Semiconductor defect detection method based on surface plasma wave

A surface plasmon and defect detection technology, applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc., can solve the problems of difficult capacitive consistency detection, insufficient spatial resolution, and inability to detect defects, and achieve fast detection speed. , The method is simple and flexible, and the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

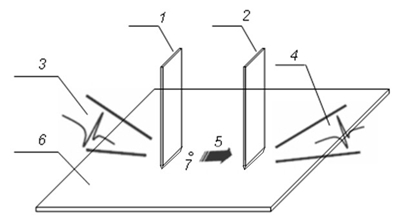

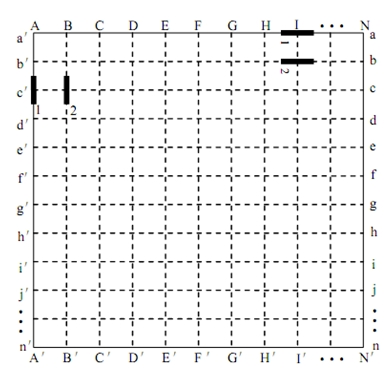

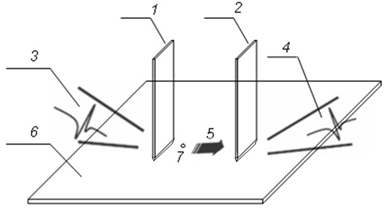

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0026] The idea of the present invention is to place two parallel blades vertically above the surface of the semiconductor to be tested, and inject an electromagnetic wave with a frequency lower than the plasma frequency of the semiconductor into the gap between the cutting edge of one of the blades and the semiconductor, thereby generating surface plasma on the semiconductor surface between the two blades The body wave moves the relative position of the semiconductor and the blade horizontally. When the surface plasmon wave passes through the defects on the surface or inside of the semiconductor, the electromagnetic wave signal emitted from the gap between the edge of the other blade and the semiconductor, and the surface plasmon wave in the semiconductor The defect on the surface that passes the same distance but does not exist on the surface or insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com