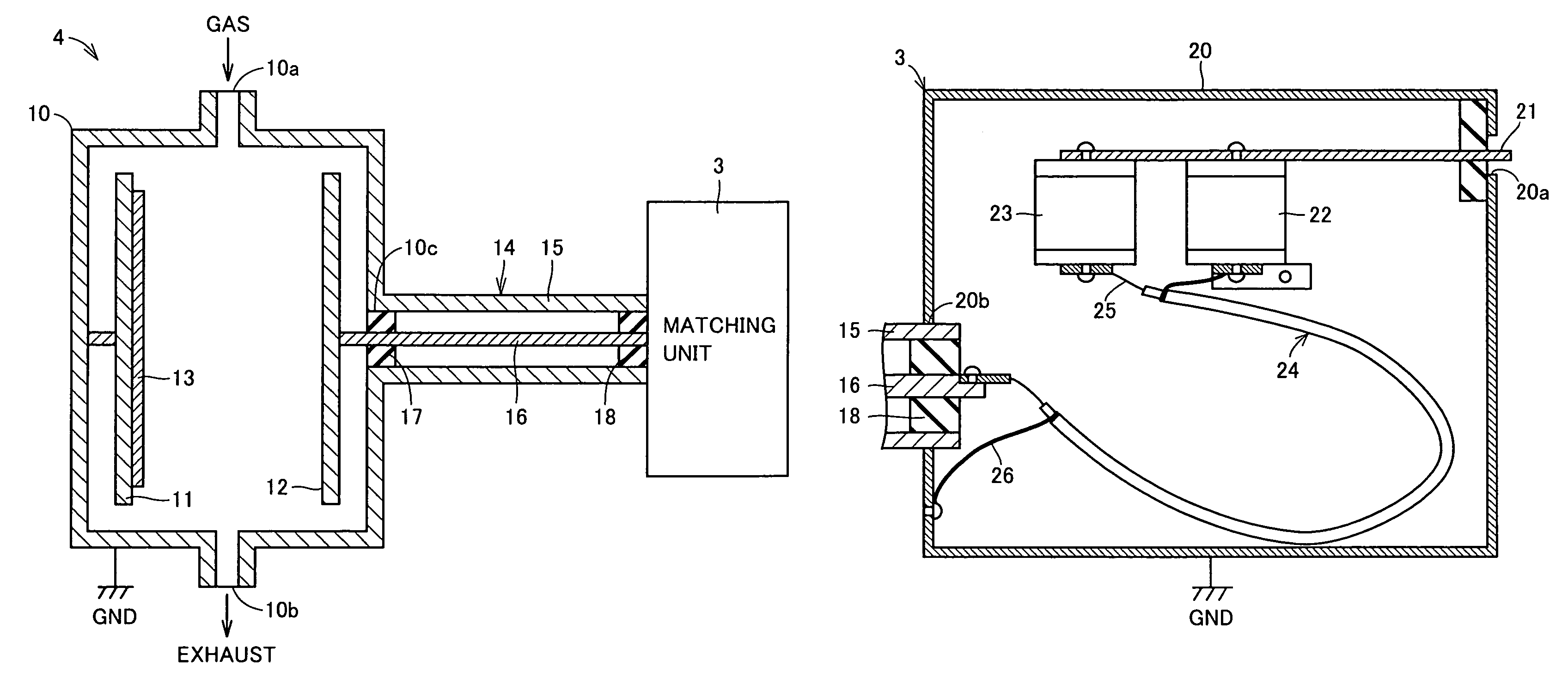

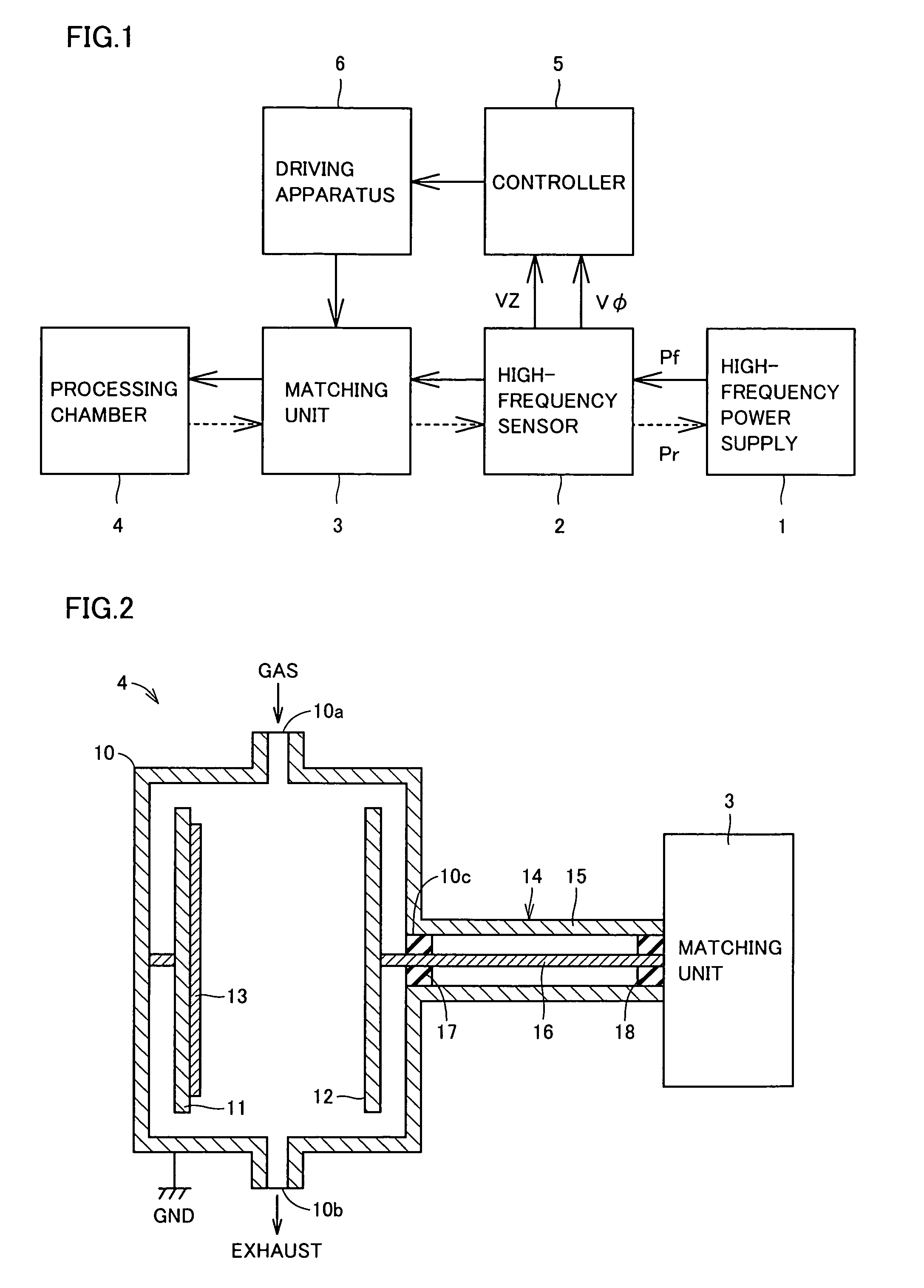

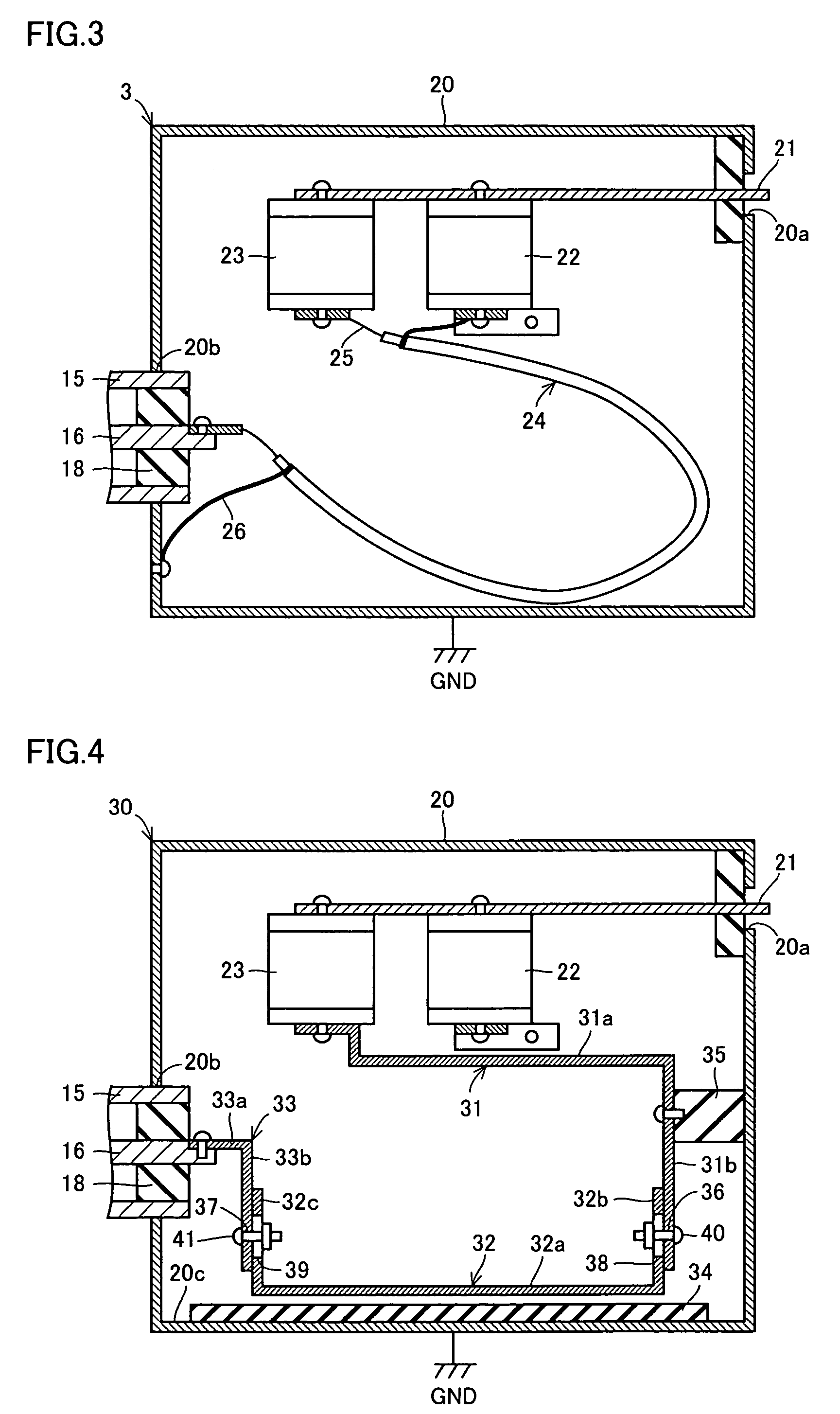

Matching unit for semiconductor plasma processing apparatus

InactiveUS7132040B2Easily attain matchingImprove matchCellsElectric discharge tubesElectrical conductorHigh frequency power

This matching unit is used for a semiconductor plasma processing apparatus supplying high-frequency power via feeding line to an electrode provided in a chamber, and includes first and second variable capacitors, and a distributed constant circuit, which is structured by copper plates connected between an electrode of the second variable capacitor and an end of an internal conductor of the feeding line and the like. The distributed constant circuit and the feeding line delay the phase of a high-frequency voltage by ½ wavelength. Therefore, the same state as those when the electrode of the second variable capacitor and the electrode inside the chamber are directly connected can be realized, and matching is easily attained.

Owner:PEARL IND

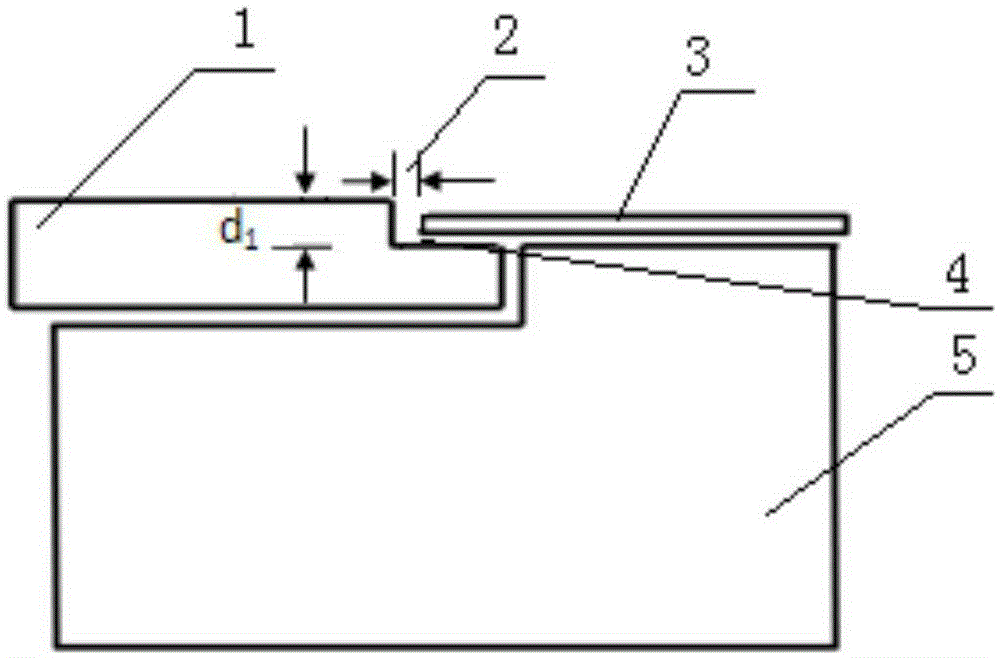

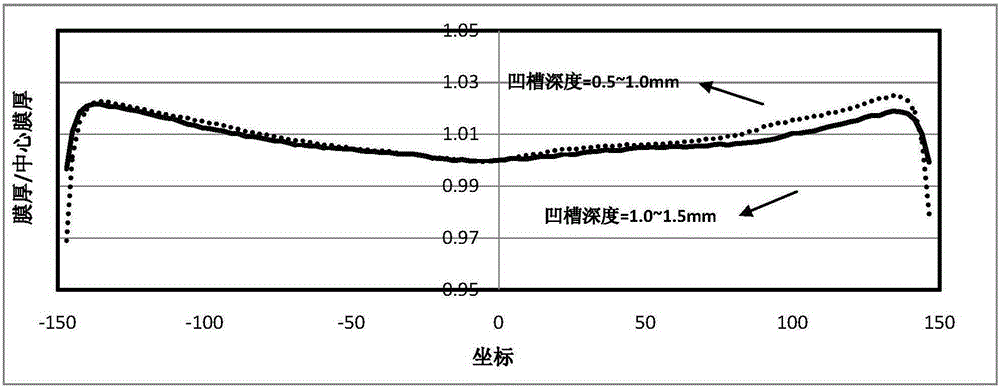

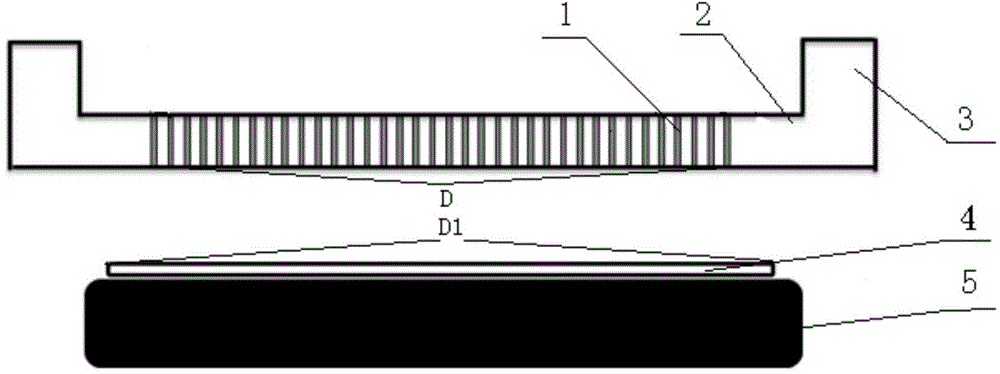

Ceramic ring capable of changing shape and appearance of surface film of wafer

InactiveCN105185732AImprove growthEffective regulationSemiconductor/solid-state device manufacturingMetallurgySemiconductor plasma

The invention provides a ceramic ring which can change the shape and appearance of a surface film of a wafer in a semiconductor plasma processing device. The ceramic ring is located on an objective table, and is used for bearing a to-be-machined wafer. An edge, supporting the step of the wafer, of the ceramic ring is at a right angle, and the height d1 of the step can be set differently. When a plasma air flow passes through the edge of the step, the height of the step exerts impact on the flowing of the air flow in a high-temperature process, thereby impacting the uniformity of a film layer. The ceramic ring can effectively adjust the air flow distribution at the step of the ceramic ring and the edge of the wafer, thereby impacting the uniformity of plasma distribution, and improving the growth condition of the edge film of the wafer. The ceramic ring is reasonable in structure, is practical and is easy to implement. The ceramic ring can be widely used in the technical field of semiconductor film deposition.

Owner:PIOTECH CO LTD

Two-dimensional semiconductor saturable absorber mirror and fabrication method, and pulse fiber laser

InactiveUS20180375282A1Low reliabilityNarrow operating bandwidthActive medium shape and constructionNon-linear opticsDeposition temperatureSemiconductor plasma

A two-dimensional semiconductor saturable absorber mirror comprises an optical fiber, a two-dimensional semiconductor thin film attached to an end surface of the optical fiber, and a gold film attached to the two-dimensional semiconductor thin film. A method for fabricating the two-dimensional semiconductor saturable absorber mirror comprises the following steps: cutting the optical fiber, putting the cut optical fiber and a two-dimensional semiconductor target into a vacuum chamber, ionizing a surface of two-dimensional semiconductor target to generate two-dimensional semiconductor plasma, depositing the two-dimensional semiconductor plasma on an exposed end surface of the optical fiber to form the two-dimensional semiconductor thin film, and by controlling deposition time and / or deposition temperature, ensuring the two-dimensional semiconductor thin film to be a desired thickness; and plating the gold film on the resulting two-dimensional semi-conductor thin film.

Owner:SHENZHEN UNIV

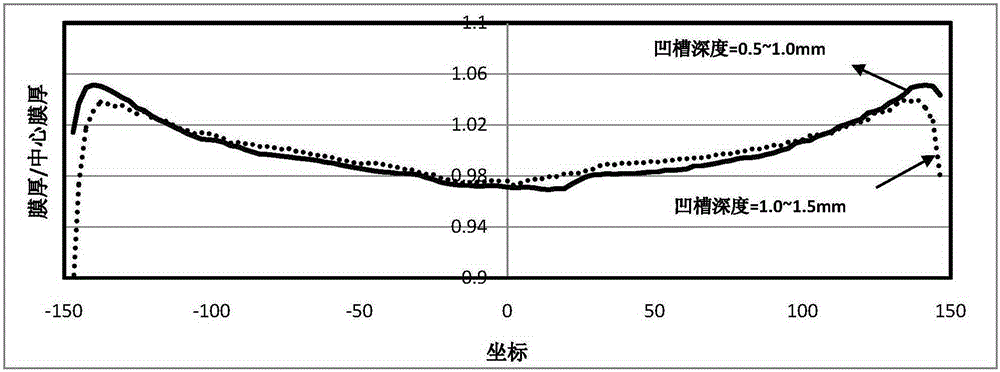

Semiconductor plasma processing device capable of improving appearance of film at surface of wafer

ActiveCN105225914AReduce the number of viasReduce gas flowElectric discharge tubesSemiconductor plasmaSubstrate surface

The invention provides a semiconductor plasma processing device capable of improving the appearance of a film at the surface of a wafer. The processing device comprises a reaction cavity and the wafer to be processed, the reaction cavity is internally provided with a spray head, an objective table and an exhausting ceramic ring, edge holes are distributed non-uniformly in the spray head, an exhausting hole of the exhausting ceramic ring moves downwardly, and the spray head is placed opposite to the objective table in the reaction cavity. The amount of edge holes of the spray head is reduced to reduce gas flow at the edge of the wafer, and the film at the edge of the wafer is avoided from too fast growth; the position of the exhausting hole of the exhausting ceramic ring moves downwardly to change the air flow path of exhausting and adjust the deposition effect of the substrate surface; and the film can grow uniformly on the substrate due to novel design of the spray head and exhausting ceramic ring in the device.

Owner:PIOTECH CO LTD

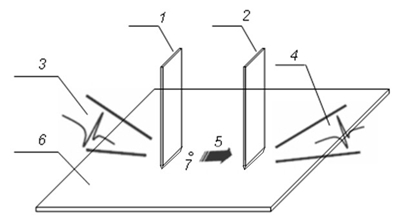

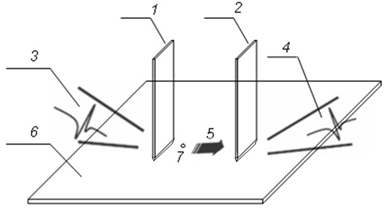

Semiconductor defect detection method based on surface plasma wave

InactiveCN102636491AThe method is simple and flexibleExtended propagation distanceOptically investigating flaws/contaminationUsing optical meansSemiconductor plasmaSurface plasmon

The invention discloses a semiconductor defect detection method based on surface plasma wave, and is used for detecting the semiconductor surface flatness or the internal defect of a semiconductor film. According to the invention, an electromagnetic wave with frequency lower than the semiconductor plasma frequency enters a slit between the blade edge and the semiconductor to be detected so as to generate a surface plasma wave on the semiconductor surface. The surface plasma wave can be coupled into a space radiation electromagnetic wave at the slit position between another blade edge and the semiconductor to be detected so as to be received by a detector. By changing the relative positions of the blade and the semiconductor in the horizontal direction, when a surface plasma wave passes through the defective position on the surface or inside of the semiconductor to be detected, the outgoing electromagnetic wave signal correspondingly changes so that the semiconductor surface unflatness or the internal defect of the semiconductor can be detected according to the principle. Compared with the prior art, the method disclosed by the invention has the advantages of wide application range, flexibility in use, high detection precision, no damage to detection sample and the like.

Owner:NANJING FANGYUAN GLOBAL DISPLAY TECH

High-purity 2-fluorobutane

ActiveUS20160016869A1Inhibit productionOrganic chemistrySynthetic resin layered productsSemiconductor plasmaPlasma reaction

The present invention is a high-purity 2-fluorobutane having a purity of 99.9 vol % or more and a butene content of 1,000 ppm by volume or less, and a method for using the high-purity 2-fluorobutane as a dry etching gas. According to the present invention, a high-purity 2-fluorobutane that is suitable as a plasma reaction gas for semiconductors is provided.

Owner:ZEON CORP

Sub thz to mid infrared tunable semiconductor plasmonics

ActiveUS20170269267A1Large penetrationReduce manufacturing costColor/spectral properties measurementsNon-linear opticsSemiconductor materialsPolariton

A tunable plasmon resonator, comprising a plasmon resonance layer made of graphene, a crystalline group-IV-semiconductor material or a crystalline group-III-V semiconductor material, and arranged on a carrier substrate, the plasmon resonance layer having a plasmon resonance region that is exposed to a sensing volume and a tuning device that is integrated into the plasmon resonator and arranged and configured to modify a density of free charge carriers in the plasmon resonance region or to modify an effective mass amount of the free charge carriers in the plasmon resonance region by applying of a control voltage to tuning control electrode(s) of the tuning device, thereby setting a plasmon frequency of plasmon polaritons in the plasmon resonance region to a desired plasmon frequency value within a plasmon frequency tuning interval, for resonance excitation of plasmon polaritons by incident electromagnetic waves of a frequency corresponding to the set plasmon frequency value.

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE +1

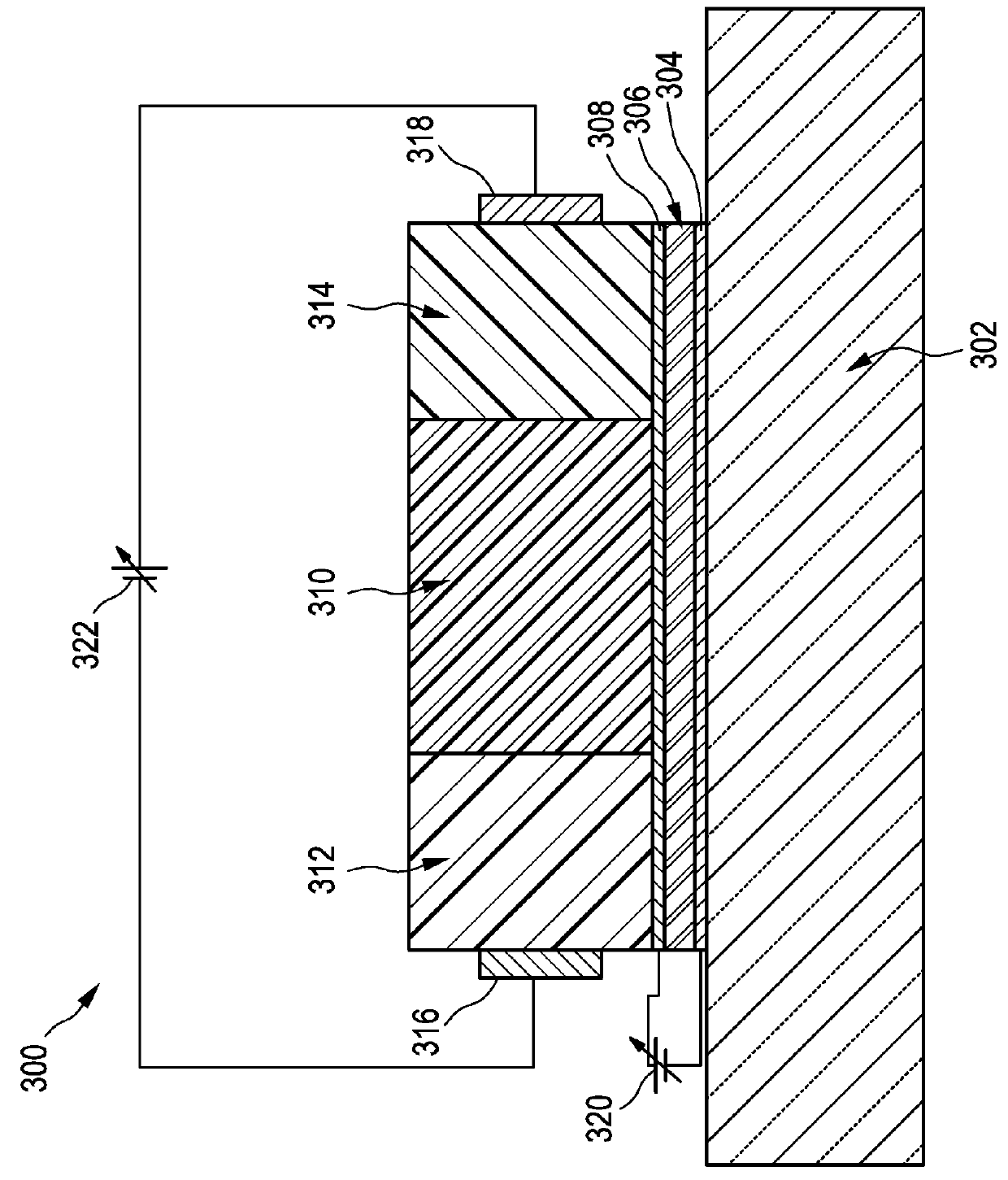

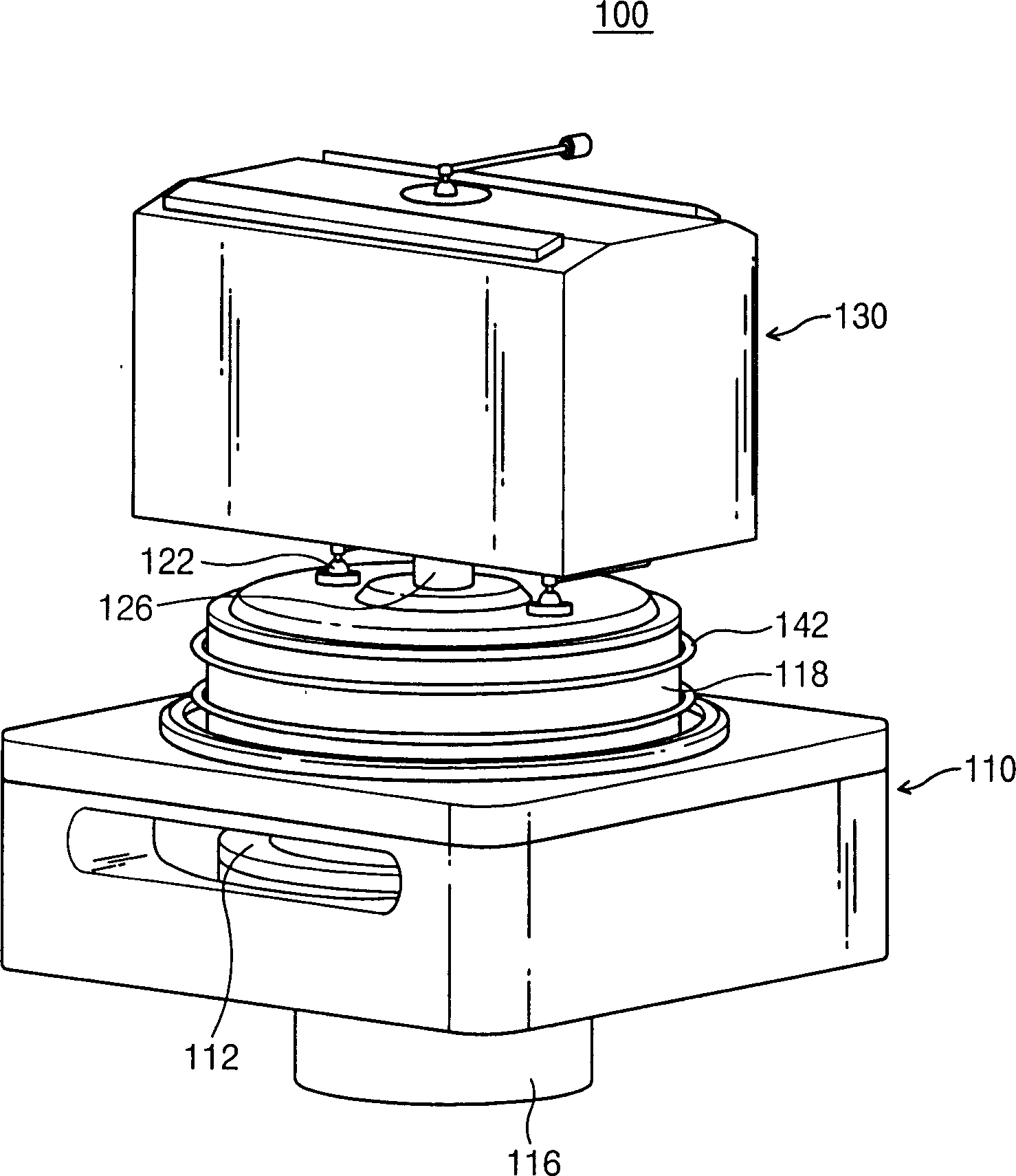

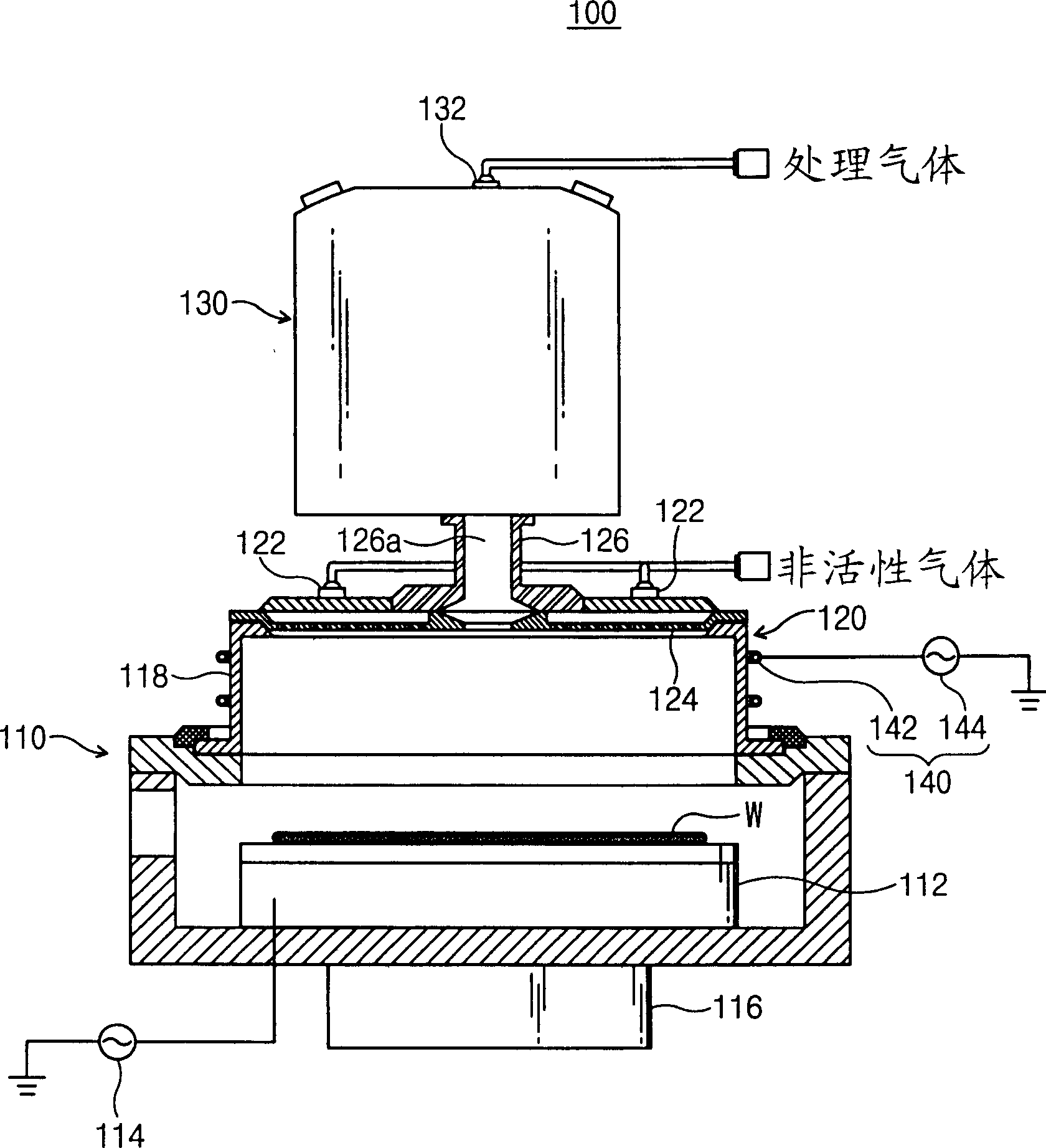

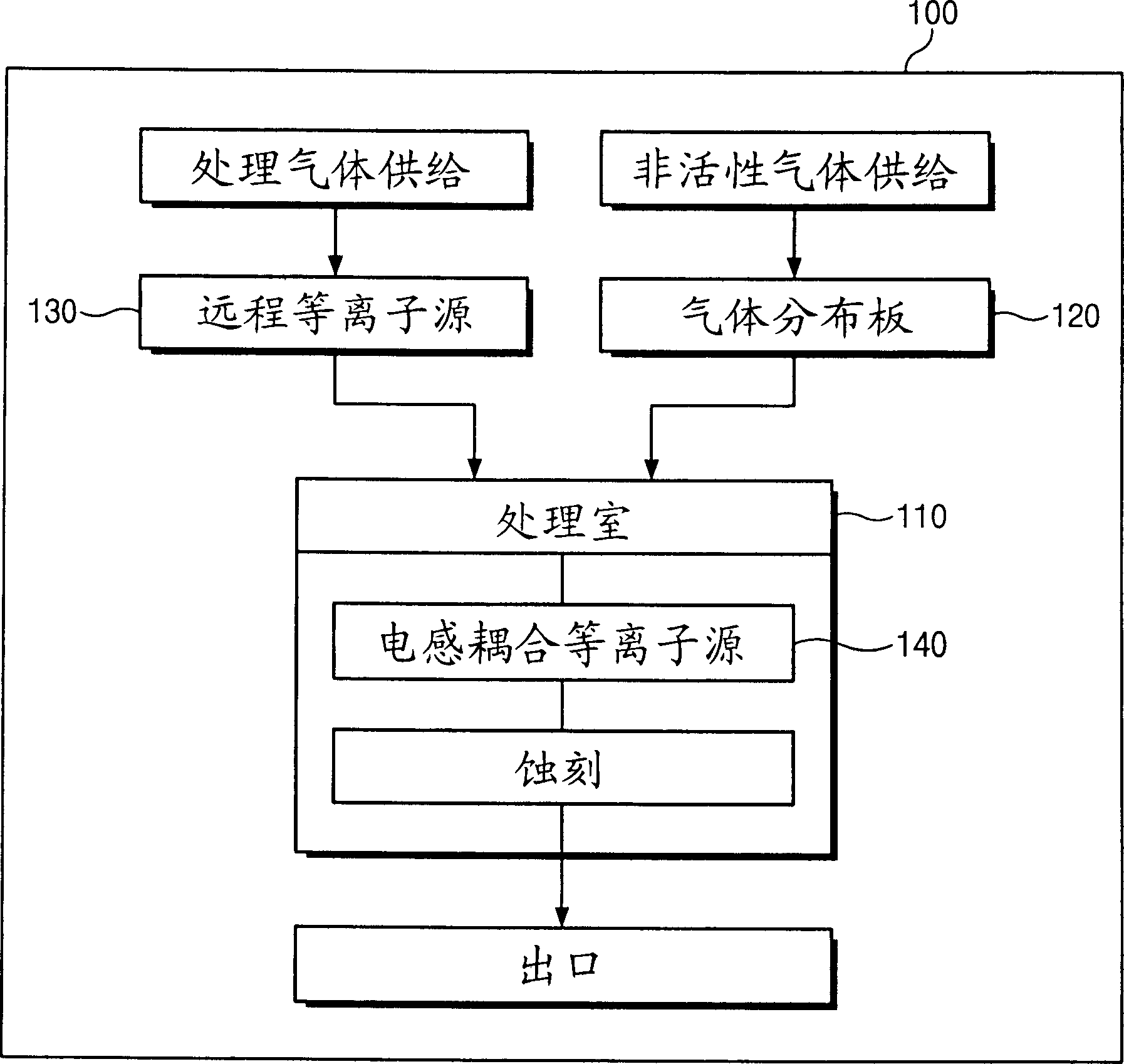

Apparatus and method for treating semiconductor device with plasma

A semiconductor plasma-processing apparatus smoothes effects of side radical-concentration, which are frequently generated by inductive-coupling plasma sources, enhancing the etching uniformity therein. The apparatus includes a remote plasma generator providing lots of radicals and ions from activating processing gas; a reaction chamber having an inflow port through which the activated processing gas; a susceptor, on which a wafer is settled, disposed in the reaction chamber; and an inductive-coupling plasma generator disposed in the reaction chamber, providing high-frequency energy to the activated processing gas. As radicals and ions are affluently generated enough to conduct an etching process, by means of the remote and inductive-coupling plasma sources, the reaction sprightly proceeds to improve the etching efficiency.

Owner:SEMES CO LTD

Spatially resolved optical emission spectroscopy (OES) in plasma processing

ActiveUS9970818B2Emission spectroscopyAnalysis by electrical excitationProcess developmentOptical emission spectrometry

Disclosed is a method, computer method, system, and apparatus for measuring two-dimensional distributions of optical emissions from a plasma in a semiconductor plasma processing chamber. The acquired two-dimensional distributions of plasma optical emissions can be used to infer the two-dimensional distributions of concentrations of certain chemical species of interest that are present in the plasma, and thus provide a useful tool for process development and also for new and improved processing tool development. The disclosed technique is computationally simple and inexpensive, and involves the use of an expansion of the assumed optical intensity distribution into a sum of basis functions that allow for circumferential variation of optical intensity. An example of suitable basis functions are Zernike polynomials.

Owner:TOKYO ELECTRON LTD

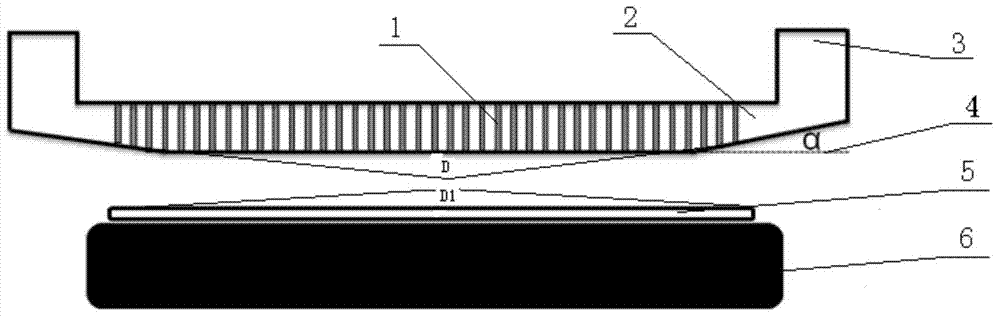

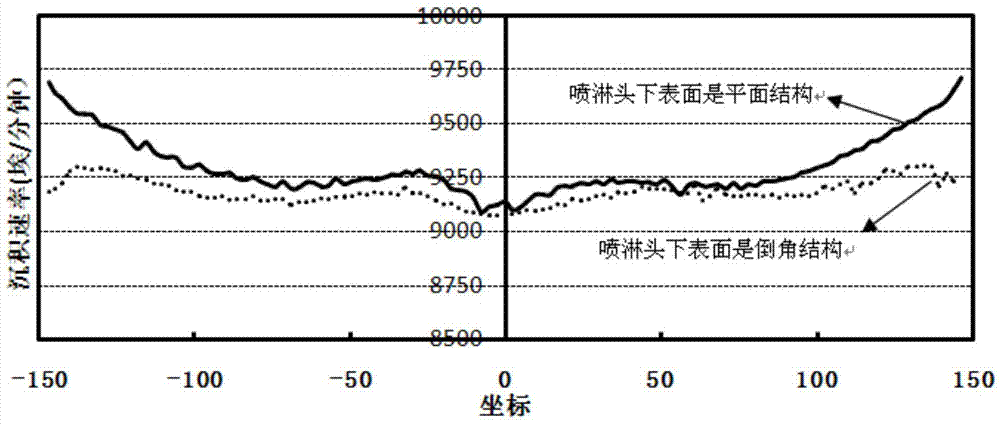

Non-complete planar spray header applied to semiconductor plasma processing device

InactiveCN104752144AScientific and reasonable structureIncrease profitElectric discharge tubesState of artSemiconductor plasma

A non-complete planar spray header applied to a semiconductor plasma processing device mainly solves the technical problems that, in the prior art, the homogeneity is not good and the gas utilization rate is low. The spray header and an object stage are arranged at opposite positions in a reaction chamber; chambering processing is performed on a lower surface of the spray header to form into a non-complete planar structure; the chamfering angle alpha is between 1 to 89 degrees; the non-planar structure area on the lower surface of the spray header occupies 1% to 100% of the lower area of the spray header. According to the non-complete planar spray header applied to the semiconductor plasma processing device, uniform processing of a semiconductor plasma processing process can be achieved through a non-complete planar structure on the lower surface of the spray header, the gas utilization rate can be simply and effectively improved, and the spray header can be widely applied to the technical field of semiconductor manufacturing.

Owner:PIOTECH CO LTD

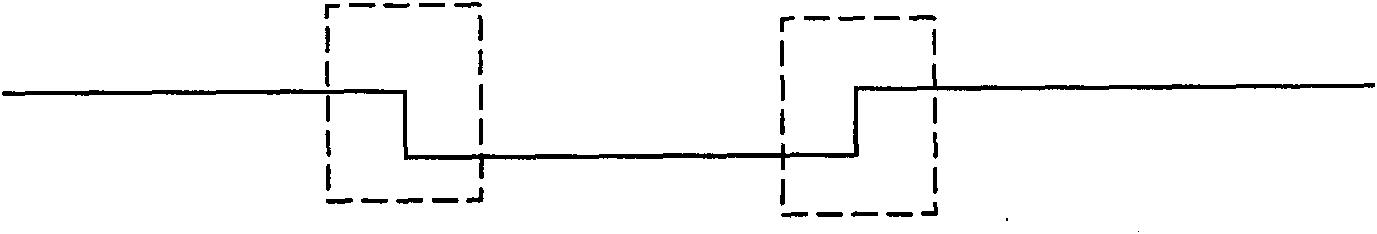

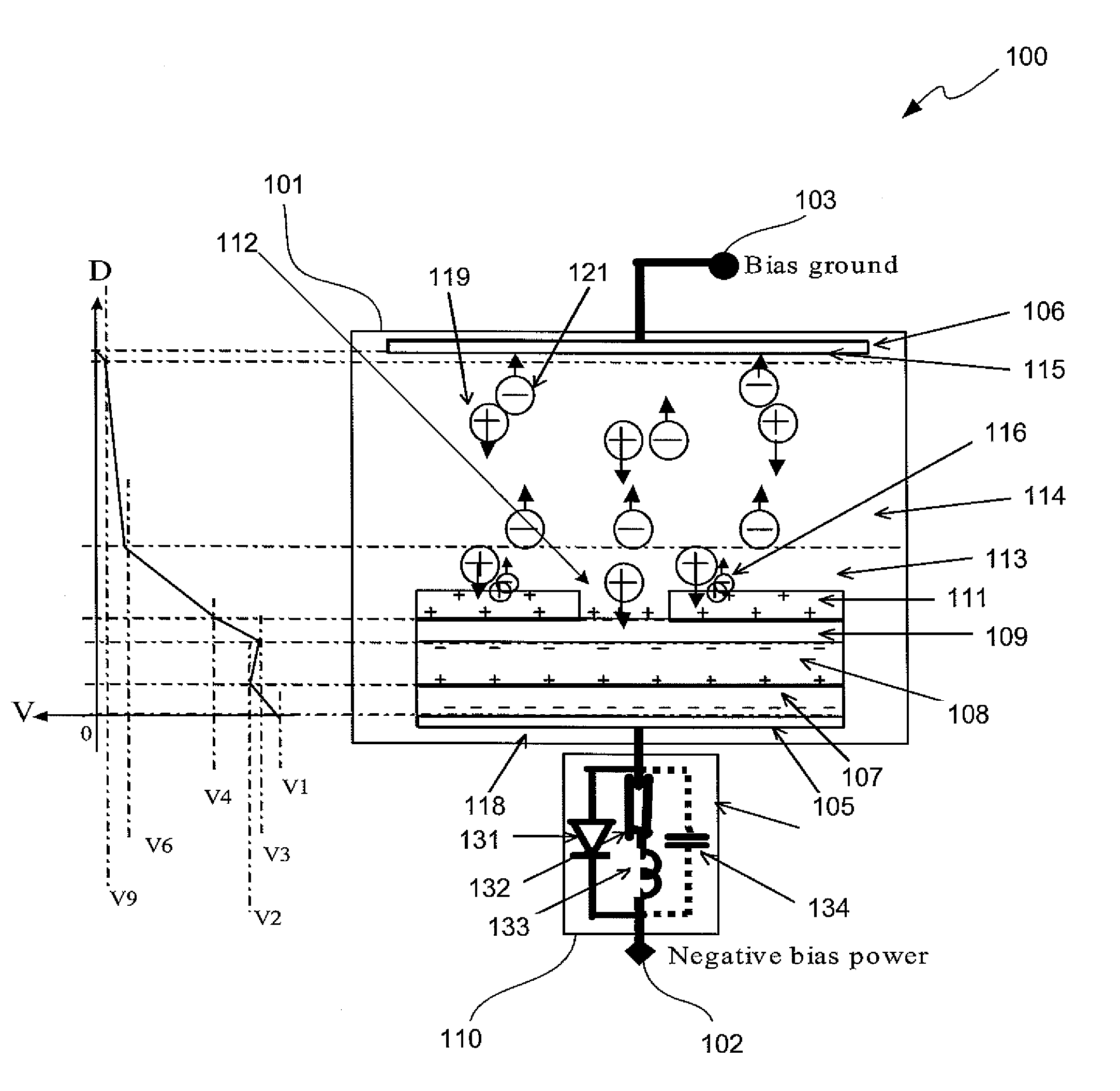

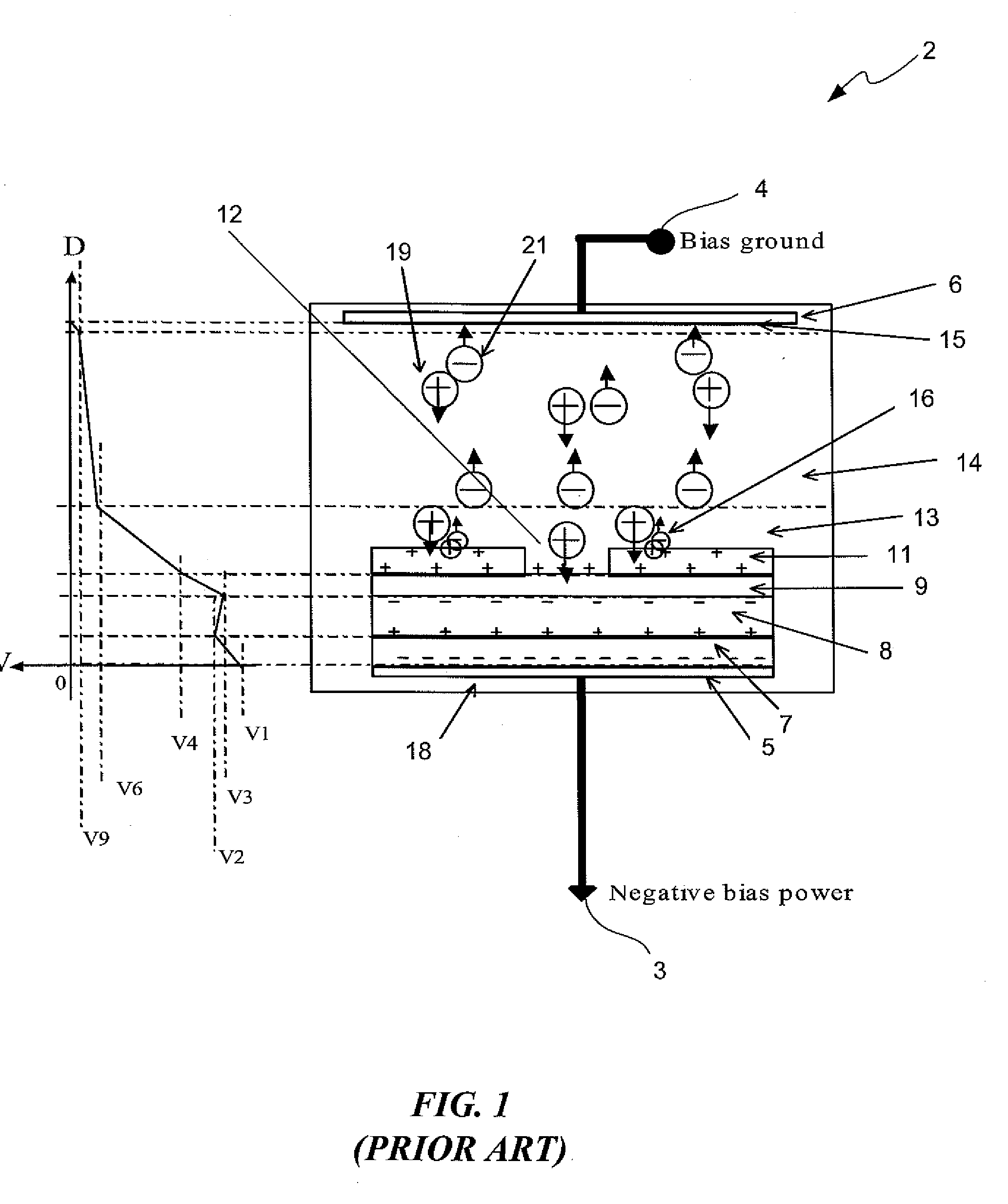

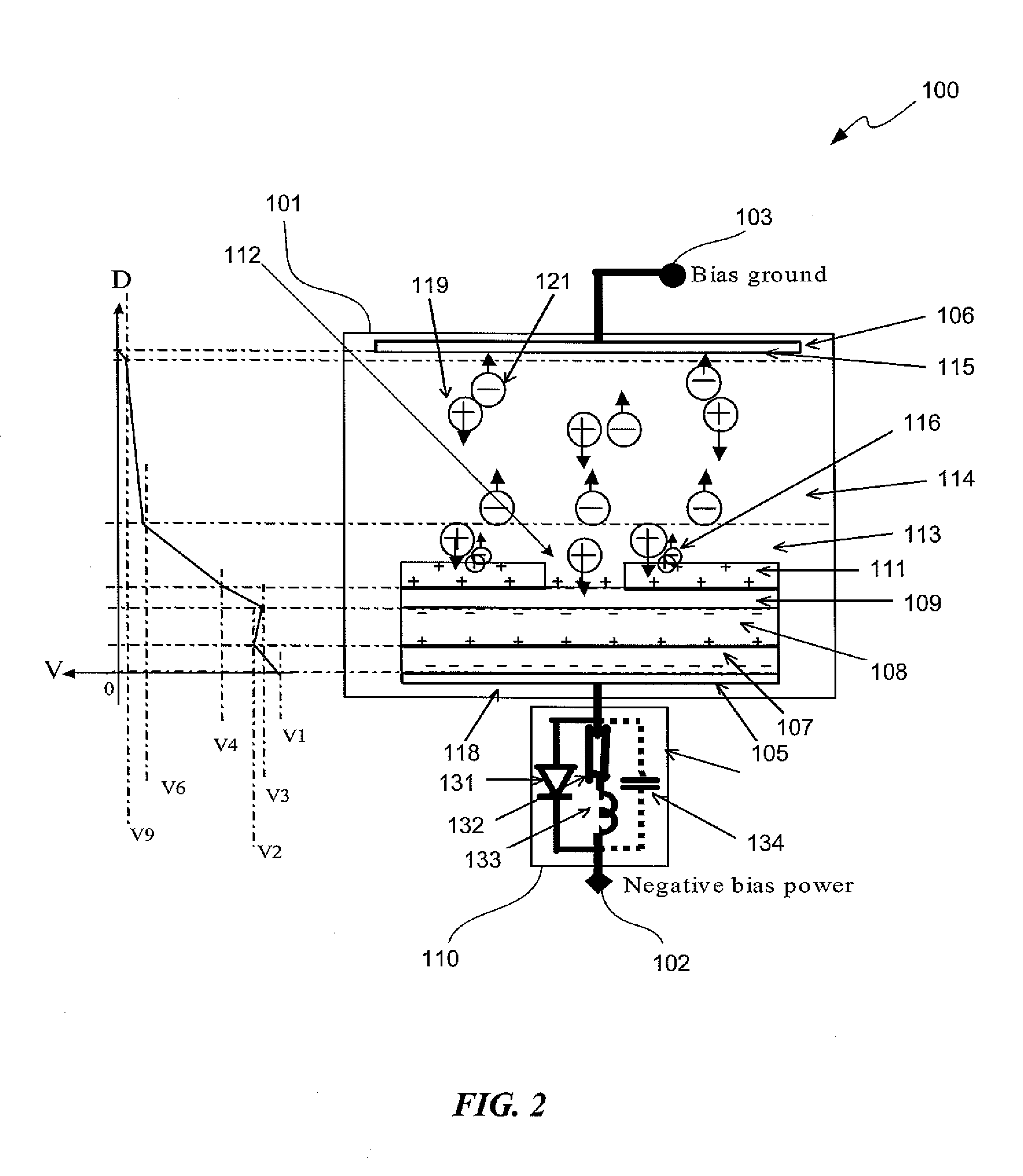

Methods and systems for controlling accumulation of electrical charge during semiconductor etching processes

InactiveUS20090139962A1Avoid accumulationSemiconductor/solid-state device testing/measurementElectric discharge tubesPower modulationSemiconductor plasma

A method and system are provided for controlling the accumulation of electrical charge during a semiconductor plasma etching process performed in a plasma etching chamber. The bias voltage supplied to the plasma etching chamber is modulated by a bias power modulation circuit to control the accumulation of electrical charge and to force the accumulated electrical charge to be periodically discharged at a controlled rate of discharge that prevents the wafer from being damaged.

Owner:AGERE SYST INC

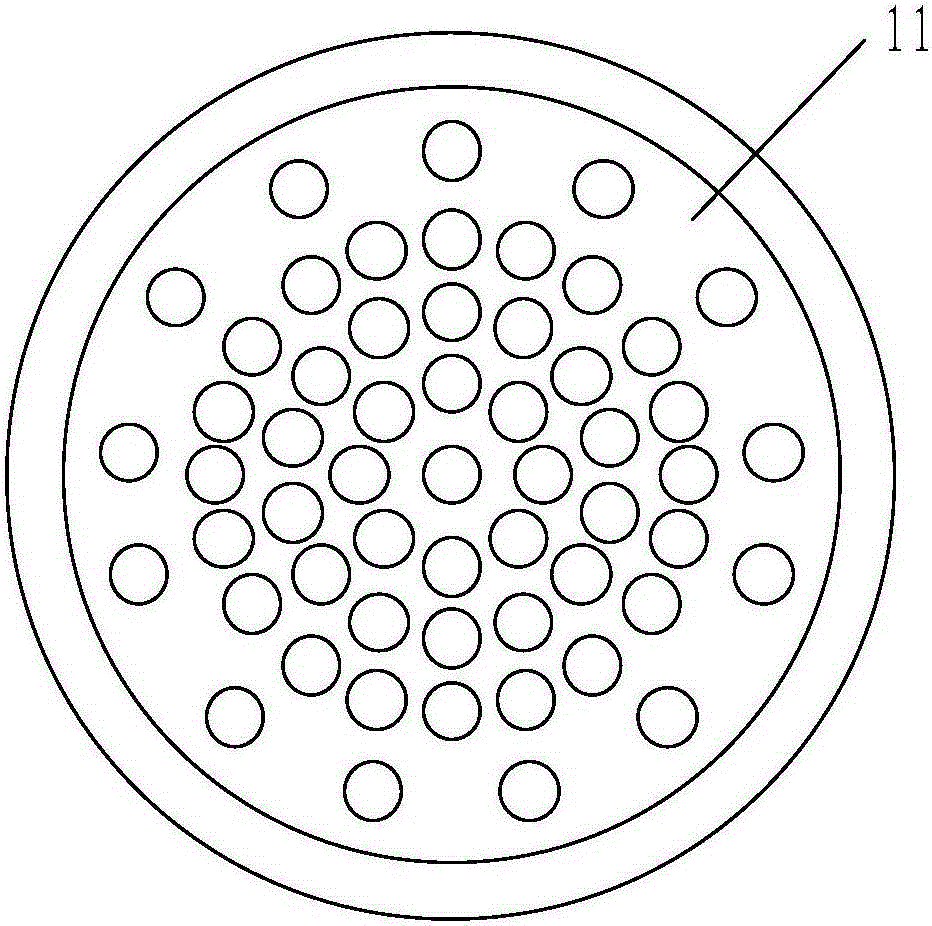

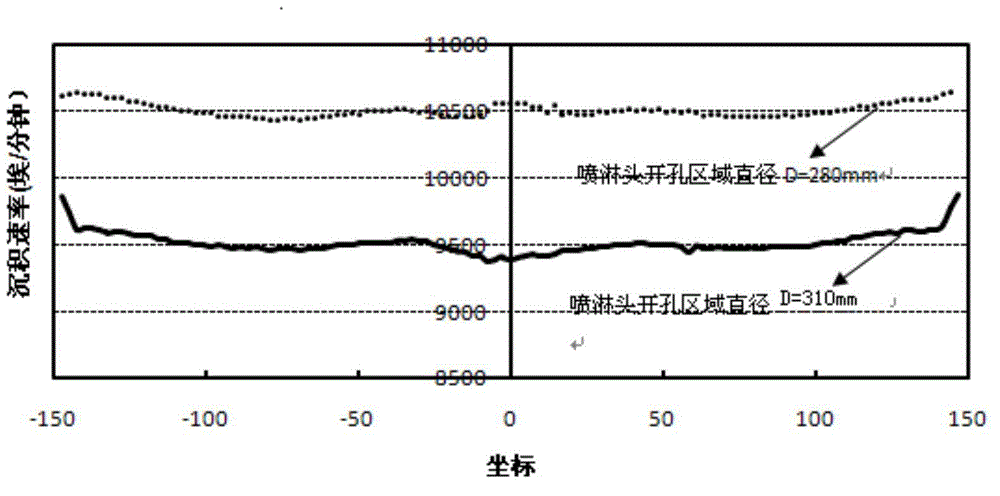

Spraying head capable of improving semiconductor plasma processing evenness

InactiveCN104785389AIncrease profitImprove uniformityElectric discharge tubesSpray nozzlesSemiconductor plasmaEngineering

The invention discloses a spraying head capable of improving the semiconductor plasma processing evenness. The technical problems that in the prior art, the evenness is not good enough, and the gas use ratio is low are mainly solved. The spraying head is structurally characterized in that a spraying head body and a carrying table are located at the opposite positions in a reaction cavity, opposite faces are formed on the spraying head body and the carrying table, and gas supplying is carried out on the carrying table from the spraying head body in a sprayed mode. A plurality of through holes are formed in a spraying hole forming region of the spraying head body, and the area of the hole forming region of the spraying head body is smaller than that of an object carried by the carrying able. Opposite electrodes are formed on the spraying head body and the carrying table, voltage is applied to the portion between the spraying head body and the carrying table to form plasmas, and plasma processing can be carried out on the carrying table and the carried object. Even processing in the semiconductor plasma processing technology procedure can be achieved by controlling the area of the through holes formed in the spraying head body. By means of the spraying head, the gas utilization ratio can be simply and effectively increased, and the evenness of plasma processing can be improved. The spraying head can be widely applied to the technical field of semiconductor manufacturing.

Owner:PIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com