Carbon-supported metal catalyst and preparation method thereof

A metal catalyst, catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problems of difficult scale, complex process, strict condition control requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A carbon-supported metal catalyst, characterized in that: the active metal is one or more transition metal elements including iron, cobalt, ruthenium, rhodium, palladium, osmium, iridium, platinum, copper, silver, gold , the content of the metal component in the carbon-supported metal catalyst can be precisely adjusted in the range of 1-50 wt%. Its preparation method comprises the synthetic process of catalyst and self-reduction process, is characterized in that comprising the following steps:

[0020] (1) The metal salt is configured into a solution with a certain concentration and placed in a continuously stirred reactor as a salt precursor. After stirring evenly, an anion resin or the same Proportional cation resin is added to it, and the temperature in the reactor is controlled not to exceed 40°C to carry out ion exchange reaction;

[0021] (2) After the ion exchange reaction, filter at room temperature, remove the filtrate, collect the filtrate, and dry it at 80°C...

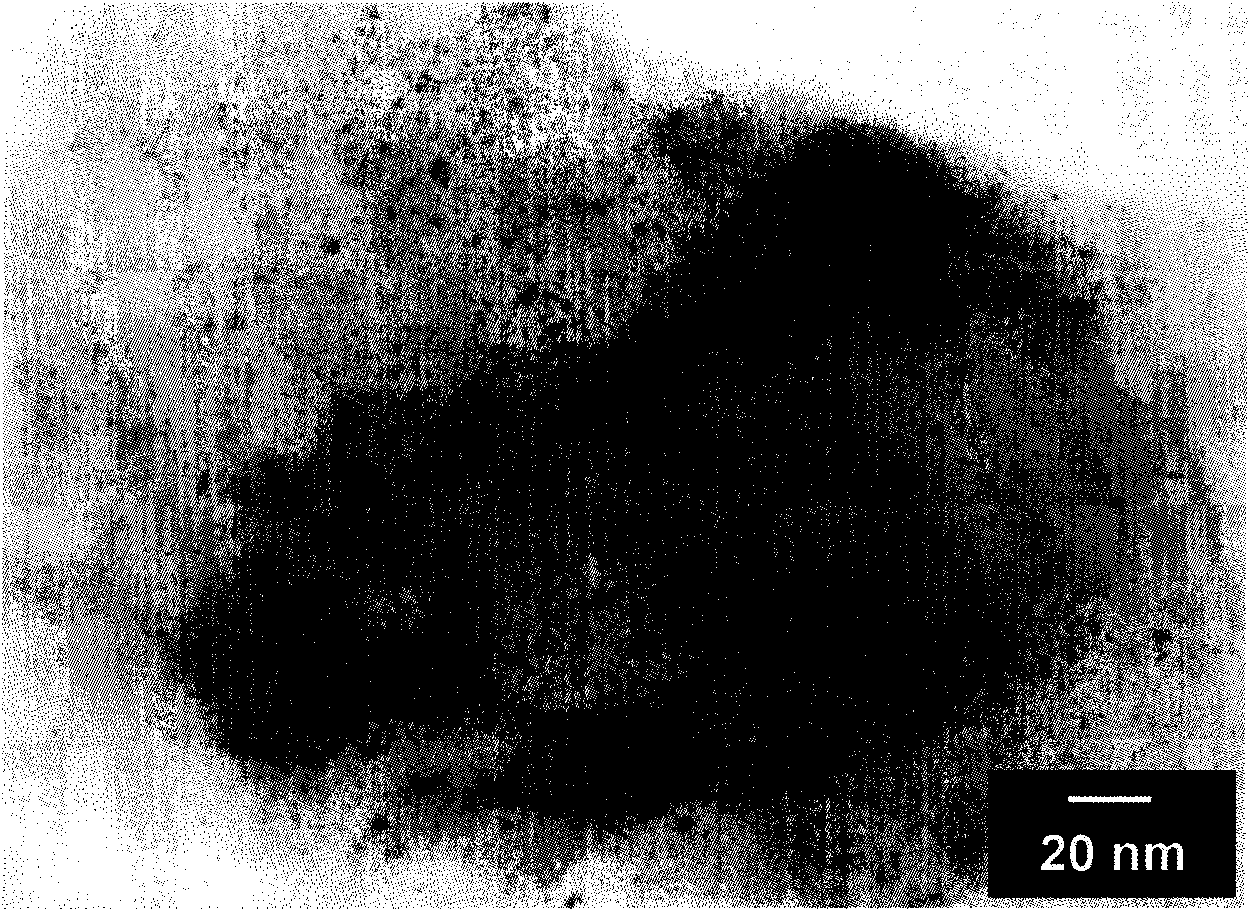

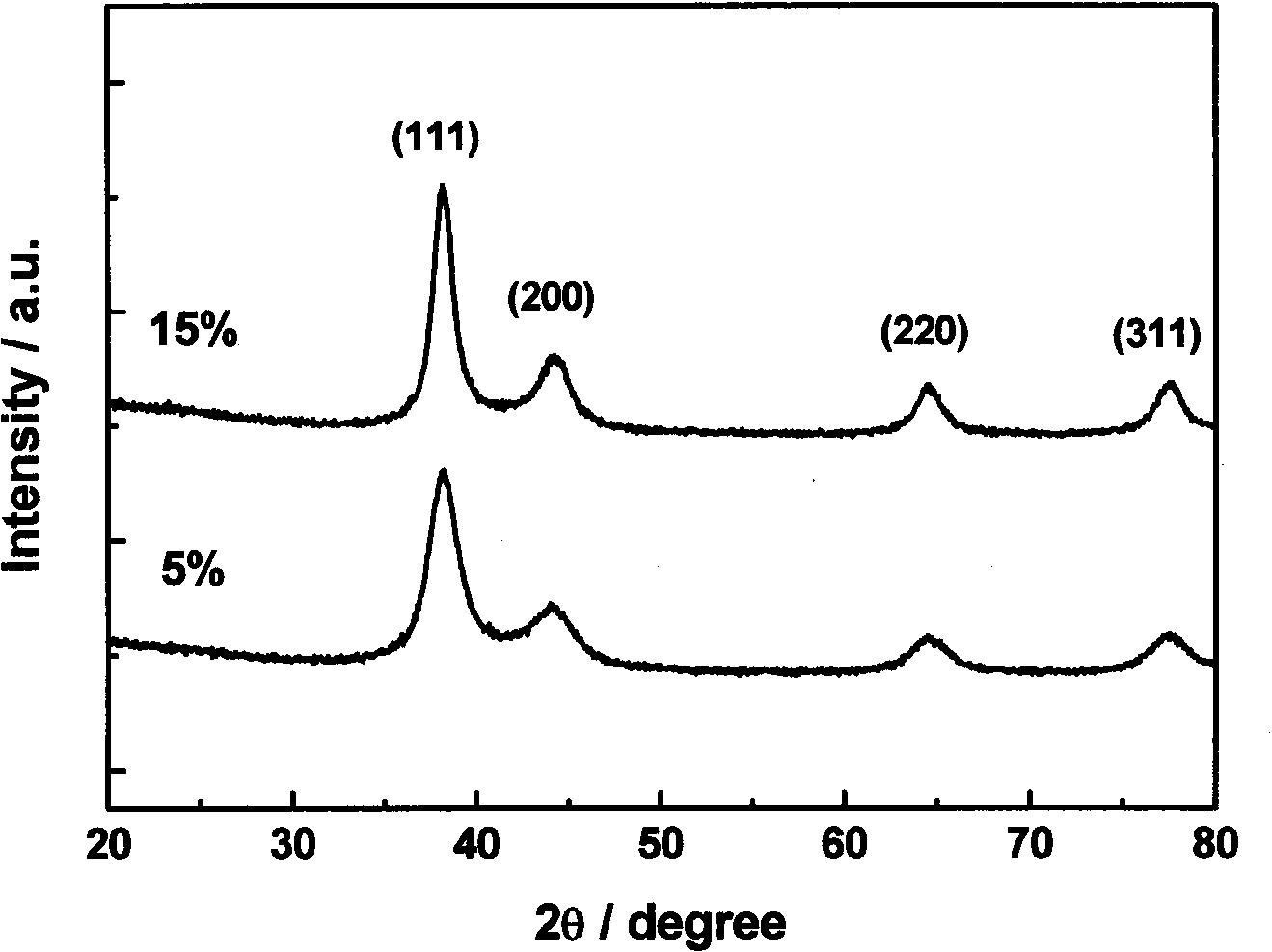

Embodiment 1

[0025] Preparation of Ag / C catalyst: silver nitrate (AgNO 3 ) 0.5g was dissolved in 50ml of deionized water at 40°C, 20ml of hydrogen-form cation exchange resin was added to the continuously stirred silver nitrate solution, stirred continuously at 40°C for 2 hours, filtered and dried at 80°C for 24 hours. After cooling, it is placed in a tube furnace, the flow rate of inert gas is 20ml / min, the heating rate is 5° / min, the temperature is kept at 500°C for 2 hours, and then it is lowered to room temperature.

Embodiment 2

[0027] Preparation of Pt / C catalyst: chloroplatinic acid (H 2 PtCl 6 .6H 2 (0) 0.5g, dissolved in 50ml of 40°C deionized water, 20ml of hydroxide type anion exchange resin was added to the continuously stirred chloroplatinic acid solution, stirred continuously at 40°C for 2 hours, filtered and dried at 80°C for 24 hours. After cooling, put it in a tube furnace, the flow rate of inert gas is 20ml / min, the heating rate is 5° / min, keep the temperature at 500°C for 2h, and then cool down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com