Process for the preparation of branched polybutadiene with a high content of 1,4-cis units

A technology for polybutadiene and butadiene, which is applied in the field of preparation of branched polybutadiene with high 1,4-cis unit content, can solve the difficulty of feeding, the preparation of catalyst is complicated, and has no practicability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Polymer Characterization

[0050] Mooney viscosity, according to ASTM D 1646 method;

[0051] Analysis of microstructure (cis content) by I.R. spectroscopy according to internal method;

[0052] · Absolute viscosity, measured in 5% w / w styrene solution at T=25°C;

[0053] Determination of molecular weight distribution (MWD) by GPC in tetrahydrofuran at T=25°C according to in-house method;

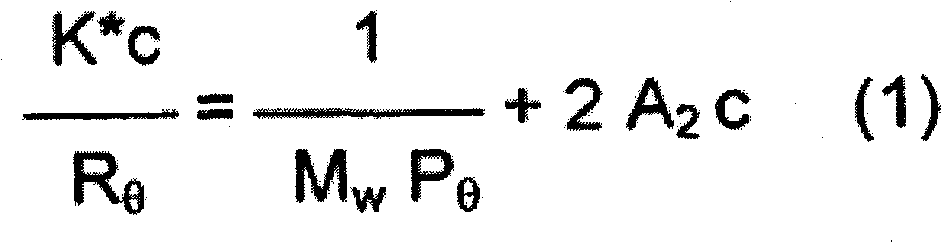

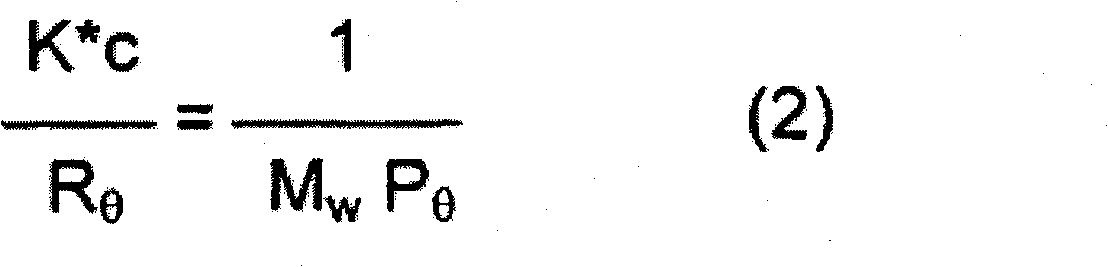

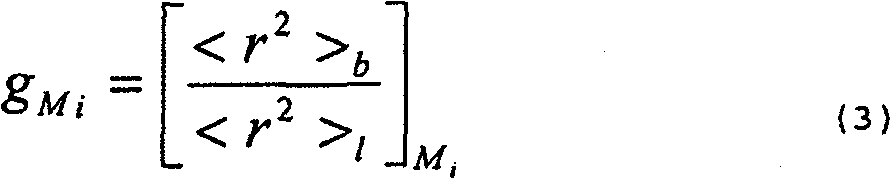

[0054] The determination of the average molecular weight and the measurement of the degree of branching is by means of the GPC / MALLS technique. By coupling a multi-angle light scattering detector (MALLS) to a conventional SEC / RI elution system, absolute measurements of the molecular weight and radius of gyration of macromolecules separated by a chromatographic system can be performed simultaneously; The amount of light scattering can be used directly to obtain its molecular weight, and the angular change of said scattering is directly related to its average size. The basic rela...

Embodiment 7-11

[0097] Examples 7-11 (polymers F, G, H, I, L synthesized in continuous reactors)

[0098] It has been shown that the use of different types of neodymium tertiary carboxylates leads to a gradual improvement in the rate of polymerization in a manner inversely proportional to the content of proton-donating species. Specifically and similarly to that observed in batch reactors, the decrease in water content leads to a gradual decrease in the Mw / Mn index.

[0099] However, unlike the batch tests performed above, for a particularly clean catalyst, at the same Mooney value, a gradual decrease in the viscosity in styrene due to the degree of branching can be observed, via g M A gradual change in the index value is shown (control polymers F, G, H, I, L).

[0100] The degree of branching increases with the increase of synthesis temperature.

[0101] Example 7-11 - Second Synthesis of Polymers F, G, H, I, L

[0102] Anhydrous butadiene and solvent dehydrated by passing over a bed ...

Embodiment 12-14

[0103] The preparation of embodiment 12-14-polymer M, N, O

[0104] Anhydrous butadiene and solvent dehydrated by passing over a bed of molecular sieve 3A were fed to the same apparatus as described in the previous example consisting of two 100 liter reactors, each equipped with a scraping wall stirrer and a specific temperature control device, added in a proportion such that the monomer concentration is confirmed to be equal to 12.5%w, and the hourly amount of butadiene is equal to 8kg / hour; the temperature of the monomer-solvent mixture is established at a value not lower than 45°C, and at In any case makes it possible to adjust (together with the amount of steam circulating in the reactor jackets) the temperature of the synthesis in both reactors, which is constant and centered at a value equal to 95°C, varying by no more than 3°C. A mixture of DIBAH and DIBAH-DEAC (1:1 by mole) was fed sequentially through the same feed line, while Nd-tert-carboxylate was fed directly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com