Ceramic ring capable of changing shape and appearance of surface film of wafer

A technology of ceramic rings and wafers, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting wafer air flow, changes in plasma distribution, changes in gas distribution, etc., to achieve improved growth and reasonable structure , practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention occurs in the SiH4 process, the reaction source is SiH4 and N2O, and the hardware and substrate used in the experiment are as follows:

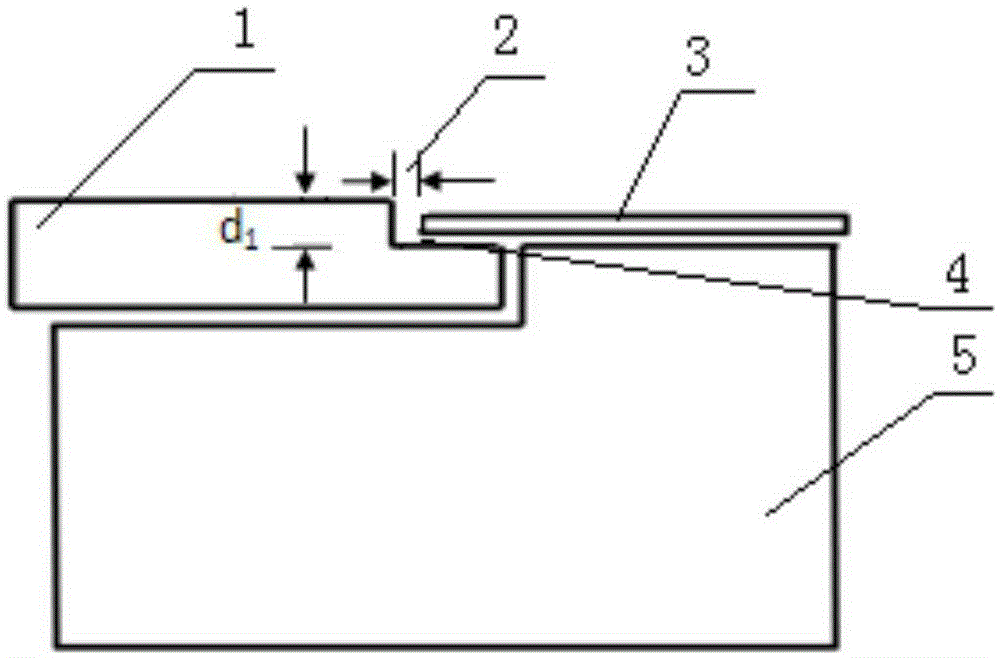

[0018] 1. Please refer to figure 1 , the groove depth of the ceramic ring used in this example is d 1 The ranges are 0.5mm-1.0mm and 1.0-1.5mm respectively, and the ceramic ring is on the stage for the support of the object to be processed.

[0019] 2. The substrate used in this embodiment is a silicon wafer with a diameter of 300 mm and a thickness of 0.775 μm.

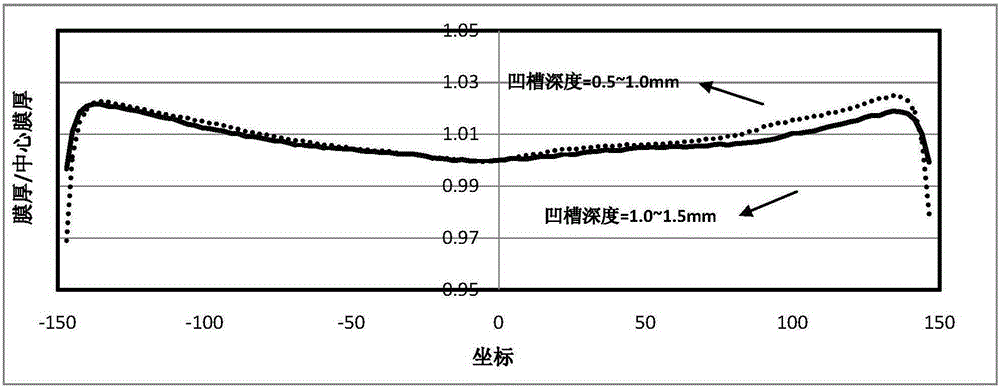

[0020] Please refer to figure 2 , which is a comparison of the deposition conditions of different ceramic ring step heights under the same process formulation. Taking the center of the silicon wafer as the origin, the x-axis is the coordinate (-147mm-147mm) along the radial direction of the silicon wafer at a distance of 3 mm from the edge of the silicon wafer, and the y-axis is the thickness of the film on the surface of the silicon ...

Embodiment 2

[0022] Embodiment 2 of the present invention occurs in the TEOS process, and the reaction source is TEOS and O 2 , the hardware and substrate used in the experiment are as follows:

[0023] 1. Please refer to figure 1 , the groove depth of the ceramic ring used in this example is d 1 The ranges are 0.5mm-1.0mm and 1.0mm-1.5mm respectively, and the ceramic ring is on the stage for the support of the object to be processed.

[0024] 2. The substrate used in this embodiment is a silicon wafer with a diameter of 300 mm and a thickness of 0.775 μm.

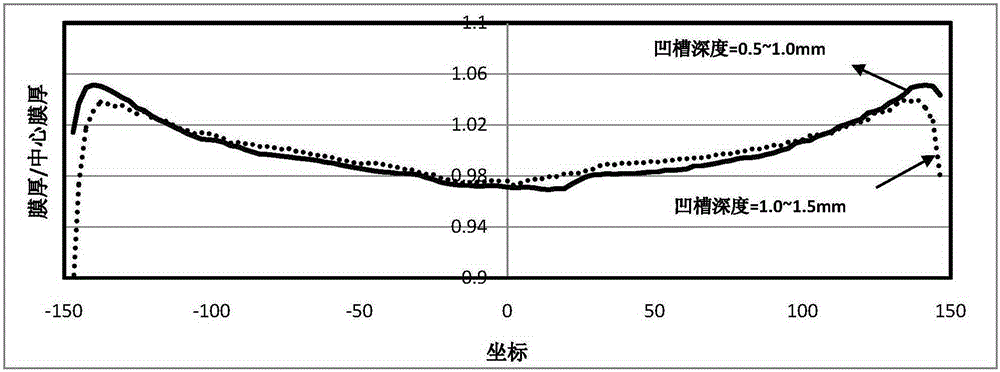

[0025] Please refer to image 3 , which is a comparison of the deposition conditions of different ceramic ring groove depths under the same process formulation. Taking the center of the silicon wafer as the origin, the x-axis is the coordinate (-147mm-147mm) along the radial direction of the silicon wafer at a distance of 3 mm from the edge of the silicon wafer, and the y-axis is the thickness of the film on the surface of the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com