Non-complete planar spray header applied to semiconductor plasma processing device

A plasma and processing device technology, which is applied in semiconductor manufacturing and application fields, can solve the problems of low gas utilization rate and insufficient uniformity, and achieve the effects of improving utilization rate, scientific and reasonable structure, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

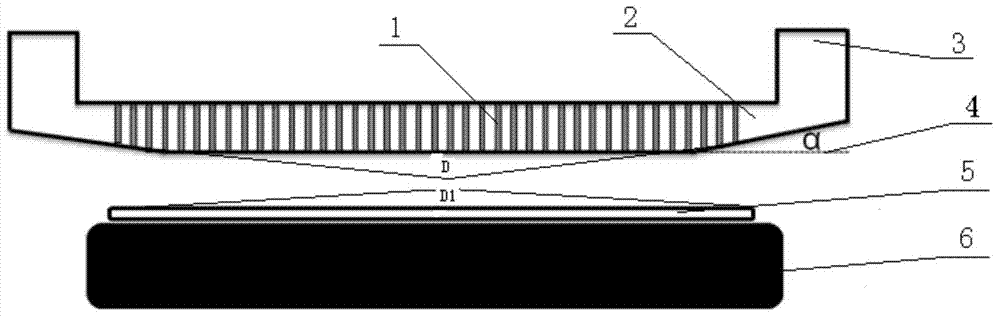

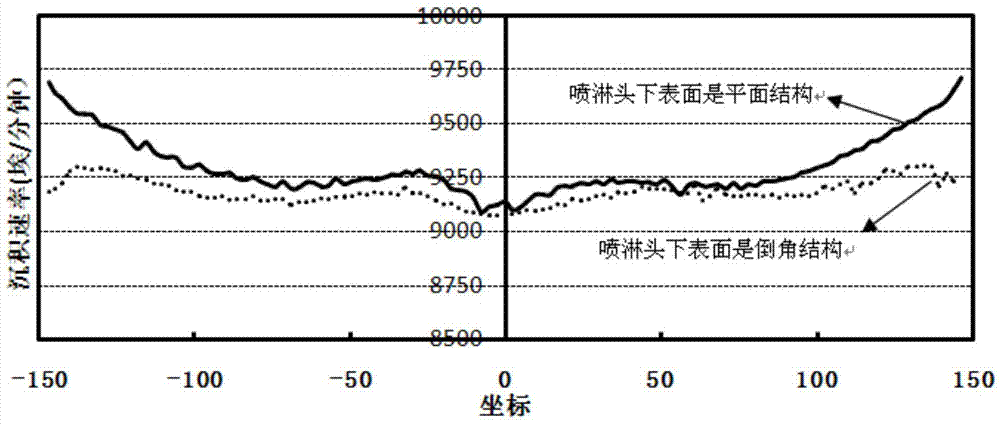

[0020] refer to figure 1 , a non-complete planar shower head applied to a semiconductor plasma processing device, the shower head forms an opposite surface with the object stage, and the lower surface of the shower head has a non-complete planar structure. The above-mentioned shower head is provided with an opening area, and the opening area is provided with a plurality of through holes, which are used to spray the reaction gas into the reaction chamber in a spray-like manner, and a voltage is applied between the shower head and the stage to form plasma, which can Plasma treatment is performed on the objects loaded on the stage.

[0021] These through holes are distributed according to a certain rule, which may be uniform or non-uniform distribution, and the uniform distribution is adopted in this embodiment.

[0022] Specific structure: it includes the main body of the shower head 2, the edge of the main body of the shower head 2 is provided with a boss 3; the concave part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com