Sintered neodymium-iron-boron magnet deposited with compound film and preparing method thereof

A composite film and NdFeB technology, which is applied in magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of expensive heavy rare earth elements, achieve easy diffusion of coating activity, high coating activity, and optimize film composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The sintered NdFeB magnets with a size of Φ10mm×3mm are degreased, derusted, and dried. Clean the sintered NdFeB magnet with nitric acid solution, and finally use deionized water and absolute ethanol to ultrasonically clean the magnet to remove impurities attached to the surface, and dry it with a hair dryer for use.

[0048] Evacuate the vacuum chamber to 1×10 -3 Pa, and then fill the vacuum chamber with high-purity Ar (purity ≥ 99.999%) for ion activation sample treatment.

[0049] The process of ion activation sample is to use ion source in vacuum chamber to ionize high-purity Ar into Ar + , apply a negative bias voltage on the sintered NdFeB magnet sample to attract high-energy Ar + Bombard the surface of the sample to further remove impurities and oxide layers to produce a clean surface.

[0050] The working parameters of the ion source are vacuum degree 0.4Pa, anode voltage 150V, anode current 1A, negative bias voltage 300V, and activation time 30min.

[0051]...

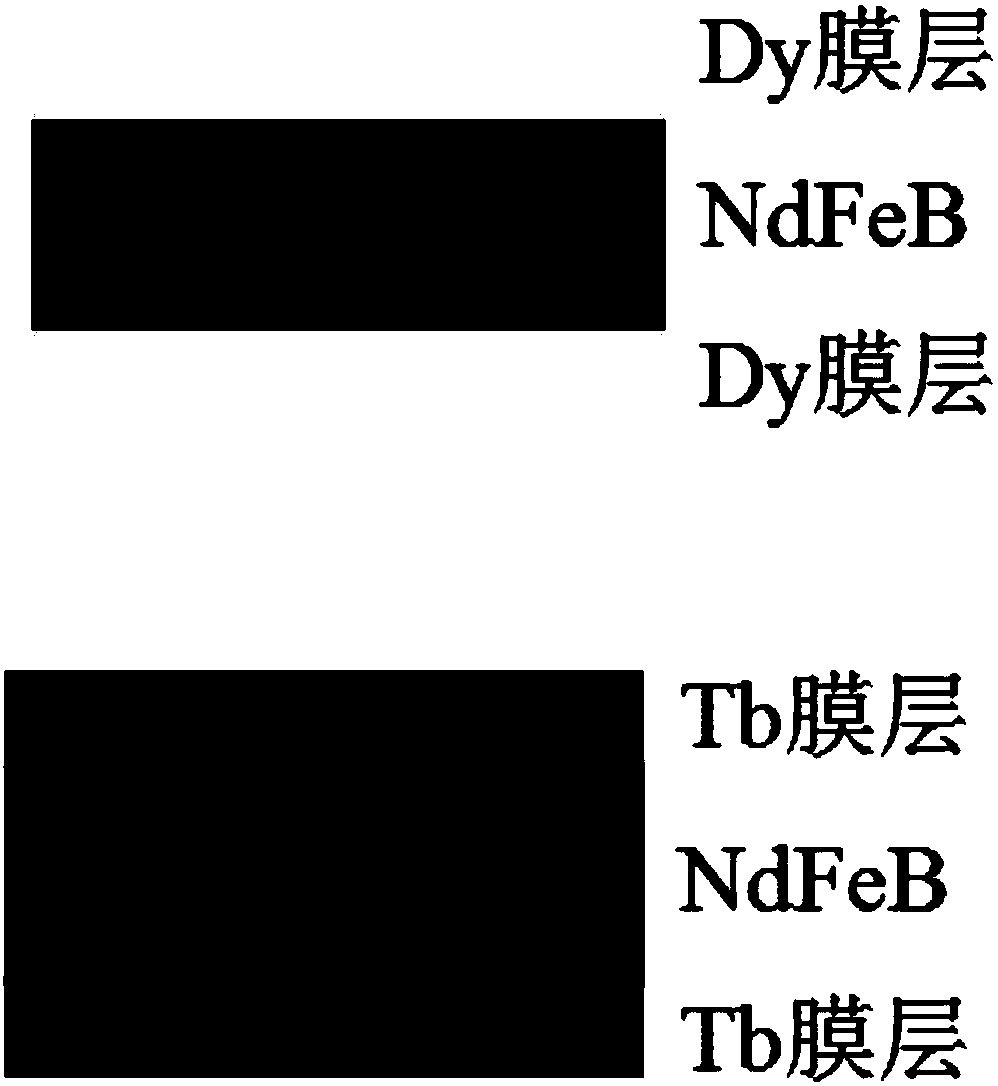

Embodiment 2

[0055] The preparation process is the same as that in Example 1, the only difference is that when depositing the heavy rare earth film, only the pure Dy target is turned on, and the coating time is controlled to obtain a pure Dy film with a film thickness of 2 μm.

Embodiment 3

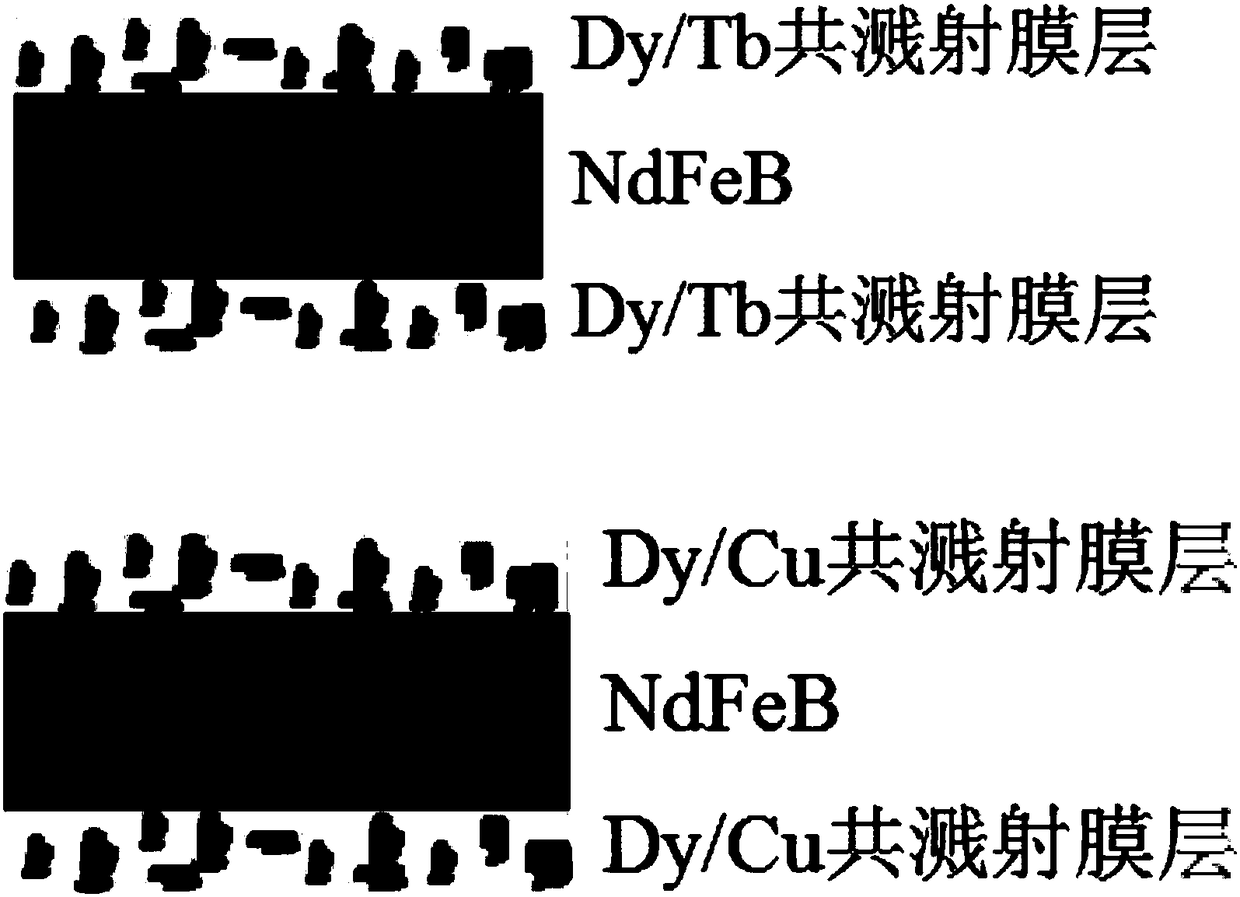

[0057] The preparation process is the same as that in Example 1, the only difference is that when depositing the heavy rare earth film, the Dy target and the Tb target are turned on at the same time, the angle between the targets is adjusted so that the glow overlaps, and the target's brightness is controlled. power to prepare a Dy / Tb co-sputtered hybrid film with a thickness of 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com